Ion emitting brush

a technology of ion-emitting brushes and brushes, which is applied in the field of grooming products, can solve the problems of not always successful removal of lint, hair and the like from clothing by conventional brushing, and the inability to provide clothing conditioning, and the fabrication of lee's tear-shaped maxisectional electrodes is relatively expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

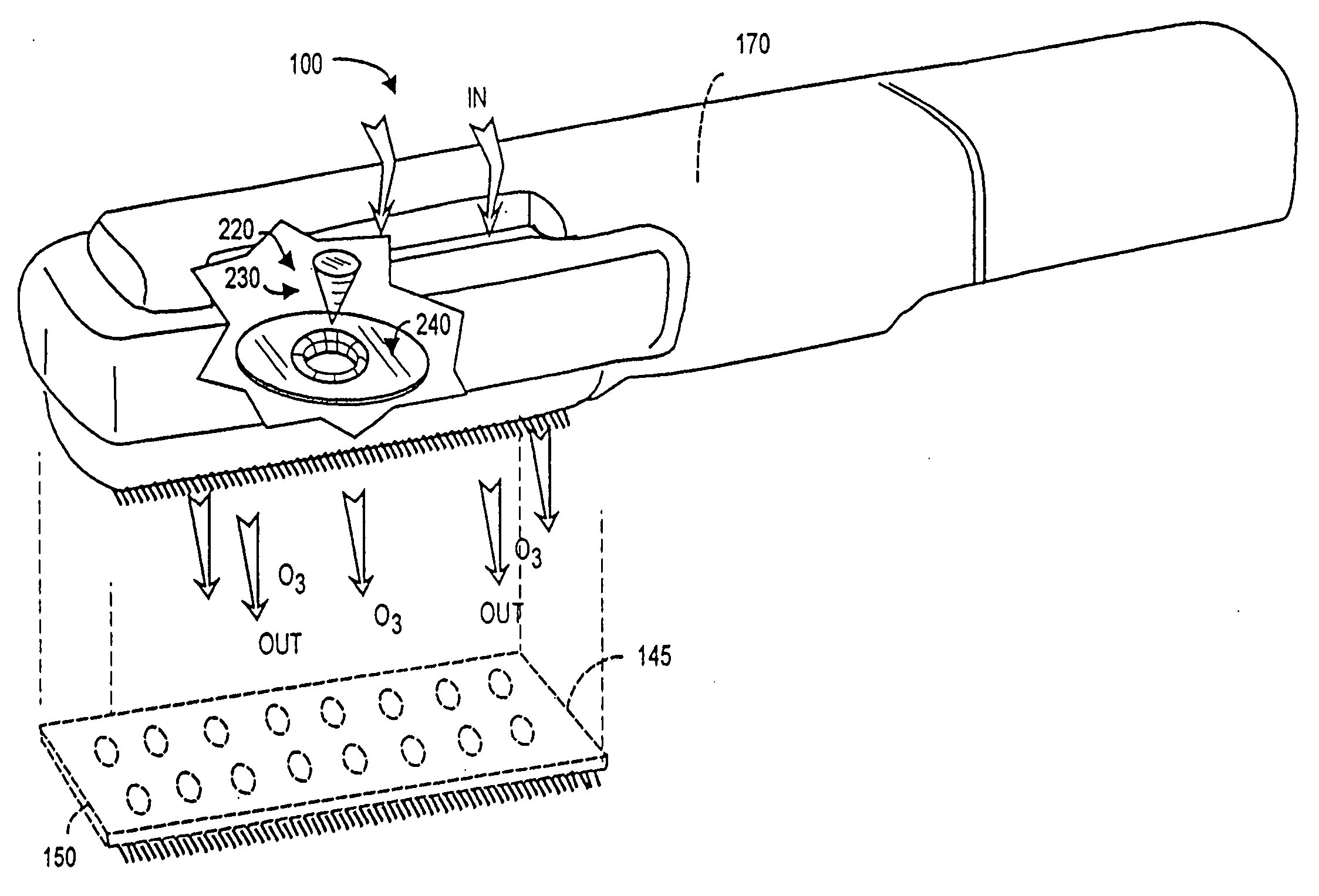

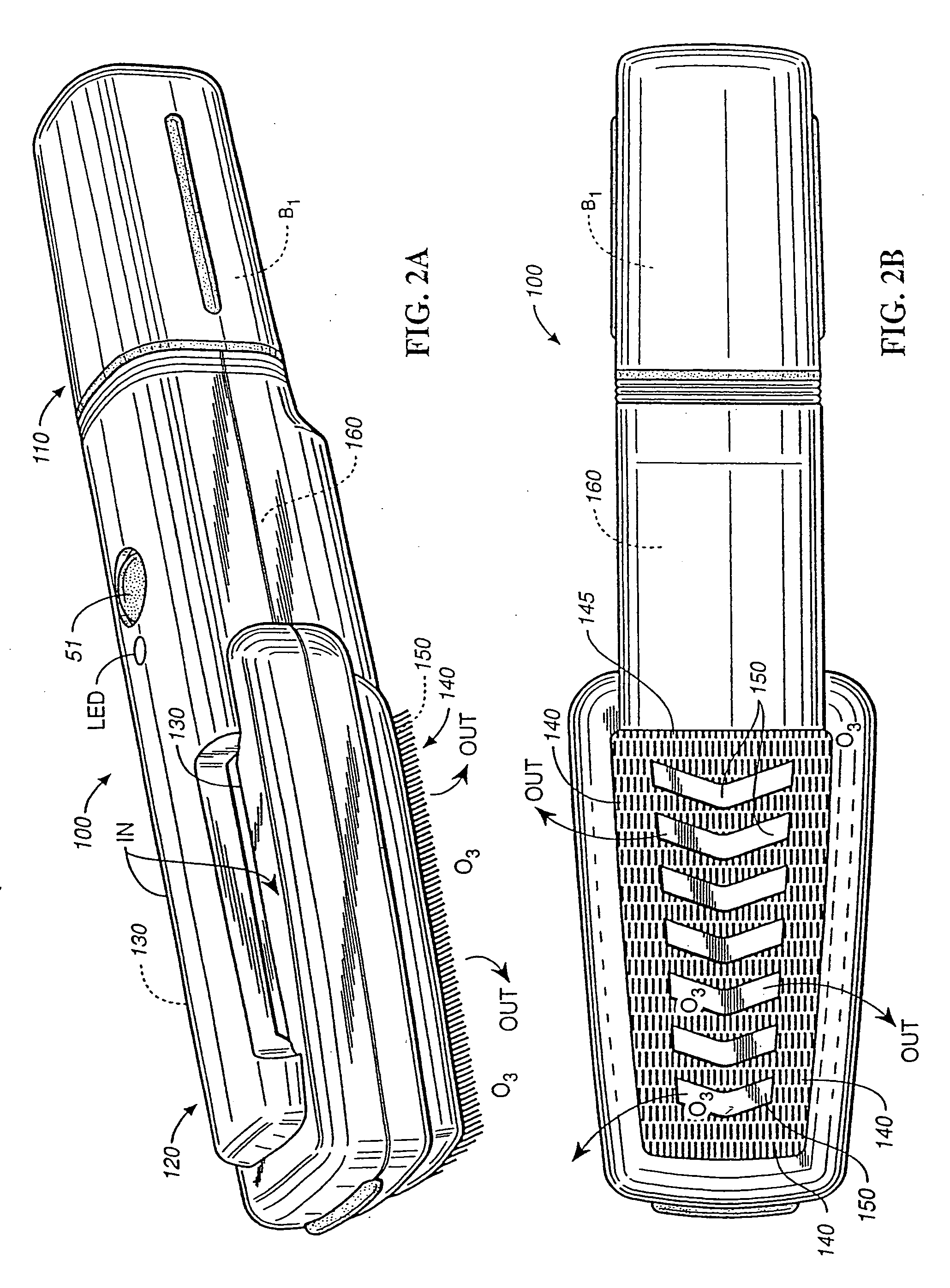

[0030]FIGS. 2A and 2B depict an ionized brush 100 according to the present invention as having a body that includes a handle portion 110 and a head portion 120. Head portion l20 includes one or more air intake vents 130, brush bristles 140 that protrude from a brush plate 145 attached to the brushing surface of the brush, and one or more outlet vents 150.

[0031] Brush 100 is similar to what was described in FIGS. 2A and 2B in the parent application, except that for a brush to remove lint, hair, etc., bristles 140 will typically be shorter and may be biased at a common angle and formed on a cloth substrate. However whether brush plate 145 includes long bristles or short bristles is unimportant to operation of the present invention.

[0032] Internal to the brush body is an ion generating unit 160, powered by a battery B1 (preferably at least 6 VDC) contained within the brush and energizable via a switch S1, preferably mounted on the brush 100. As such, ion generating unit 160 is self-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com