Cooking fume remover

A range hood and oil pumping technology, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of affecting the effect of oil fume extraction and easy blowing to the operator, so as to prevent the spread of oil fume and improve The effect of the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

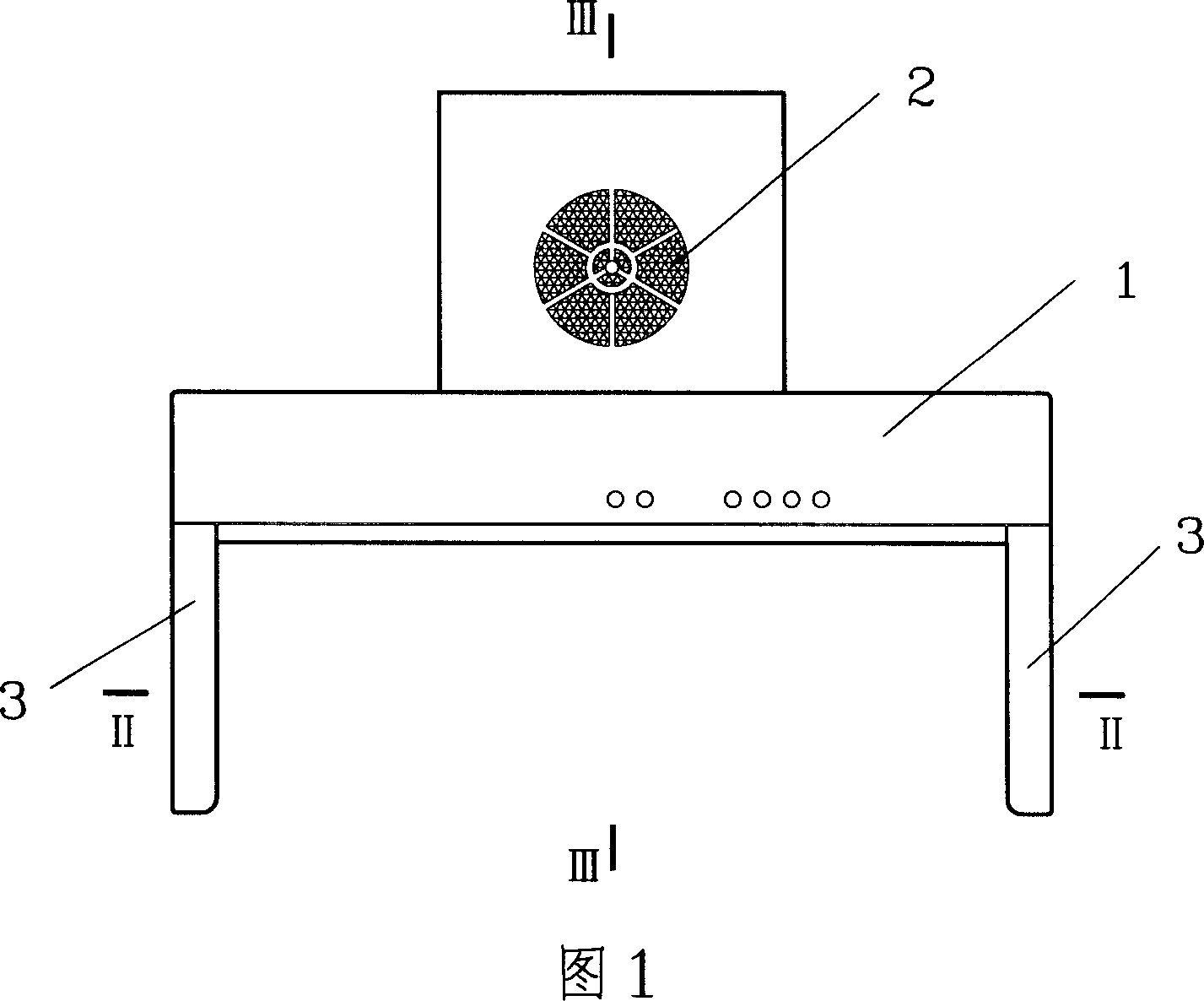

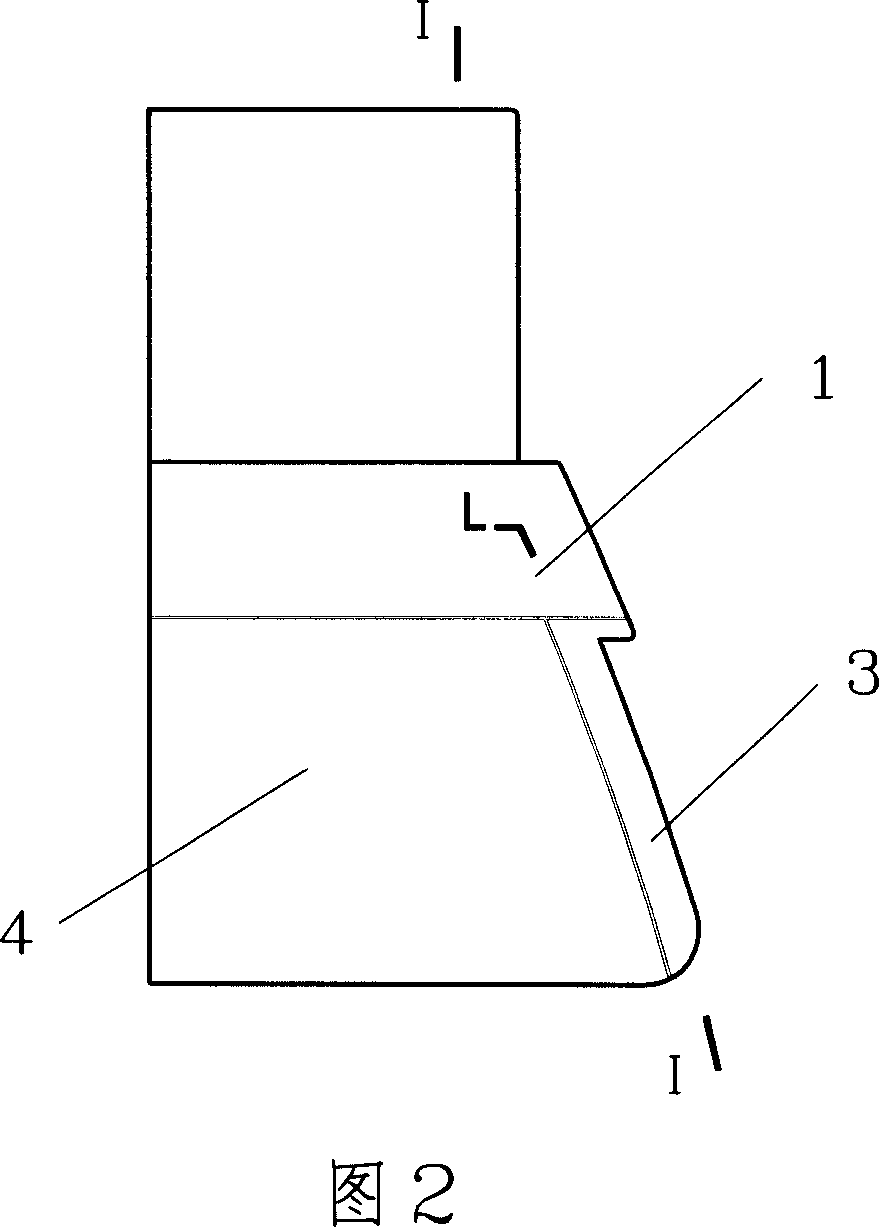

[0016] In the embodiment shown in the figure, FIG. 1 shows that an air curtain fan air inlet 2 is opened on the housing of the range hood hood 1 , and air curtain nozzles 3 are provided on the left and right sides of the front, lower, and left sides of the hood 1 . FIG. 2 shows the sides of the hood 1 and the air curtain nozzles 3 and the side windscreens 4 below the front.

