Transparent film masterbatch and its preparing method

A transparent film and masterbatch technology, applied in the field of transparent film masterbatch and its preparation, can solve the problems of light transmittance decrease, cost reduction, transparency decrease, etc.

Inactive Publication Date: 2007-04-25

SHANGHAI LINDA PLASTIC CHEM CO LTD

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problem that not only the mechanical properties of the plastic film decrease after using the filler masterbatch, especially the light transmittance, but also the transparency. Good light transmittance, high transparency, and can greatly reduce costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0061] Embodiment 1: formula ratio is as follows:

[0062]

Embodiment 2

[0063] Embodiment 2: formula ratio is as follows:

[0064]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Login to view more

Abstract

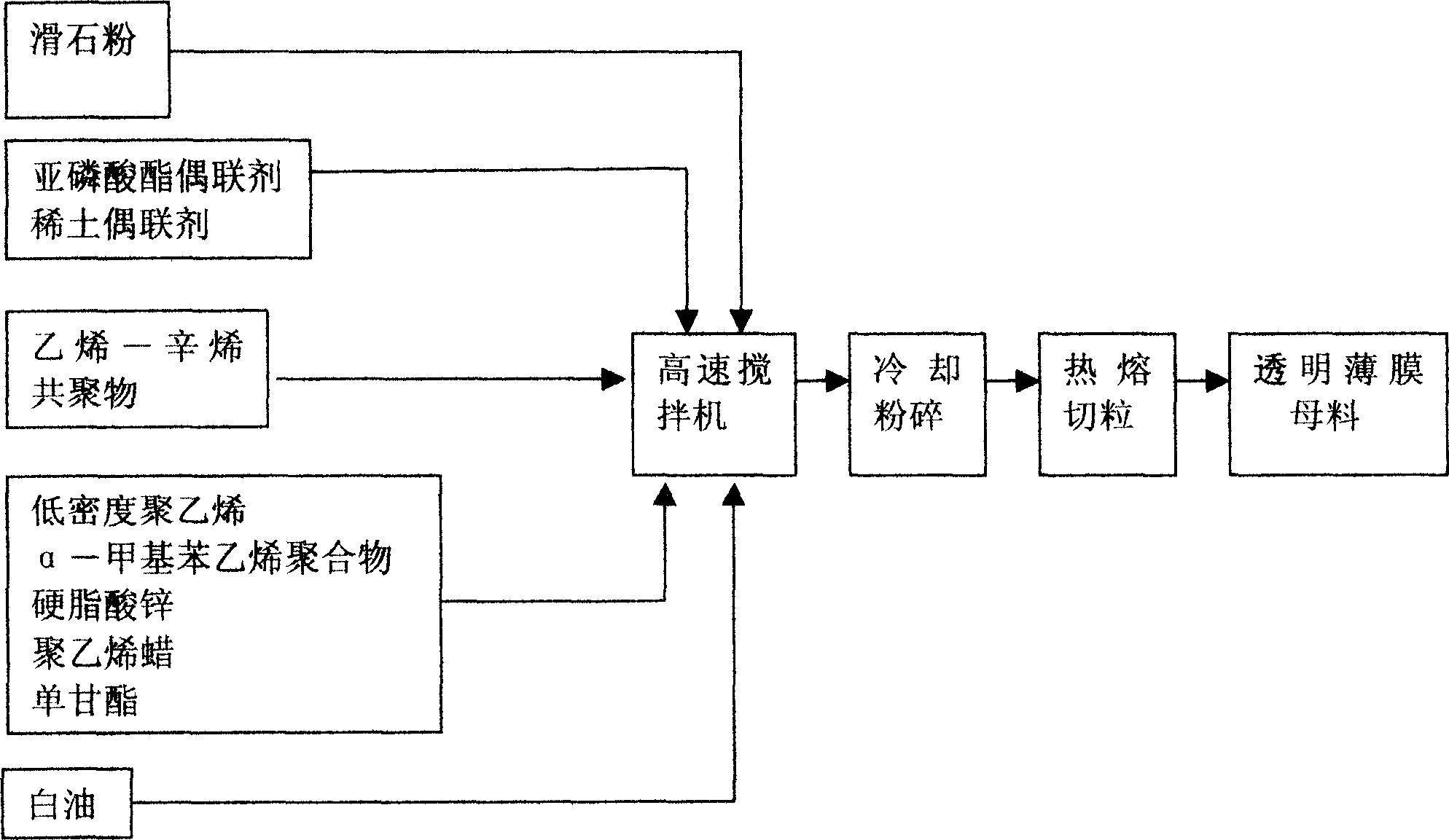

The invention discloses a transparent film mother material and preparing method, which comprises the following parts: 75-85% talcum powder, 5-16% low-density polyethylene, 5-8% ethane-octanolefin copolymer, 0.5-1% alpha-methyl phenylethene polymer, 0.5-2% zinc stearate, 0.5-2% polyethylene wax, 0.5-2% monoglyester, 0.5-2% phosphite ester coupler, 0.5-2% rare earth coupler and 0.5-2% white oil. The making method comprises the following steps: cladding surface of talcum powder through phosphite ester coupler and rare earth coupler in the high-speed blender; cladding talcum powder through ethane-octanolefin copolymer; cladding talcum powder through low-density polyethylene, alpha-methyl phenylethene polymer, zinc stearate, polyethylene wax and monoglyester; adding white oil to stir 2min; placing composite materials into twin-screw extruder; plastifying; graining; heating to cut; winding to obtain the particle-shaped mother material.

Description

1. Technical field: [0001] The invention relates to a masterbatch and a preparation method thereof, in particular to a transparent film masterbatch and a preparation method thereof. 2. Background technology: [0002] In China's plastic processing industry, the plastic packaging industry and the agricultural plastic industry are the industries with the largest output. Among them, various and varied plastic films such as packaging films, agricultural land films, and greenhouse films, whether blow-molded or tape-cast, and extended products of films, such as composite films and geocomposites, use a large amount of resin , mainly high-density polyethylene, low-density polyethylene and linear low-density polyethylene. [0003] In the context of rising oil prices, the price of resin has soared, but the price of products cannot be increased, which makes plastic processing enterprises fall into a very difficult situation. How to face the price increase of plastic raw materials, man...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08K5/524C08J5/18C08J3/12C08L23/08C08K5/09

Inventor 王梓刚

Owner SHANGHAI LINDA PLASTIC CHEM CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap