Pump pulsation dampening attachment and method for dampening pump pulsations

a technology of pump pulsation and attachment, which is applied in the direction of pulse equalisation, pump components, positive displacement liquid engines, etc., can solve the problems of excessive wear, difficult to achieve precise and accurate flow rates in such systems, and the typical generation of significant pressure surges by positive displacement pumps, so as to reduce manufacturing costs, quick and efficient fluid delivery, and minimize the effect of flow pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

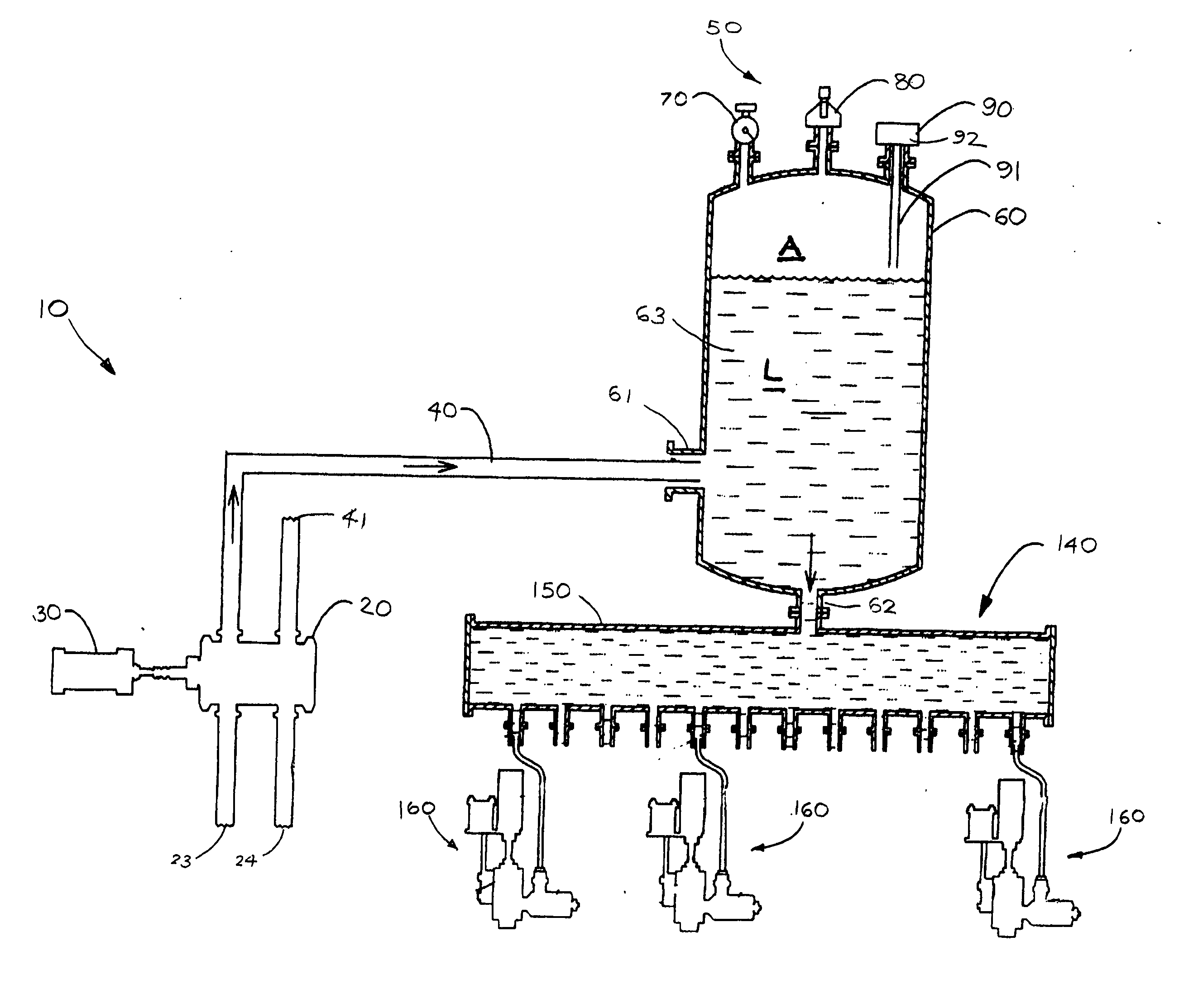

[0041] As shown in FIG. 1, in a first embodiment of the invention, a pump delivery system 10 adapted for use in a sanitary filling operation that includes a filling machine 140 whereby a viscous fluid or liquid (L) is delivered to a fluid manifold 150 in communication with a plurality of fill heads 160 which dispense the fluid to respective containers (not shown).

