Dispensers for bags

a technology for dispensers and bags, applied in the field of dispensers, can solve the problems of increasing the manufacturing cost of stacks, requiring glue spots, and requiring regions of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

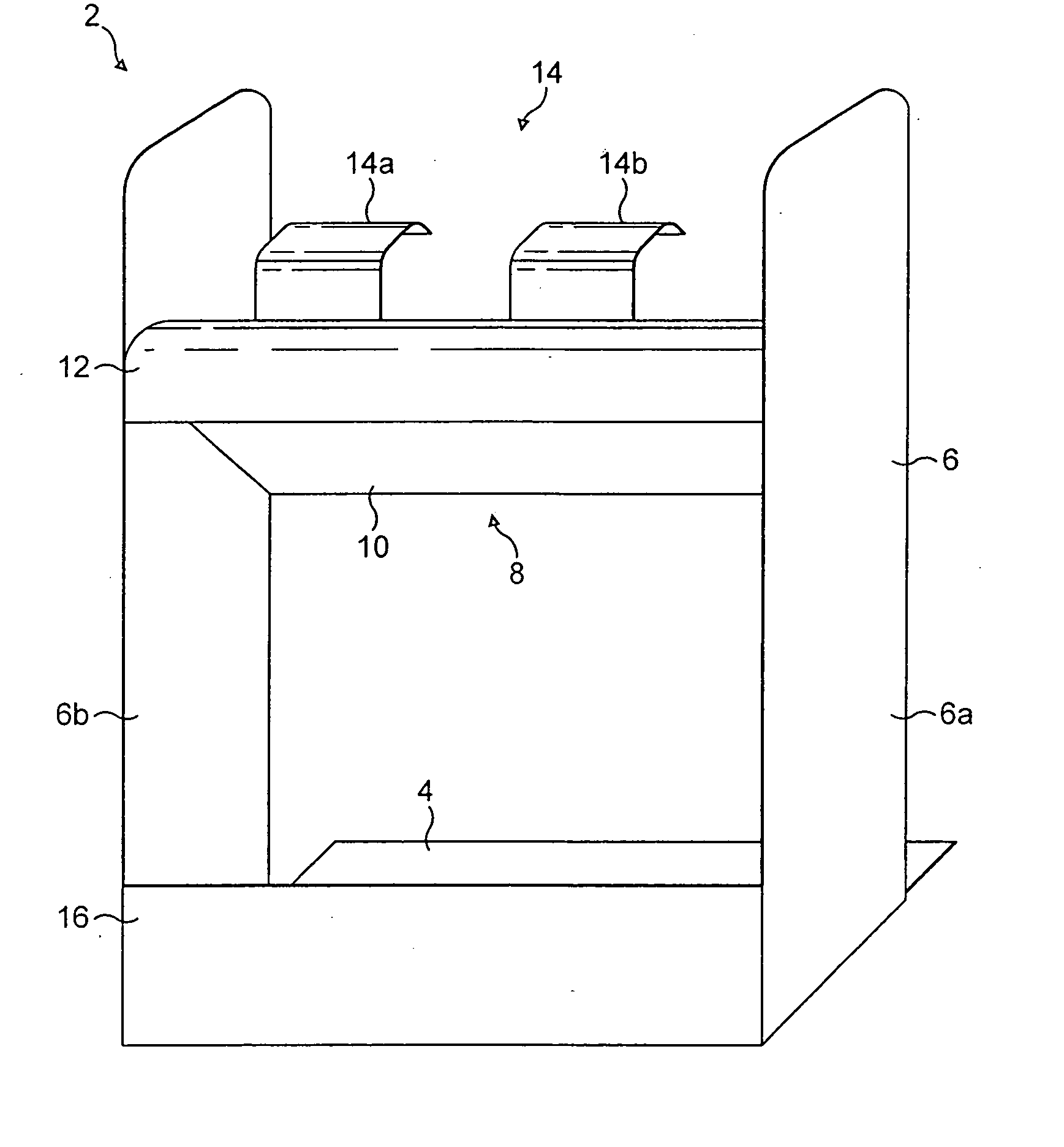

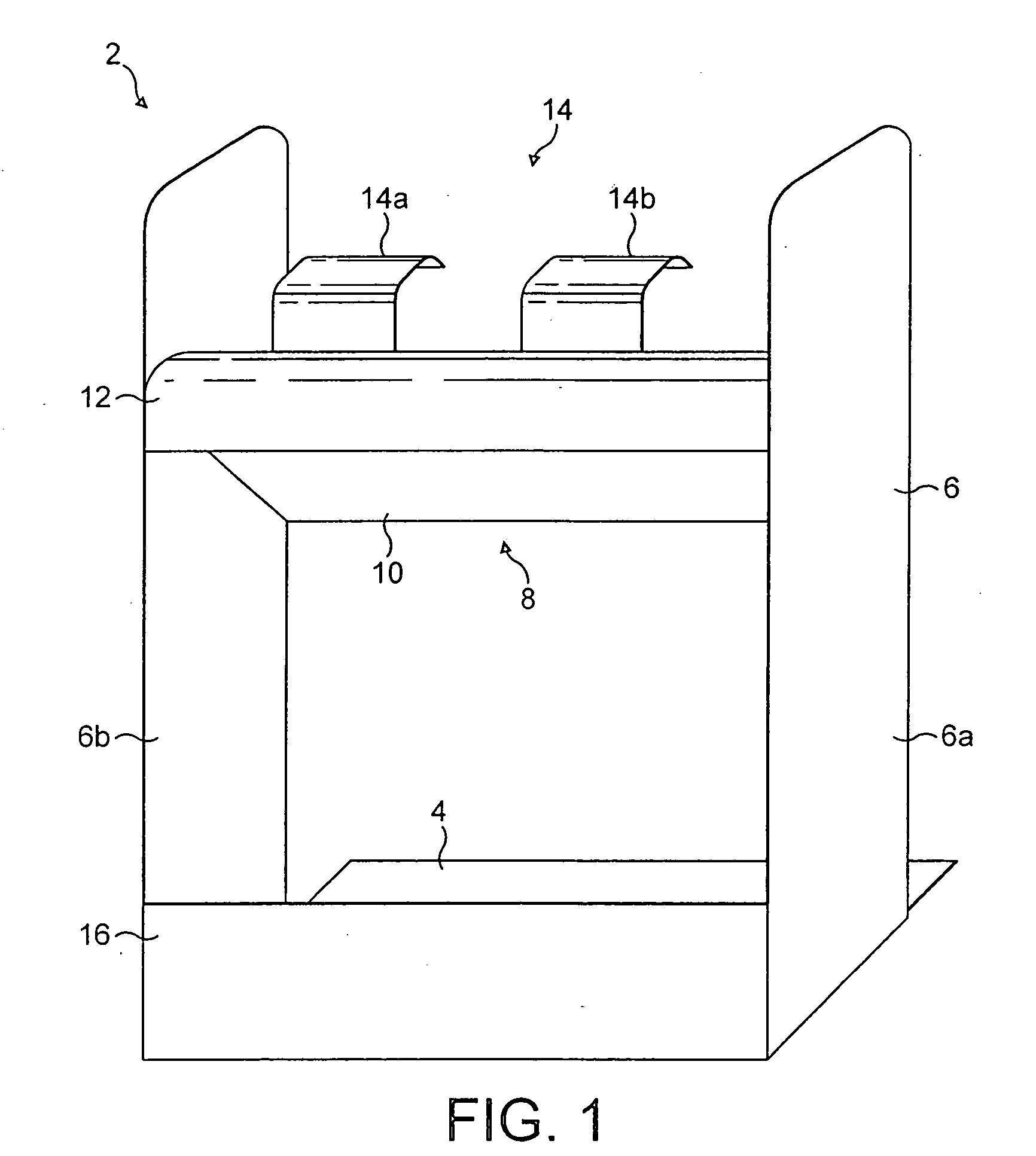

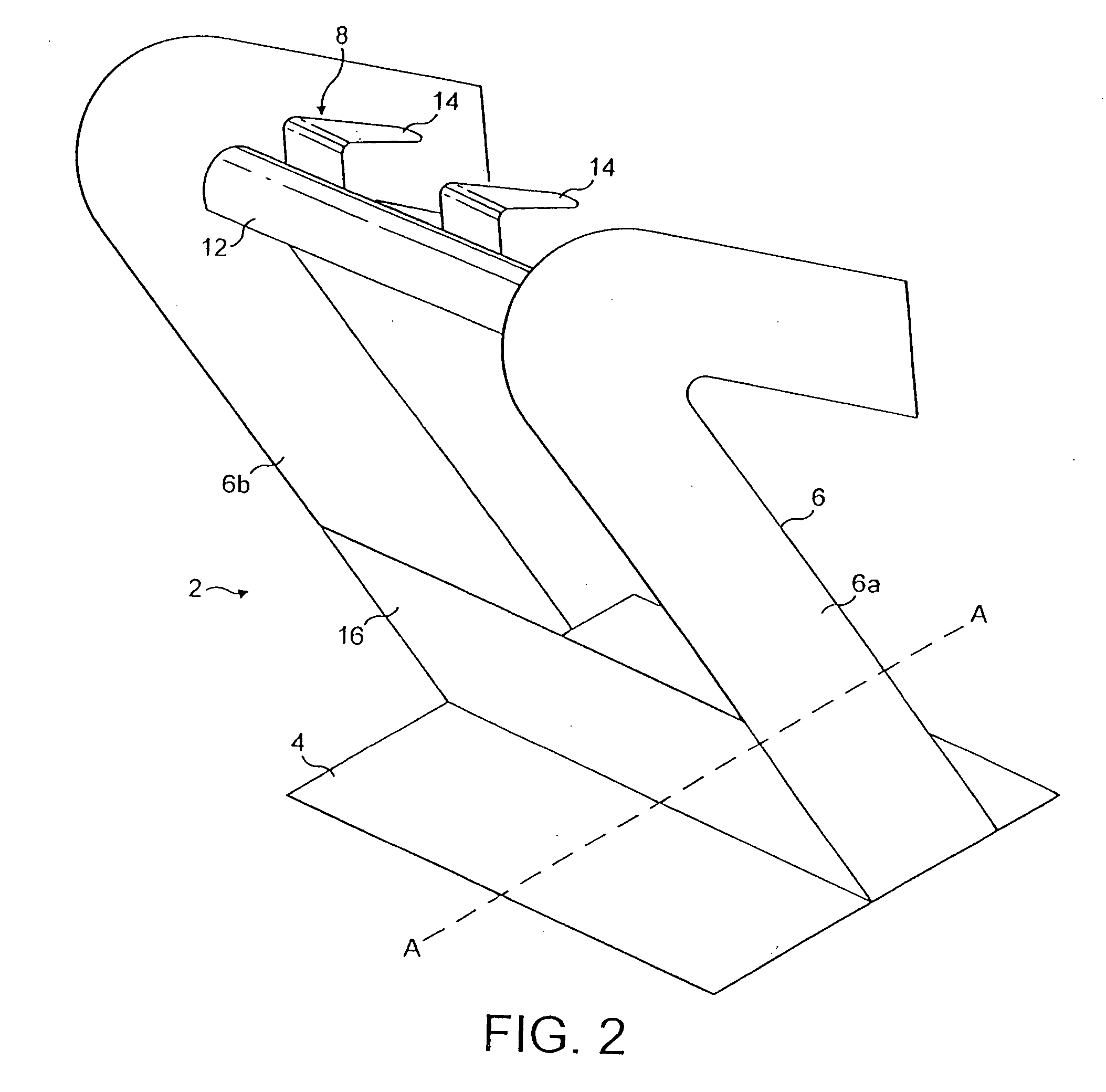

[0031] Referring firstly to FIG. 1, there is shown a dispenser 2 for dispensing individual pre-formed bags from a stack of such bags, the dispenser comprising a base 4 in the form of a planar sheet, and a body part 6 extending therefrom. The dispenser 2 is of the type commonly provided in retail outlets and in particular is of the type designed to be mounted at the checkout of a supermarket. Consequently, the base 4 may be in the form of a planar sheet or it may be in the form of a mounting suitable for attaching the dispenser 2 to a surface.

[0032] The body part 6 is in the form of two parallel side walls 6a, 6b. The side walls 6a, 6b extend perpendicularly upwards from the base 4 and support a stack support member 8 therebetweeen. The stack support member 8 has a first region 10 and a second region 12. The first region 10 is planar and is inclined upwards, at approximately 45° with respect to the base 4, from the back of the dispenser 2 to the front. The second region 12 of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com