Mounting structure for center rail of slide door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

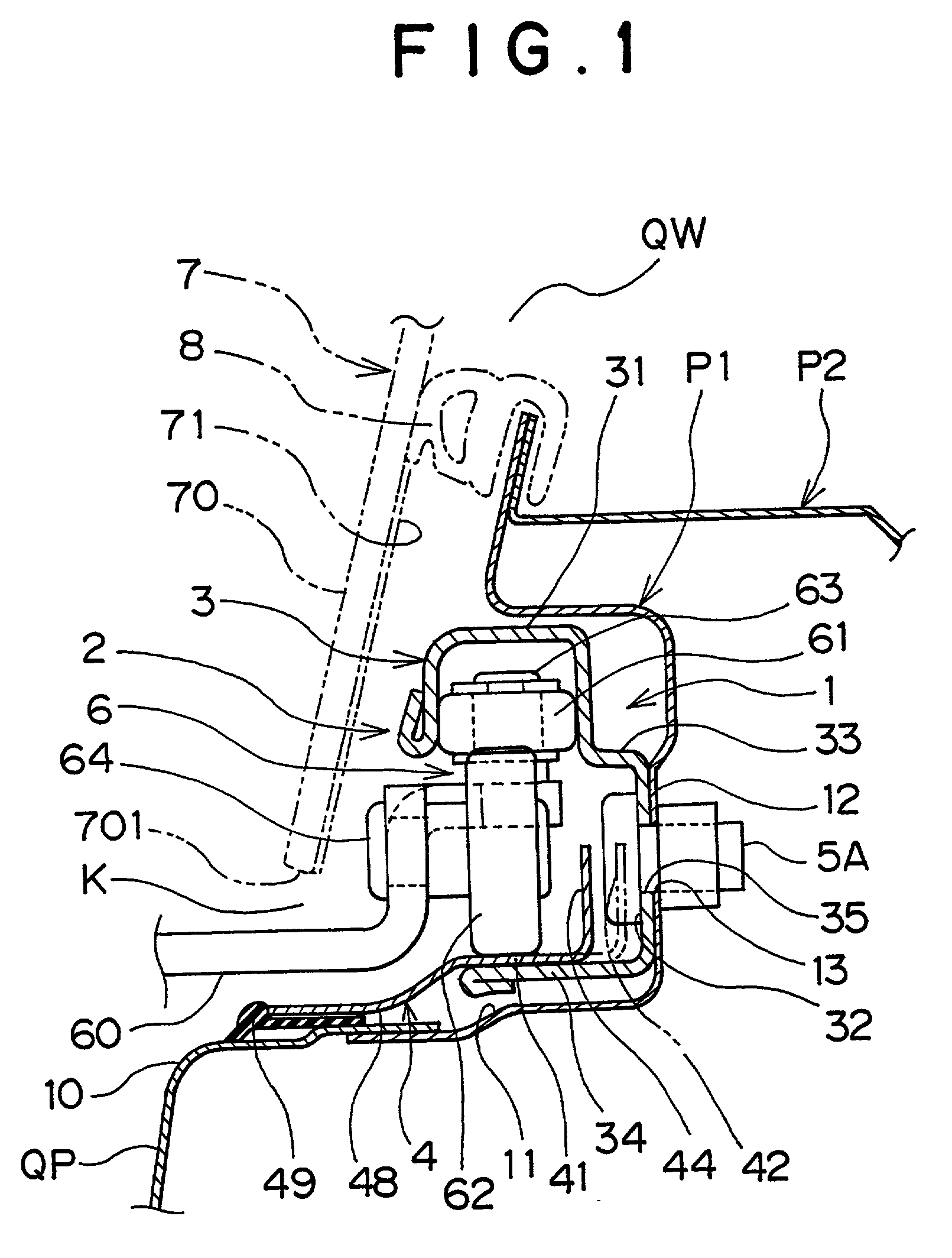

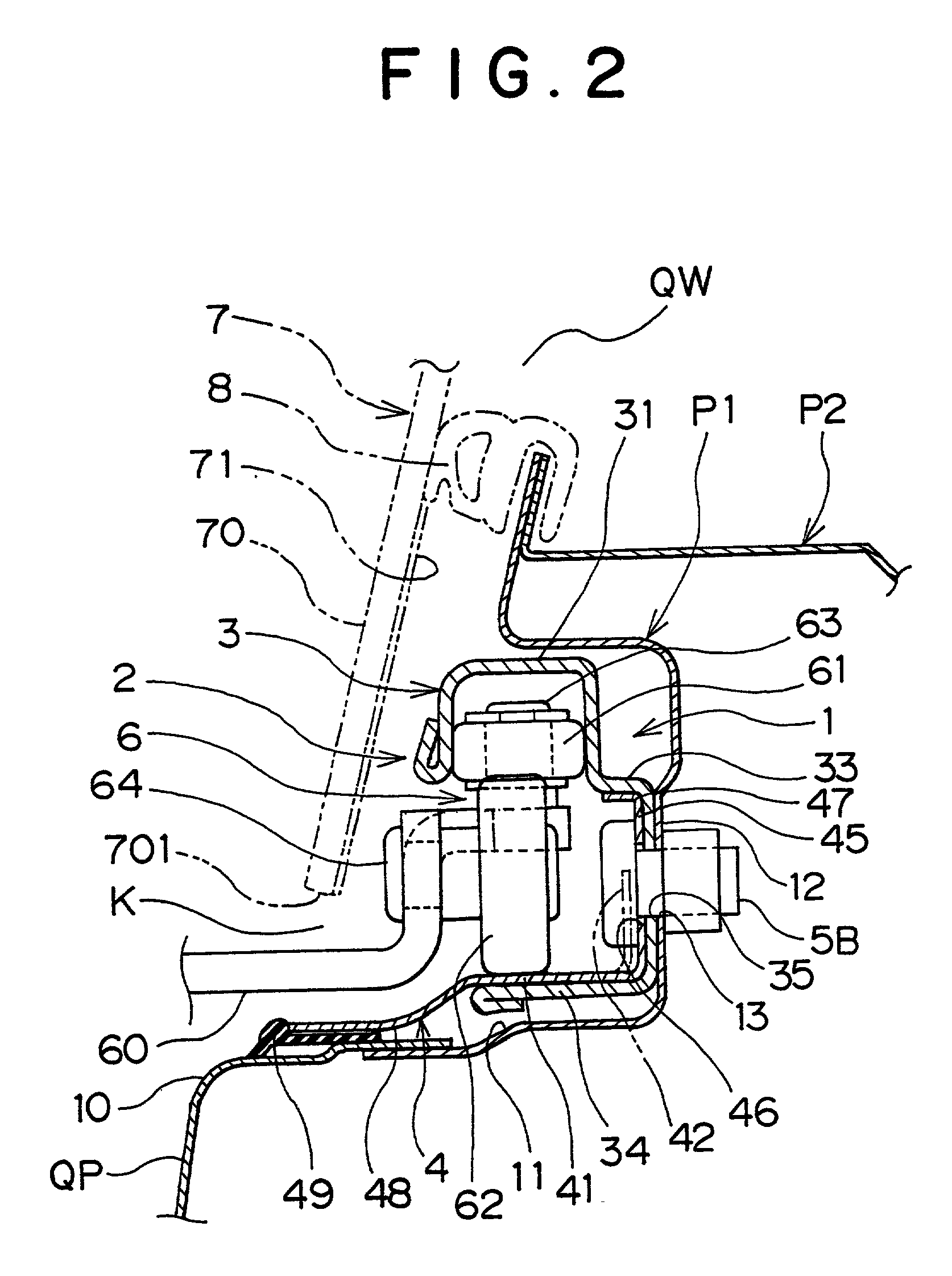

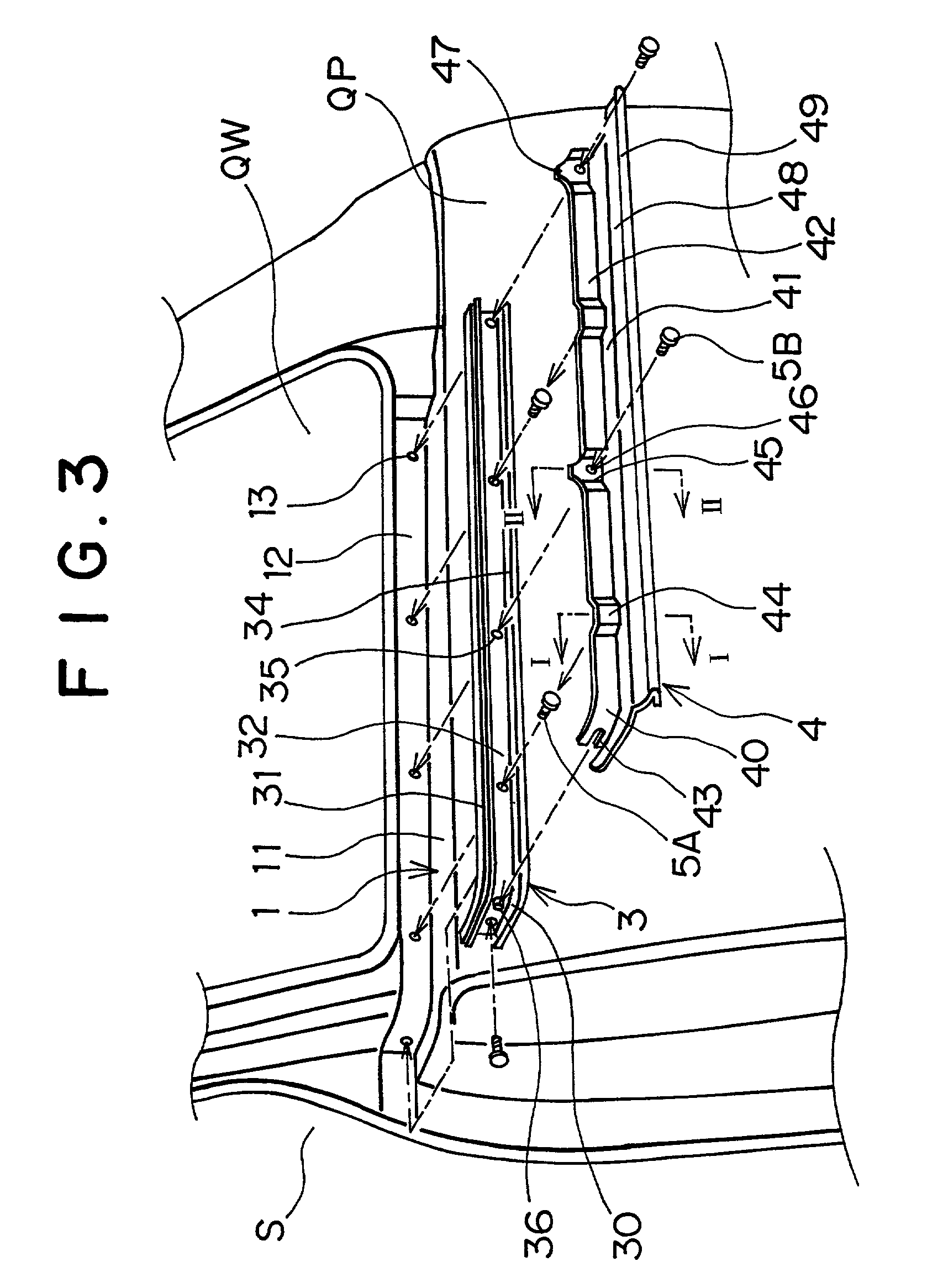

[0021] Hereinafter, a preferred embodiment of the invention will be described with reference to the drawings.

[0022] This embodiment is applicable to a lateral part of a vehicle as shown in FIG. 4. That is, a recess 1 is formed in an upper edge of a quarter panel QP along an opening lower edge of a quarter window QW on the lateral face of the vehicle behind a slide door SD, and a center rail 2 is securely fitted to the recess 1. The recess 1 and the center rail 2 are covered with an opaque elongation 70 formed in a lower edge portion of a window glass 7 of the quarter window QW. In the lateral face of the vehicle body, a gap K between a lower edge 701 of the elongation 70 of the window glass 7 and a lower edge 10 of the recess 1 is matched with belt lines B1, B2 of a front door FD and the slide door SD, so that the belt lines B1, B2 and the gap K constitute a side line extending straight and continuously.

[0023] As shown in FIGS. 1, 2, the recess 1 is formed in a panel member P1 of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com