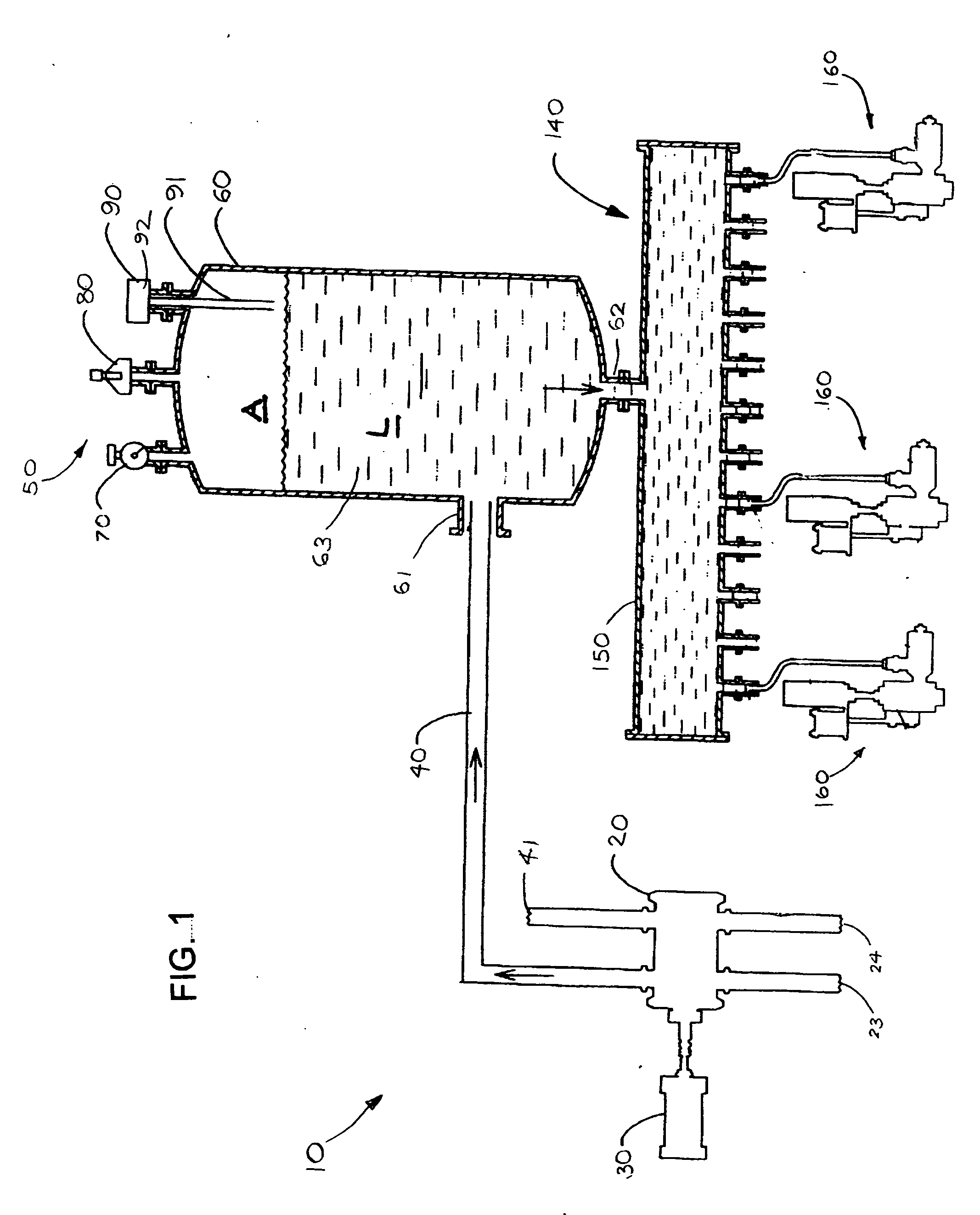

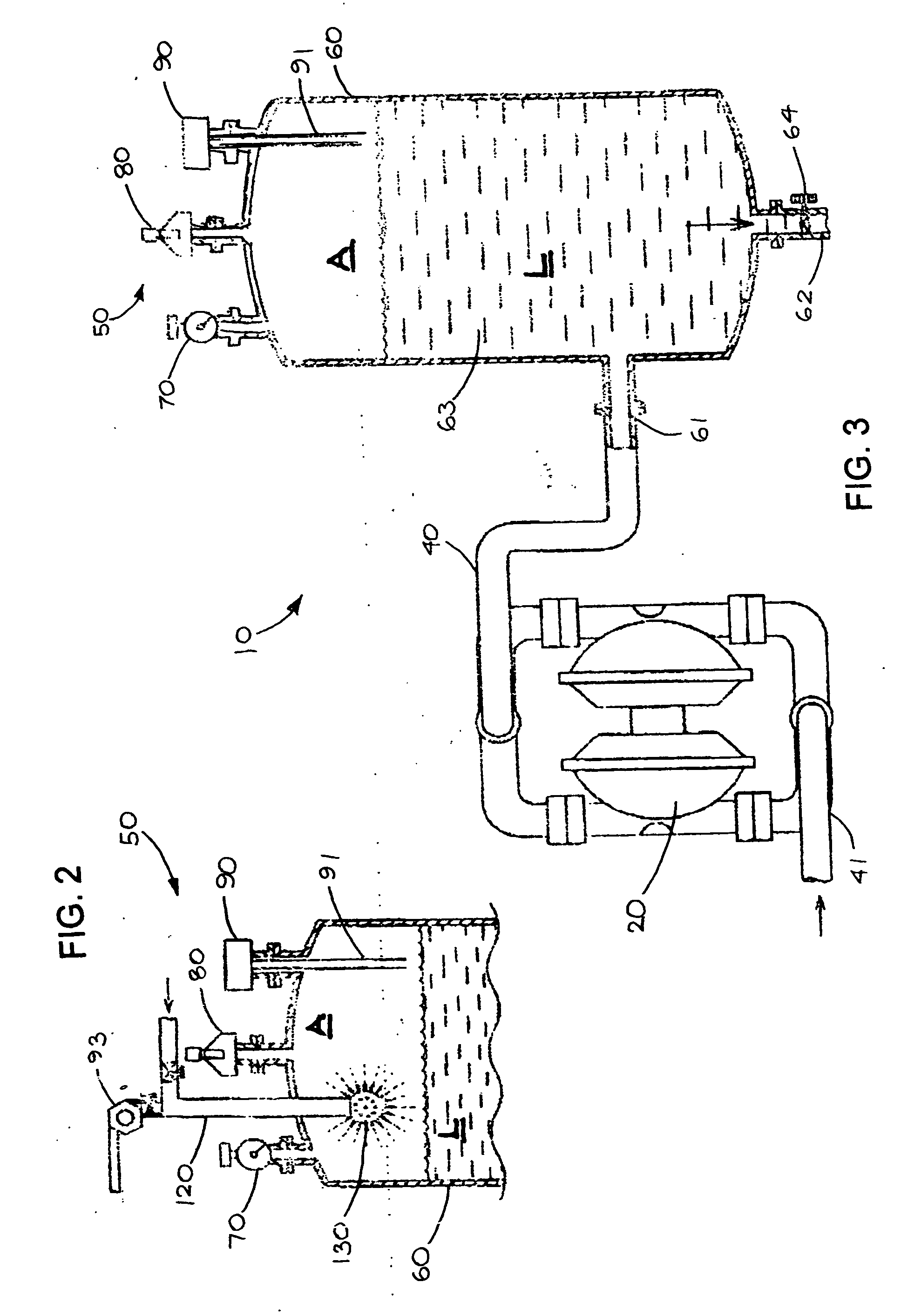

[0042] As shown in FIGS. 1, 6, 8 and 13, the pump delivery system 10 of the invention includes a pump mechanism 20 mechanically driven by a motor 30 for delivering the liquid (L) under pressure to the filling machine 140, the pump mechanism 20 generating a pulsating output during operation. As shown in FIGS. 1 and 11, the pump mechanism 10 may include a double acting piston head 21 driven by a drive shaft 22 having a pair of inlet ports 23, 24 for receiving the liquid (L) and a pair of outlet ports 40, 41 in communication with a pump pulsation dampening attachment or assembly 50 for transporting the liquid (L) thereto. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com