Steel material cutter and locking method of knife head of steel material cutter

A cutting machine and cutter head technology, which is applied in the directions of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of many parts, high cost, complex device structure, etc., and achieves few parts, simple structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

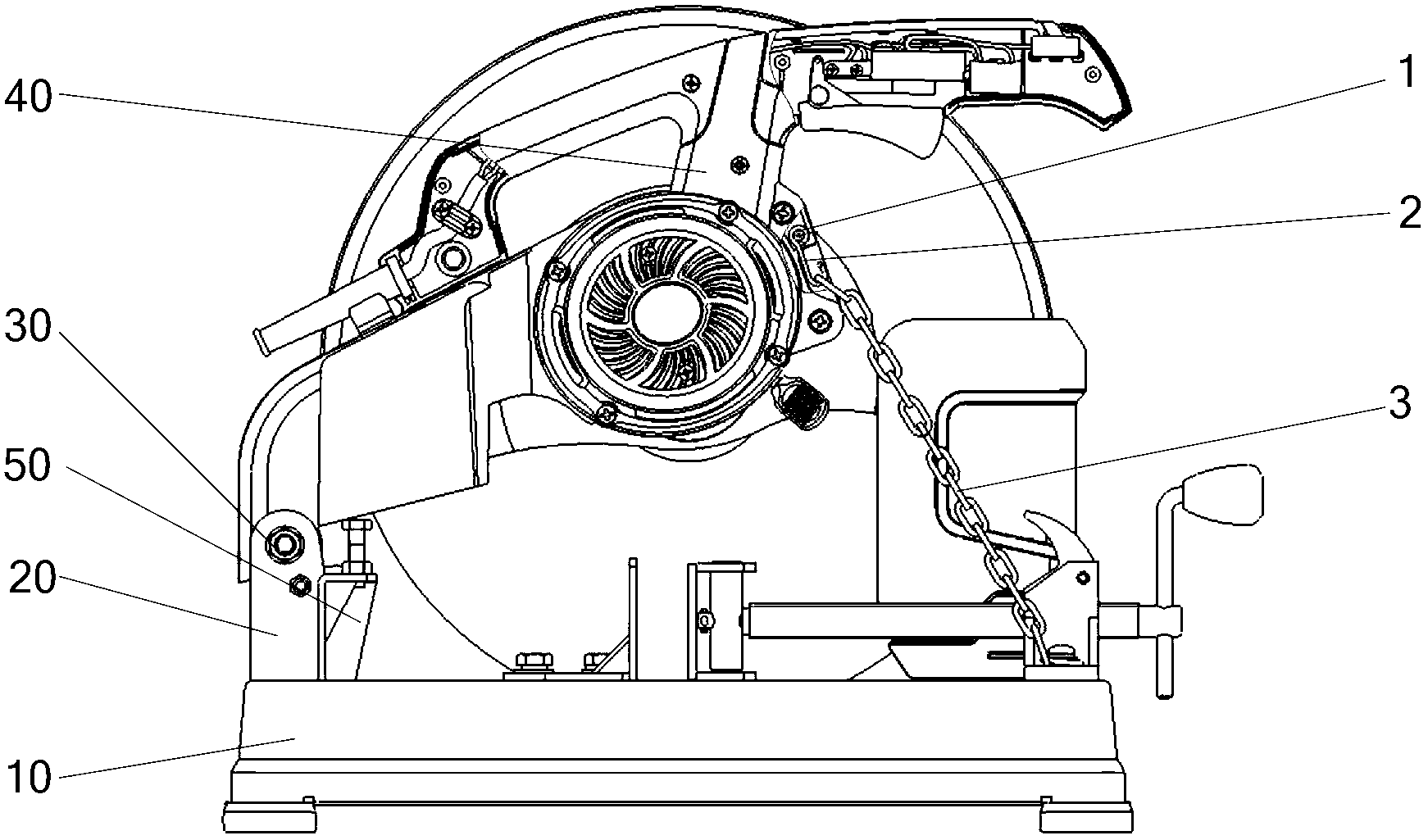

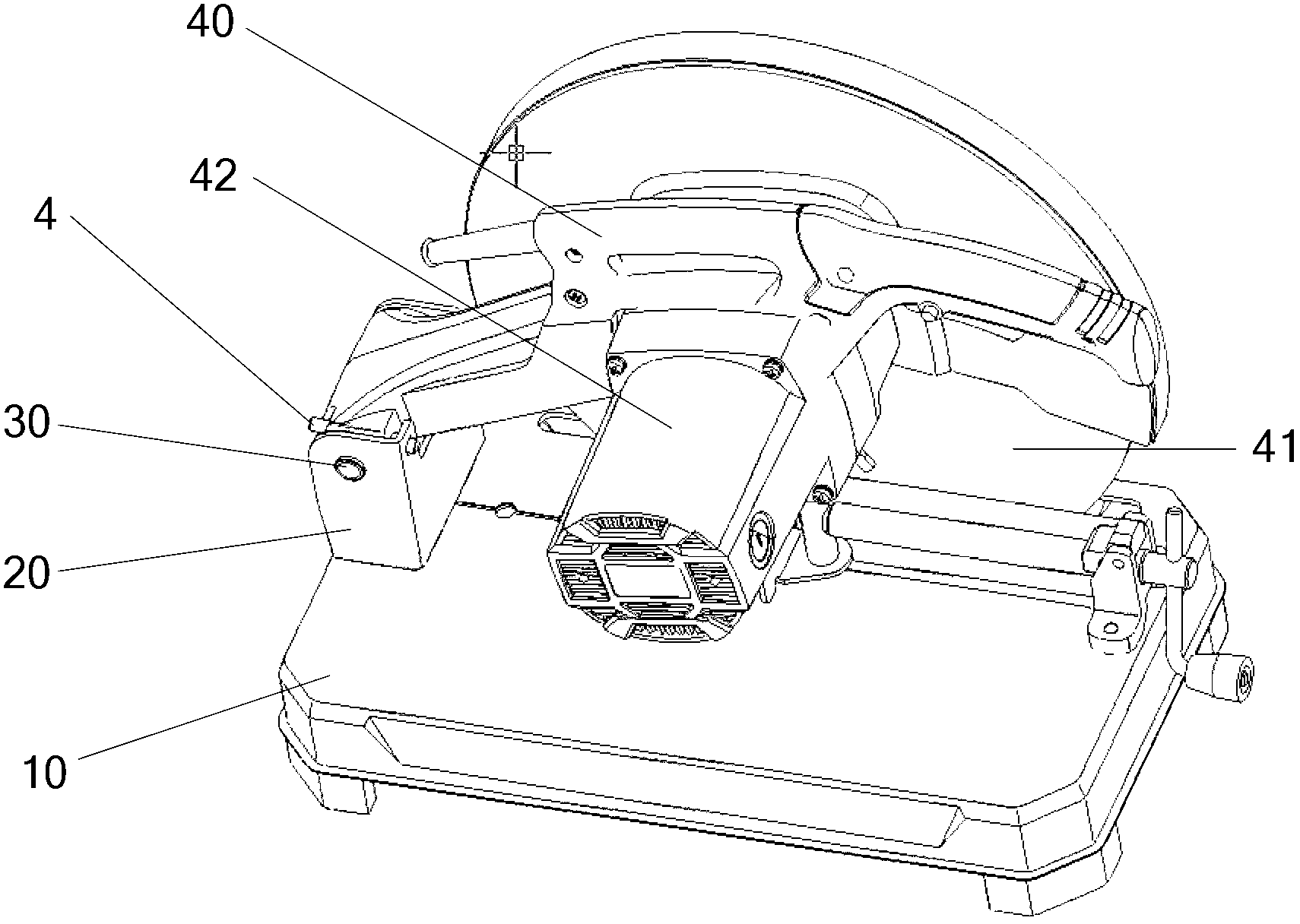

[0020] Please refer to figure 2 and image 3 , the present embodiment provides a method for locking a cutter head of a steel material cutting machine. A steel material cutting machine is provided, and the steel material cutting machine at least includes a cutter head 41 and a bottom plate 10. First, the cutter head 41 is installed on a On the rotating arm 40, the cutter head is circular. When the cutter head 41 is installed, the center of circle of the cutter head 41 is connected with the rotating motor 42 provided on the rotating arm 40, and then a bolt 30 is used to Pass through one end of the rotating arm 40 and a connecting seat 20 fixed on the bottom plate 10, so that the bolt 30 is parallel to the bottom plate 10, and the rotating arm 40 can rotate around the axis of the bolt 30 Rotate to the direction, and then make the cutter head 41 realize the axial rotation around the bolt 30 by the rotation of the rotating arm 40; The rotation position of the rotation arm 40 is ...

