Transformer

A technology for transformers and flanges, which is applied in the field of transformers and can solve problems such as difficulty and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0068] Fig. 5 is a sectional view related to the second embodiment.

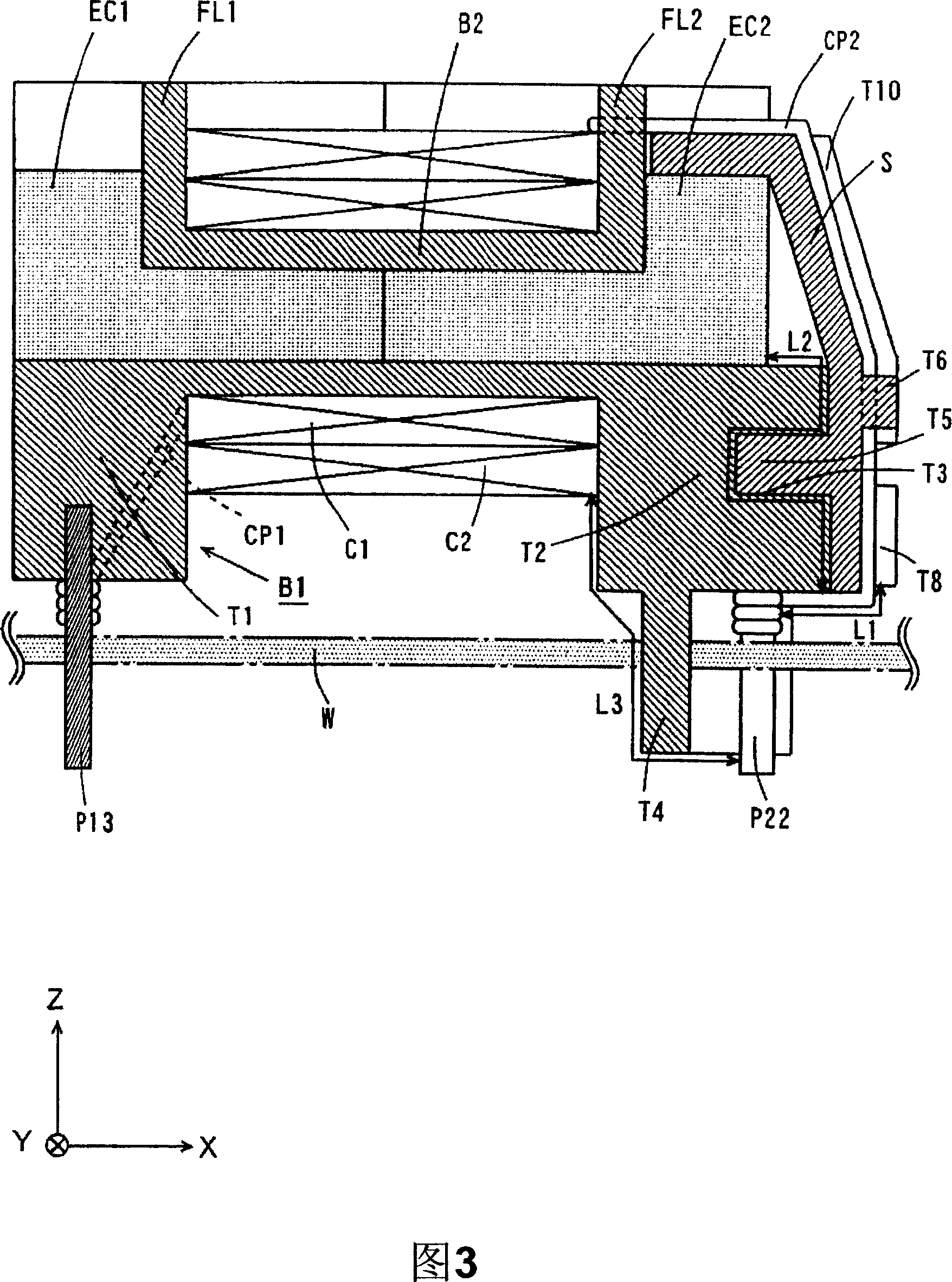

[0069] In FIG. 5 , directions perpendicular to each other are indicated by X, Y, and Z axes. The direction of the arrow X is the front side, the direction opposite to the arrow X is the back side, the direction of the arrow Y is the side side, the direction of the arrow Z is the upper side, and the direction opposite to the arrow Z is the lower side side.

