Pneumatic tire

A technology of pneumatic tires and tire shoulders, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as inconsistency in operation stability and riding comfort, and achieve excellent appearance and flexibility. Consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

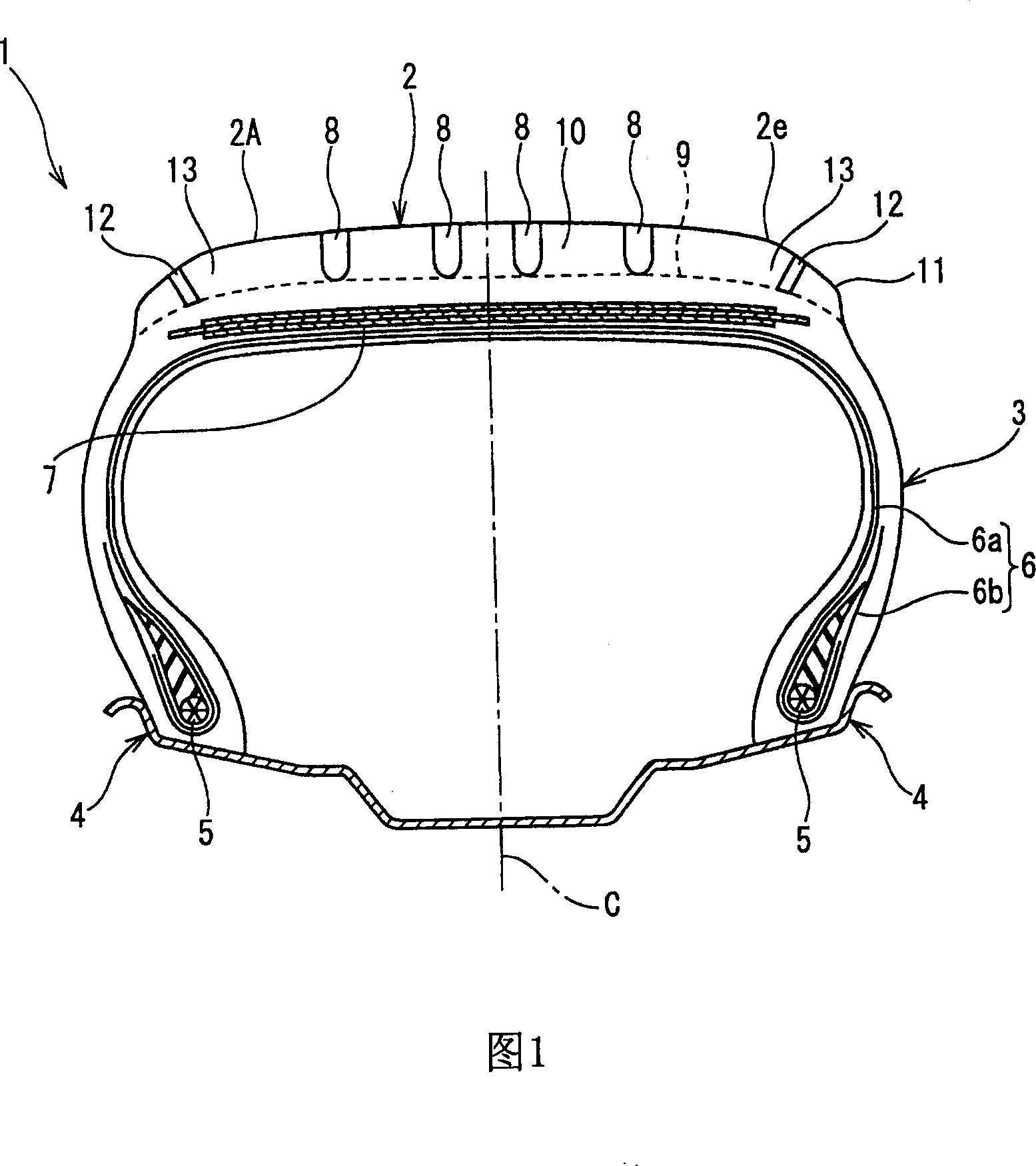

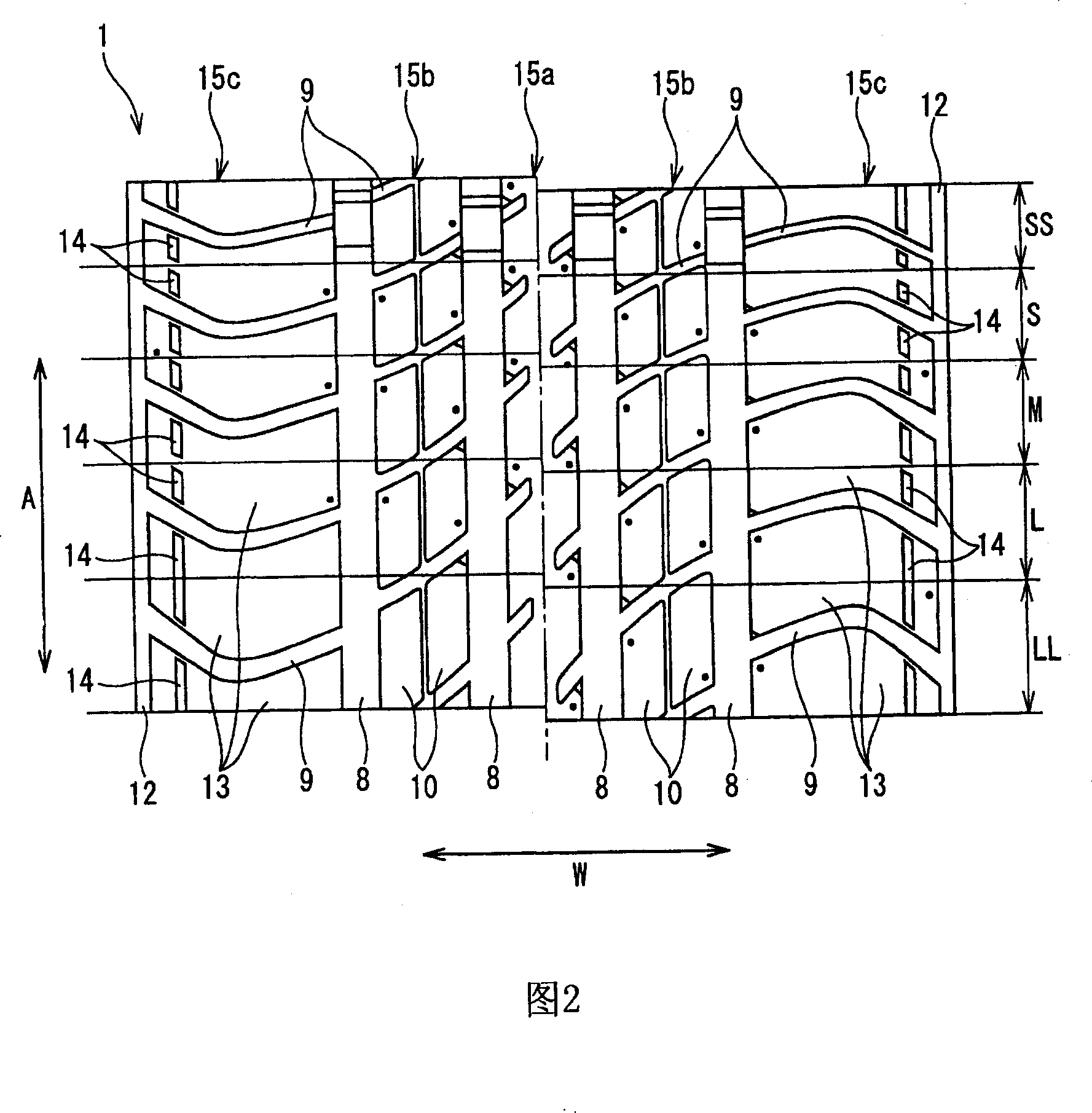

[0034] Pneumatic tires according to embodiments of the present invention will be described below with reference to the drawings.

[0035] As shown in FIG. 1 , an axial sectional view of a pneumatic tire of a first embodiment of the present invention is shown and a partially enlarged plan view of a tread pattern of the pneumatic tire is shown in FIG. 2 , the pneumatic tire of the first embodiment 1 (Hereinafter often simply referred to as a tire) consists of a tread portion 2, a sidewall portion 3, and a bead portion 4. The sidewall portion 3 extends radially inward from both ends of the tread portion 2, and the bead portion 4 It is connected to the radially inner end of the sidewall portion 3 .

[0036] The tire 1 has a carcass 6 constituted by a body portion 6 a extending from a tread portion 2 through a sidewall portion 3 to a bead portion 4 . The carcass 6 is folded back around the bead cores 5 of the bead portions 4 in a direction from the axially inner side to the axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com