High speed materials sorting using x-ray fluorescence

a high-speed material and fluorescence technology, applied in the direction of sorting, instruments, radiation measurement, etc., can solve the problems of limited analysis, system that enables use of high-intensity x-ray sources, and inability to implement high-intensity x-ray sources, etc., to achieve the production of x-rays from other objects, the accuracy of the determination of the x-ray fluorescence spectrum is not significantly compromised or complicated, and the effect o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

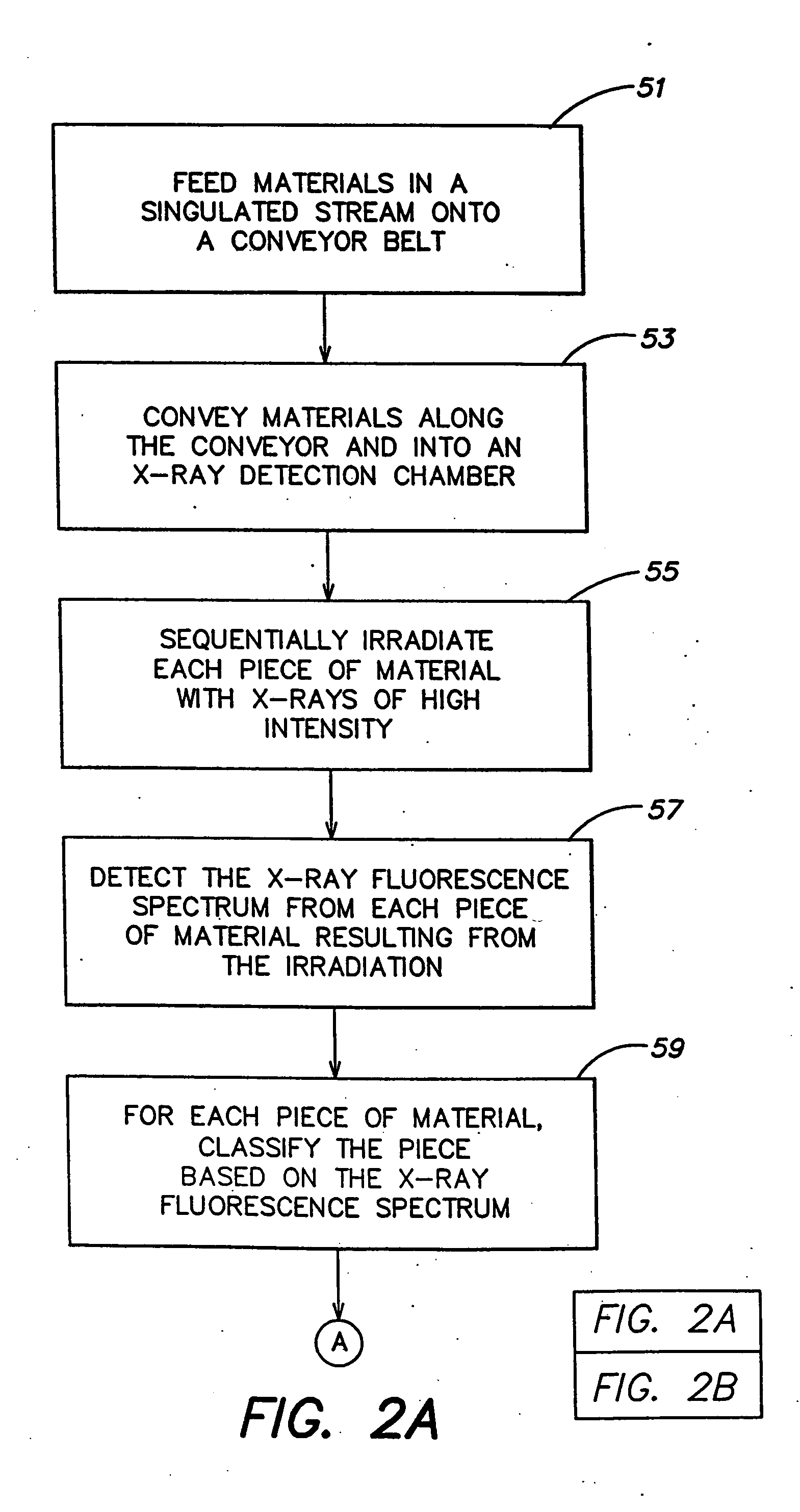

The combination of the high speed x-ray irradiation and detection techniques and the execution of a complex sorting algorithm described herein permit highly accurate classification and sorting of materials at very fast rates, at least one to two orders of magnitude faster than currently used techniques.

