Shoulder prosthesis with anatomic reattachment features

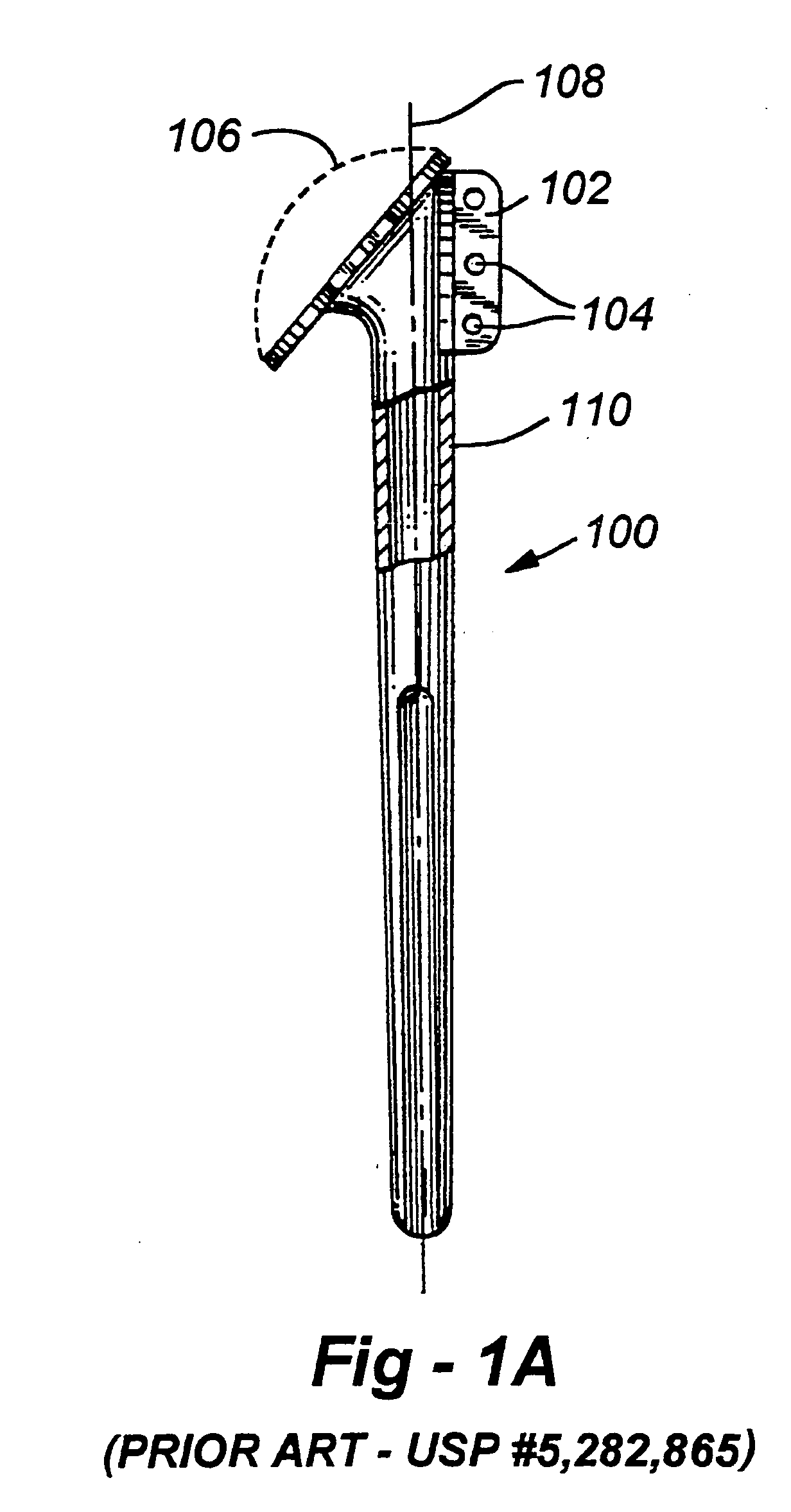

a shoulder and anatomic technology, applied in the field of orthopaedic surgery, can solve the problems of poor fixation in a non-anatomic arrangement, reduced range of motion and strength following the procedure, and vertical orientation tabs such as tab 102 in fig. 1 do not adequately accommodate human anatomy, so as to improve the anatomic attachment area of tendon or bon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] As discussed above, this invention is directed to humeral prostheses providing more anatomical attachment configurations for bone and / or tendons, with the goal being a greater range of post-operative motion and / or strength. Before discussing the various embodiments of the invention in detail, it will be helpful to introduce aspects of the anatomy associated with procedures contemplated herein.

