Bidirectional non-return valve

A check valve, valve body technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of inconvenient driving, danger, high internal pressure of tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The accompanying drawings and preferred specific embodiments will be described in detail below, so as to further understand the structure, features and purpose of the present invention.

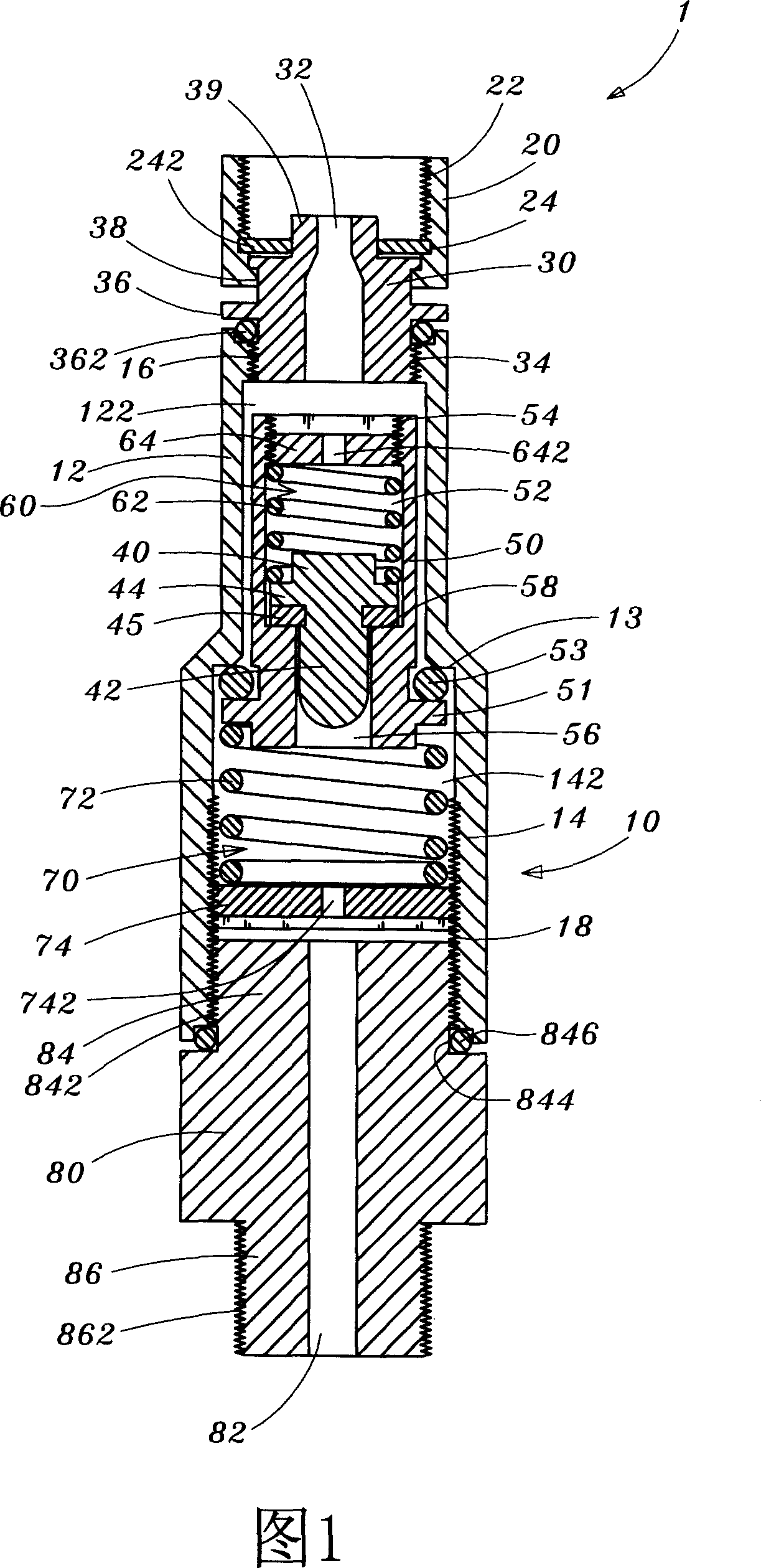

