Cleaner dust-collection paper-bag carriage structure

A frame structure and dust bag technology, applied in the direction of suction filter, etc., can solve the problems of inconvenient power cord, short body of horizontal vacuum cleaner, inability to hang the fuselage, etc., and achieve the effect of reducing parts and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

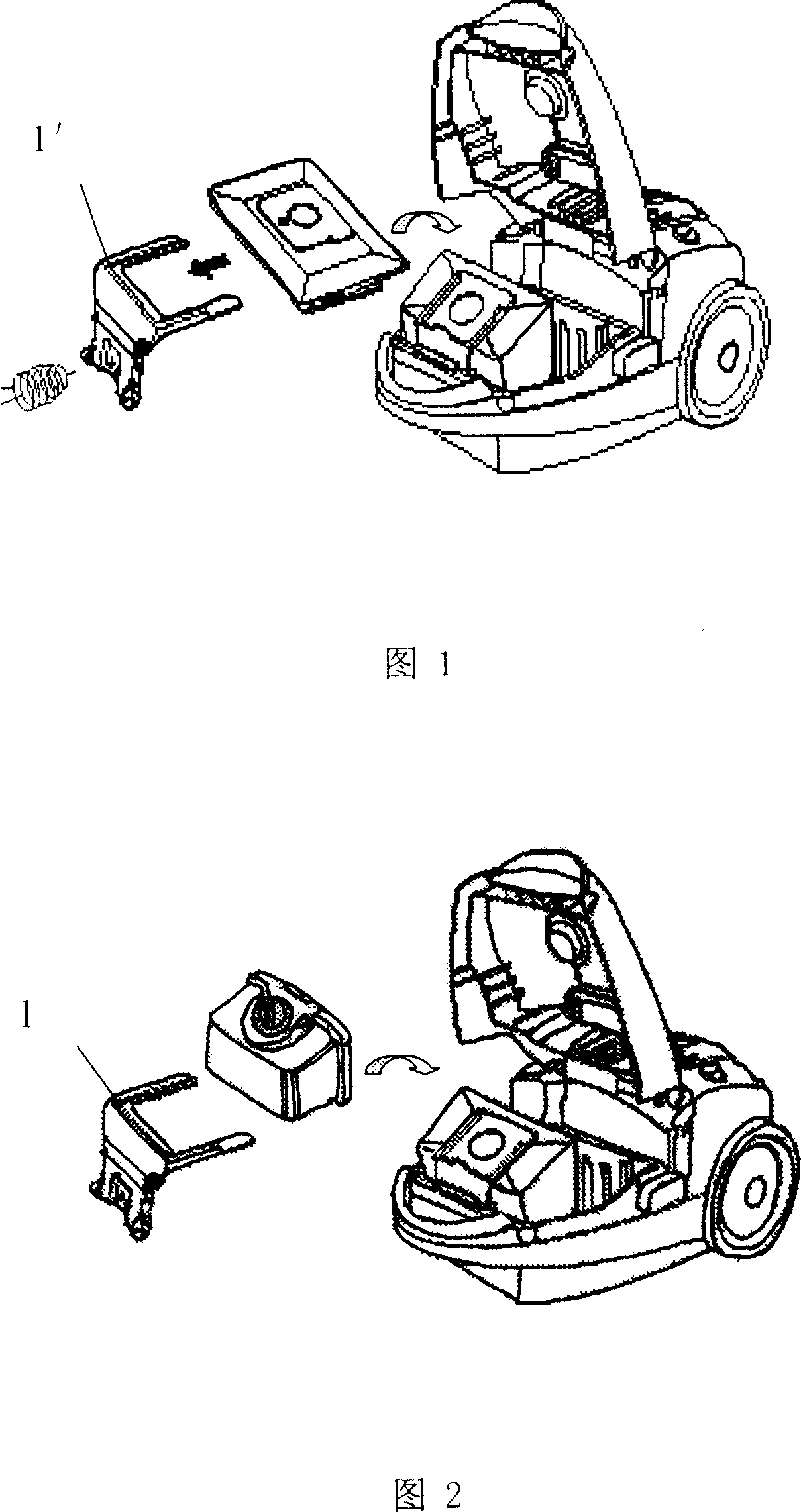

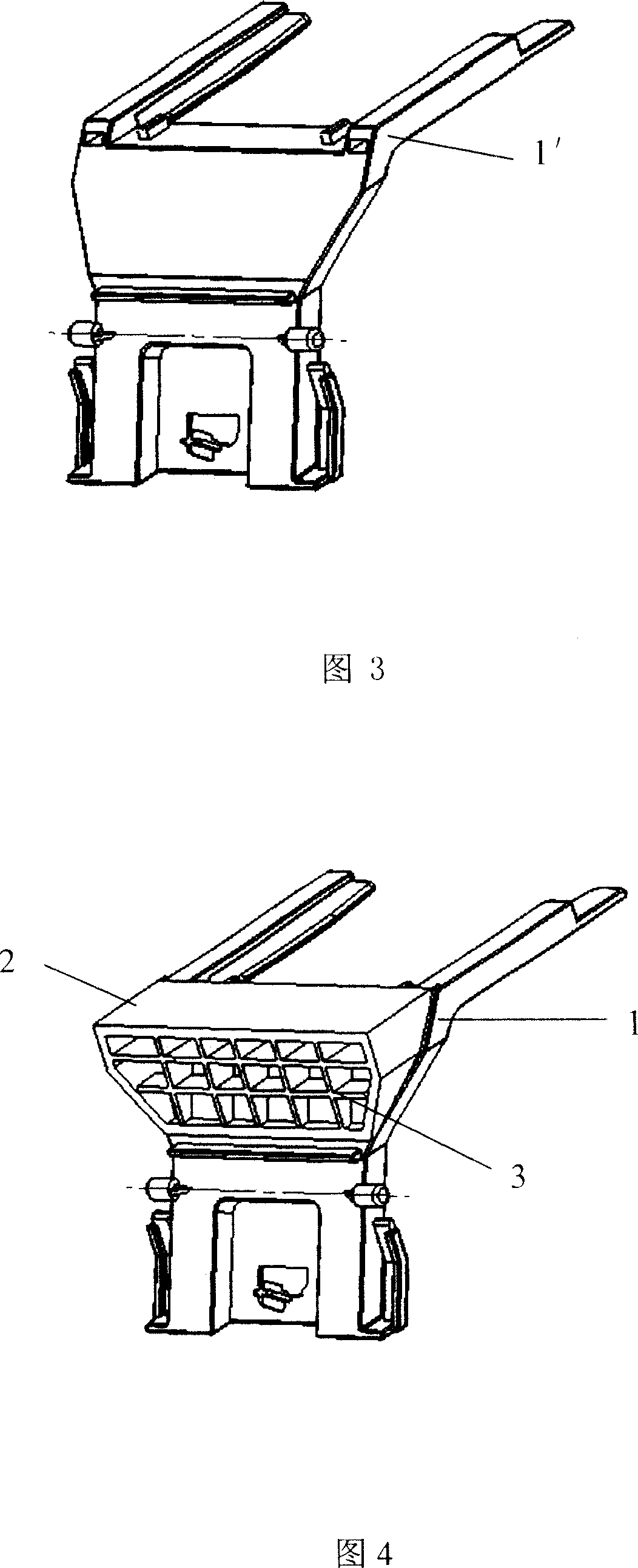

[0013] The structure of the dust collecting paper bag holder for the vacuum cleaner of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0014] As shown in Figures 3 and 4, the structure of the dust collection paper bag holder for the vacuum cleaner of the present invention includes a paper bag holder for installing dust bags, and an extension part 2 extending forward is provided on the front end surface of the paper bag holder 1. A plurality of grids 3 are opened on the front end surface of the paper bag holder 1 .

[0015] The dust collecting paper bag frame structure of the vacuum cleaner of the present invention is realized in this way.

[0016] The paper bag frame 1 on which the dust bag is installed is processed by mold injection molding and manufactured in one shot. The structure of the part of the paper bag holder 1 is thickened due to the extension part 2 on the upper part of the front end surface, which makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com