Cutting device for flush cut of plastic product

A technology for a plastic product and a cutting device, which is applied to the field of cutting devices for flush incisions of plastic products pipes, can solve the problems of processing and uneven incisions of plastic pipes, and achieve the effects of easy processing, maintaining flushness, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

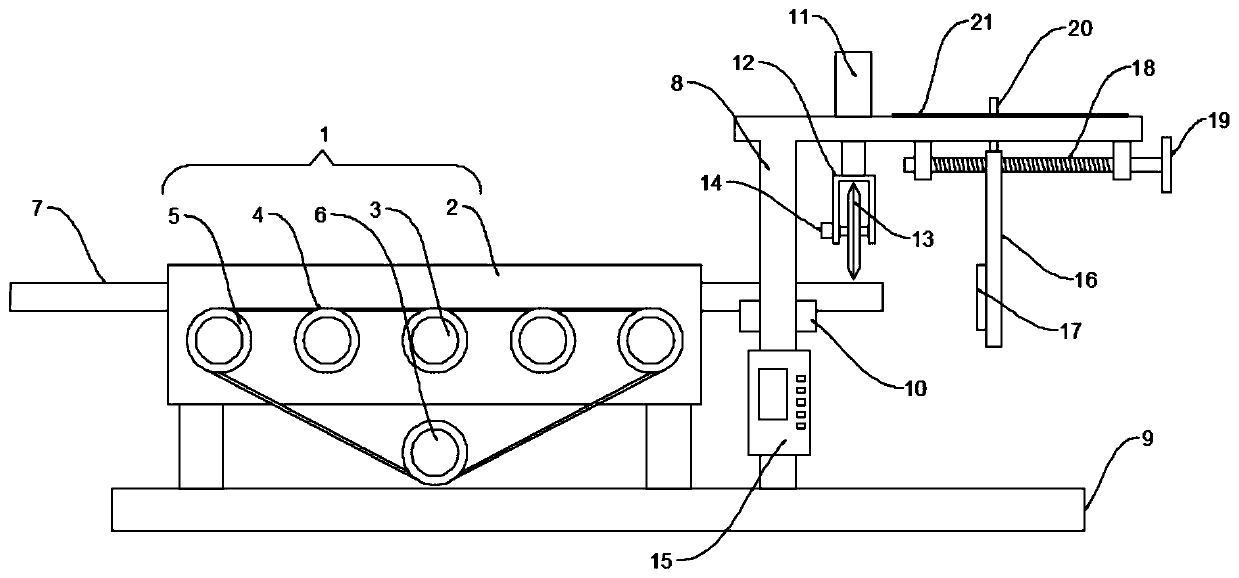

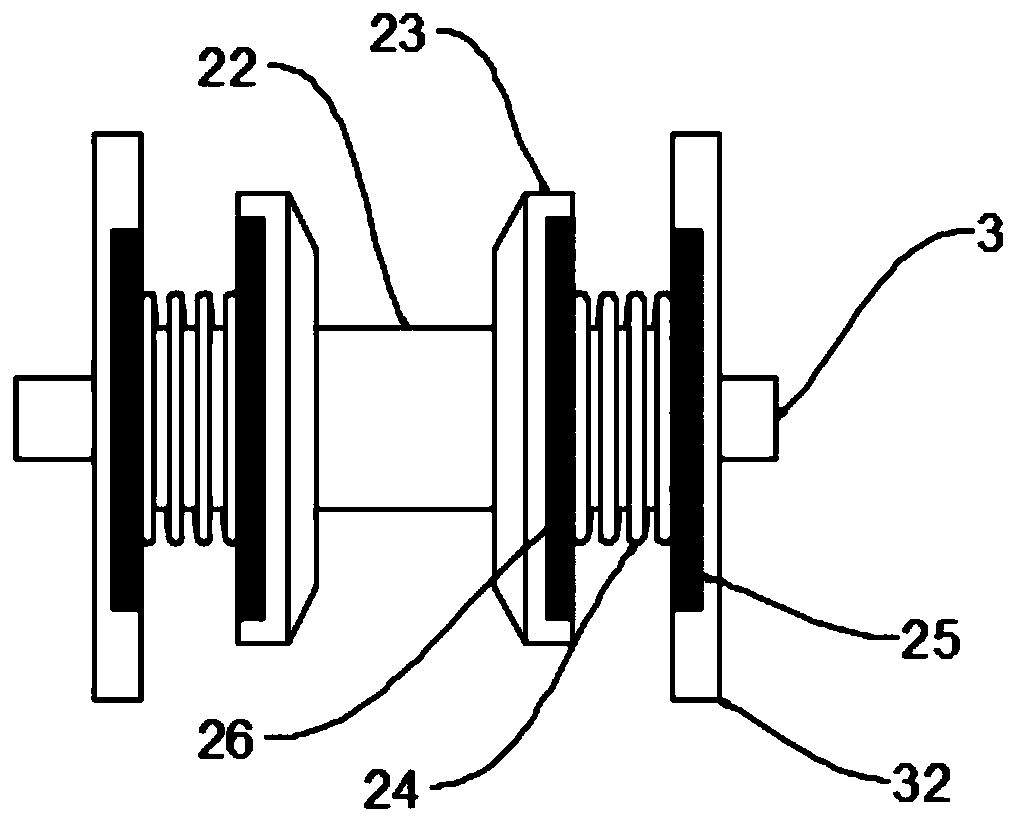

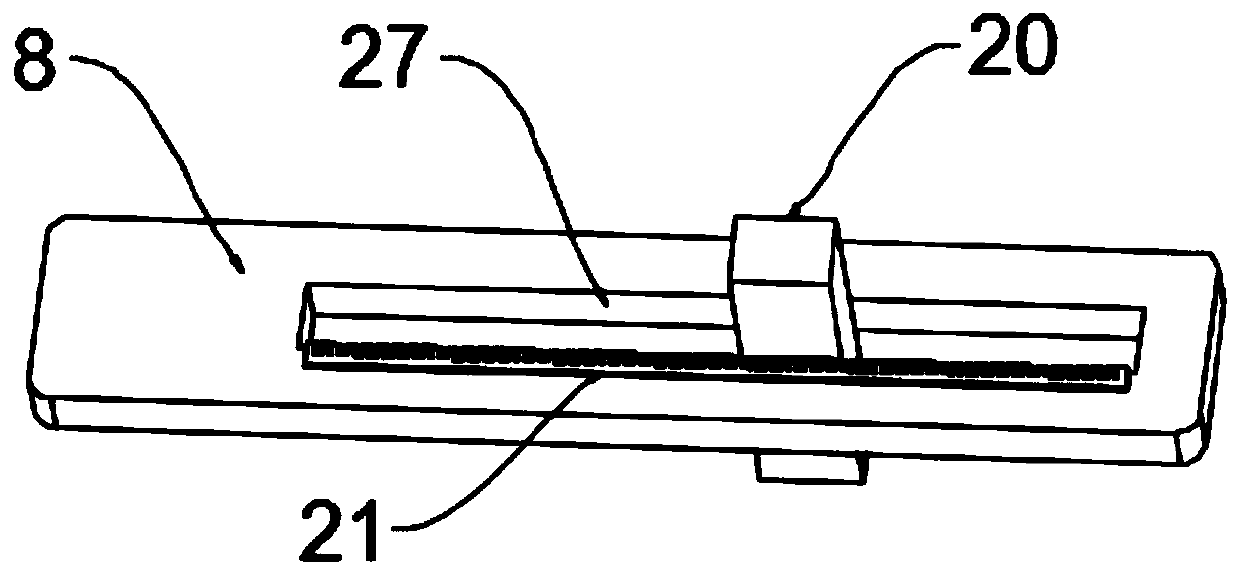

[0024] see Figure 1~3 , in an embodiment of the present invention, a cutting device for a flush cut of a plastic product tube includes a feeding and pushing mechanism 1, a cutting mechanism and a base substrate 9, the feeding and pushing mechanism 1 is arranged on the base substrate 9 and the feeding and pushing mechanism The mechanism 1 includes a conveying frame body 2, a plurality of conveying rod shafts 3 arranged horizontally on the conveying frame body 2 and a push motor 6 arranged on the base substrate 9, each end of the conveying rod shaft 3 and the output end of the push motor 6 Both are provided with a sprocket 5, and a plurality of sprockets 5 are connected by a chain 4 around it, and each delivery rod shaft 3 is also fixed with a fixed sleeve 22, and the fixed sleeve 22 is provided with two slides on it. Clamping disc 23, the diameters of the two clamping discs 23 gradually become smaller from the opposite end to the opposite end, both ends of the fixing sleeve 22...

Embodiment 2

[0028] see Figure 4 The difference between the embodiment of the present invention and embodiment 1 is that: the horizontal rod of the installation rod frame 8 is also provided with a suspension vertical plate 16 at the end of the feeding push mechanism 1, and the suspension vertical plate 16 is provided with a pressure Inductor 17, a control box 15 that electrically controls the lifting cylinder 11 and the push motor 6 is also provided on the wall of the rod frame 8, and the control box 15 is equipped with an electric control system, and the electric control system includes a receiving unit 29. The central processing unit 28 and the output unit 30, the receiving unit 29 is used to electrically connect the pressure sensor 17 and receive the signal transmitted by the pressure sensor 17; the central processing unit 28 is used to generate according to the signal transmitted by the receiving unit 29 The control command is transmitted to the output unit 30, and the output unit 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com