3D non-contacting type coordinates equipment for measuring fabric or garment material

A non-contact, coordinate measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of time-consuming, difficult to achieve real-time measurement, scanning blind spots, etc., to improve accuracy, avoid measurement blind spots, reduce unnecessary deterministic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

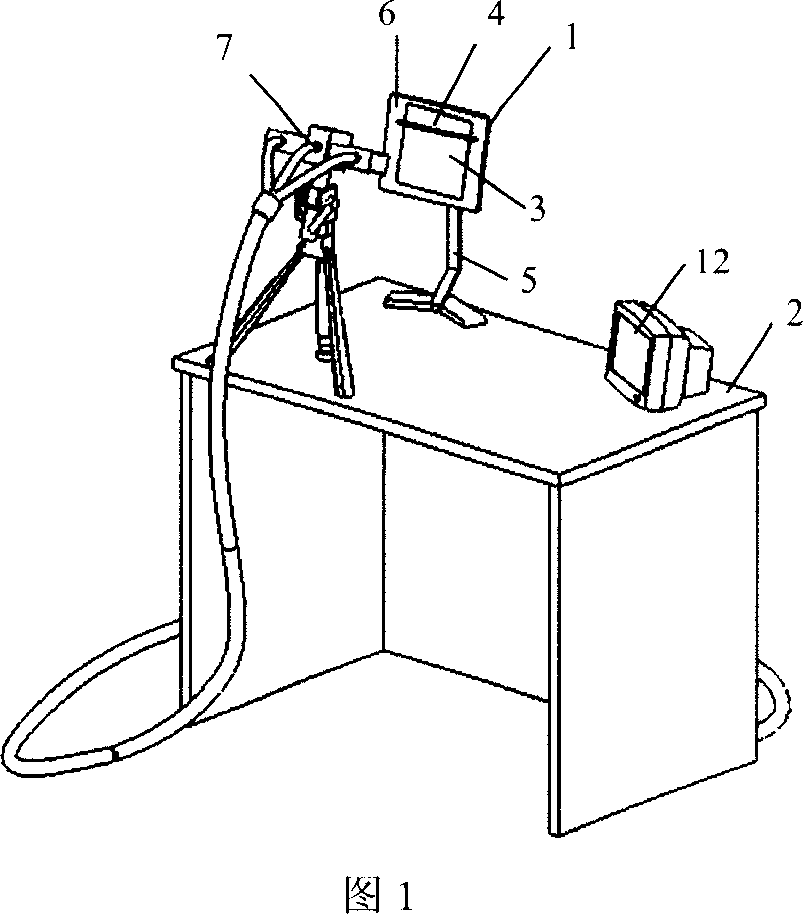

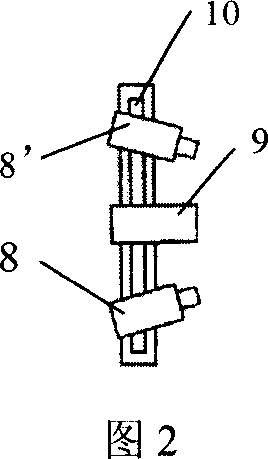

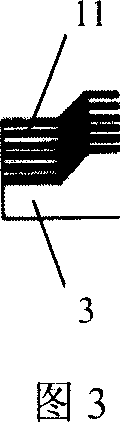

[0022] With reference to accompanying drawing 1-7, the present invention comprises fabric clamping device 1, sensor 7 and microcomputer 12, and described fabric clamping device 1 comprises the rotating shaft 5 and black magnetic plate 6 of movably connected, and fabric clamping device 1 lays flat on On the horizontal desktop 2, the fabric to be tested 3 is adsorbed on the black magnetic plate 6 through the magnetic strip 4; the sensor 7 is composed of a left camera 8, a right camera 8' and a grating projector 9 stuck in the chute 10, and the left The positions of the camera 8 and the right camera 8' can be adjusted, and the grating projector 9 is equipped with a white projection bulb and a coded grating that can produce regularly changing frequency-conversion stripes; the center of the sensor 7 is as high as the center of the fabric 3 to be tested; Camera 8, right camera 8' are connected with microcomputer 12.

[0023] In order to minimize the interference of external light, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com