Low-density, open-cell, soft, flexible, thermoplastic, absorbent foam and method of making foam

a technology of absorbent foam and low density, applied in the field of low density, open-cell, thermoplastic, absorbent foam, can solve the problems of difficult to achieve low densities with absorbency, difficult to produce foam, and thin membranes between cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

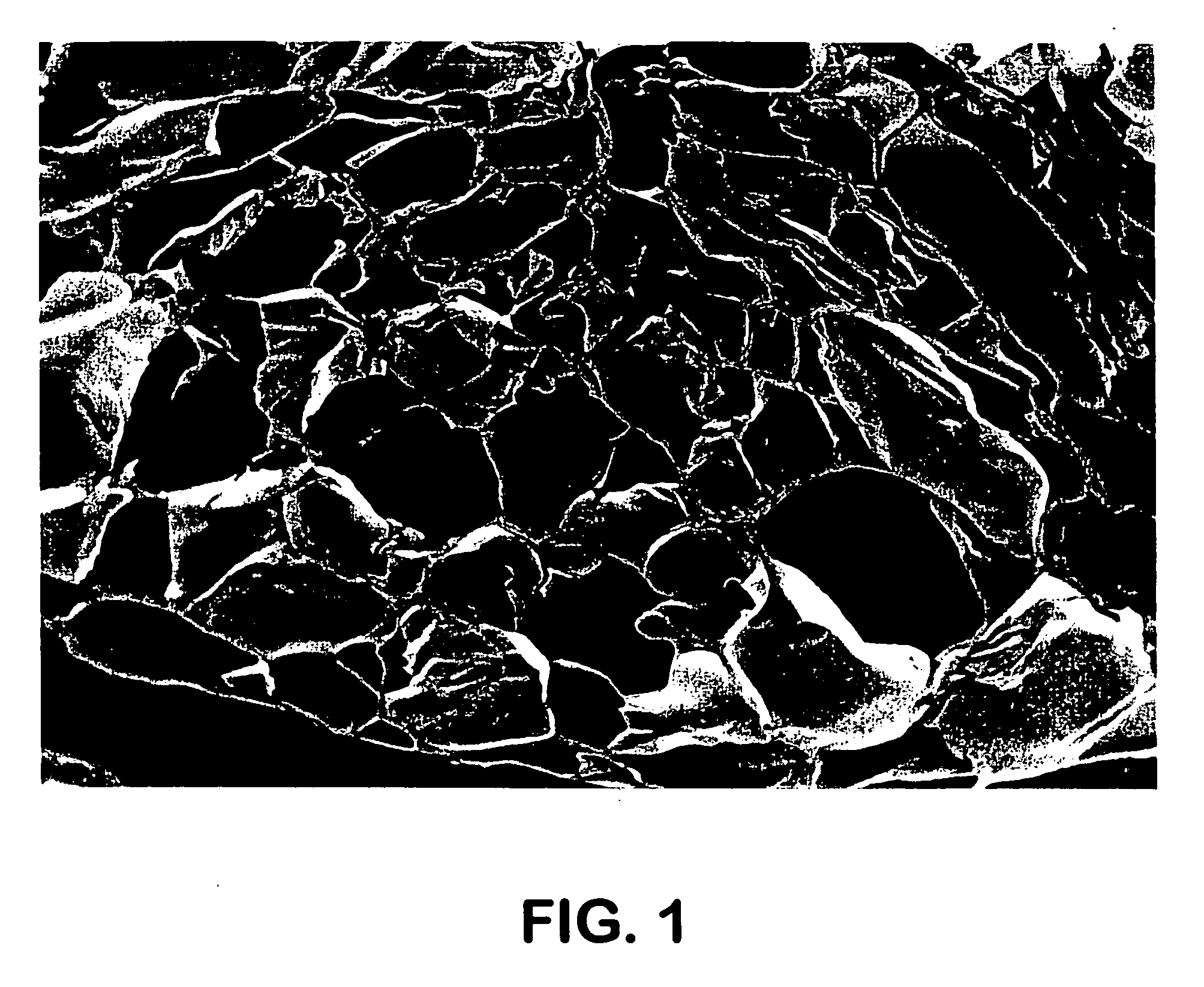

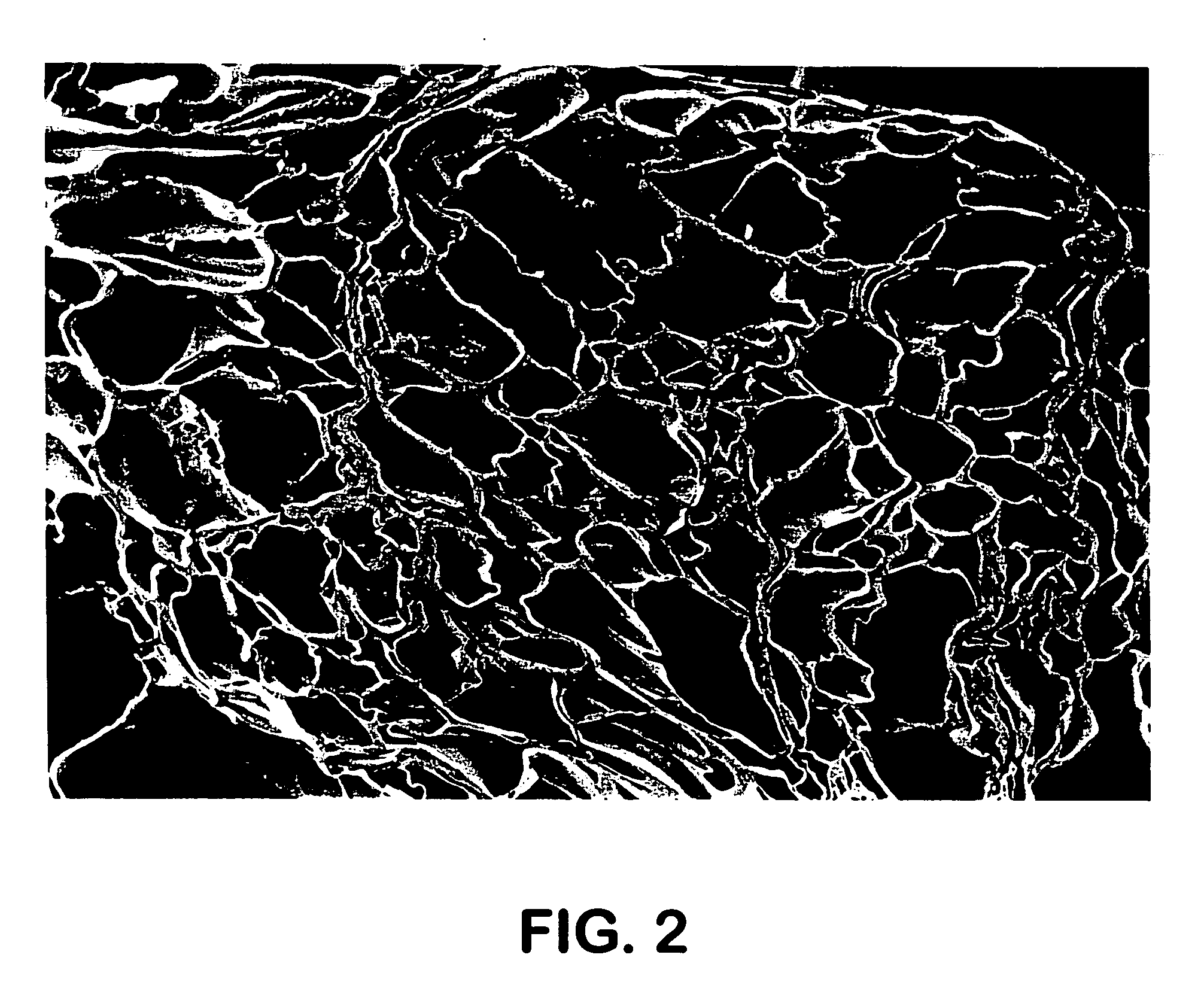

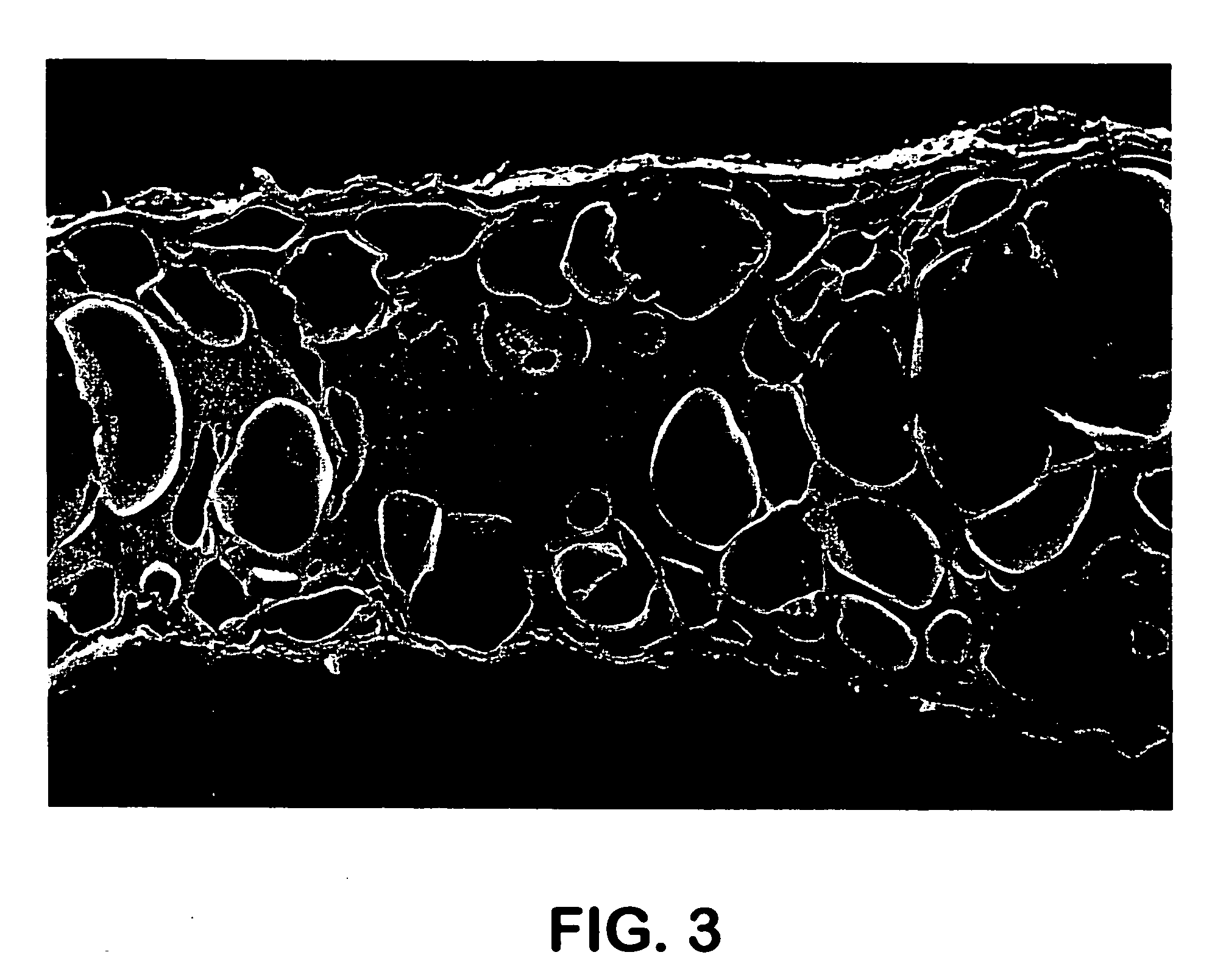

Image

Examples

example 1

[0108] Foam polymer formulas were made from blends of Dow STYRON® 685D polystyrene pelletized resin and KRATON® G1657 styrene-ethylene-butylene-styrene (SEBS) block copolymer pelletized thermoplastic elastomer resin. Low molecular weight polyethylene wax (Eastman EPOLENE® C-10) was added to certain samples to plasticize the foam polymer formula. A surfactant, Dow-Corning 193, available from Dow-Corning Company in Midland, Mich., U.S.A., was added to certain samples to improve wettability. A nucleating agent, CLOISITE® 20A, was also added at 5%, by weight, to the foam polymer formula. All foams were extruded using a 27-mm Leistritz co-rotating twin screw extruder, available