Clapper valve

a technology of clapper valves and clappers, which is applied in the field of clapper valves, can solve the problems of premature deterioration the effect of reducing the effectiveness of the clapper valve in preventing or at least reducing the clapper valve, and significant wear to the internal components of the clapper valve, so as to reduce the vibration and wear of the hanger and/or the clapper. , the effect of preventing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

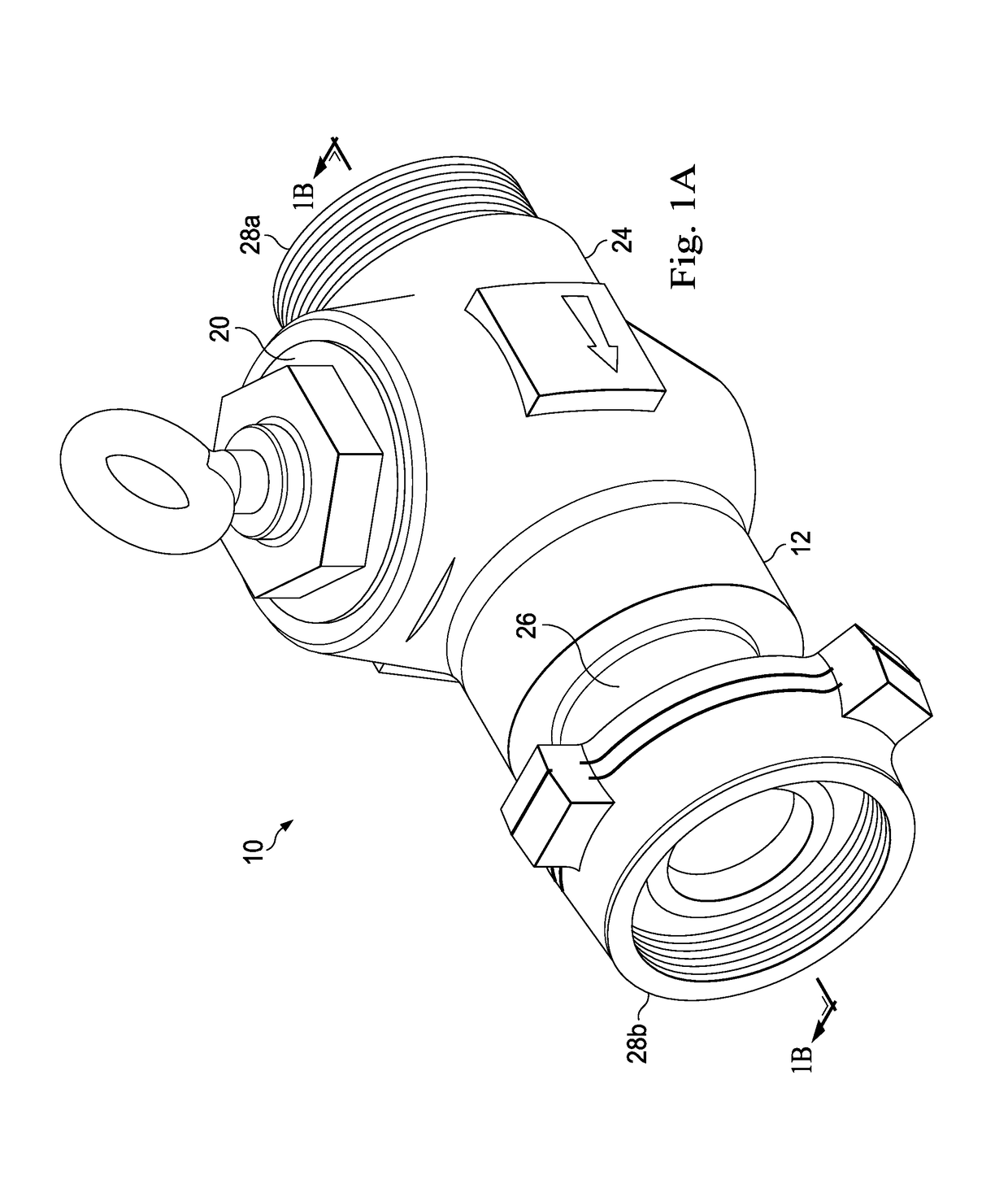