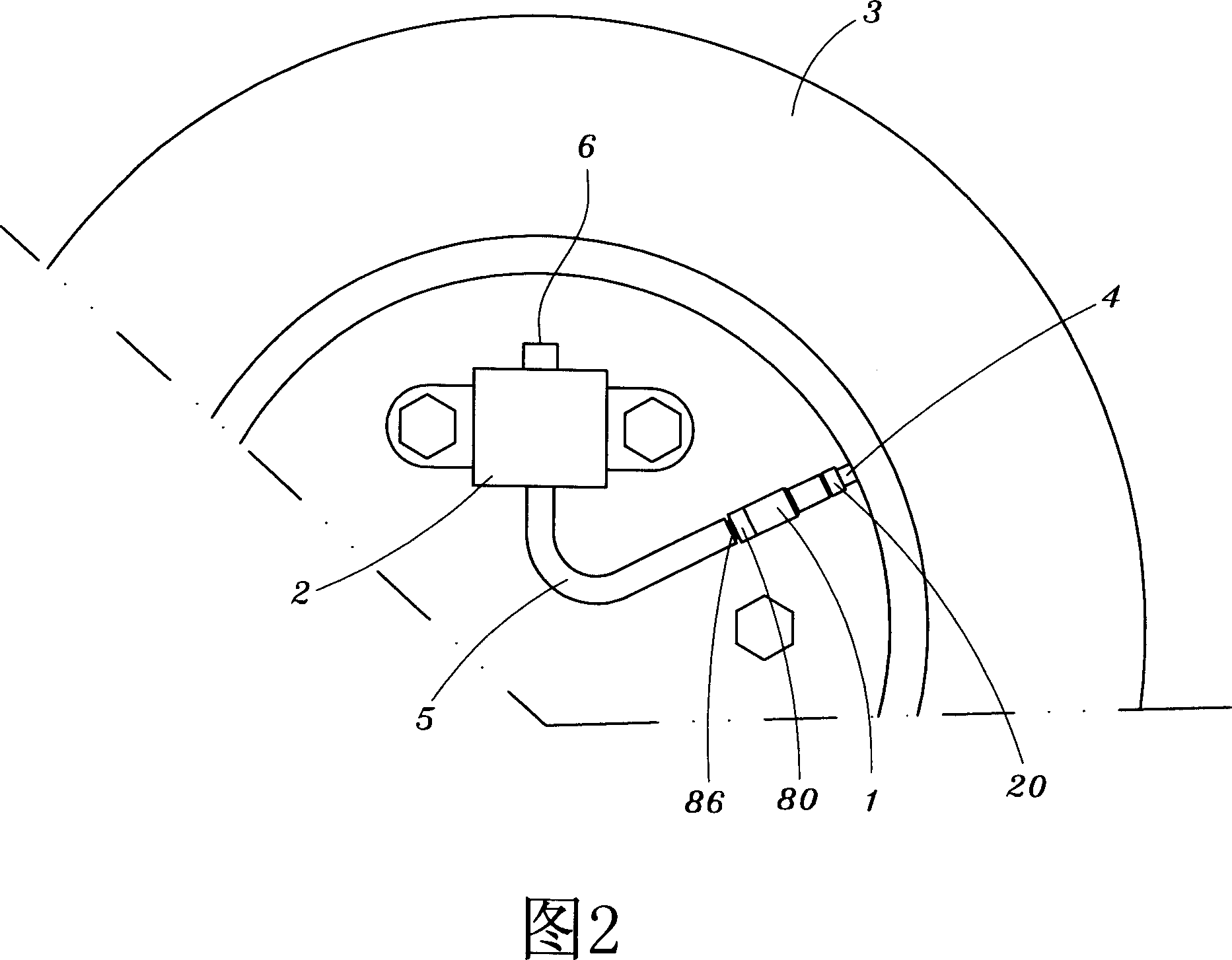

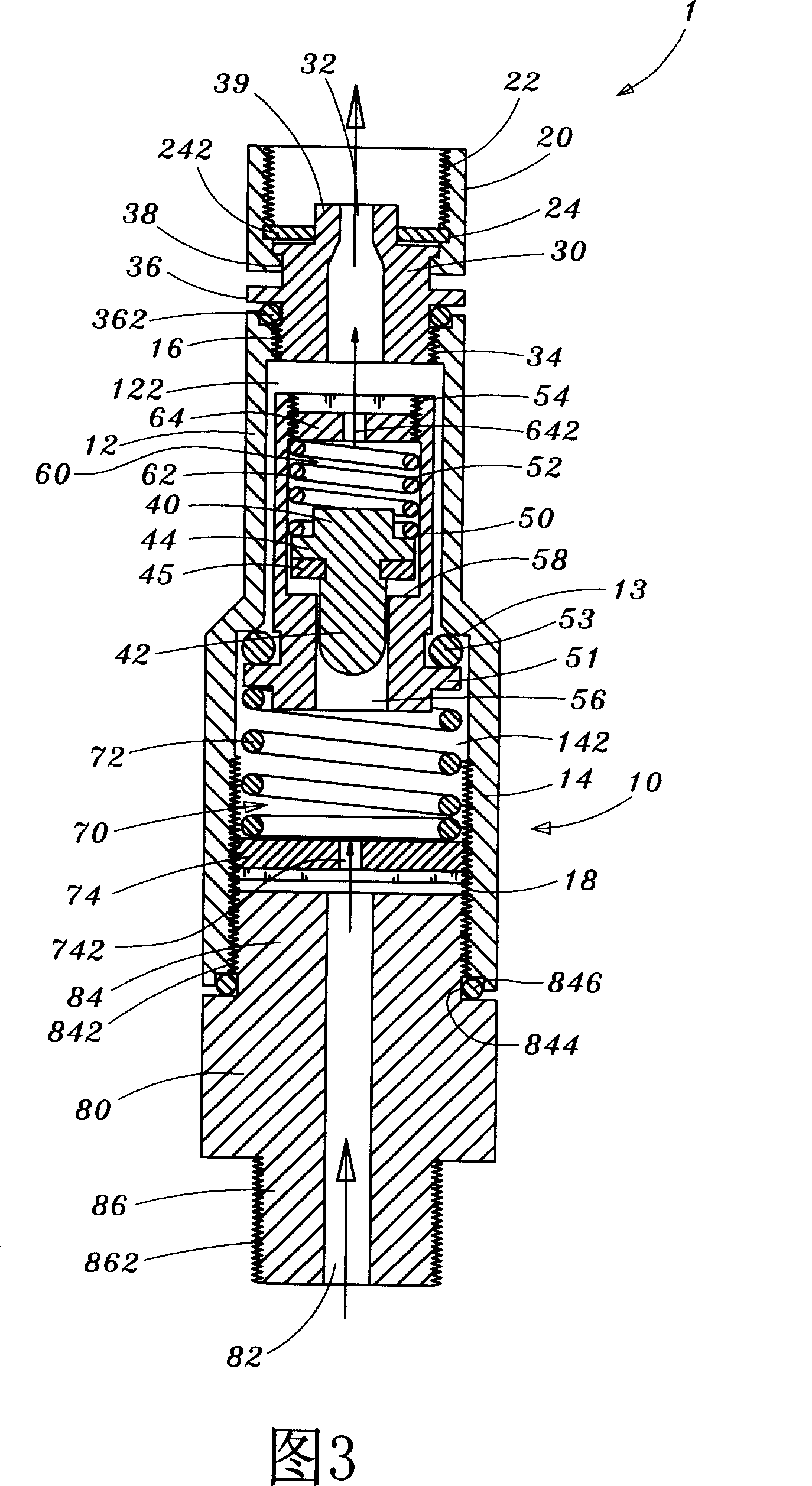

[0041] Please refer to FIG. 1 , which is a schematic cross-sectional view of an embodiment of the present invention. As shown in the figure, the two-way check valve 1 of the present invention includes a hollow sleeve 10, a connecting sleeve 20, a valve push rod 30, a first valve body 40, a second valve body 50, a first pressure The adjustment assembly 60 , a second pressure adjustment assembly 70 and an air inlet joint 80 . In terms of the combined structure, both ends of the hollow sleeve 10 are respectively screwed to the air nozzle push rod 30 and the air inlet joint 80 , and the connecting sleeve 20 is sheathed on the air nozzle push rod 30 . Moreover, the hollow sleeve 10 has a first sleeve portion 12 and a second sleeve portion 14, and a first accommodating chamber 122 and a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com