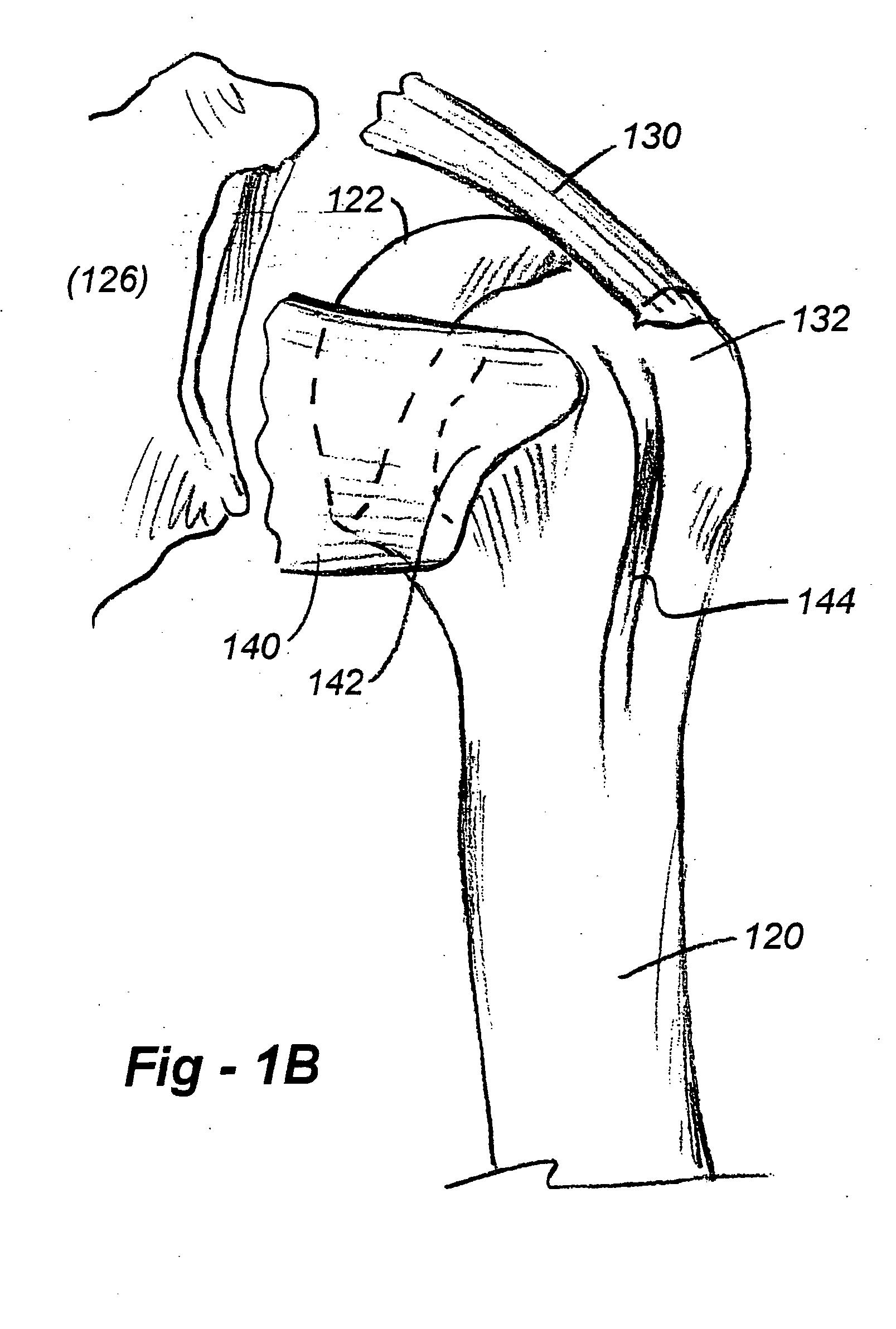

[0019]FIG. 1B is a drawing of a human proximal humerus showing the natural anatomic tendon attachment areas. The humerus, 120, includes a proximal portion having a head 122 with an articulating surface adapted to co-act with the glenoid bone 126 in the shoulder joint. The supraspinatus tendon 130 lies flat on the proximal humerus, and attaches at a section of bone called the greater tuberosity 132. The subscapularis tendon 140 extends across the side of the joint and attaches at the lesser tuberosity 142. A groove 144 receives the biceps tendon (not shown).