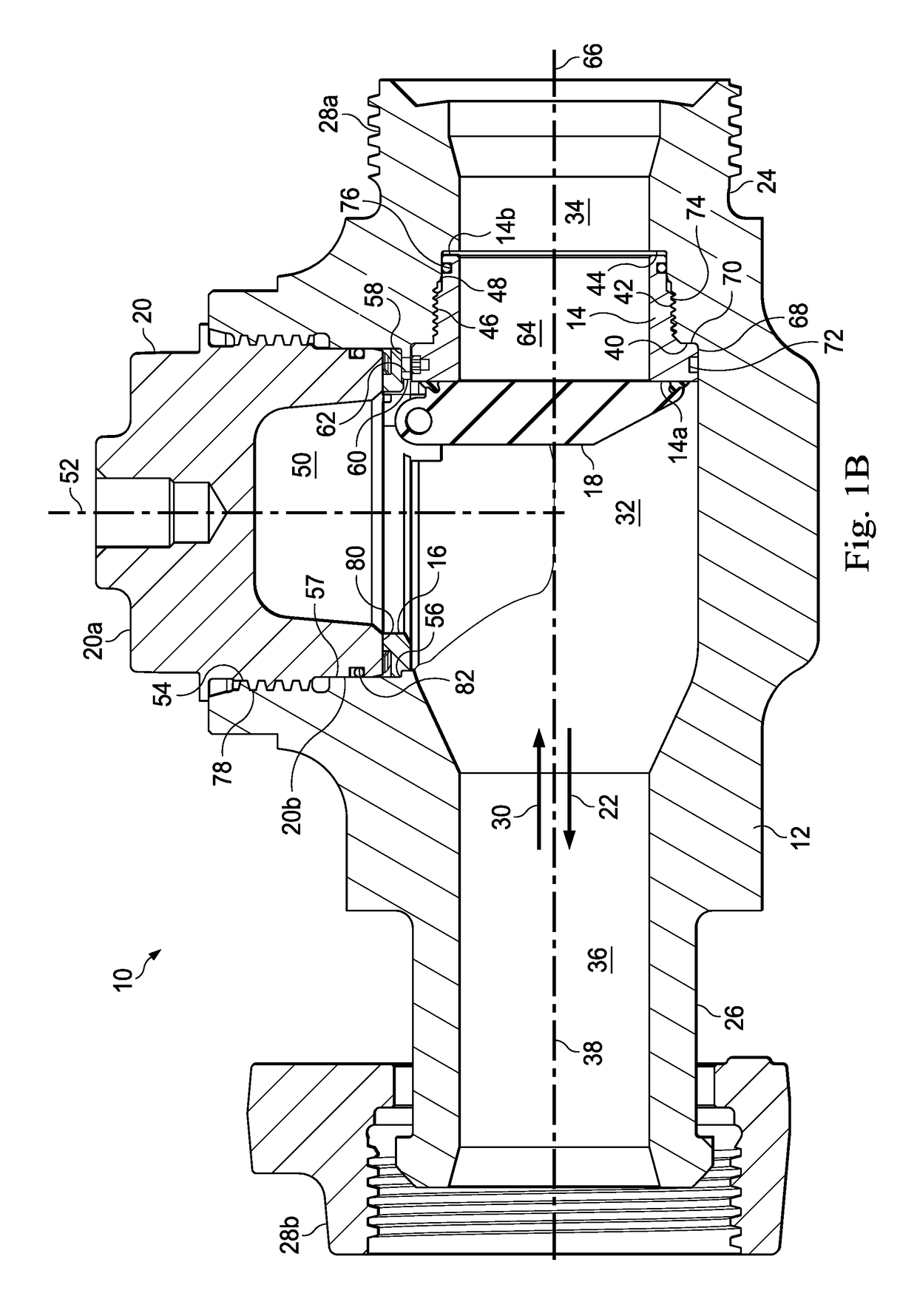

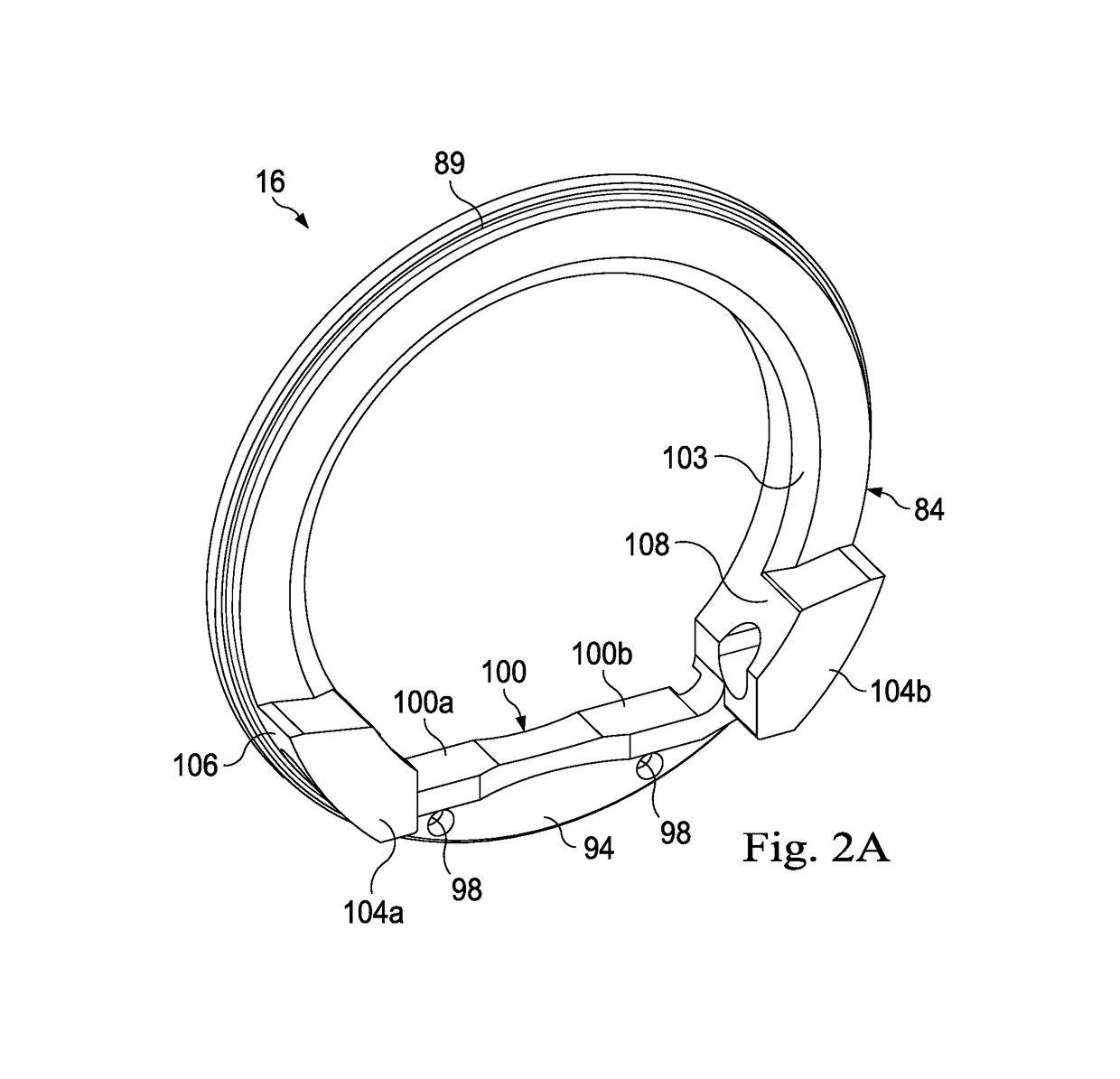

[0107]Referring initially to FIGS. 1A and 1B, an example embodiment of a clapper valve, generally referred to by the reference numeral 10, is illustrated. The clapper valve 10 includes a valve body 12; a valve seat 14 connected to the valve body 12; a hanger 16 extending within the valve body 12 proximate the valve seat 14; a clapper 18 pivotably connected to the hanger 16 and actuable between an open configuration, in which fluid flow is permitted through the valve body 12, and a closed configuration, in which the clapper 18 is seated against the valve seat 14 to at least partially restrict fluid flow through the valve body 12; and a cap 20 connected to the valve body 12 to secure the hanger 16 in position relative to the valve seat 14. The clapper valve 10 is adapted to be incorporated into a flowline through which fluid ordinarily flows in an axial direction 22. Accordingly, the valve body 12 includes an inlet end 24 and an outlet end 26. A pair of flowline connectors 28a and 28b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com