Composite elastic material

a composite material and elastic material technology, applied in the field of elastic composite materials, can solve the problems of material that will not long recover and unusable as a bandage material

Inactive Publication Date: 2004-06-24

KIMBERLY-CLARK WORLDWIDE INC

View PDF49 Cites 69 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0007] The present invention is directed to an elastic composite material having an elastic layer having a first side and a second side; at least one gatherable layer bonded to at least one of the first side and second side of the elastic layer; and a fibrous material entangled and intertwined with both the elastic layer and the gatherable layer. The resulting elastic composite provides a stretchable material which can conform to surfaces and has desirable properties of the fibrous material entangled and intertwined with both the elastic layer and the gatherable layer and does not suffer from the loss of the fibrous material from the stretchable substrate.

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

[0091] The 120 gsm composite of Example 1 was coated onto both sides with about 2 gsm of an Ato Findley H 2174-01 hot melt adhesive, while in the relaxed condition. The adhesive containing composite was cut into a bandage 3 inches wide and 20 inches long. With the adhesive coated on the composite and cut to size, the composite was useful as an absorbent bandage.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The present invention is directed to an elastic composite material having an elastic layer having a first side and a second side; at least one gatherable layer bonded to at least one of the first side and second side of the elastic layer; and a fibrous material entangled and intertwined with both the elastic layer and the gatherable layer. The resulting elastic composite provides a stretchable material which can conform to surfaces and has desirable properties of the fibrous material entangle and intertwined with both the elastic layer and the gatherable layer and does not suffer from the loss of the fibrous material from the stretchable substrate. The composite is usable in as bandages, durable wipes, durable mops and personal care products, such as diapers and feminine napkins. Also disclosed is a method for making the composite.