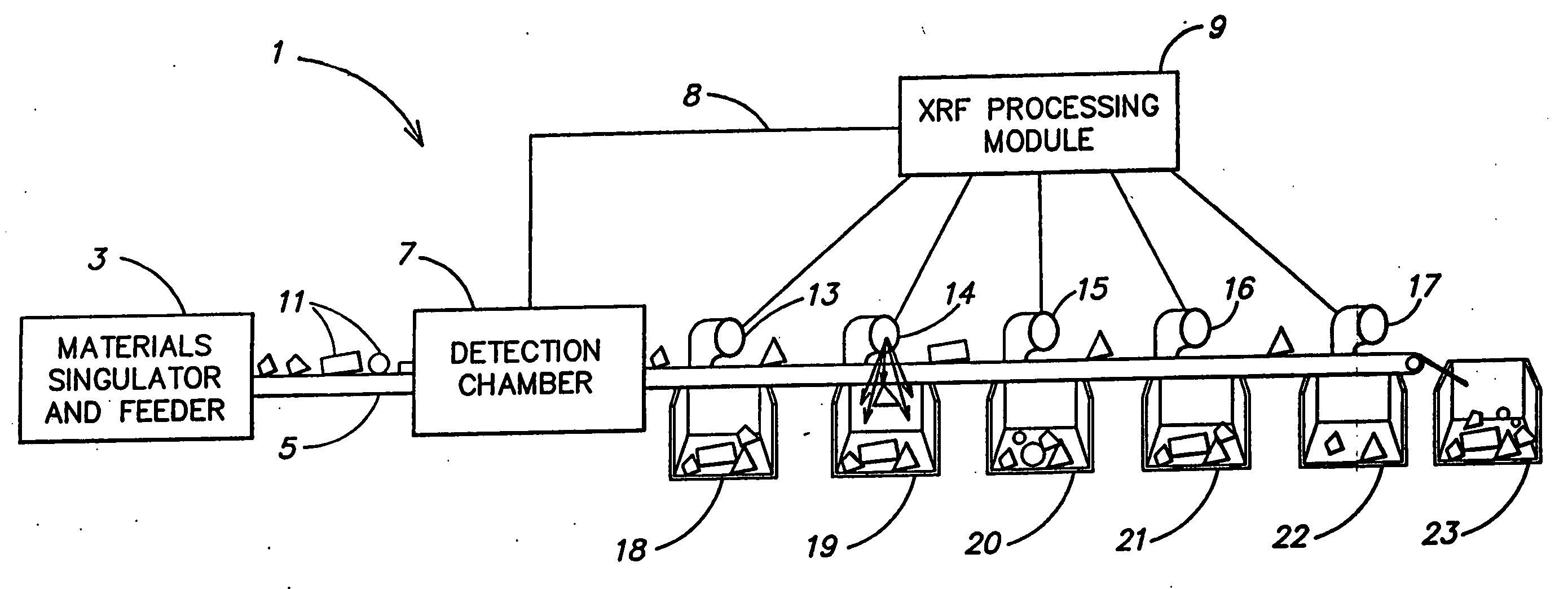

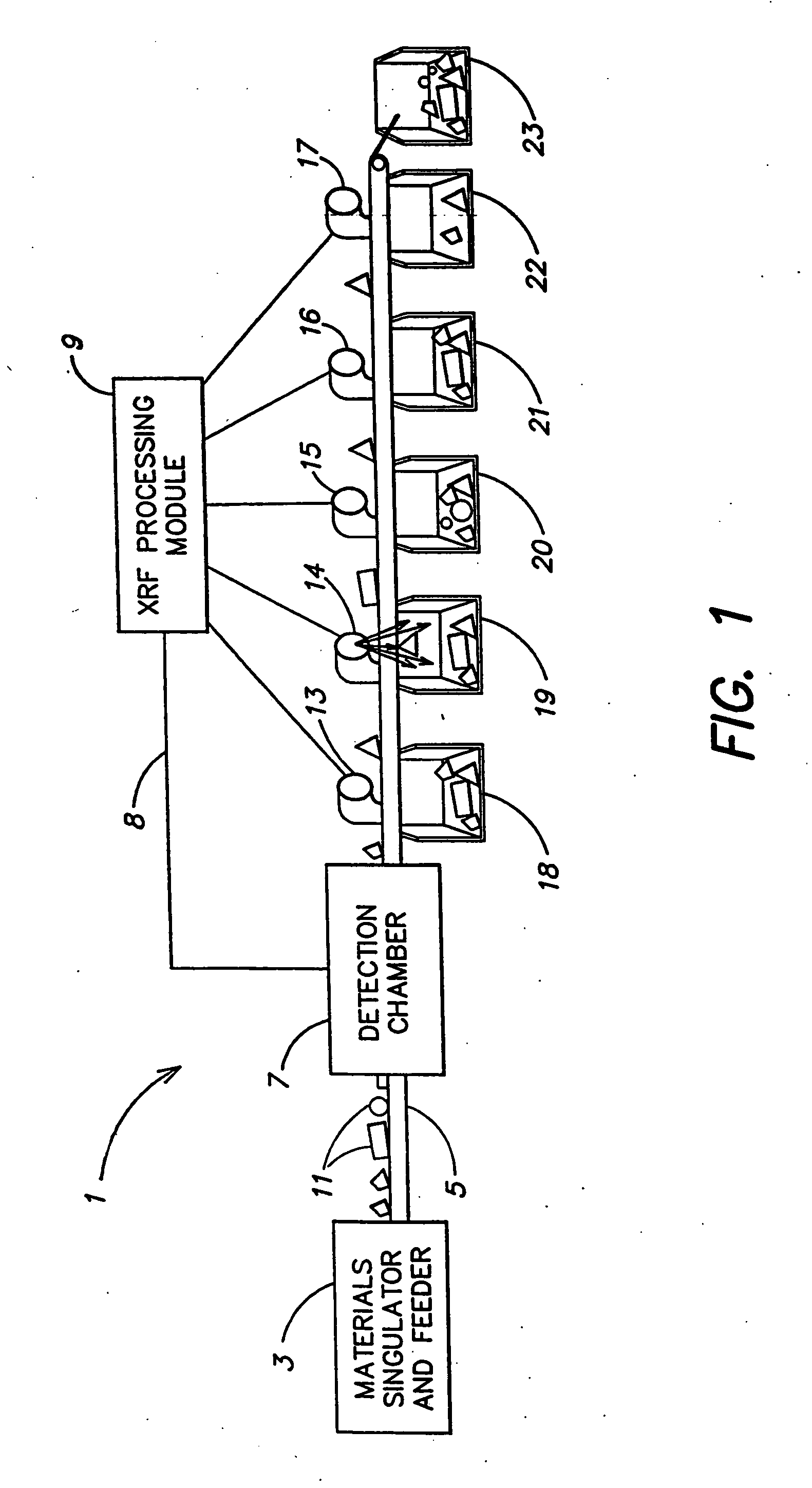

FIG. 1 depicts an illustrative embodiment of a high speed material sorting system. A materials singulator and feeder 3 feeds a singulated stream of pieces of material 11 onto a conveyor belt 5. The conveyor belt 5 receives the pieces of material 11 and conveys the pieces of material through an x-ray detection chamber 7 downstream to be sorted into sorting bins 18-23. Although a conveyor belt is used in the illustrative embodiment of FIG. 1, any suitable conveying means may be used.

An x-ray detection chamber 7 receives each piece of material, irradiates the material with x-rays, and detects the x-ray fluorescence (xrf) from the materials as a result of the irradiation. The detectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com