Endurance performance testing method for starter

A test method and starter technology, applied in the direction of engine test, machine/structural component test, vehicle test, etc., can solve problems such as adjustment, failure to truly reflect the whole process of engine starting, failure to truly reflect, etc. Achieve accurate measured parameters, improve the effects of simulated loading and inaccurate simulated engine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

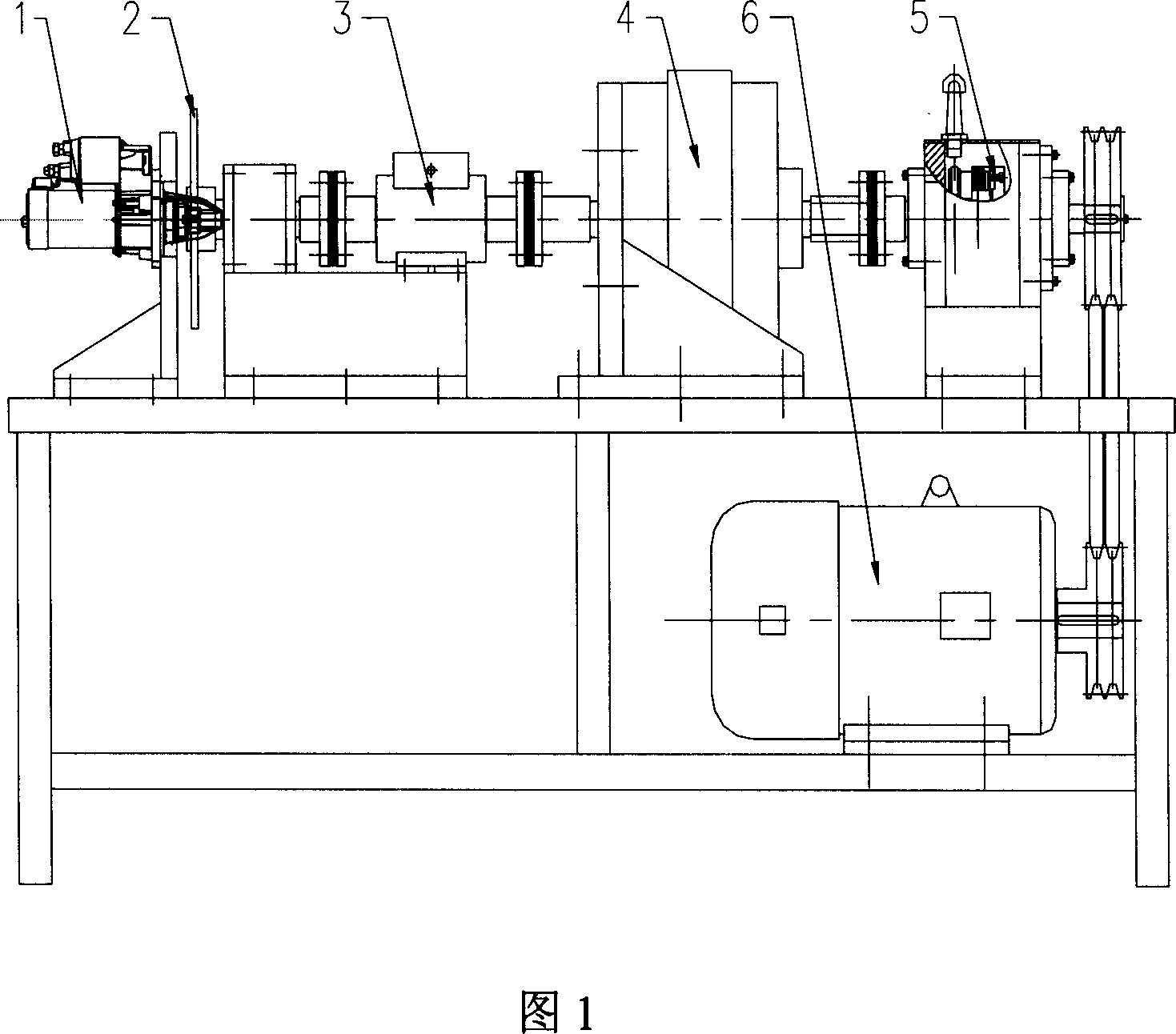

[0012] Firstly, the curve of the resistance torque changing from large to small during the engine starting process is measured on the engine test bench, and then copied to the control system of the simulated engine starter durability test bench shown in Figure 1. According to this curve, the brake is dynamically loaded with resistance torque in the starter durability test.

