Operating device of weaving machine

A technology for operating devices and looms, applied in looms, auxiliary equipment for weaving, weaving, etc., can solve the problems of fabric defects, inability to reliably eliminate thick and thin sections, and inability to apply opening devices, and achieve the effect of preventing thick and thin sections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

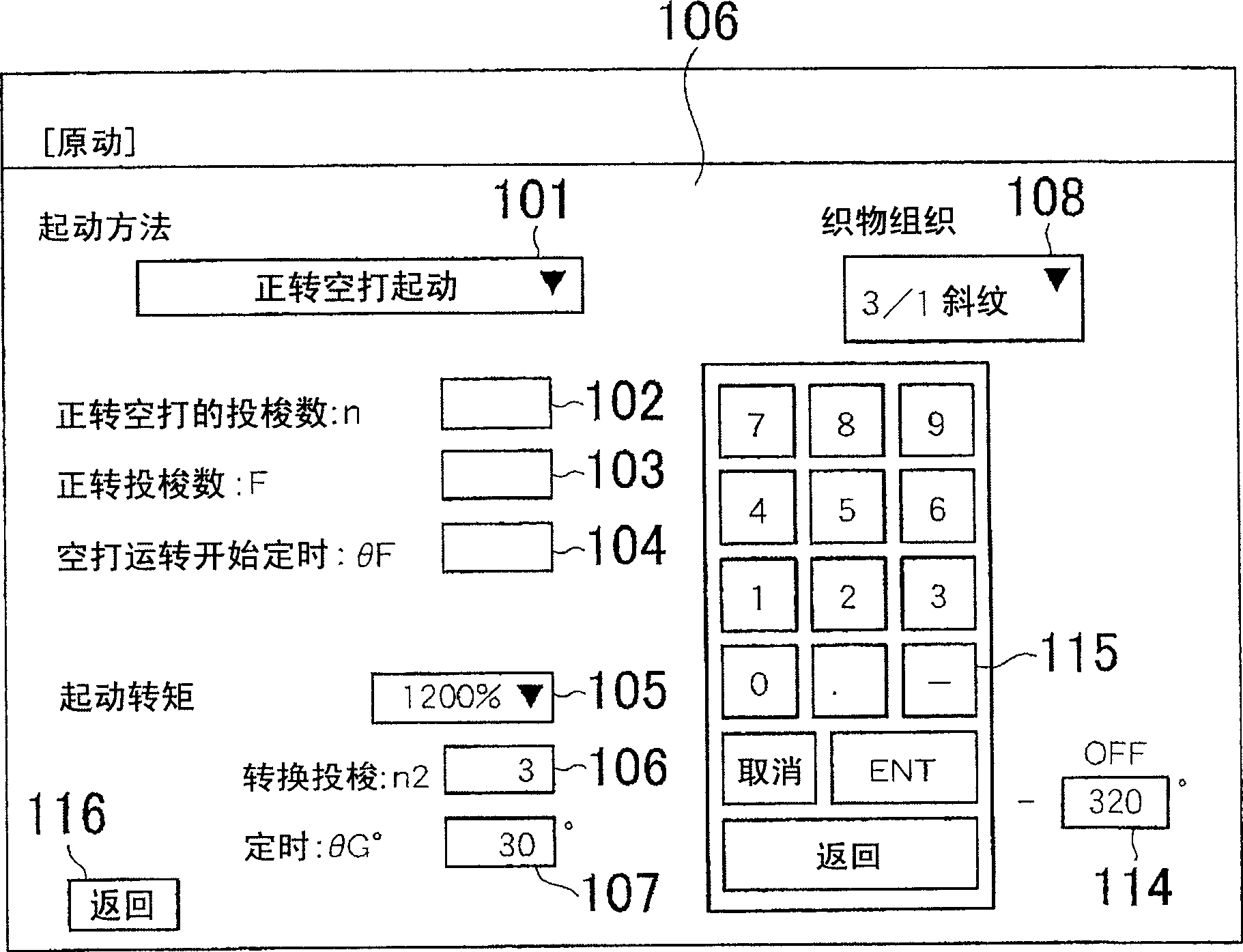

[0039] [Example of loom]