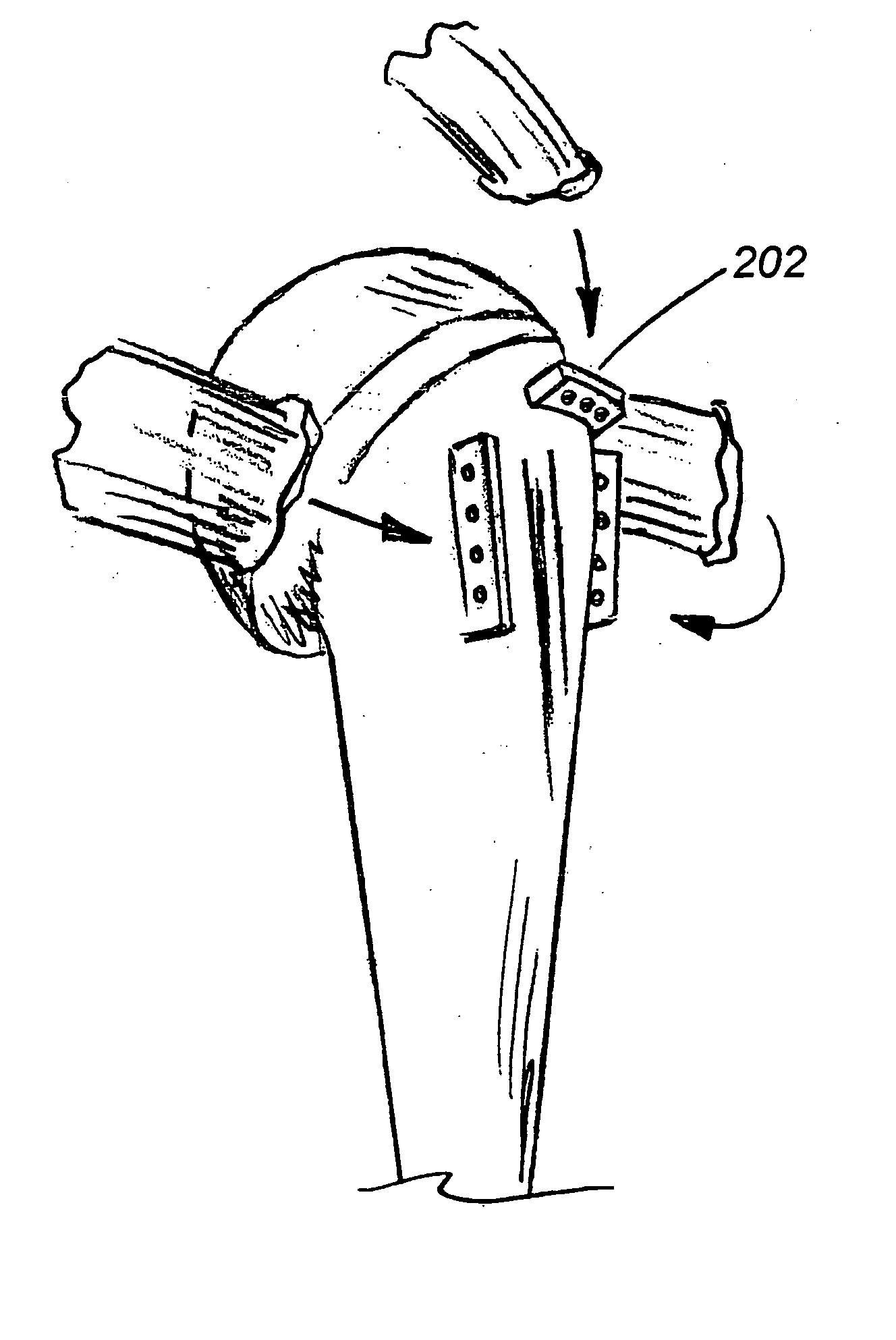

[0020]FIG. 1C is a drawing wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com