Novel underground constant-pressure biogas storage device

A storage device and biogas technology, applied in gas/liquid distribution and storage, container discharge methods, container filling methods, etc., can solve the problems of large floor area, short service life of double-film plastics, easy cracking and leakage of concrete pool walls, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

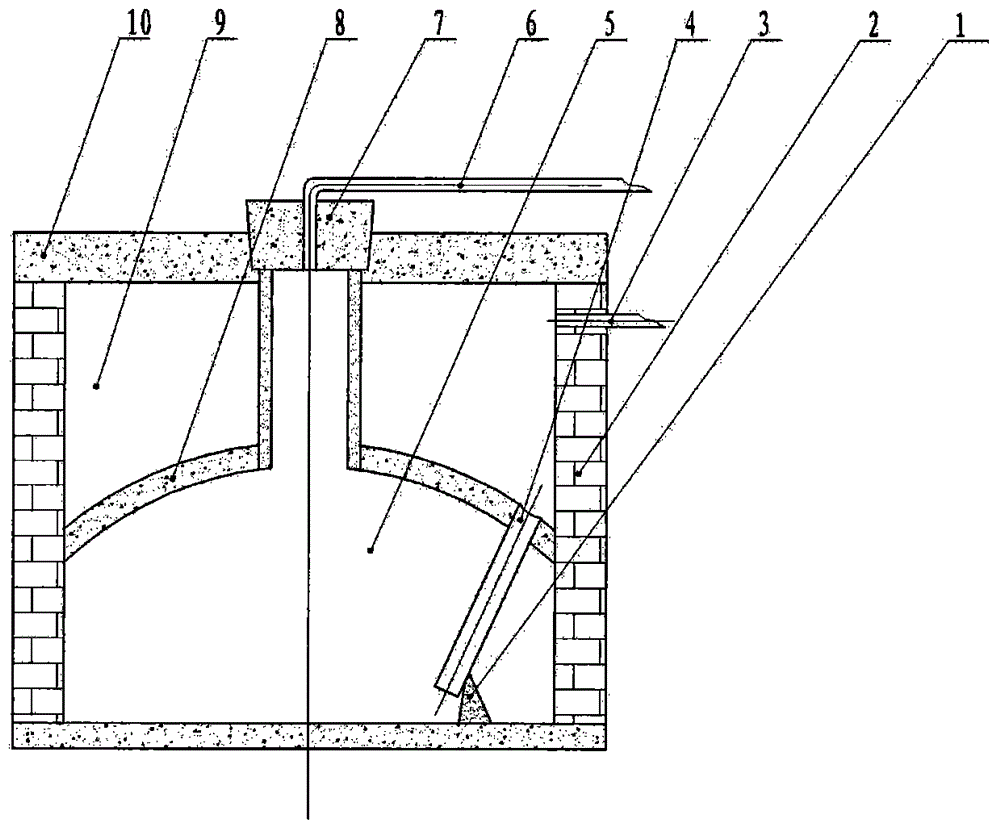

[0007] Fix the block (1) at a certain position on the bottom of the pool, install the water supply pipe (3) in the wall (2), connect the arch cover (8) to the wall (2), adjust and fix the water pressure pipe (4) and the pad block (1), then install the cover plate (10) on the wall (2), install the movable cover (7) with the air duct (6) on the cover plate (10), and the air chamber (5 ) and the water pressure room (9) keep the air chamber constant pressure by the water pressure pipe (4) and the water supply pipe (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com