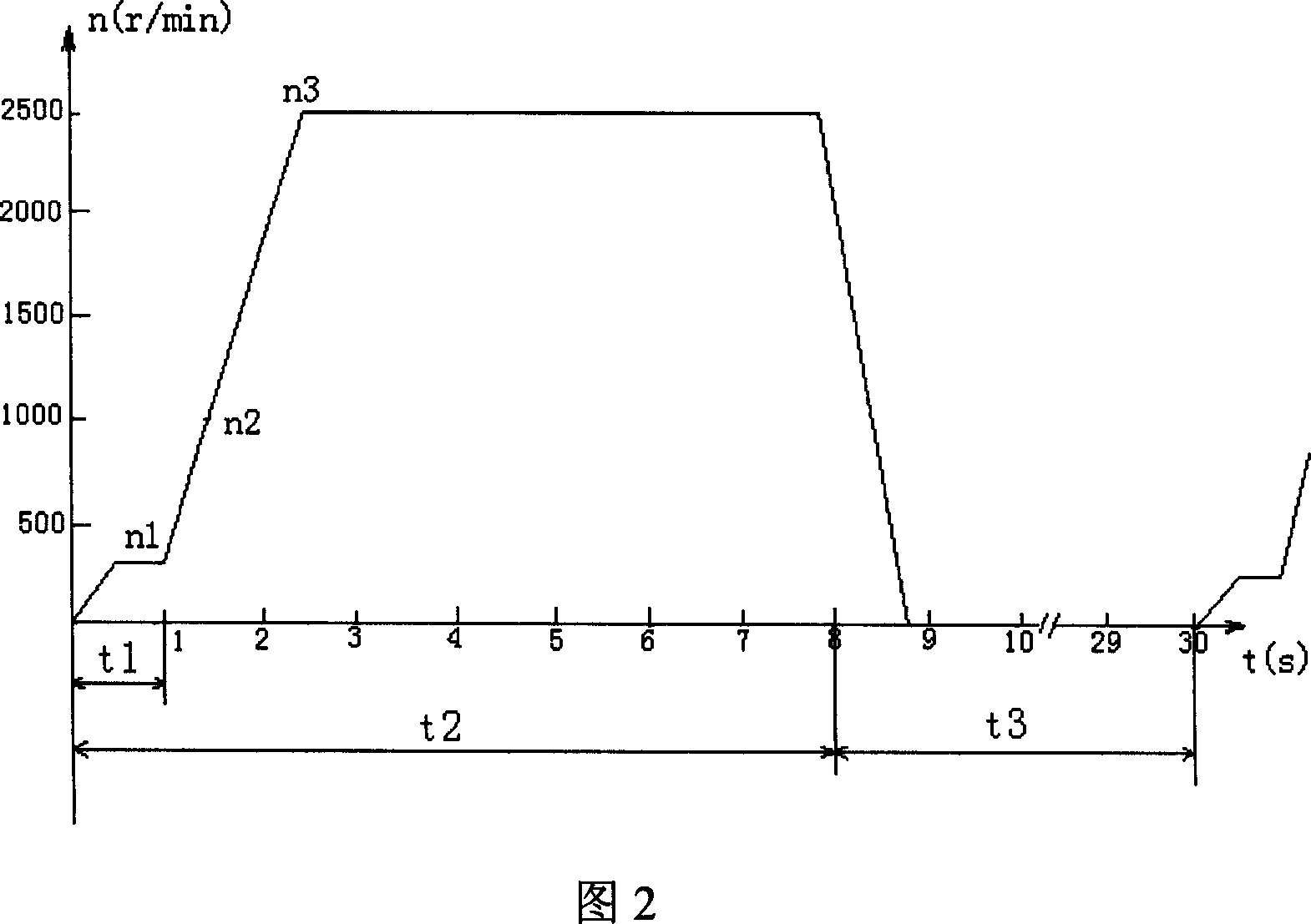

[0013] As shown in Fig. 1 and Fig. 2, when performing the starter durability test, the computer control system simulating the engine starter durability test bench first gives a maximum resistance torque that needs to be overcome when the engine is started to the magnetic powder brake 4, and closes the switch , the starter motor 1 starts. According to the above-mentioned measured resistance torque change curve in the process of starting the engine in the loaded state, the computer control system sends a dynamic torque to the magnetic powder brake 4, after a dead start time t 1 =1s, while the control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com