Plunger-type rationing filling valve

A filling valve and plunger type technology, applied in the field of plunger type quantitative filling valve, can solve the problems of large filling volume error, no quantitative filling, and blocked liquid level in the return air pipe, so as to achieve faster flow speed, Simple structure, ensure the effect of bottle mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

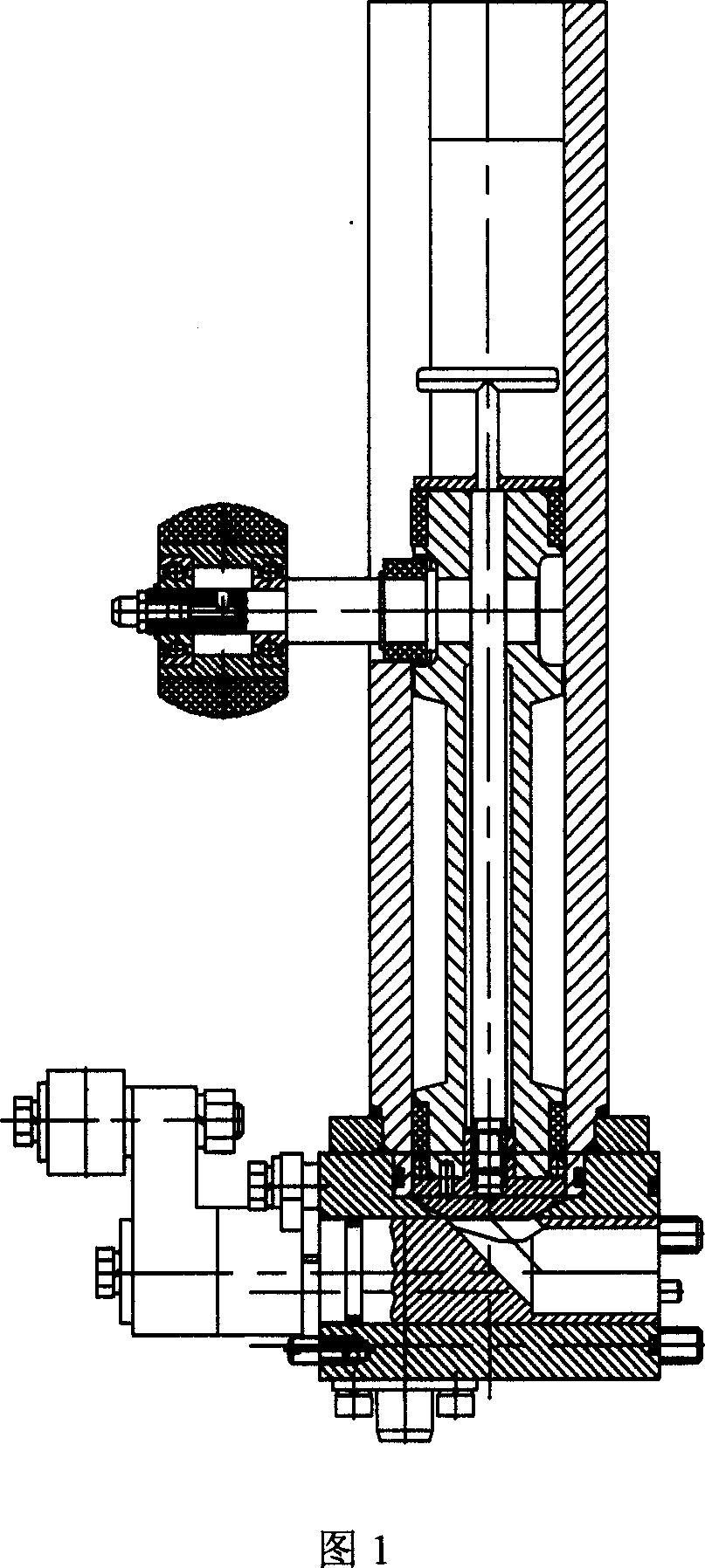

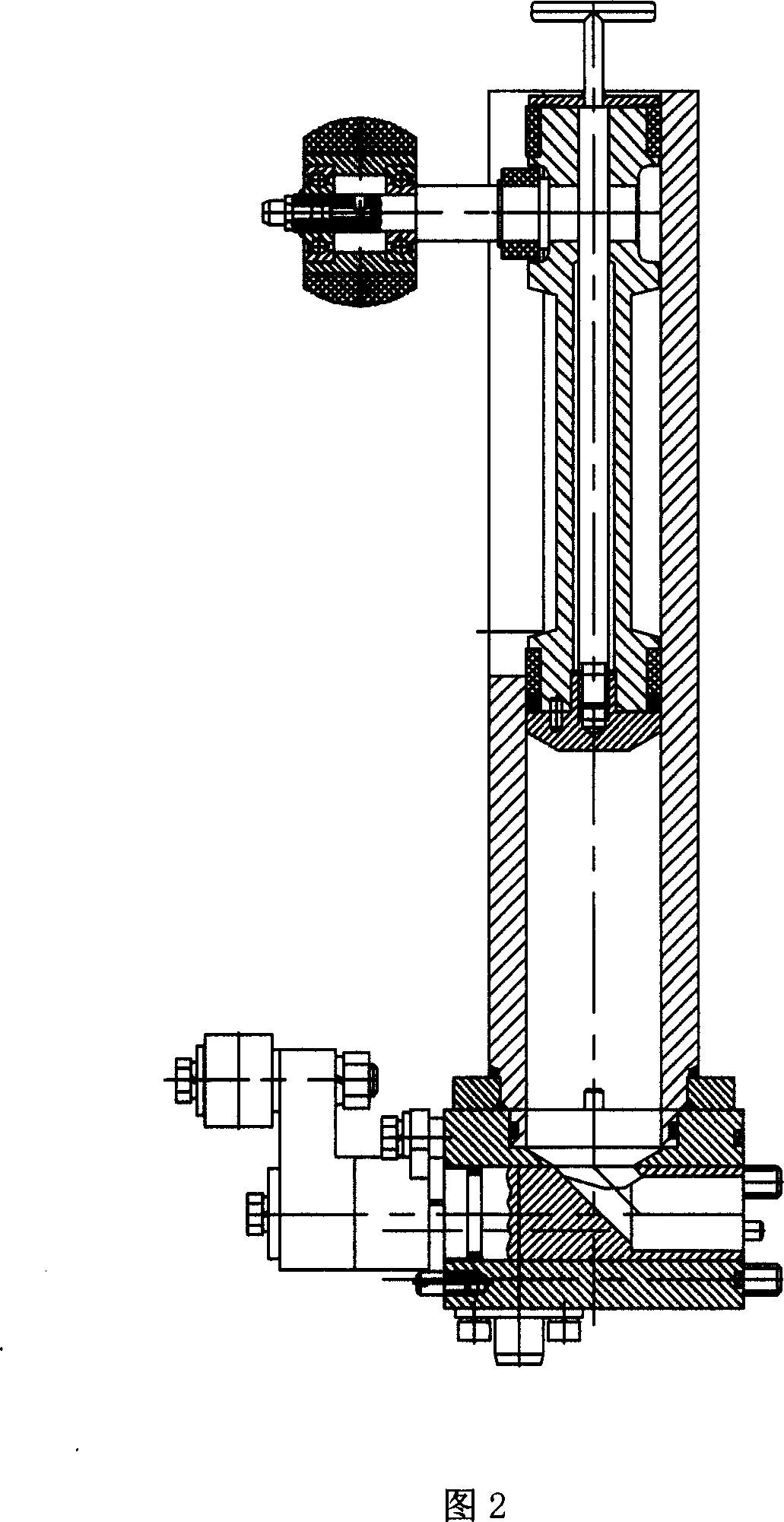

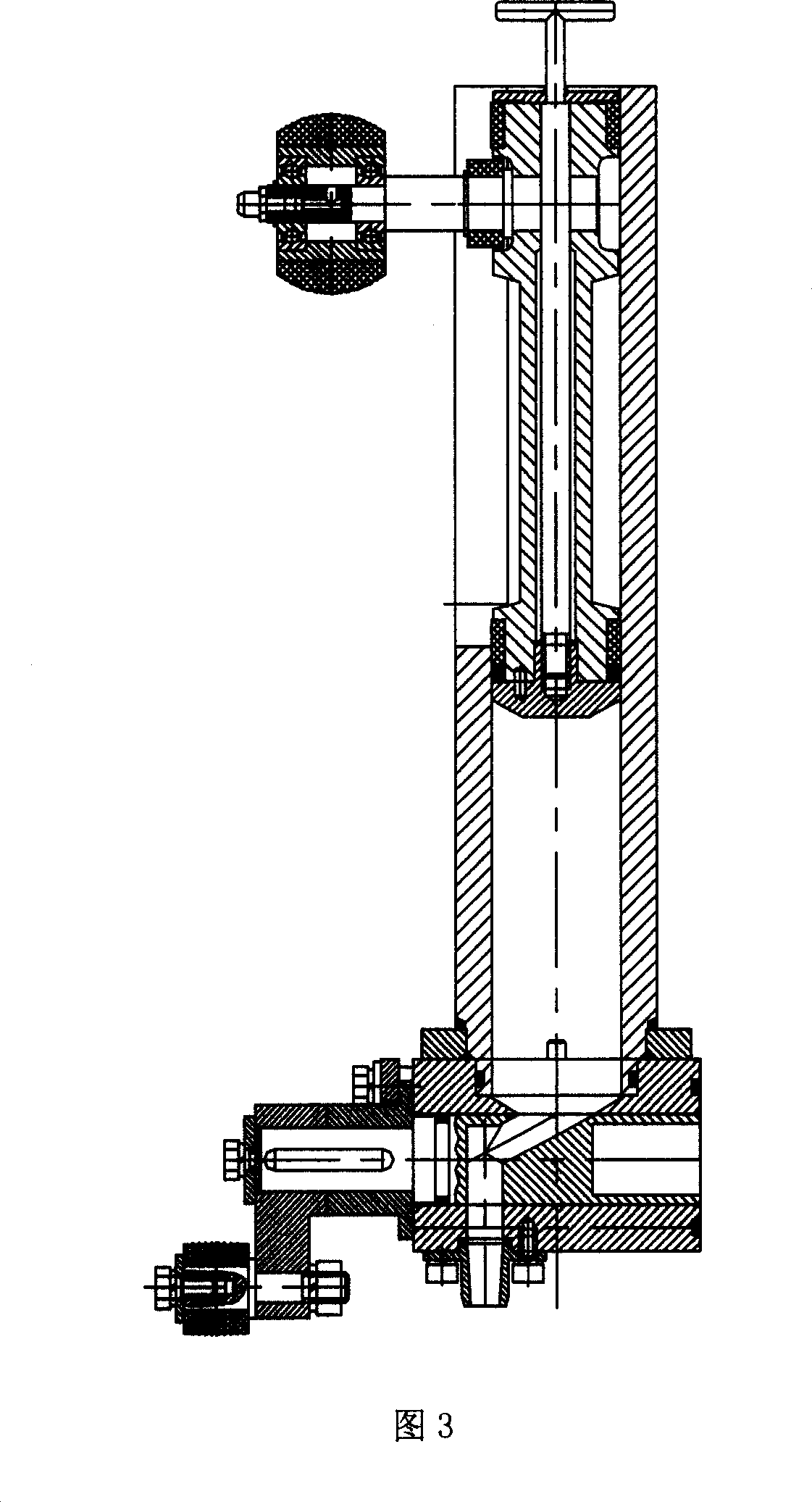

[0047] The plunger type quantitative filling valve of the present invention is mainly composed of a plunger 5, a plunger barrel 9 and a valve body, wherein the plunger 5 and the plunger barrel 9 are shown in Figure 5, and the plunger 5 Extending into the cavity of the plunger barrel 9 from top to bottom, the lower part of the plunger barrel 9 has an opening. The plunger 5 includes a plunger rod, a pull rod 6, an anti-friction ring 7, a plug 8, and a sealing ring 10, and the pull rod 6 passes through the through hole of the plunger rod axis from top to bottom to connect with the plug 8 and install it At the lower end of the plunger rod, the pull rod 6 compresses the anti-friction ring 7 by applying force to the plug 8 , and a sealing ring 10 is sandwiched between the plug 8 and the anti-friction ring 7 . One side of the plunger barrel 9 is provided with a strip groove, and the small shaft 3 is horizontally connected with the plunger 5 and protrudes from the strip groove. A bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com