Miniaturized continuous-flow fermenting apparatus

a continuous-flow, fermentation apparatus technology, applied in mechanical apparatus, alcoholic beverage preparation, laboratory glassware, etc., can solve the problems of ruined entire batches of wine, small chance to adjust variables, slow and cumbersome testing, etc., to improve large-scale winemaking processes, reduce alcoholic fermentation time, and improve the effect of large-scale winemaking processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

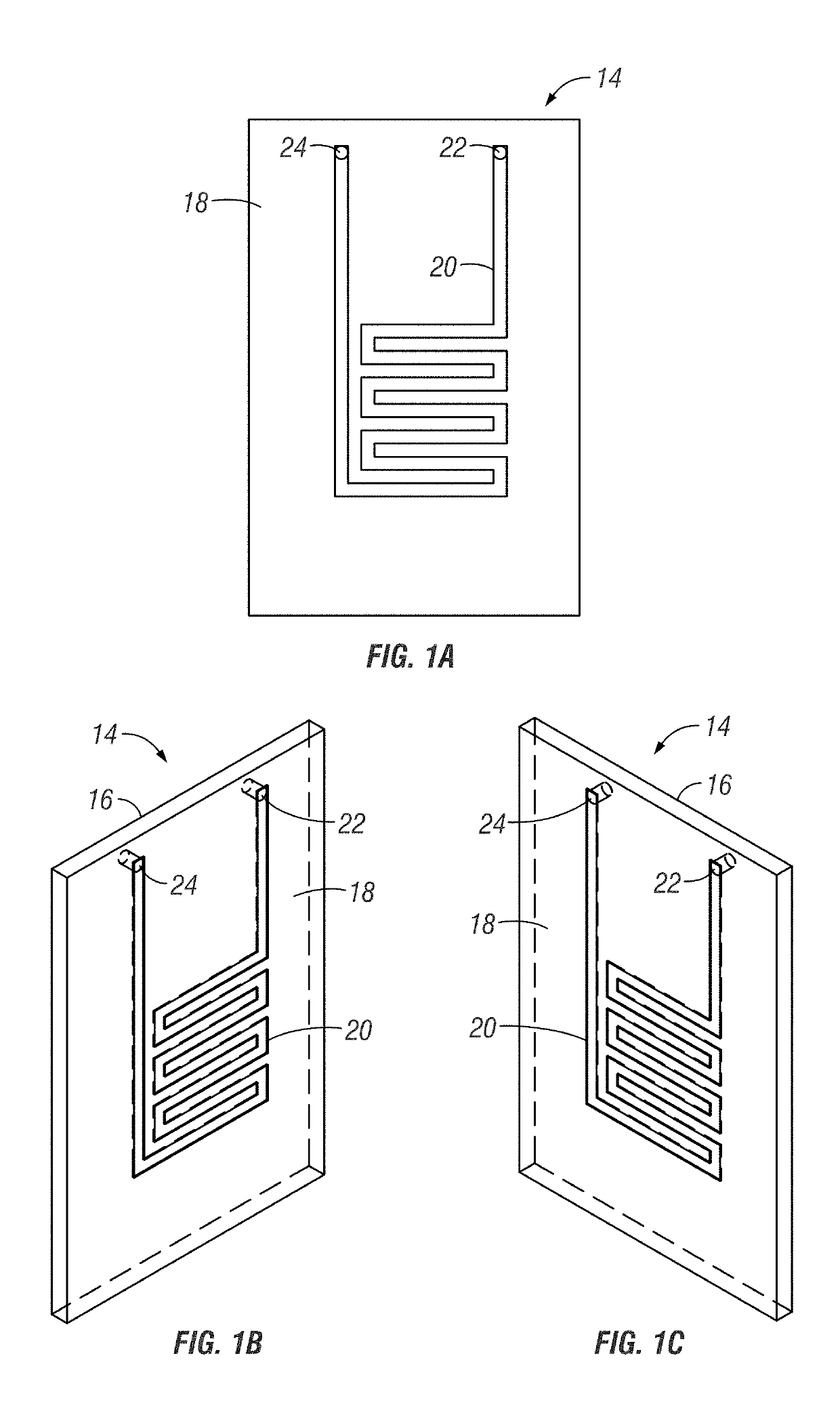

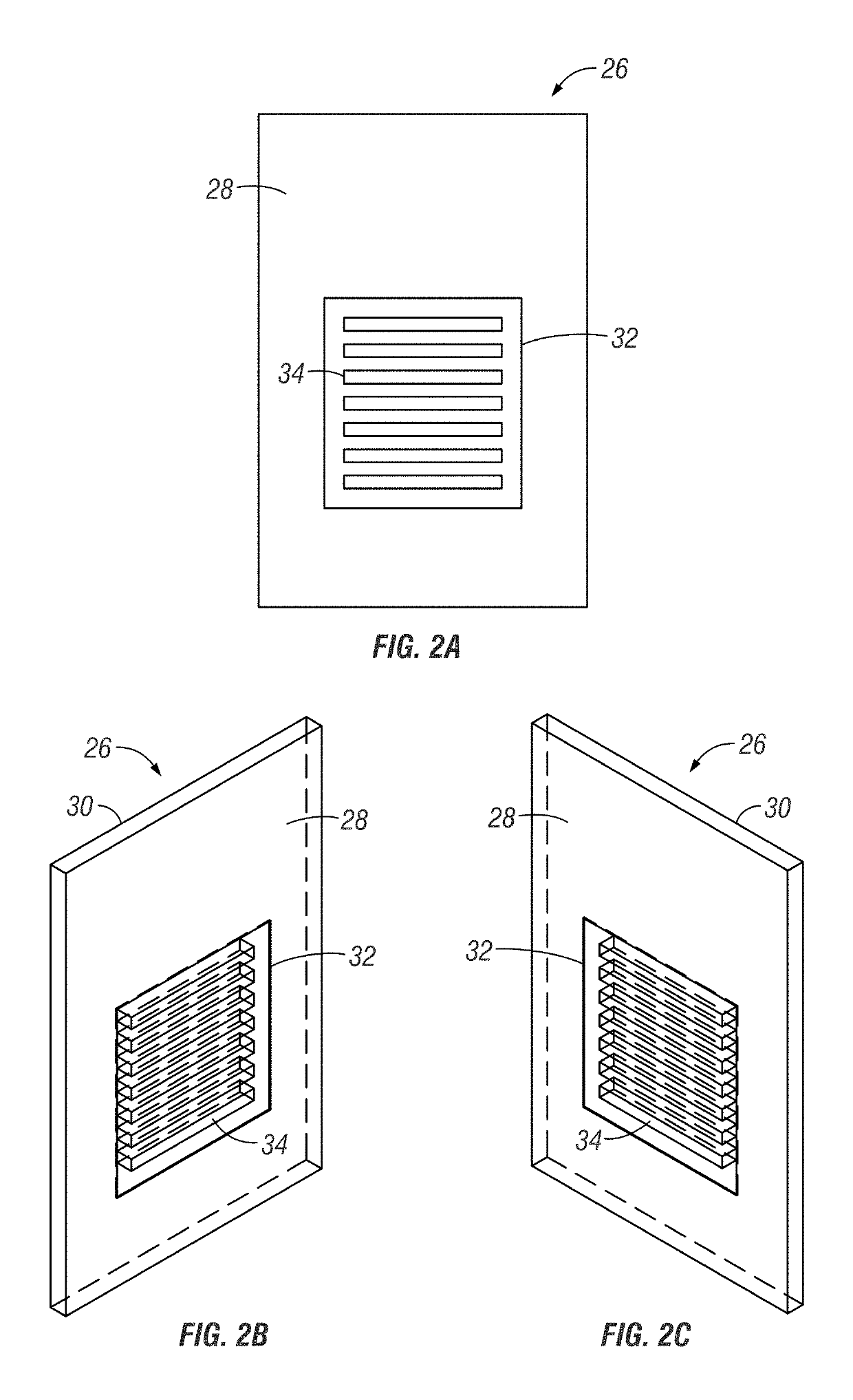