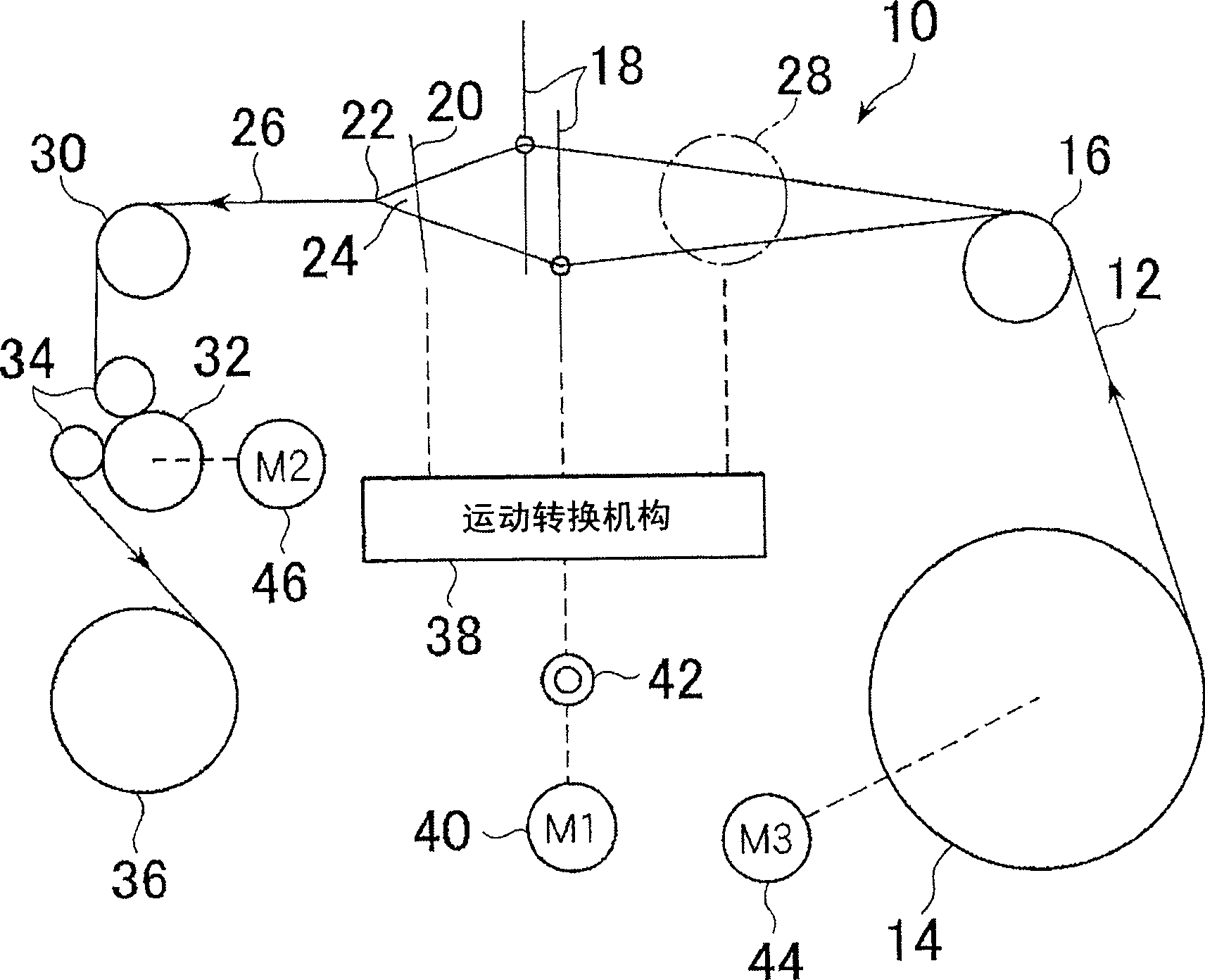

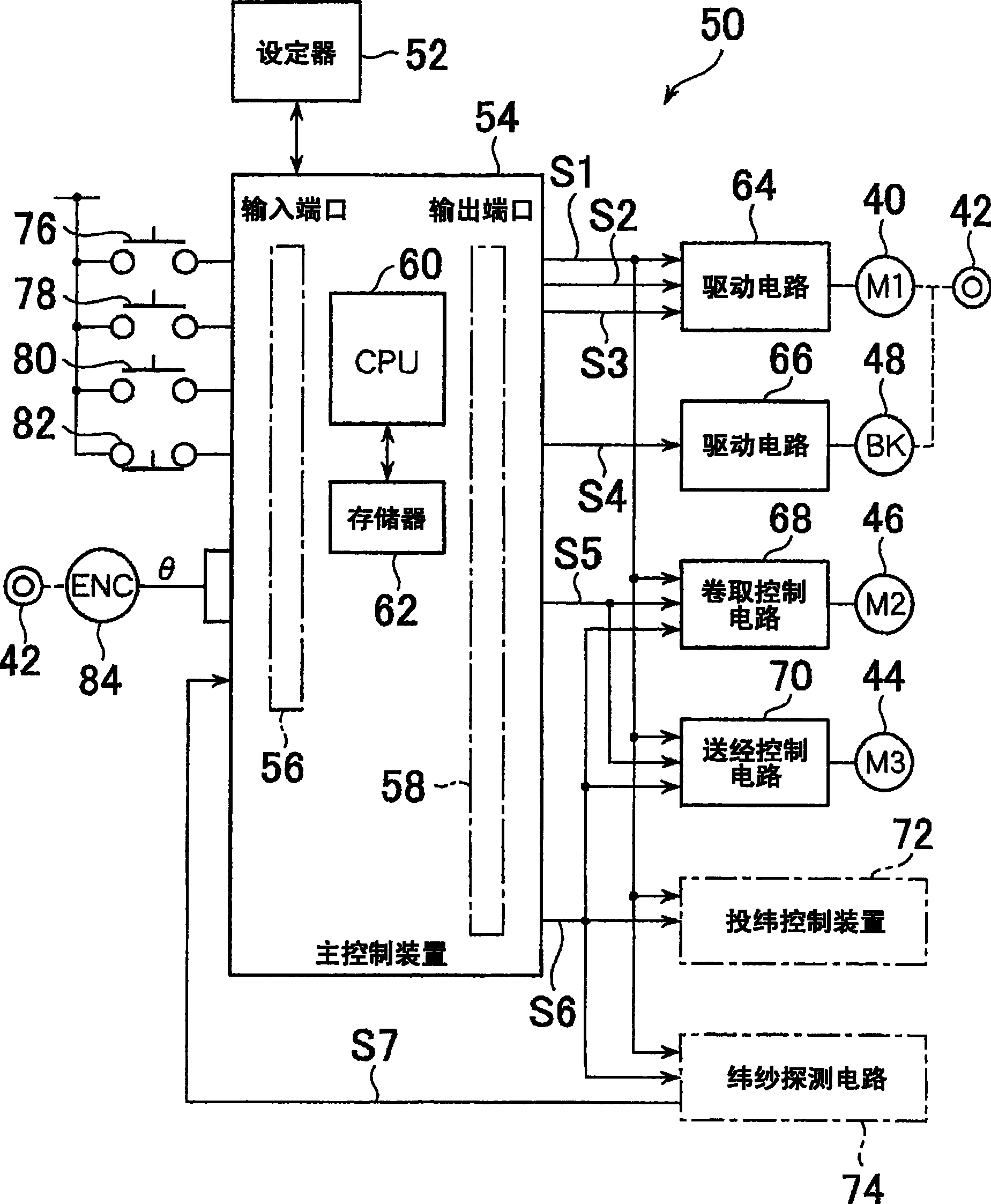

[0040] refer to figure 1 , in the loom 10, a plurality of warp yarns 12 and a plurality of sets of side yarns (not shown) are pulled out in sheet form from the warp beam 14 that winds them up, and pass through the back roller 16, a plurality of heald frames 18 And the reed 20 is connected to the cloth fell 22.

[0041] The warp yarn 12 also passes through the healds attached to the heald frames 18 and is opened by the reciprocating motion of each heald frame 18 . In the opening 24 of the warp yarn 12, the weft yarn 130 is dropped into by an unillustrated weft inserting device (refer to Figure 6 ). The weft yarn 130 that has been picked is beaten to the cloth fell 22 by the reed 20 . In this way, the fabric 26 is woven.

[0042] A plurality of sets of side yarns arranged near both ends of the fabric are respectively opened by the side yarn shedding device 28 arranged between the back roller 16 and the heald frame 18 . Drive the side yarn sheddi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com