Bolt for vacuum apparatus

A vacuum device and screw technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as affecting vacuum acquisition and small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

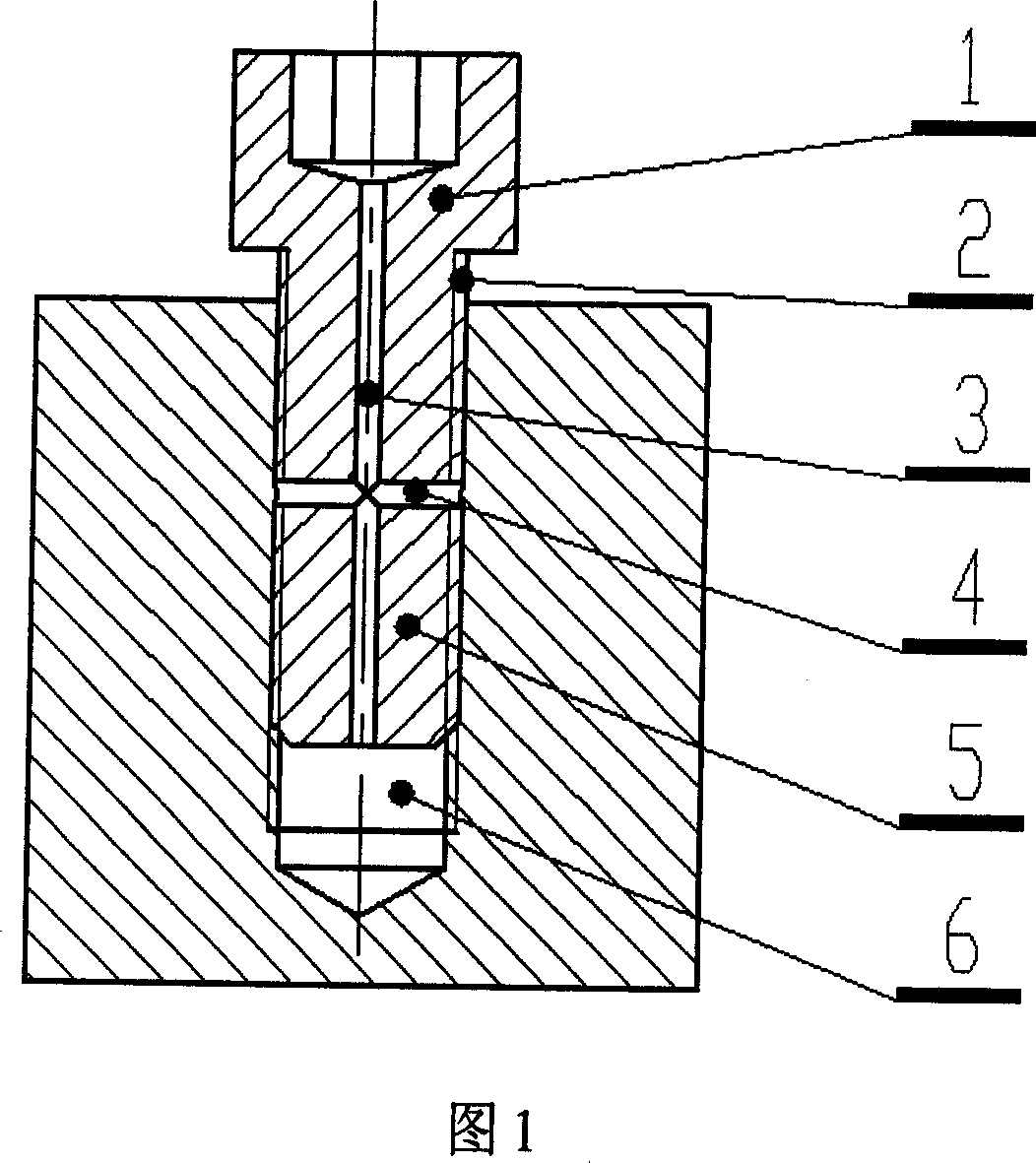

[0007] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The screw of the present invention consists of a nail head 01 and a nail body 05. The outer edge surface of the nail body 05 is provided with an external thread 02, and a through hole 03 is opened in the axial direction of the nail body 05, and a through hole 04 is opened in a direction perpendicular to the outer edge surface of the nail body 05. The axial through hole 03 facilitates the removal of gas in the space between the screw and the head of the screw hole 06, and the vertical through hole 04 facilitates the removal of gas between the screw and the thread on the outer edge of the screw hole, thereby contributing to the vacuum of the vacuum device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com