A quasi-three-dimensional flow virtual numerical test method for turbine engines

A turbine engine, numerical test technology, applied in image data processing, electrical digital data processing, special data processing applications, etc., can solve the problem of not providing quasi-three-dimensional flow aerodynamic modeling capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

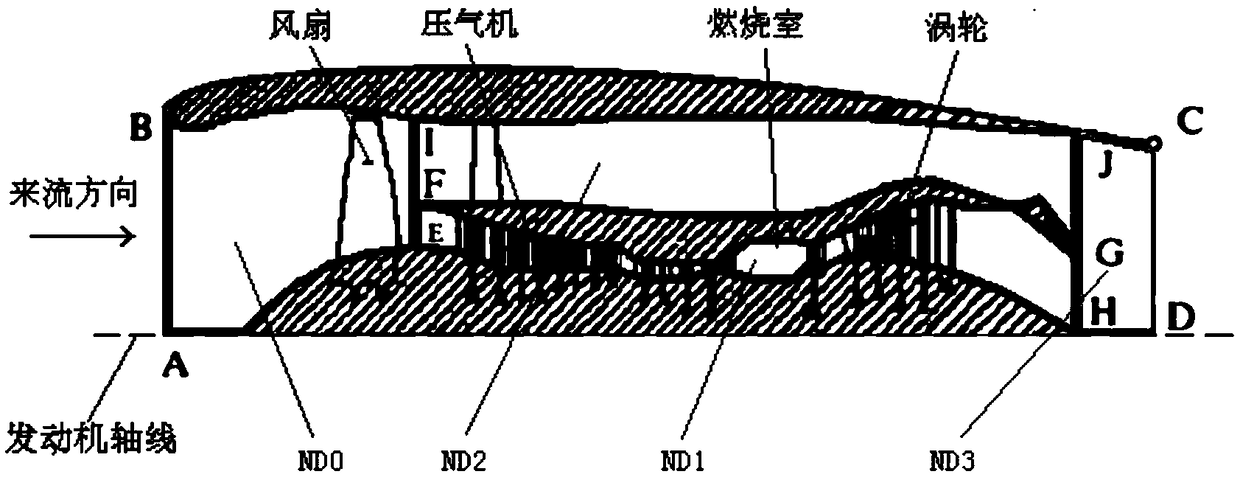

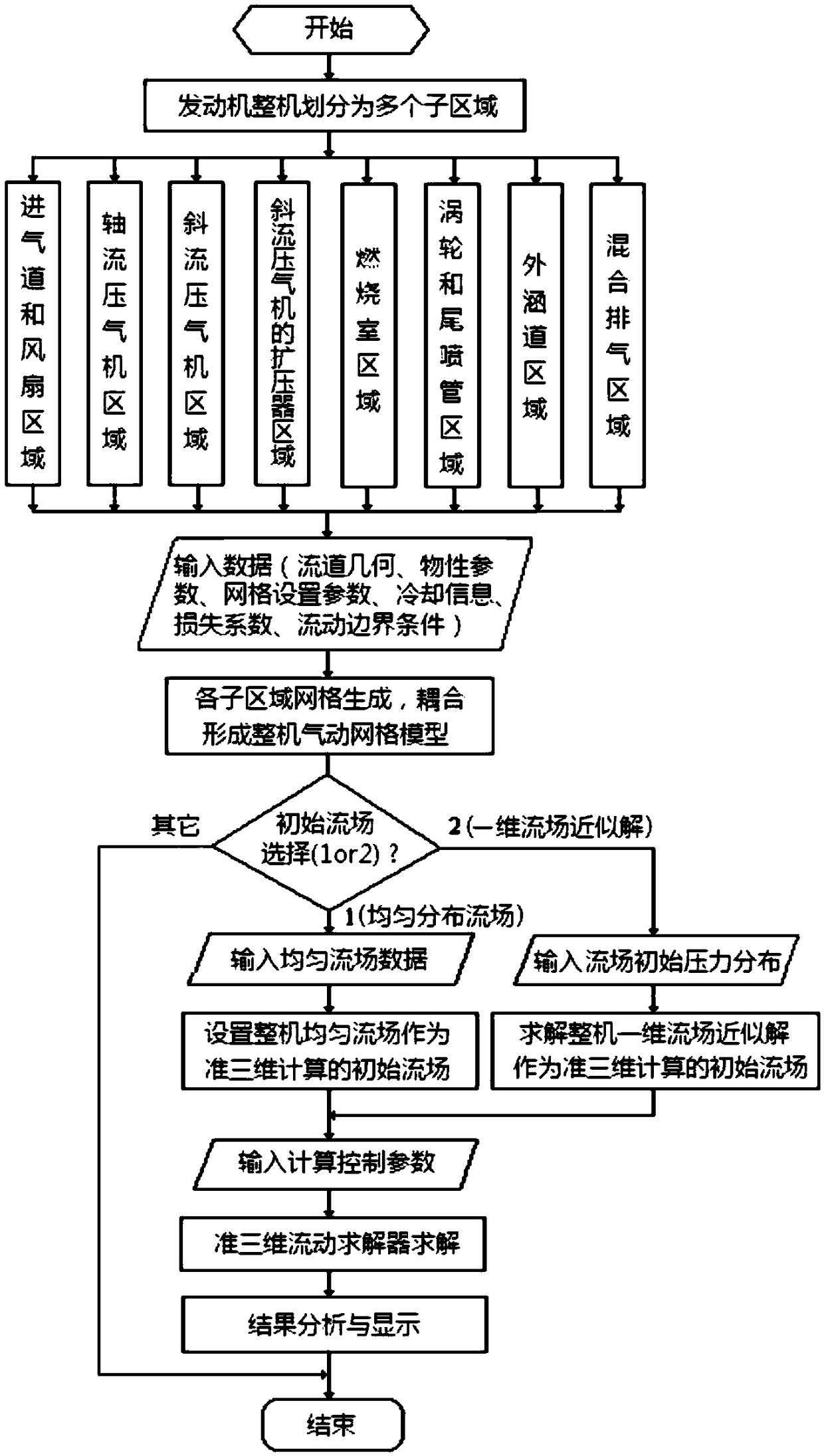

[0043] The test object of the present invention is turbine engine (comprising turbofan and turbojet engine). figure 1 It is the whole structure of the turbofan engine (if the fan part, the outer duct part and the mixed exhaust part are removed, it will become a common turbojet engine), including the ND0 area, the ND1 area, the ND2 area and the ND3 area. Among them, the ND0 area (ABIE area) is the air inlet and fan area; the ND1 area (EFGH area) is the inner channel part, including high-pressure axial flow compressor, diagonal flow compressor, diffuser, combustion chamber, high-pressure turbine, low-pressure Turbine and tailpipe area; ND2 area (FIJG area) is the outer duct area; ND3 area (HJCD area) is the inner and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com