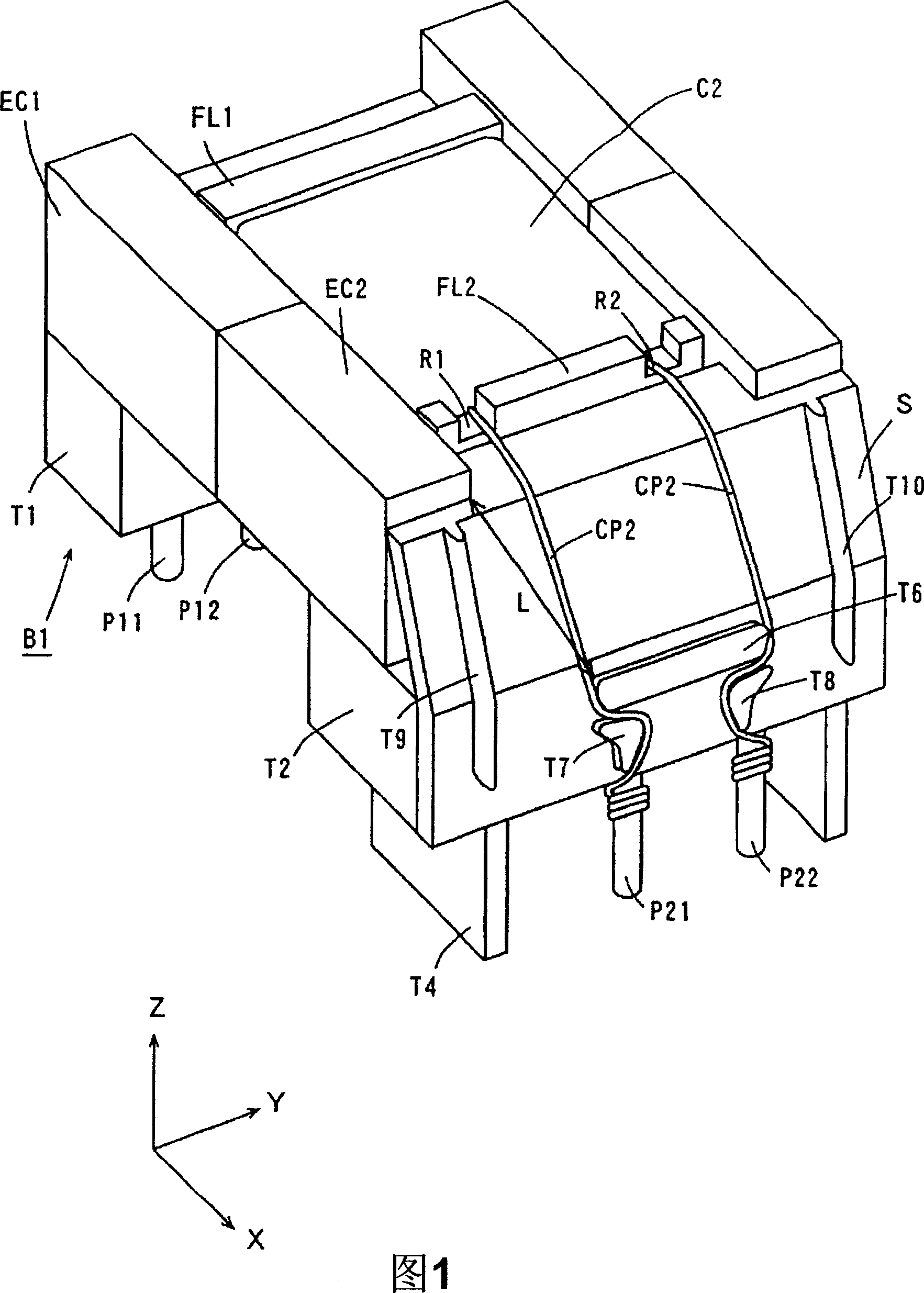

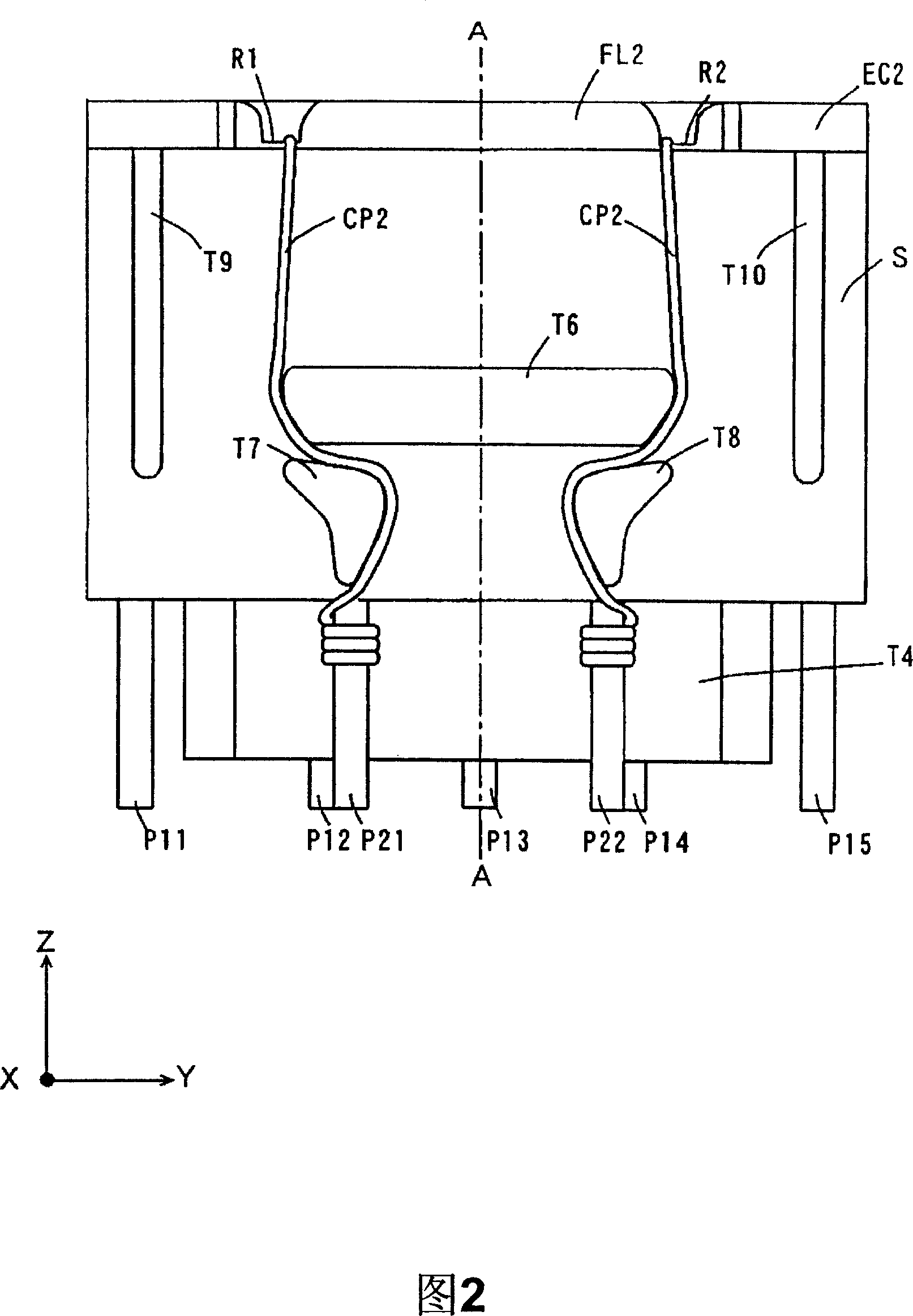

[0070] The transformer shown in FIG. 5 includes a bobbin B11, a primary coil C1, a secondary coil C2, E-shaped cores E1, E2, pin terminals P31, P32, and an insulating member S1.

[0071] Coil B11 is composed of winding part B12 around which primary coil C1 and secondary coil C2 are wound, flange part FL11 formed at the lower end of winding part B12, and flange part FL12 formed at the upper part of winding part B2. Wherein, the bobbin B11 is integrally formed of an insulating material such as plastic.

[0072] On the back side of the flange portion FL11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com