from American Leistritz Extruder Corporation in Somerville, N.J., U.S.A., equipped for direct injection of carbon dioxide gas. The foam polymer formulas were heated to about 200 degrees Celsius in the extruder and subsequently foamed using carbon dioxide (added at 6%, by weight, of the foam polymer formula) as a b...

example 2

[0117] This example illustrates the importance of surfactant structure to enable the production of low-density foams from a blend of polystyrene with soft, flexible polymers. The foam polymer formula in this example included 50.0 parts of Dow STYRON® 685D polystyrene and 45.2 parts of KRATON® G1657 SEBS, and 4.8 parts CLOISITE 20A nanoclay. Foam extrusion method was the same as Example 1. Samples of the foam polymer formula with various surfactants, and levels of surfactant, and results of these samples are shown in Table 3.

TABLE 3Foaming Soft, Flexible Polymers With Various SurfactantsSurfactantAmount(parts per100 partsFoamOpen-of foamDensity,LiquidCellpolymerlb / ft3PenetrationContentSampleSurfactant Descriptionformula)(g / cm3)into Foam(%)1bNo Surfactant057 (0.91)No242bClariant HOSTASTAT2.7 7 (0.11)Yes84HS-1(sulfuric acid head C12-C18saturated tail)3bDow Corning 1934.613 (0.21)Yes76(ethoxylated siliconepolymer)4bCognis EMEREST 26502.710 (0.16)No82(PEG 400 headC12 saturated tail)5bC...

example 3

[0120] This example illustrates the effect of multiple surfactants in comparison to single surfactants in the foam polymer formula. Table 4 illustrates the results of adding various dosages of surfactants and surfactant mixtures to a polymer blend of 54.45 parts of Dow STYRON® 685D polystyrene, 44.55 parts of KRATON® G1657 with 1 part of MISTRON® VAPOR talc, used as a nucleant, and available from Luzenac America, Inc., of Englewood, Colo., U.S.A. The surfactants utilized were: HOSTASTAT® HS-1, an alkyl sulfonate available from Clariant Corporation in Winchester, Va., U.S.A.; MMF 184 SW, an ethoxylated siloxane available from Siltech LLC in Dacula, Ga., U.S.A.; and MASIL® SF-19, an ethoxylated siloxane available from BASF Corporation in Mount Olive, N.J., U.S.A. Foam extrusion method was the same as Example 1 except that the maximum extrusion temperature utilized was 195 degrees Celsius and carbon dioxide addition rate was about 15%, by weight of the foam polymer.

[0121] In Table 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| wicking height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com