Electrical plug connector and electrical plug connection

一种插塞连接器、连接电缆的技术,应用在连接、电气元件、连接装置的零部件等方向,能够解决不再保持密封作用、扣紧力矩大、电气插塞连接器损坏等问题,达到防止过度挤压的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

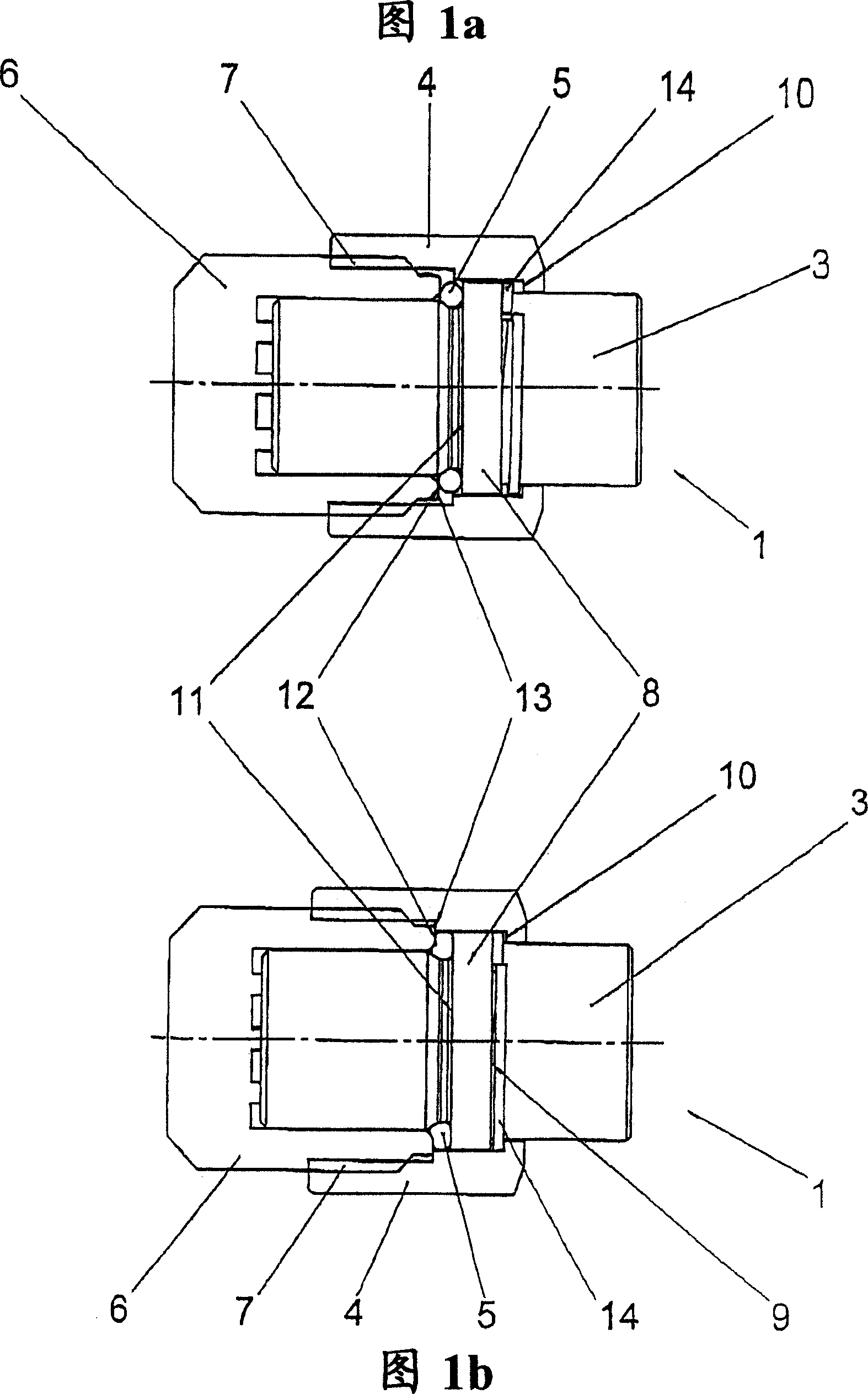

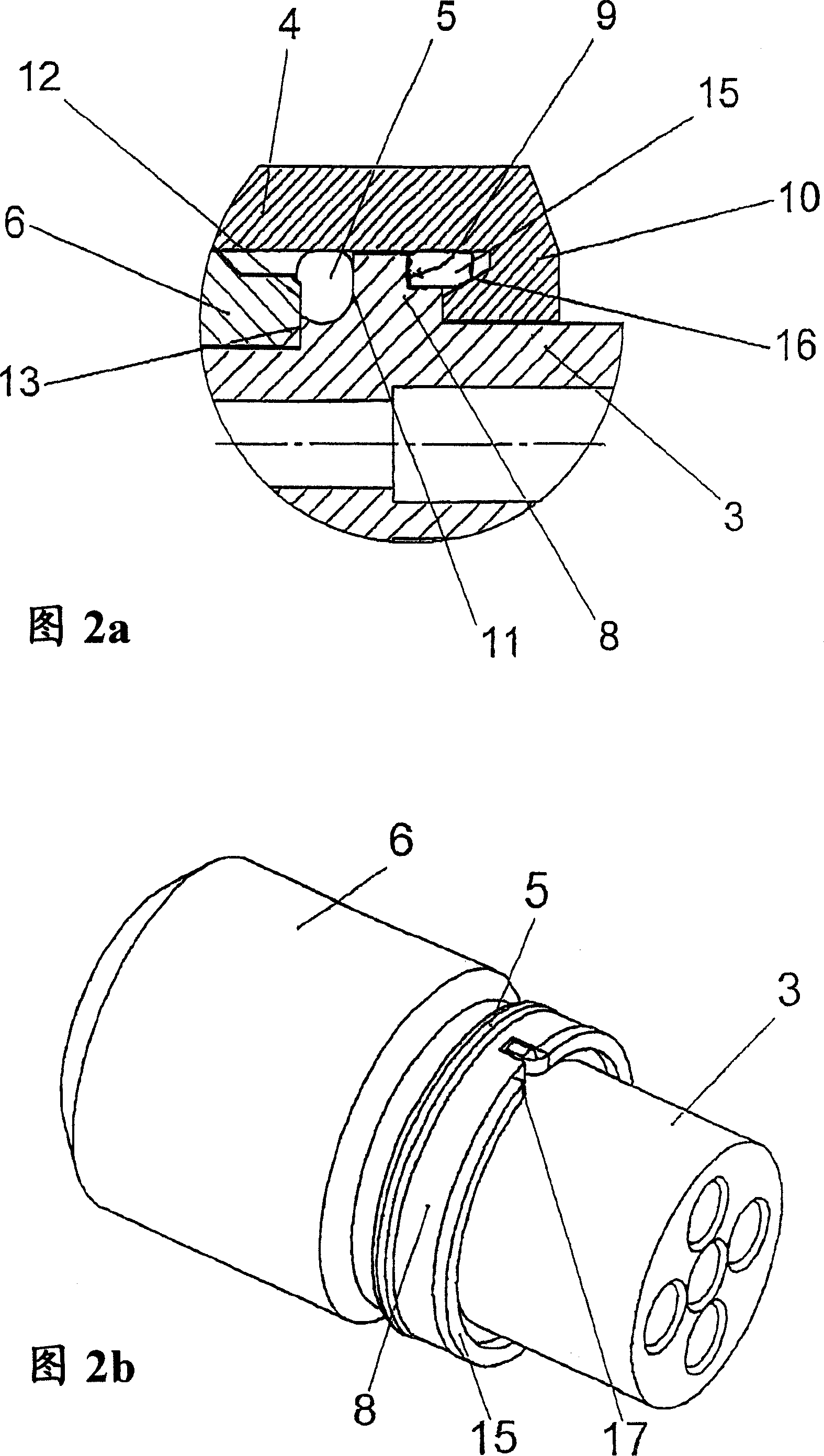

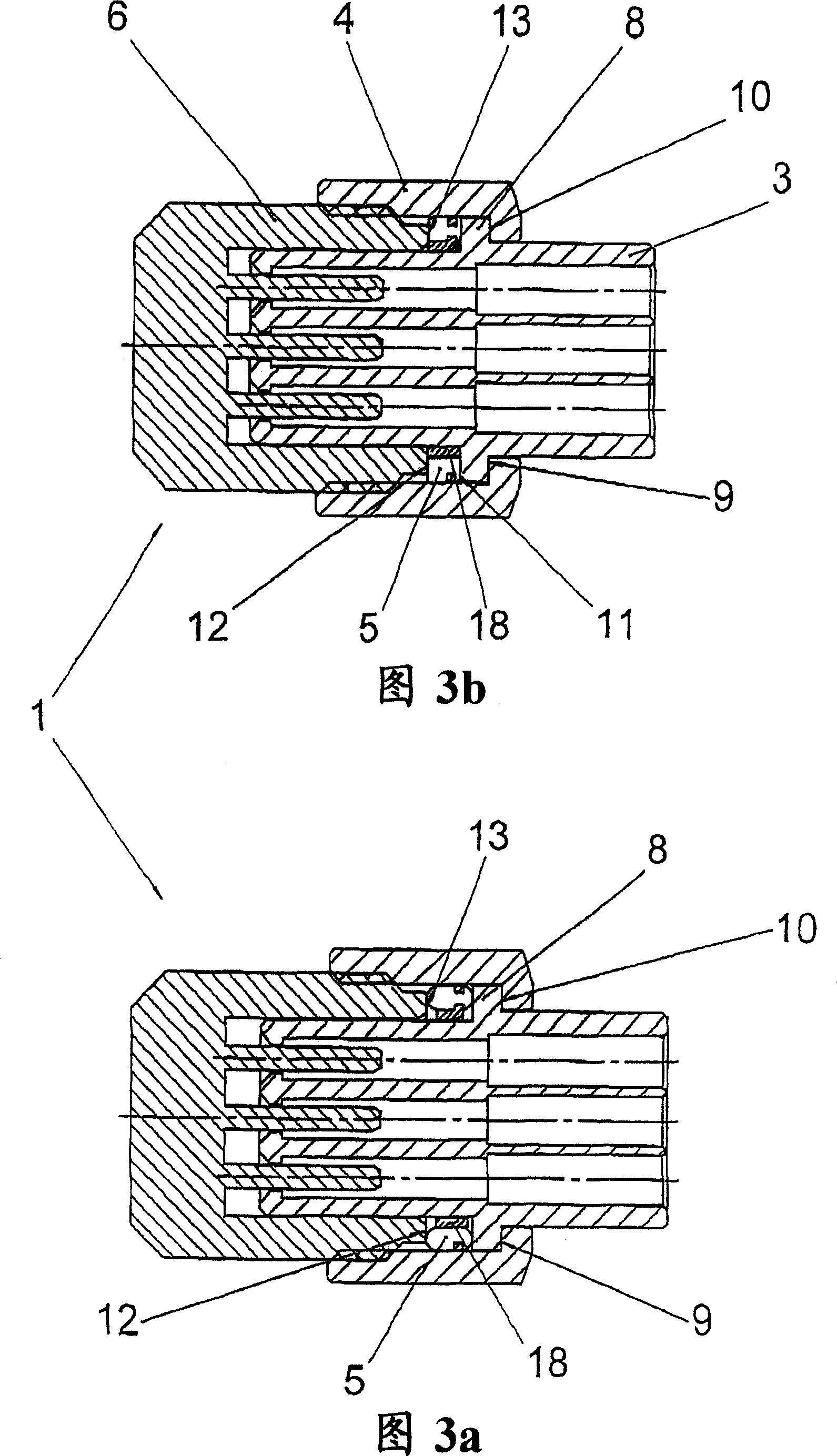

[0036] The figures show different configurations of an electrical plug-in connector 1 or rather individual components of such an electrical plug-in connector 1 . Such an electrical plug connector 1 has a handle 2 ( FIG. 12 ) enclosing a connecting cable not shown here, and a contact support 3 is arranged on the contact support 3 in a rotatable and limited axially displaceable manner. The locking nut 4, and the elastic seal 5 arranged on the contact support 3 in the form of a sealing ring. At the same time, since the electrical plug connector 1 can be connected to its corresponding mating plug connector 6 , the lock nut 4 is screwed onto the thread 7 formed on the outer sleeve of the mating plug connector 6 .

[0037] As can be seen from FIGS. 1 to 7 , the contact carrier 3 has a circumferential collar 8 which is located approximately in the middle region of the contact carrier 3 . The surrounding flange 8 has a first end face 9 which serves as a stop for a shoulder 10 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com