Rotary injection molding apparatus and method for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

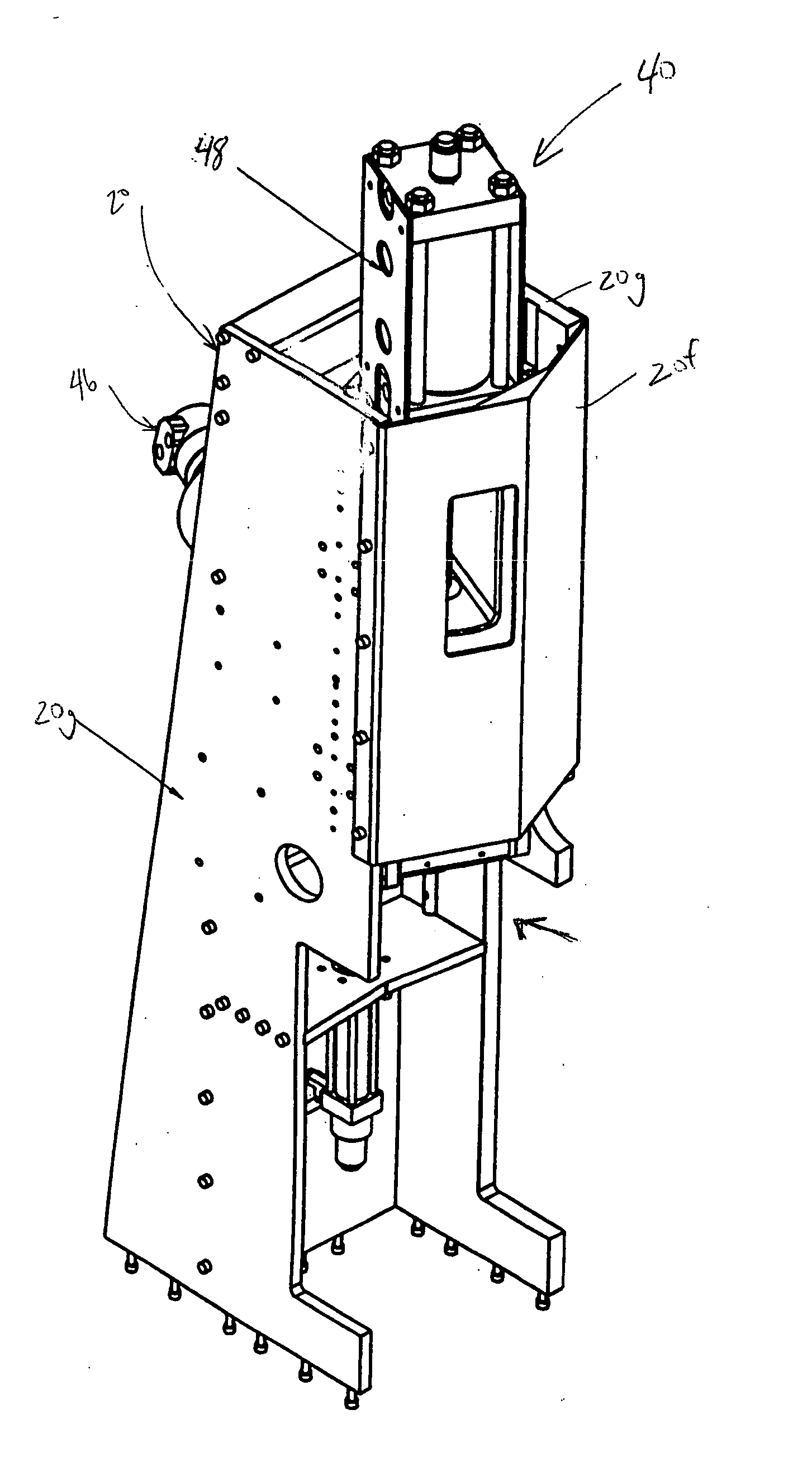

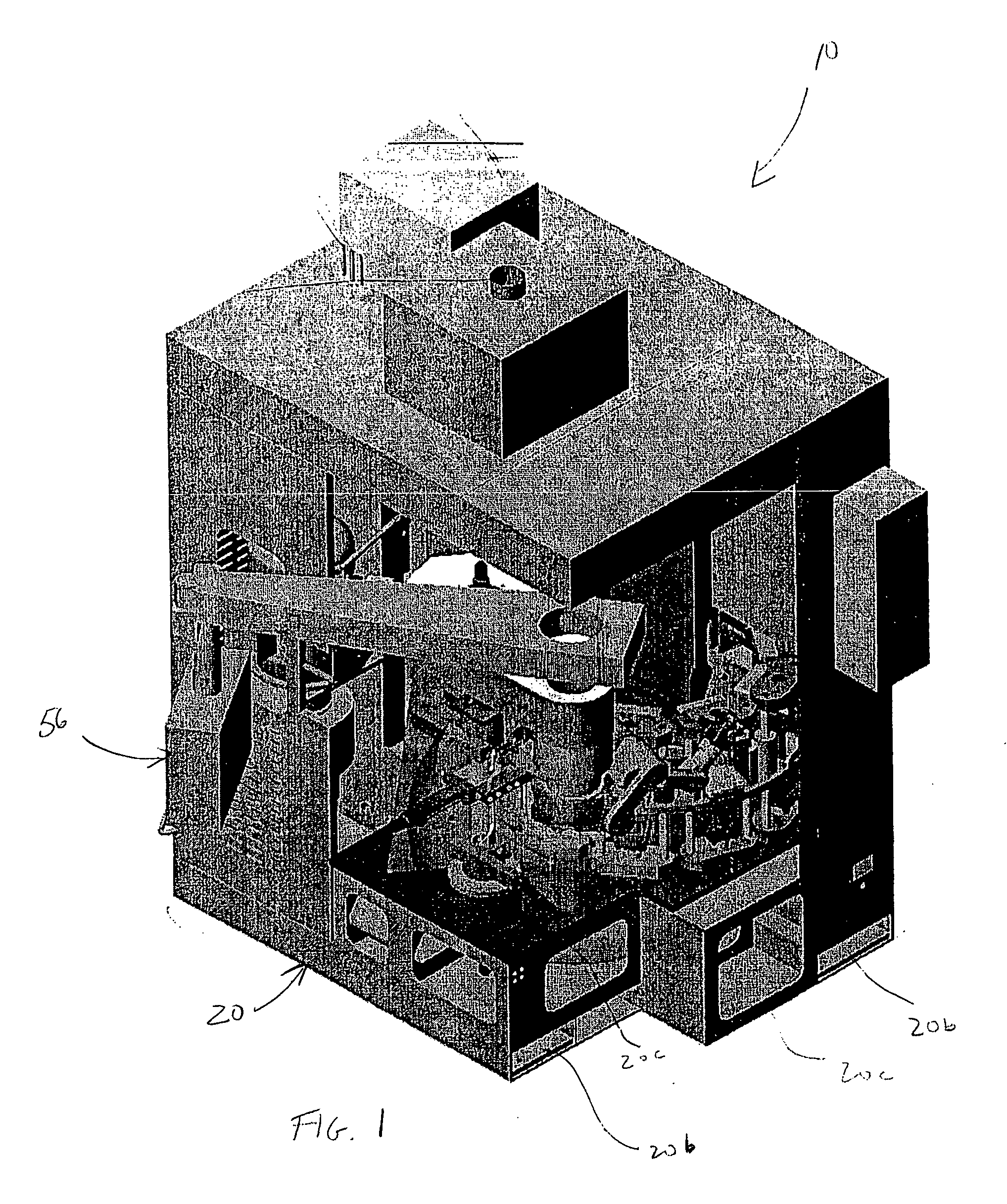

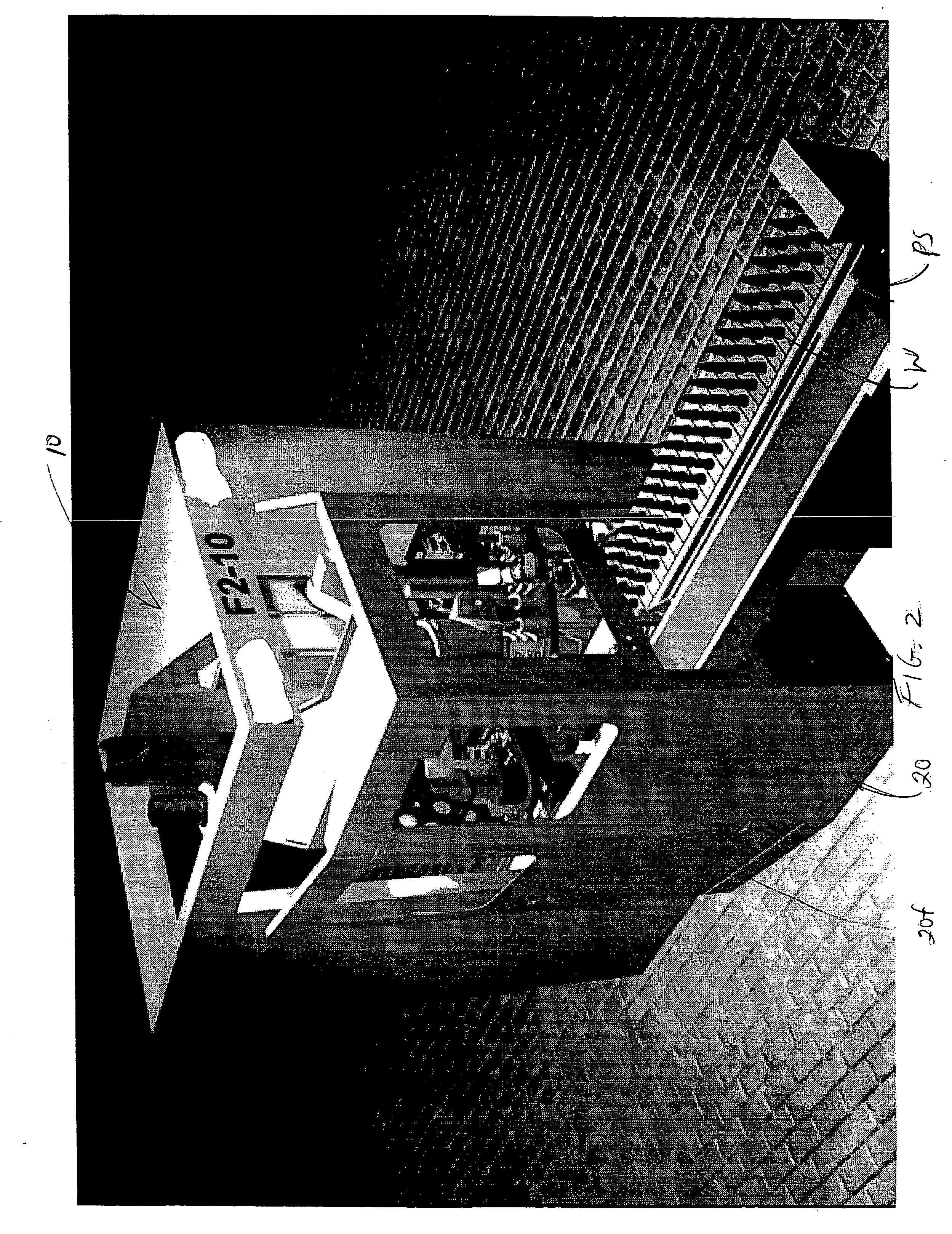

[0056] Turning now to the illustrations of the present embodiment, a multi station rotary injection molding apparatus 10 provides high production injection molding of manufactured products M. In the illustrated embodiment, the rotary injection molding apparatus 10 is supported on a modular frame 20 and includes a rotating table 22 having 10 work stations 24 positioned along the periphery of the rotating table 22. Independent clamp assemblies 28 are supported on the rotating table for engagement with a single extruder and injector assembly, also supported on the modular frame 20. In the preferred embodiment of the apparatus, cure times for manufactured products M are between approximately 75 to 160 seconds per product, and preferably approximately 80 seconds per product. With small multi-section single cavity molds 30, cycle times for movement between positions or stations may be 20 to 30 seconds.

[0057] All press operations are automatic and cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com