Air-valve locking mechanism of automobile engine

A locking mechanism and valve technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as loss of locking effect, falling into, engine scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing.

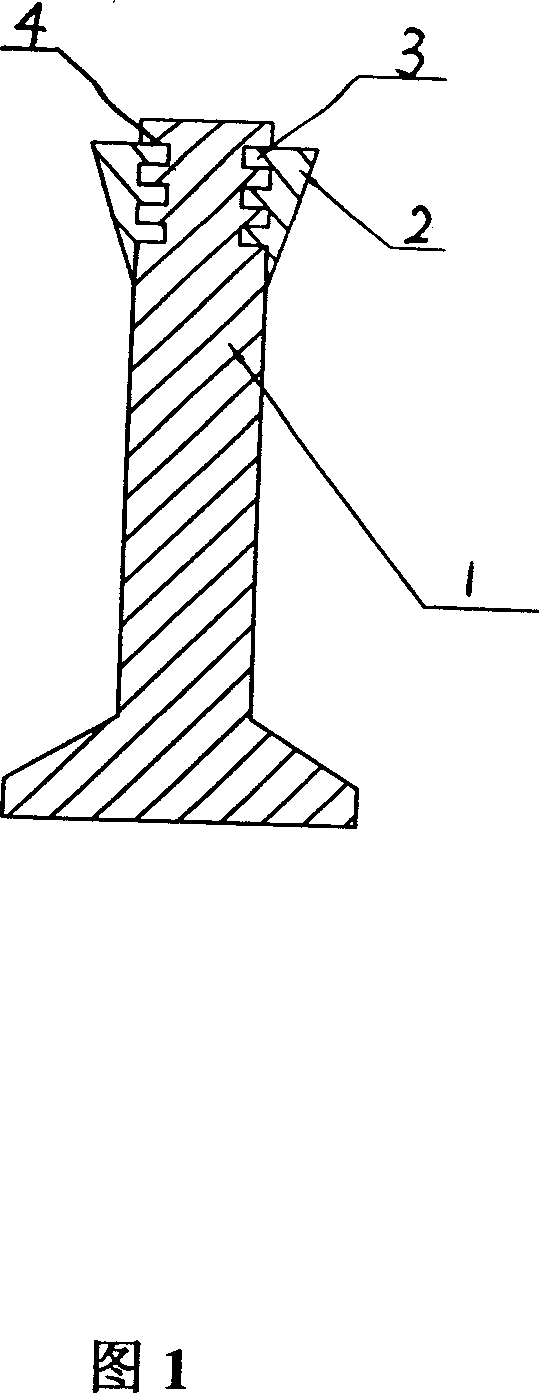

[0008] Referring to Fig. 1, the multi-channel valve locking mechanism is provided with three rings 4 for locking on the small end of the valve stem 1, the rings 4 are integrally formed with the valve stem, and each ring is arranged at equal intervals On the small end of the valve. Correspondingly, there are three half-ring protrusions 3 equally spaced on the tapered locking block 2, so that the three half-ring protrusions 3 and the three rings 4 form multiple valve locking mechanisms for locking.

[0009] Because the present invention has multiple locking effects on the air valve, it has a good locking effect, and at the same time, its service time is greatly extended.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com