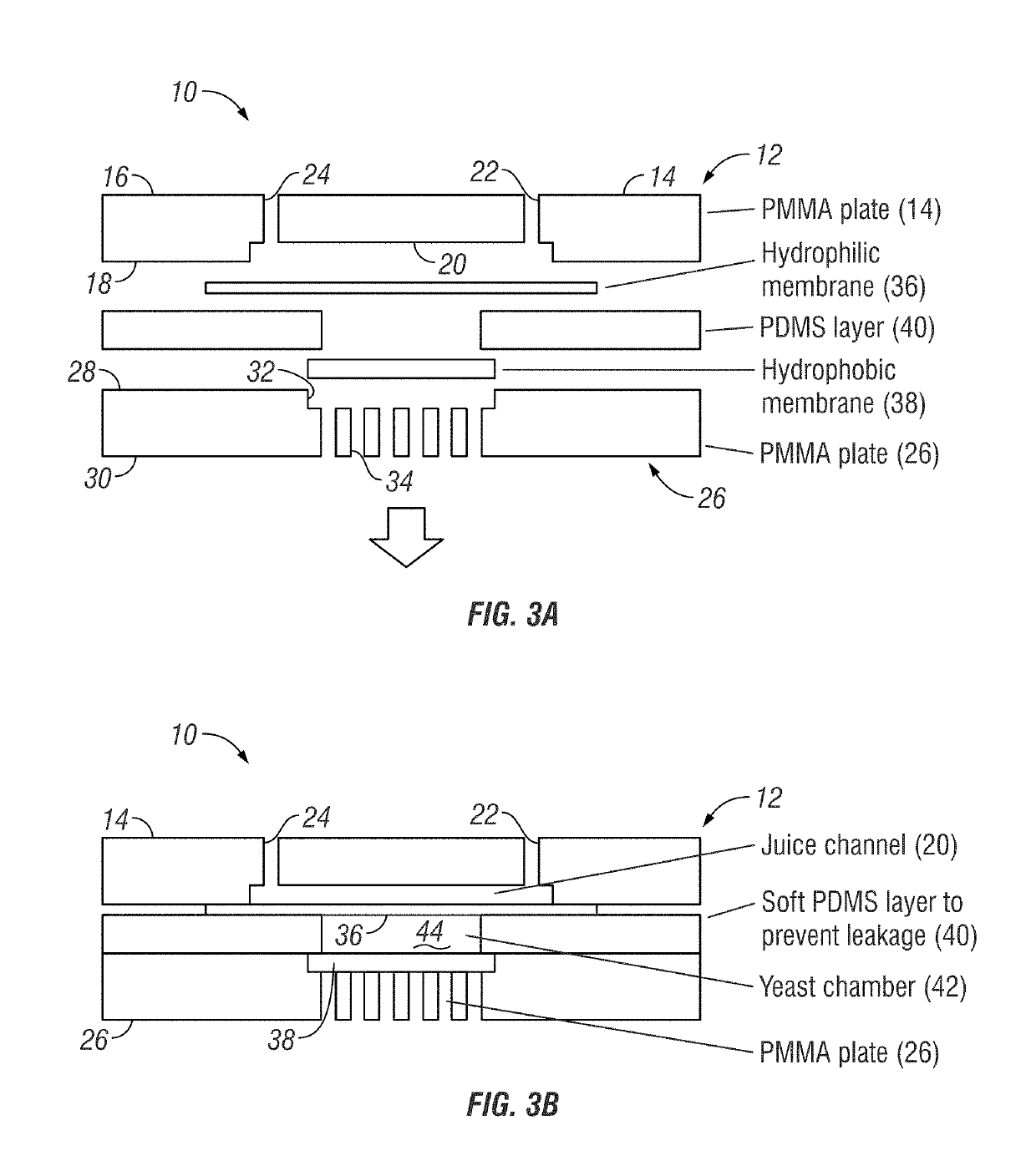

[0028]The invention is for a beverage fermenting system, which utilizes a continuous flow rather than batch approach for the fermentation of a beverage, such as a fermentation of grape juice to make wine. This is done on a miniaturized or very small scale, such as wherein the volume produced by the system may be on the order of 1 ml per unit. The alcoholic fermentation can occur within one to three days, as opposed to one to two weeks, which is required for large batch alcoholic fermentation. To accomplish such, and as will be understood, the yeast is not dispersed in the liquid, such as grape juice, but is separated from the liquid by a porous hydrophilic membrane, and from the ambient air by hydrophobic membrane. In-line electrical impedance sensing monitors the alcohol content of the liquid as it is circulated through the system. An alcohol sensor and / or temperature control can be integrated with the system as well to monitor the system and to control the variable of temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumes | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap