Down blow type membrane foam internal spray coating functional liquid coating technology and device

A functional liquid and down-blowing technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of reduced functionality and service life, poor transparency, poor adhesion, etc., to prolong the life of functional effects and service life, enhanced cooling effect, and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

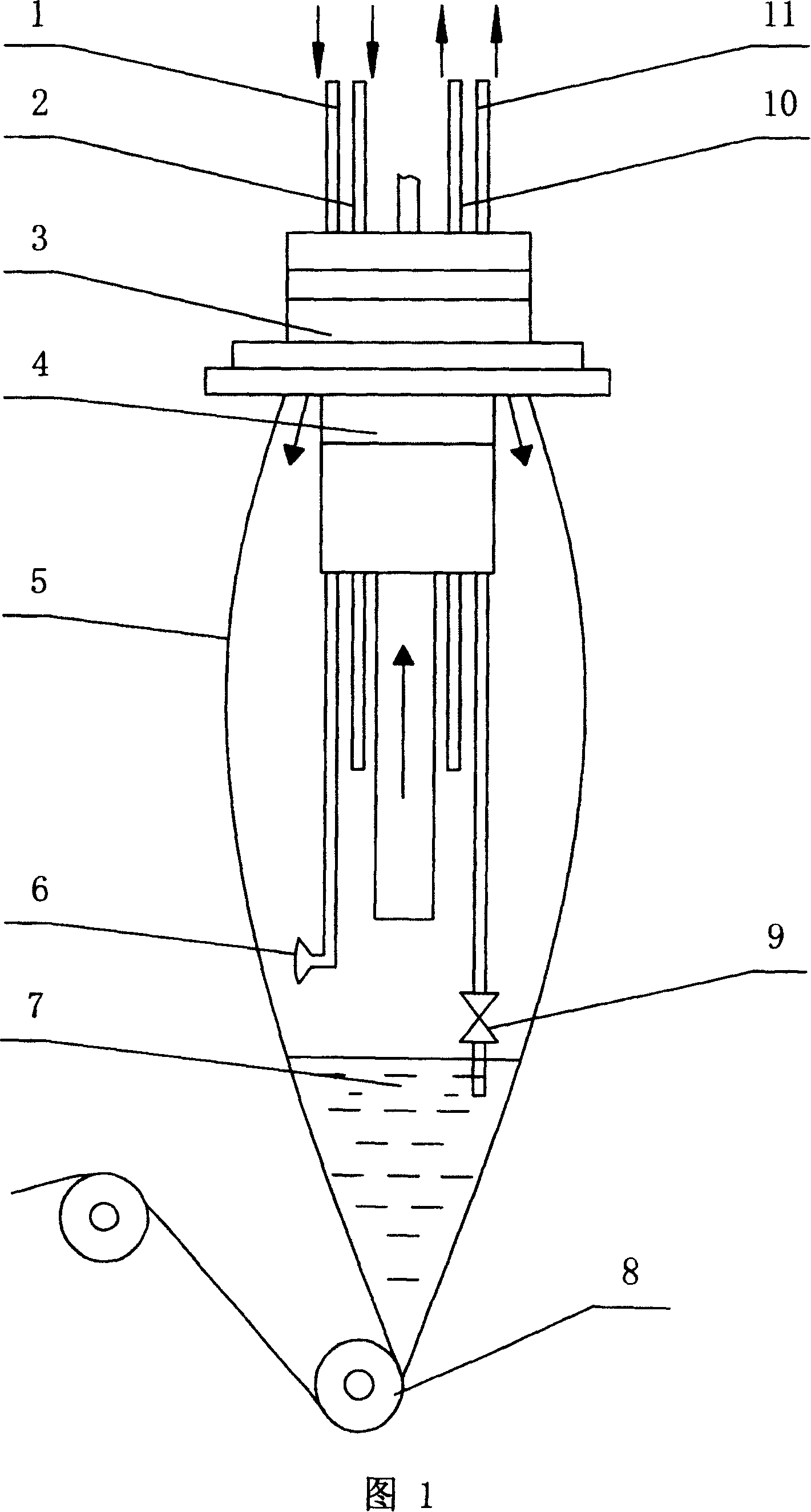

[0013] The present invention is installed as shown in Figure 1.

[0014] When the down-blowing blow molding machine starts to work, after the head body 3 blows out the film bubble 5, the next step of winding work is carried out through the lower traction roller 8 according to the existing conventional operation mode. At this time, the functional liquid 7 passes through the medium pumping device The connected functional liquid inlet pipe 1 is injected into the film bubble 5, and the inner wall of the film bubble is sprayed and coated by the spray head 6. In order to obtain uniform coating on the inner wall of the film bubble, the nozzle body 3 Multiple groups of spray heads 6 are arranged in a ring shape on the top, and one or more sets of functional liquid outlet pipes 11 and the suction pump 9 provided thereon can be provided according to actual needs. When the liquid level of the functional liquid 7 in the film bubble 5 reaches a certain amount, the suction pump 9 provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com