Embodiment 2

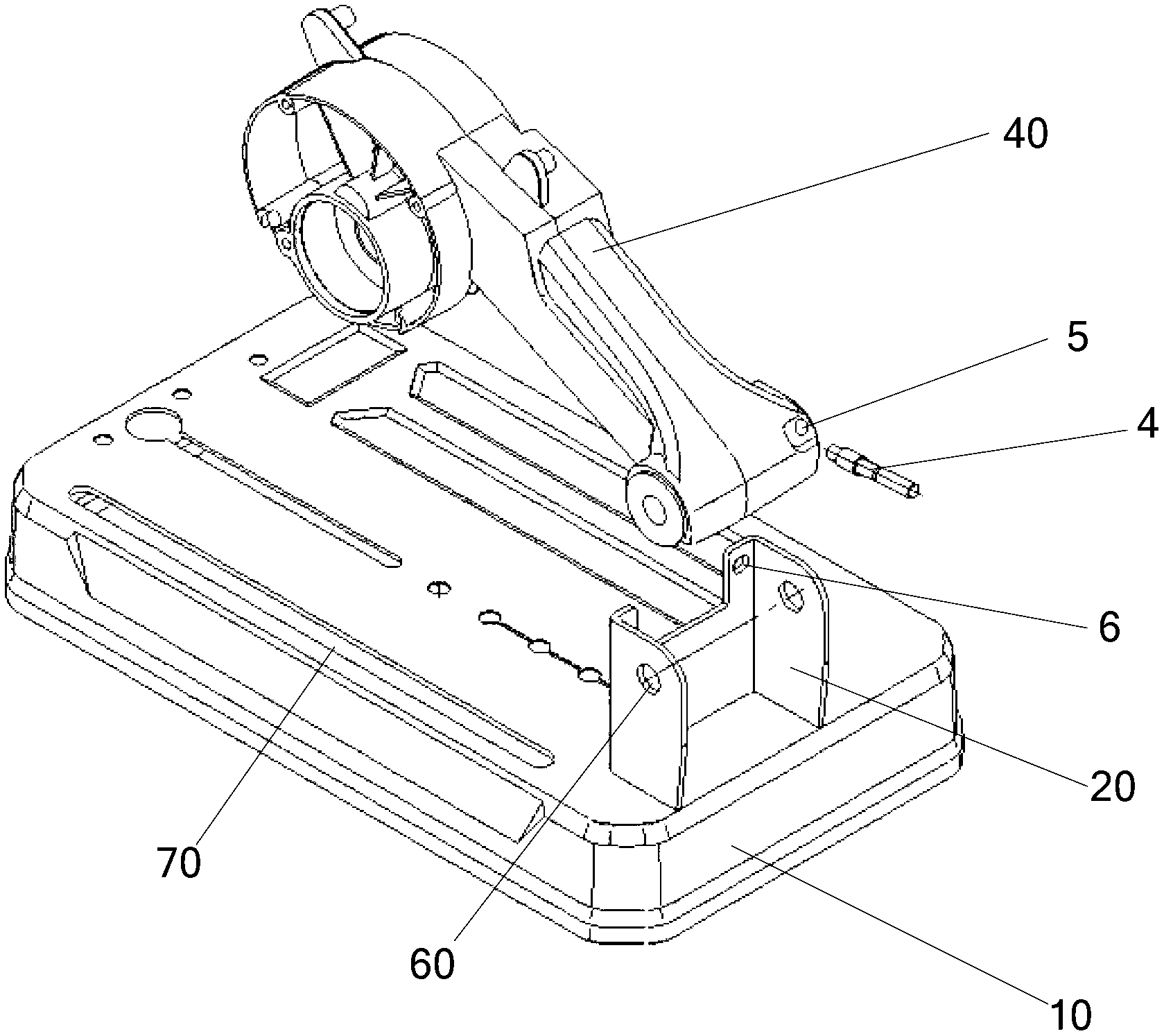

[0027] In this example, please refer to Figure 4 and Figure 5 , the locking bar 4 is arranged parallel to the bolt 30 .

[0028] Please refer to Figure 4 and Figure 5 , The difference between this embodiment and Embodiment 1 is only that when the locking rod 4 passes through the first through hole 5 and the second through hole 6 at the same time, the locking rod 4 is parallel to the latch 30 . This setting is conducive to the stability of the lock bar 4 when locked, the effect is better, and it is not easy to fall off. Please refer to Figure 5 , the connection seat 20 includes two opposite sides and a connecting surface connecting the two sides, pin holes 60 are respectively arranged on the two sides for the shaft pin 60 to pass through, in this embodiment, the second through hole 6 is set On one side, the positions of the first through hole 5 and the second through hole 6 correspond, that is, when the rotating arm 40 is in the locked position, the heights of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com