Description

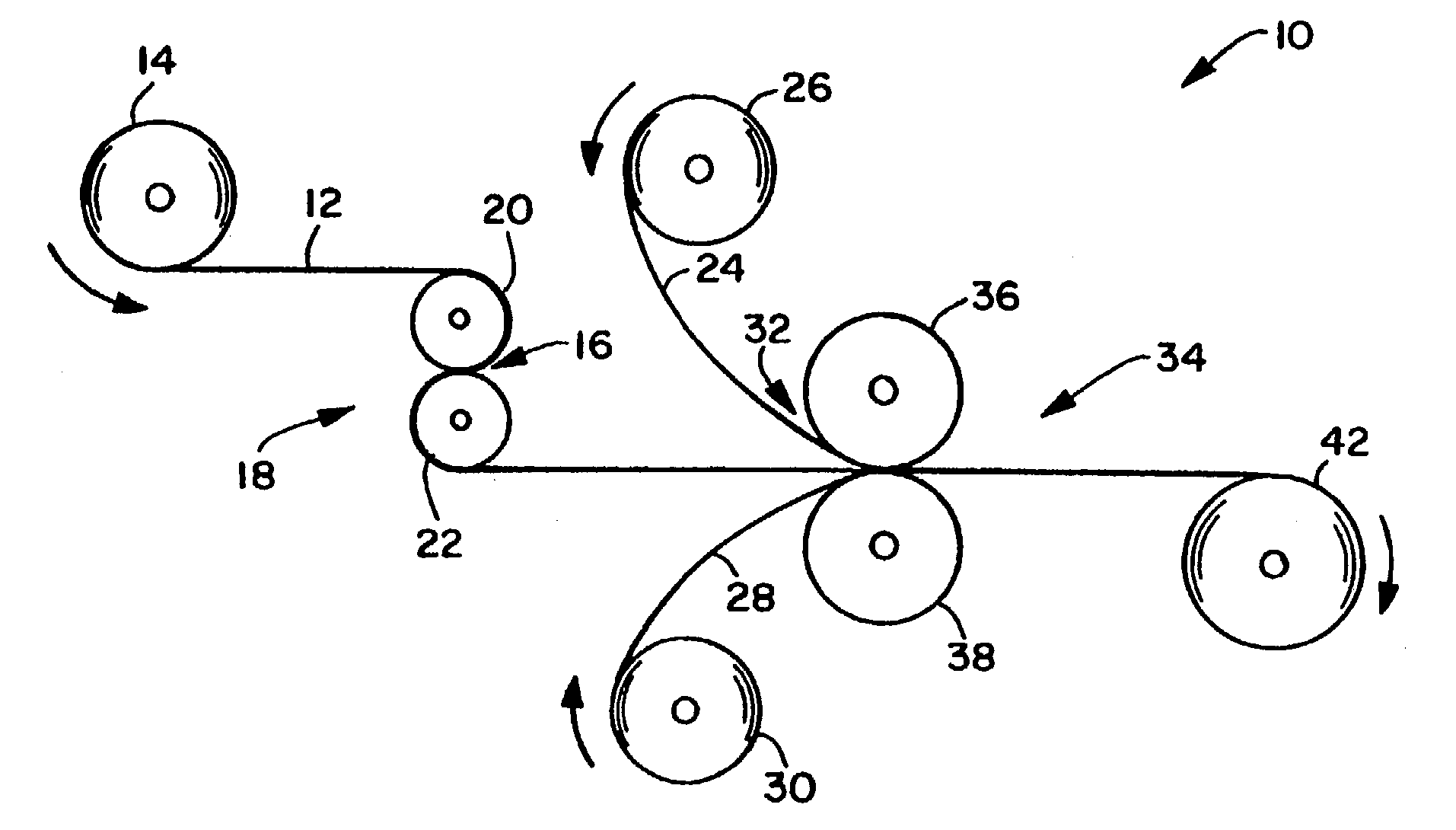

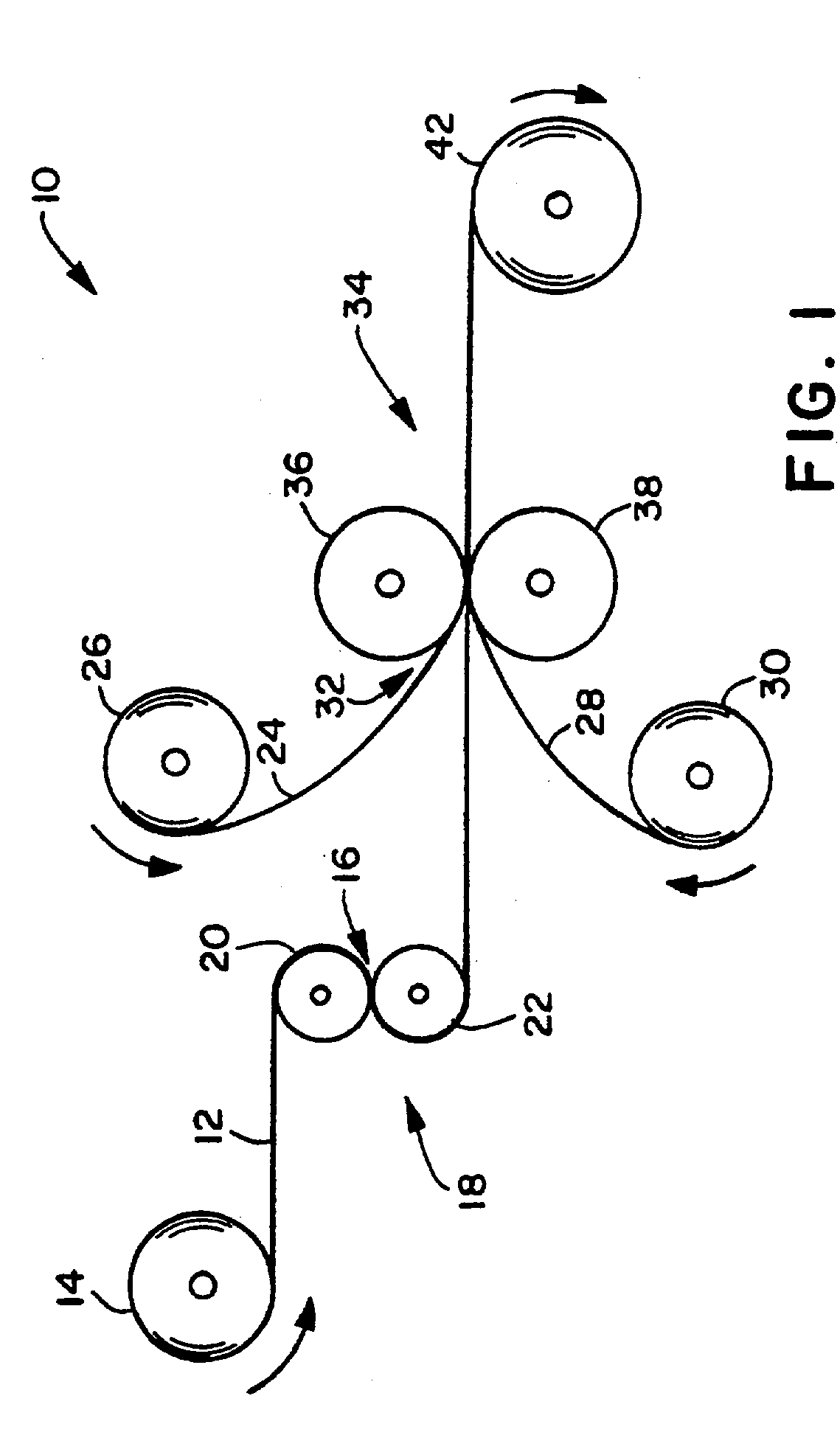

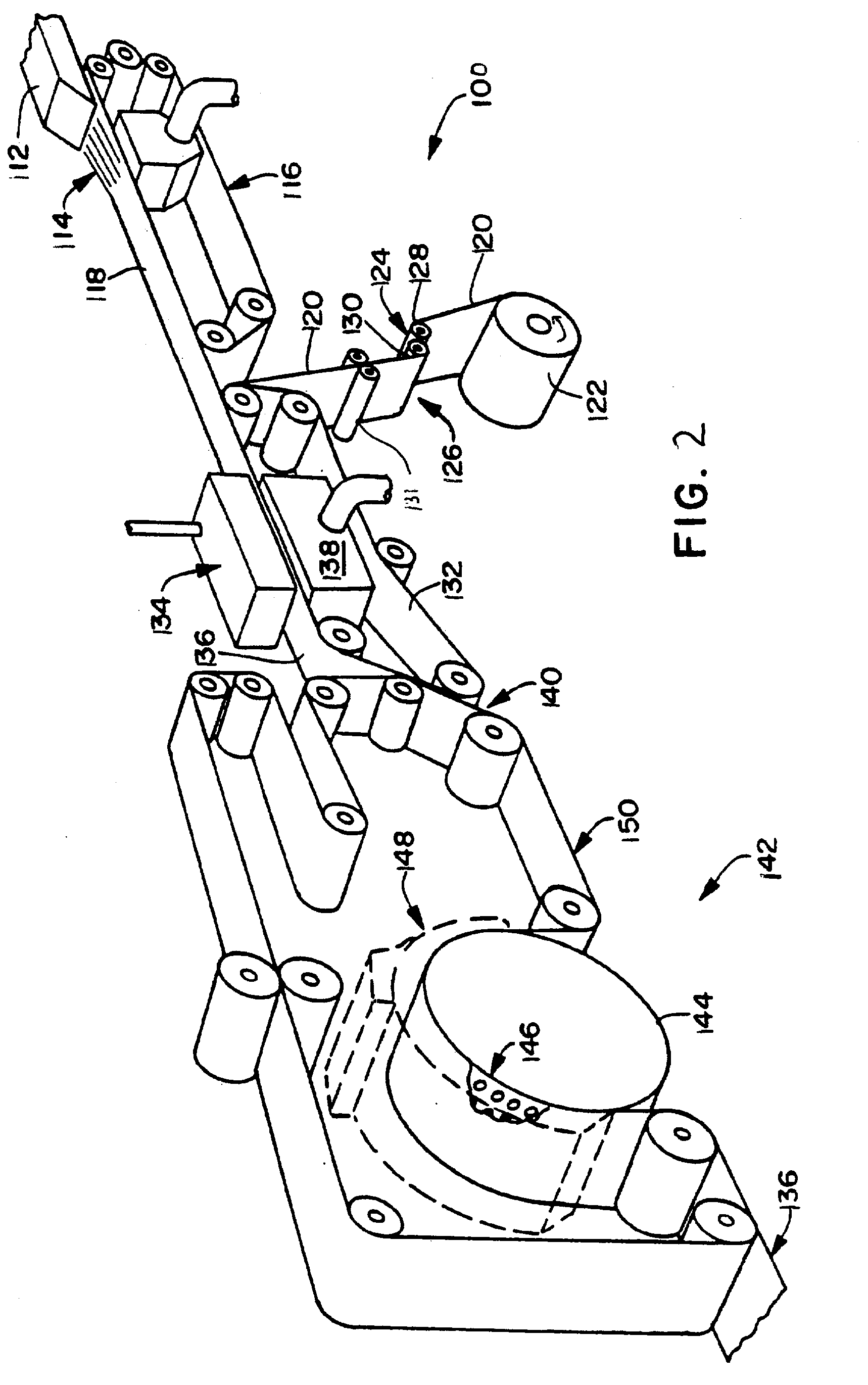

[0001] The present invention relates to a composite elastic material, uses of the composite elastic material and the method of making the composite elastic material.[0002] Composites of elastic and nonelastic materials have been made by bonding nonelastic materials to elastic materials in a manner that allows the entire composite material to stretch or elongate. These composites can be used in garment materials, pads, diapers, training pants and other personal care products where elasticity is needed.[0003] In one such composite material, a nonelastic material is joined, for example pattern bonded, to an elastic sheet while the elastic sheet is in a stretched condition. These materials are often referred to as "stretch-bonded laminates." When the elastic sheet is relaxed, the nonelastic material gathers between the locations where it is joined to the elastic sheet. The resulting composite elastic material is stretchable to the extent that the nonelastic material, gathered between th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): B32B5/04B32B5/08B32B5/26B32B7/08B32B23/02B32B25/10B32B25/14B32B37/14D04H13/00

CPCB32B5/04B32B5/08B32B5/26B32B7/08D04H13/007B32B25/10B32B25/14B32B37/144B32B2307/51B32B23/02D04H1/492D04H1/498Y10T442/40Y10T442/659Y10T442/30Y10T442/494Y10T442/601Y10T442/60Y10T442/3707Y10T442/3008Y10T442/674Y10T442/3854Y10T442/413B32B2555/00B32B2535/00B32B2038/0028

Inventor JORDAN, JOYMATELA, DAVID MICHAELROLSTEN, GINA KAYSCHMIDT, RICHARD JOHN

Owner KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com