Particle separator

A particle separator and particle technology, applied in the direction of dispersed particle separation, separation method, chemical instrument and method, etc., can solve the problem of low separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

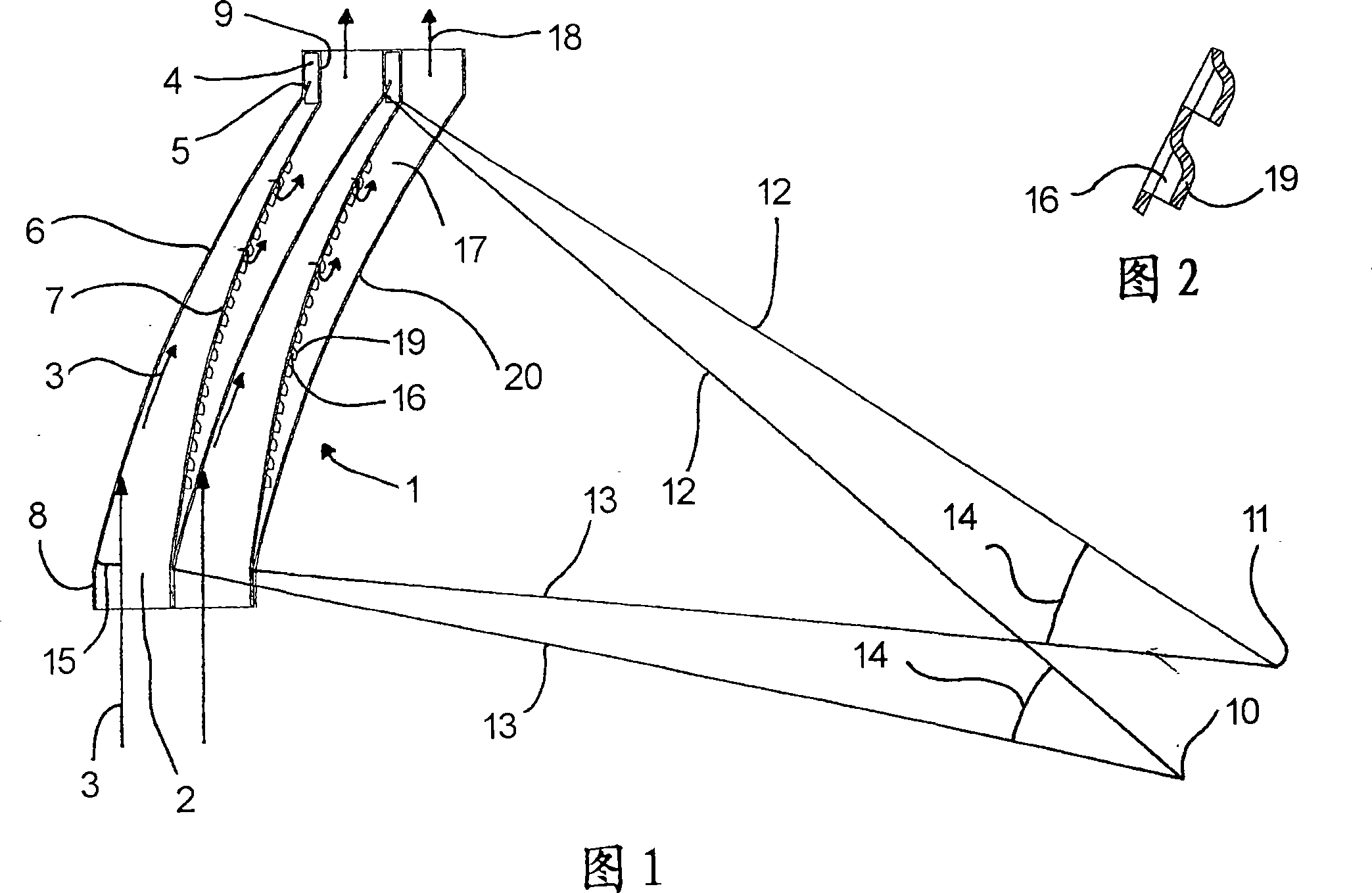

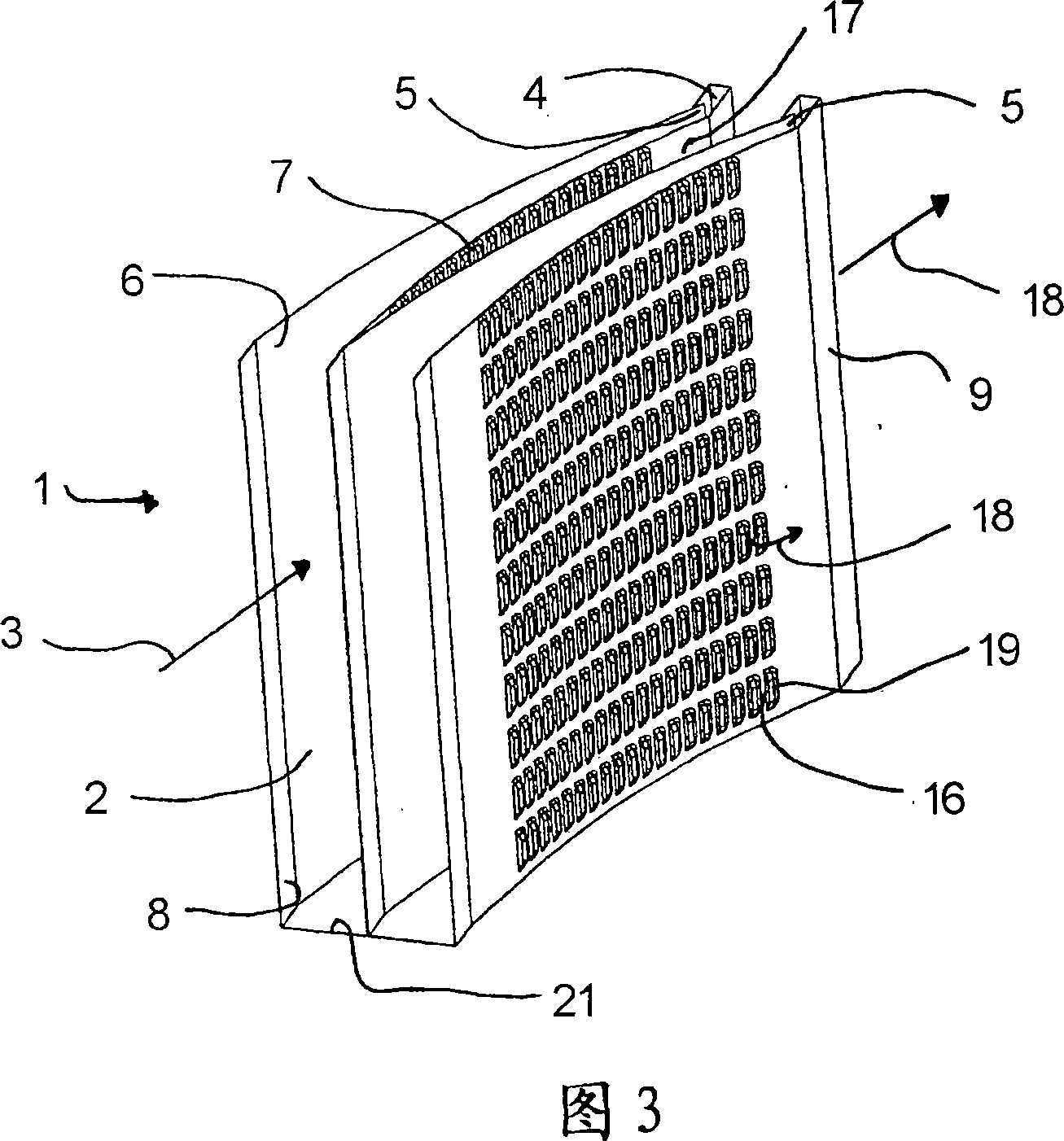

[0027] The particle separator shown in FIG. 1 and indicated generally by the reference number 1 for an air supply (not shown) has two substantially identical, parallel to each other, for the particle-contaminated air flow 3. Input channel 2.

[0028] The inlet channel 2 narrows gradually in the direction of the incoming polluted gas flow 3 . The inlet channels each open into an outlet channel 4 for the particles.

[0029] Furthermore, in the region of the outlet channel 4 in which the respective inlet channel 2 opens, a retaining unit 5 for the particles is realized in each case from a planar sheet metal, by means of which the particles are prevented from flowing back into the respective inlet channel 2 .

[0030] The input channels 2 are respectively bounded by air-guiding surfaces, ie an outer air-guiding plate 6 and an inner air-guiding plate 7 . The outer air deflectors 6 are respectively bent towards the inside of the inlet channel 2 , that is, convex when viewed from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com