Stee concrete prefabricated plate with rib

A technology of reinforced concrete and prefabricated slabs, applied to floors, building components, buildings, etc., can solve the problems of affecting the stability of floors, large loss of formwork, and short construction period, and achieve the effect of ensuring application safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

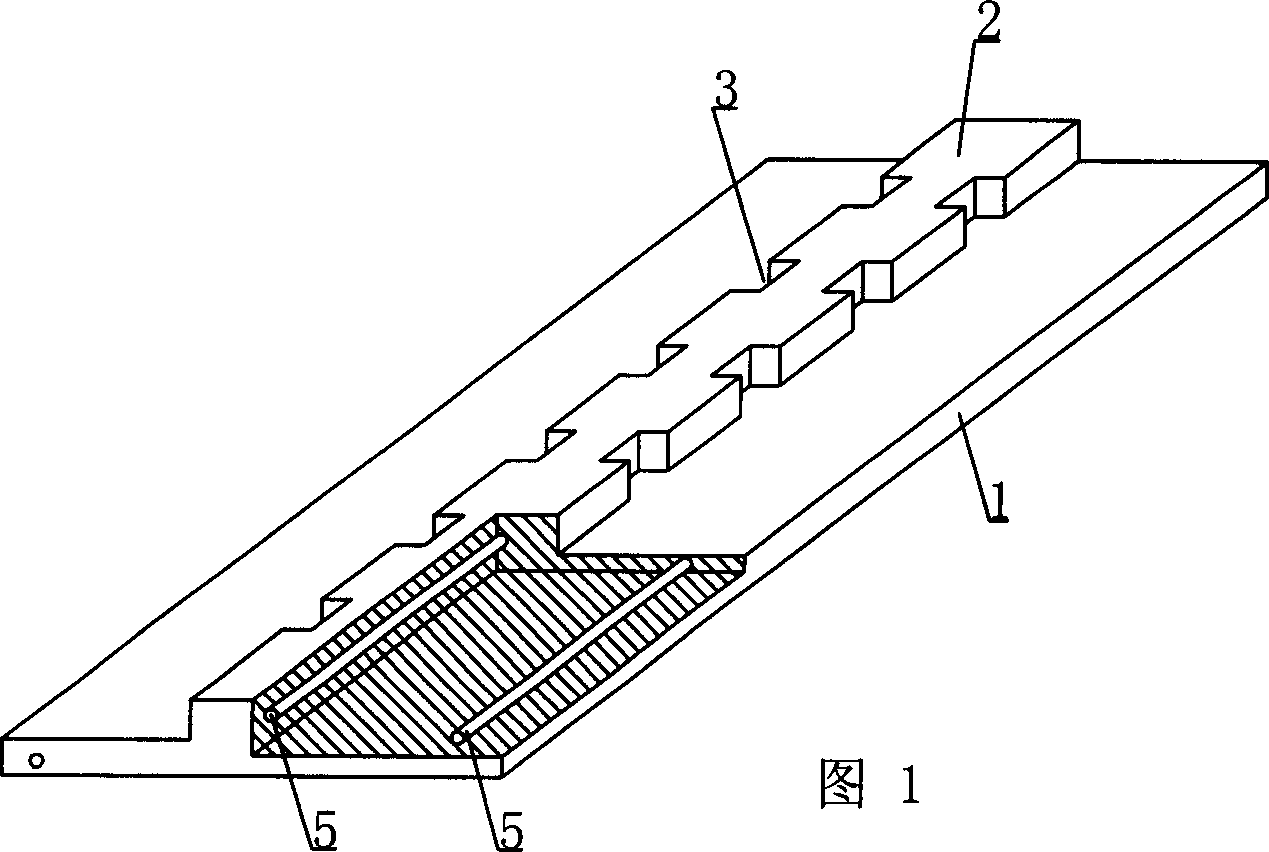

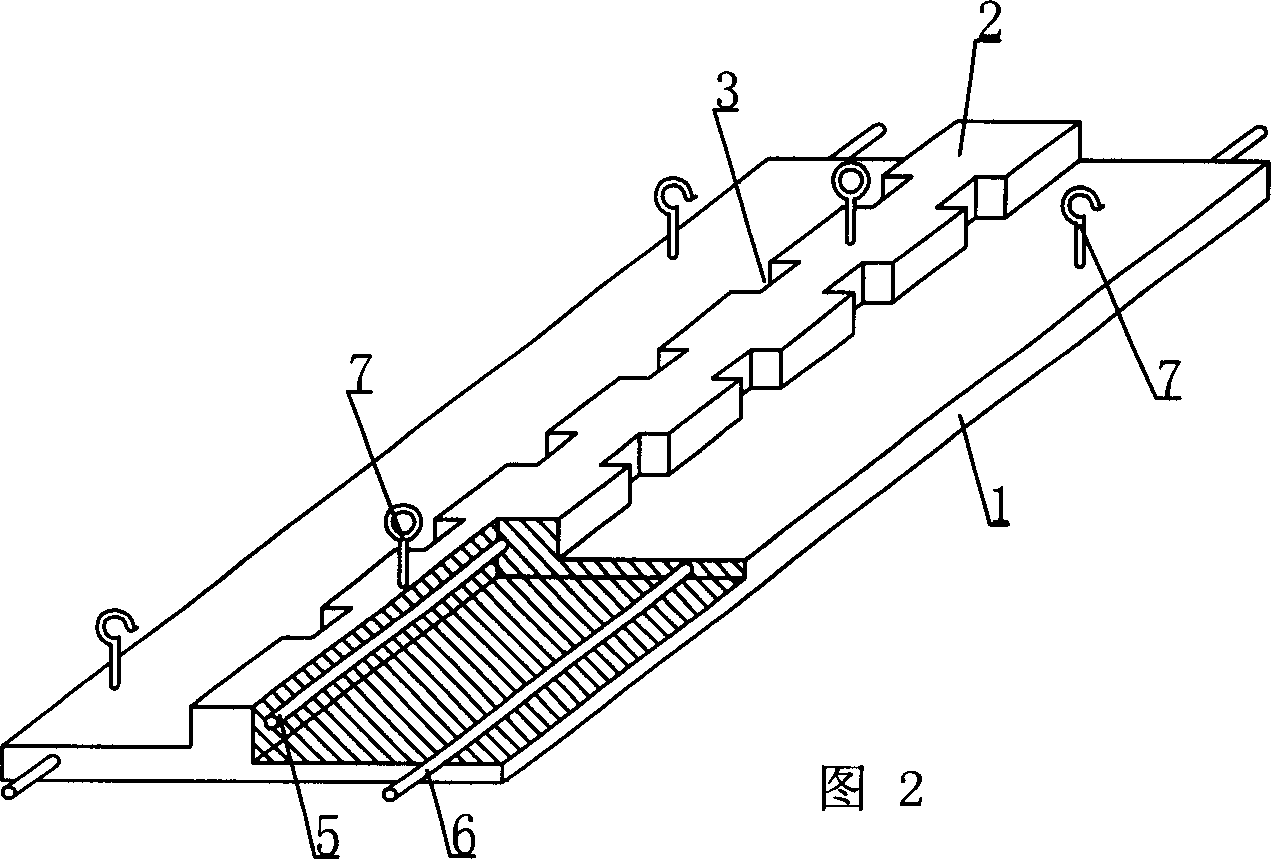

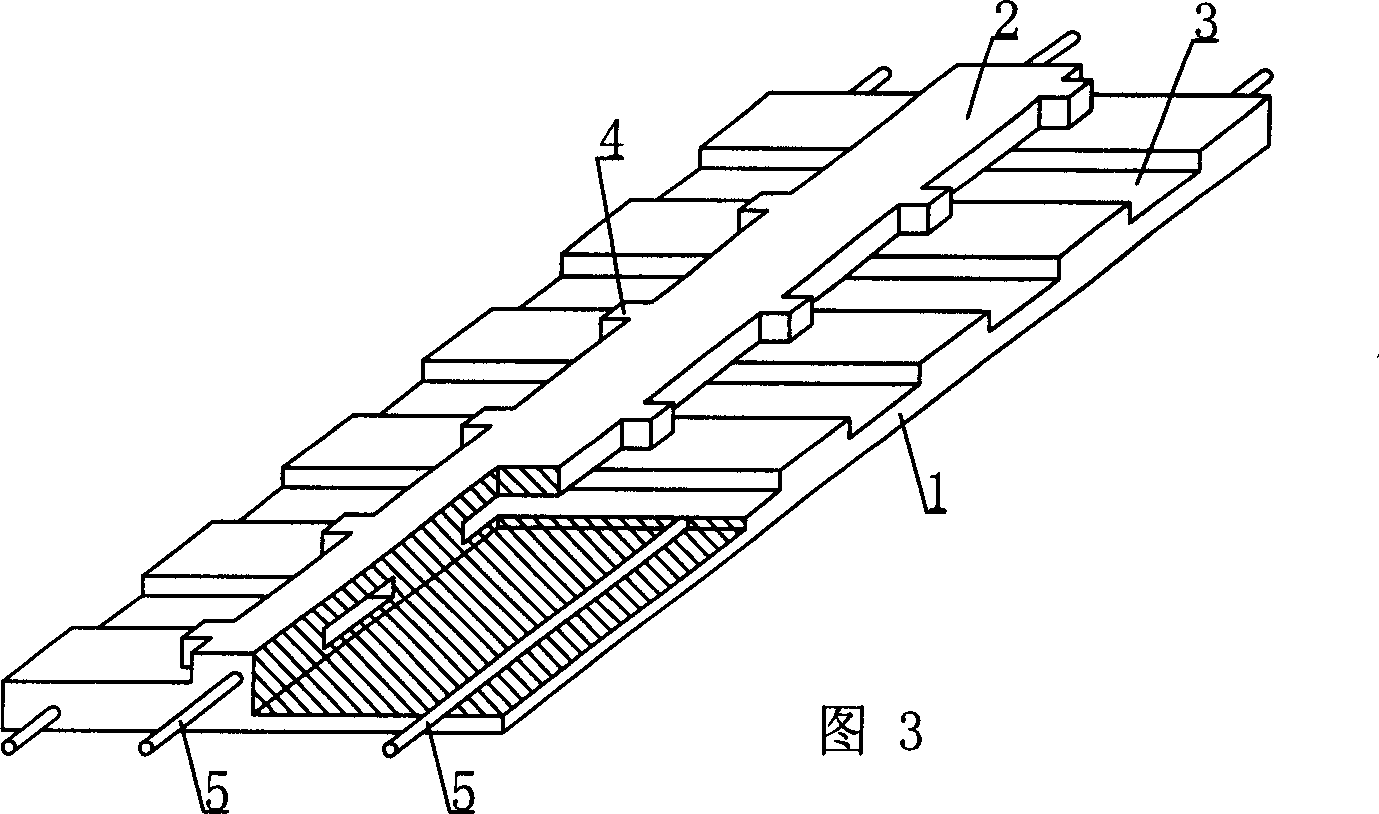

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0059] As shown in the accompanying drawings, the present invention includes a reinforced concrete strip bottom plate 1 and a reinforced concrete longitudinal long rib (2), and is characterized in that there are vertical grooves 3 or / and on one or two rib sides of the longitudinal long rib 2 The protruding strip 4, the longitudinal steel bars 5 of the longitudinal long ribs 2 and the longitudinal steel bars 5 in the long bottom plate 1 are arranged in parallel. In each accompanying drawing, 1 is a bottom plate, 2 is a long rib, 3 is a groove, 4 is a convex line, and 5 is a steel bar. In the following accompanying drawings, those with the same number have the same description. As shown in Figure 1, the reinforced concrete ribbed prefabricated slab includes a reinforced concrete bottom plate 1 and a reinforced concrete longitudinal rib 2, and vertical gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com