Engine test stand device

A technology of bracket device and engine, which is applied in the direction of engine test, measurement device, machine/structural component test, etc., can solve problems such as low efficiency, easy damage to engine bracket and dial indicator, and uncontrollable force, so as to avoid damage. , Reduce the amount of manual labor, the effect of high adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

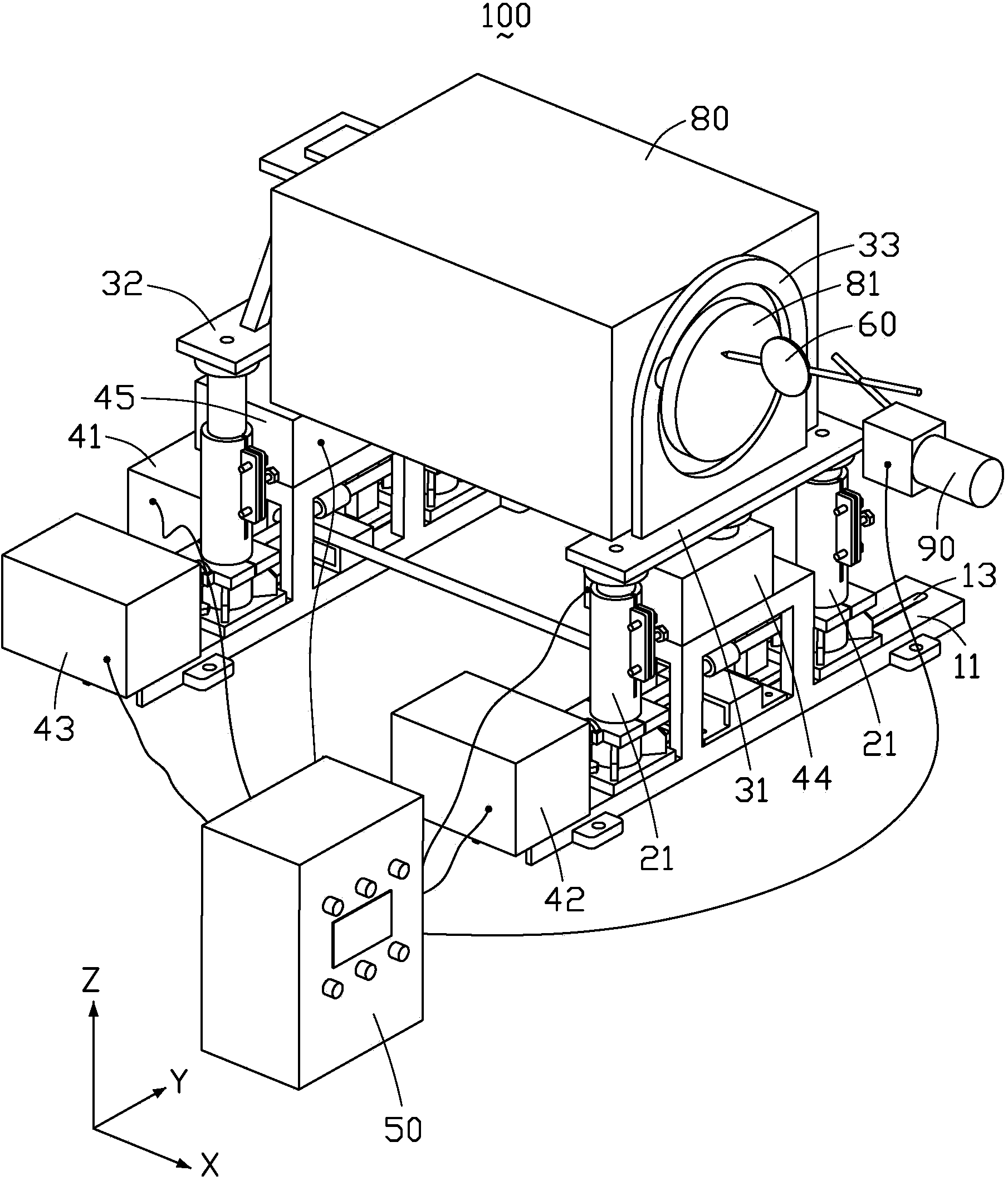

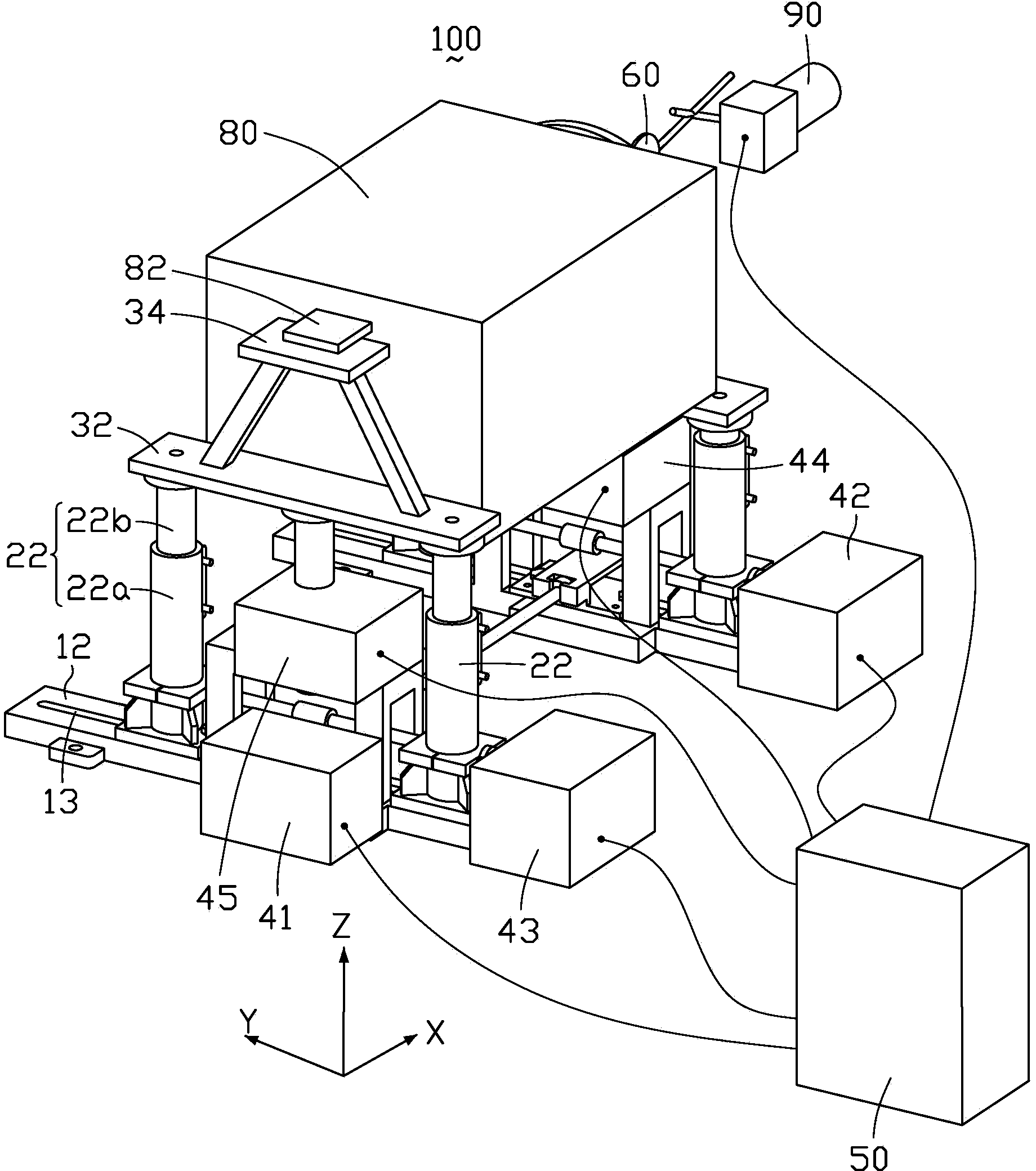

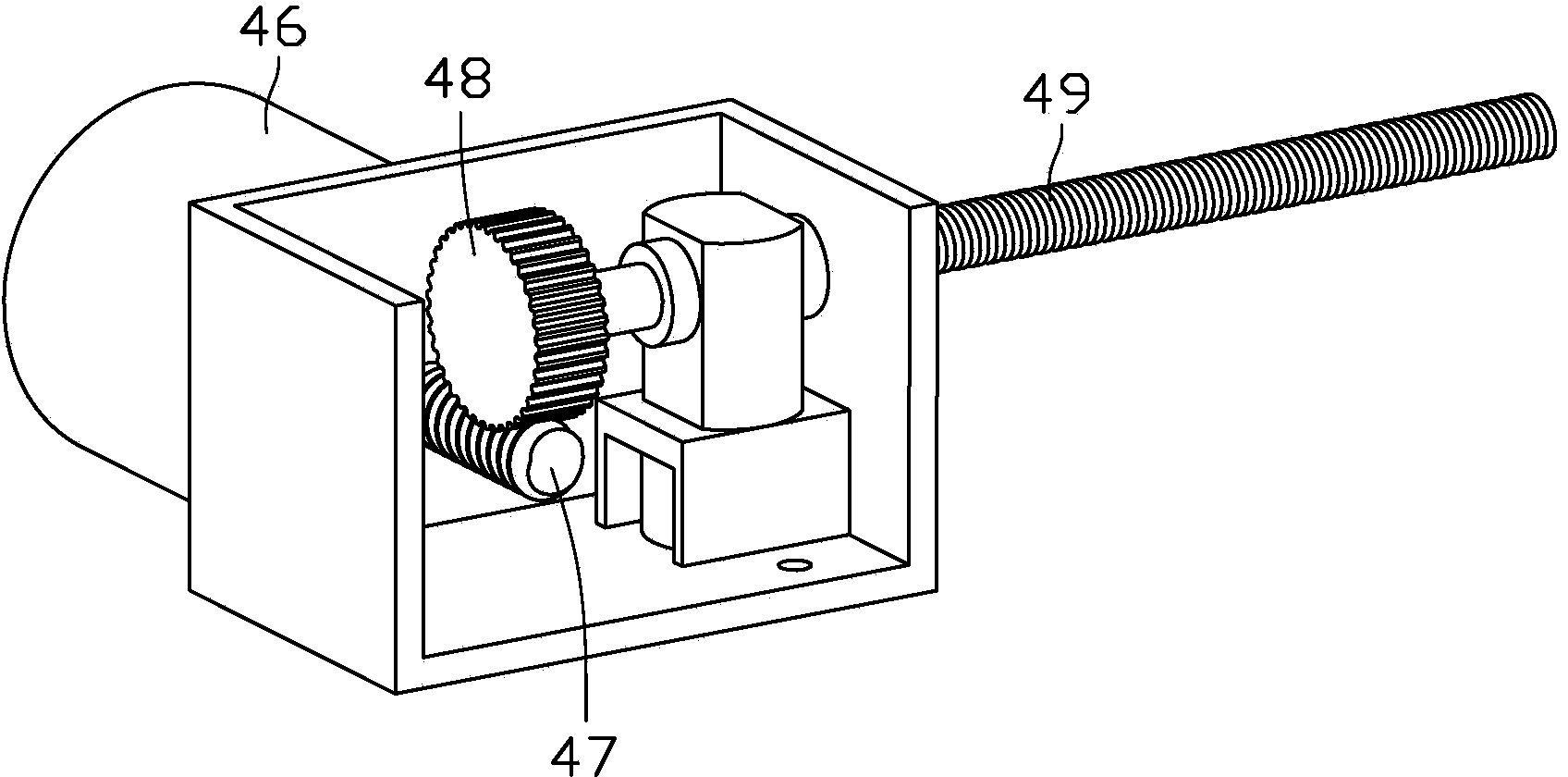

[0014] Please refer to figure 1 and figure 2 The engine test support device 100 provided by the embodiment of the present invention comprises a front support base 11, a rear support base 12, a first support 21, a second support 22, a front support top plate 31, a rear support top plate 32, a front and rear automatic adjustment mechanism 41, a front end Left and right automatic adjustment mechanism 42, rear end left and right automatic adjustment mechanism 43, front end up and down automatic adjustment mechanism 44, rear end up and down automatic adjustment mechanism 45, control box 50 and detection sensor 60.

[0015] The front support base 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com