Carding structure of needle selecting equipment

A needle selector and combing bar technology, which is applied in knitting, weft knitting, warp knitting, etc., can solve the problems of inability to disassemble and adjust the bottom plate of the needle selector, and achieve the effect of easy maintenance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

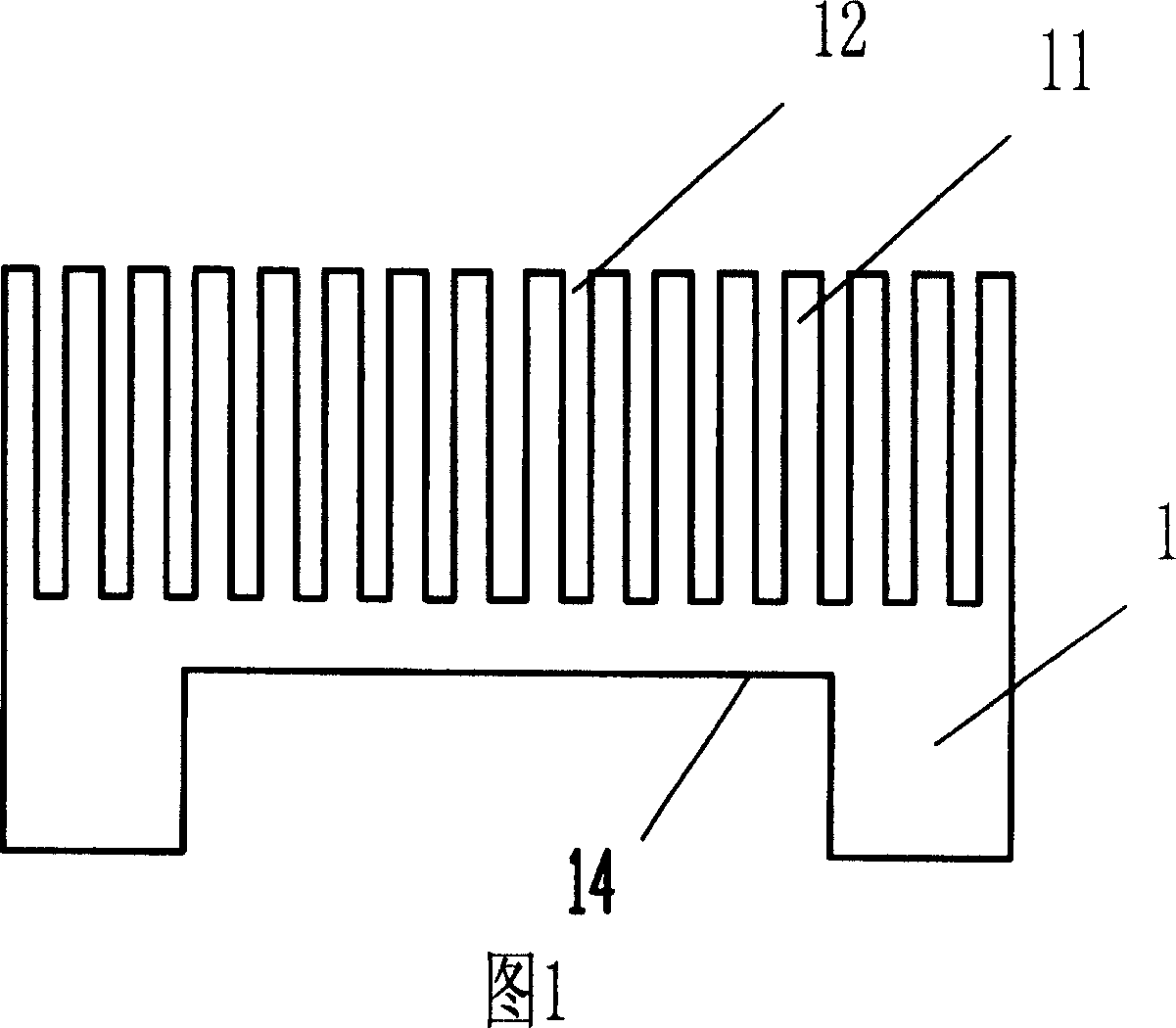

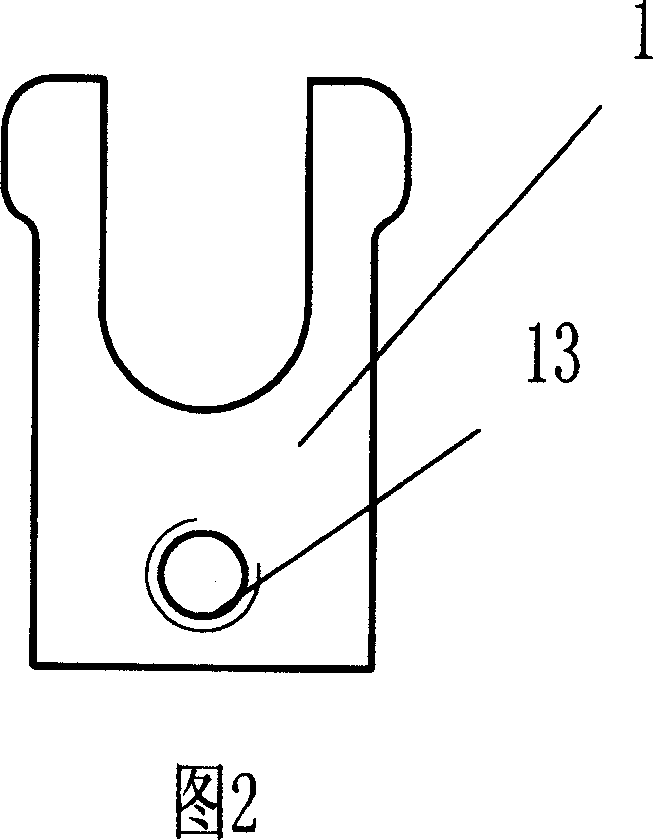

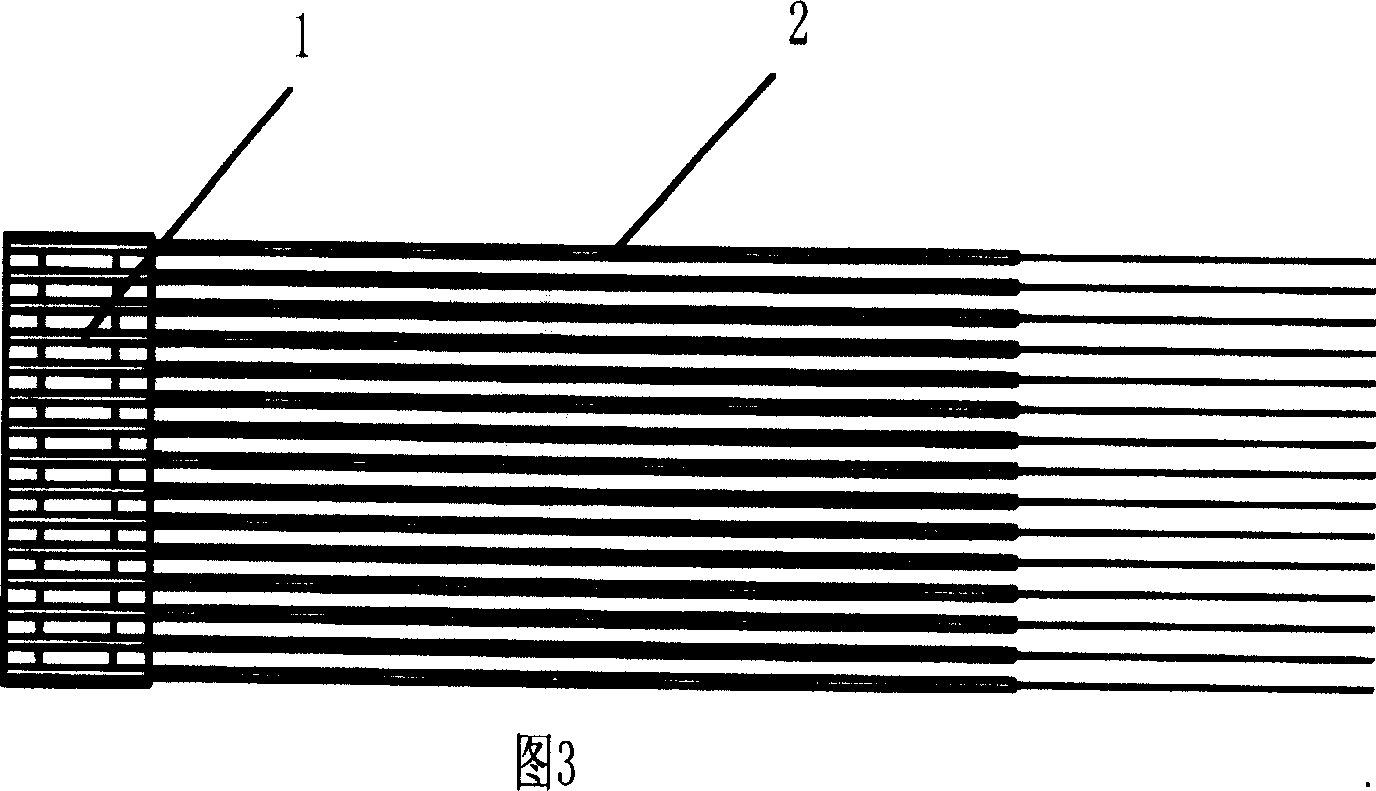

[0012] In conjunction with Figures 1 to 5, the following is a detailed description:

[0013] A comb structure of a needle selector, used to connect the piezoelectric driving piece and the bottom plate, is composed of a comb 1 and a bottom plate 3, and the upper part of the comb is divided into grid grooves 12 by a group of comb pieces 11, which can be fixed side by side. A group of piezoelectric driving pieces 2, and the lower part is an inverted groove part 14, and a pair of gaps 31 are provided on both sides of the bottom plate. After the groove part of the comb bar is inserted into the corresponding gap, the comb bar and the bottom plate are respectively Keep the sides and bottom flush.

[0014] The side of the comb bar and the notch side of the bottom plate are fixed based on the screw hole 13 and the embedded screw, and keep the side of the comb bar and the side of the bottom plate flush.

[0015] In Fig. 5, the piezoelectric driving piece 2 is connected to the comb bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com