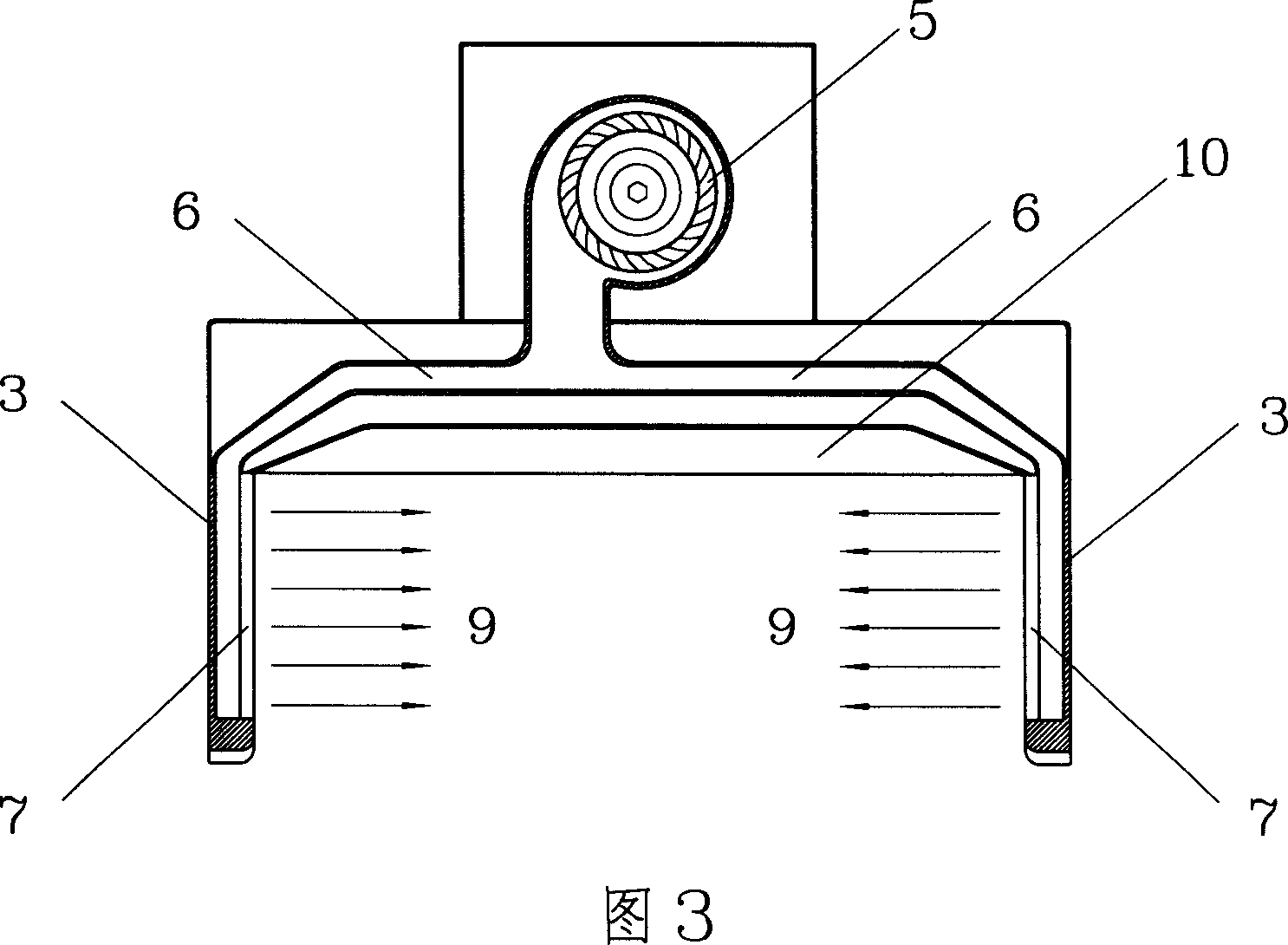

[0017] As shown in Figure 3, when the air curtain fan 5 is started, the generated wind is blown into the air curtain nozzles 3 on the left and right sides of the lower front of the hood through the air channel 6, and blows along the slit-shaped air outlets of the nozzles on the left and right sides. 7 is blown out along the direction shown by arrow 9, forms air curtain.

[0018] In the II-II sectional schematic diagram shown in Fig. 4, the air curtain formed by the wind blown out by the slit-shaped air outlet 7 of the side windshield panel 4 and the air curtain nozzle 3 along the arrow 9 and the wall 8 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com