Thighbone outer side wall protection steel plate

A technology of lateral wall and steel plate, applied in the direction of external plate, internal bone synthesis, fixer, etc., can solve the problem of lack of effective support on the lateral wall, and achieve the effect of reducing the incidence rate and reoperation rate, and reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

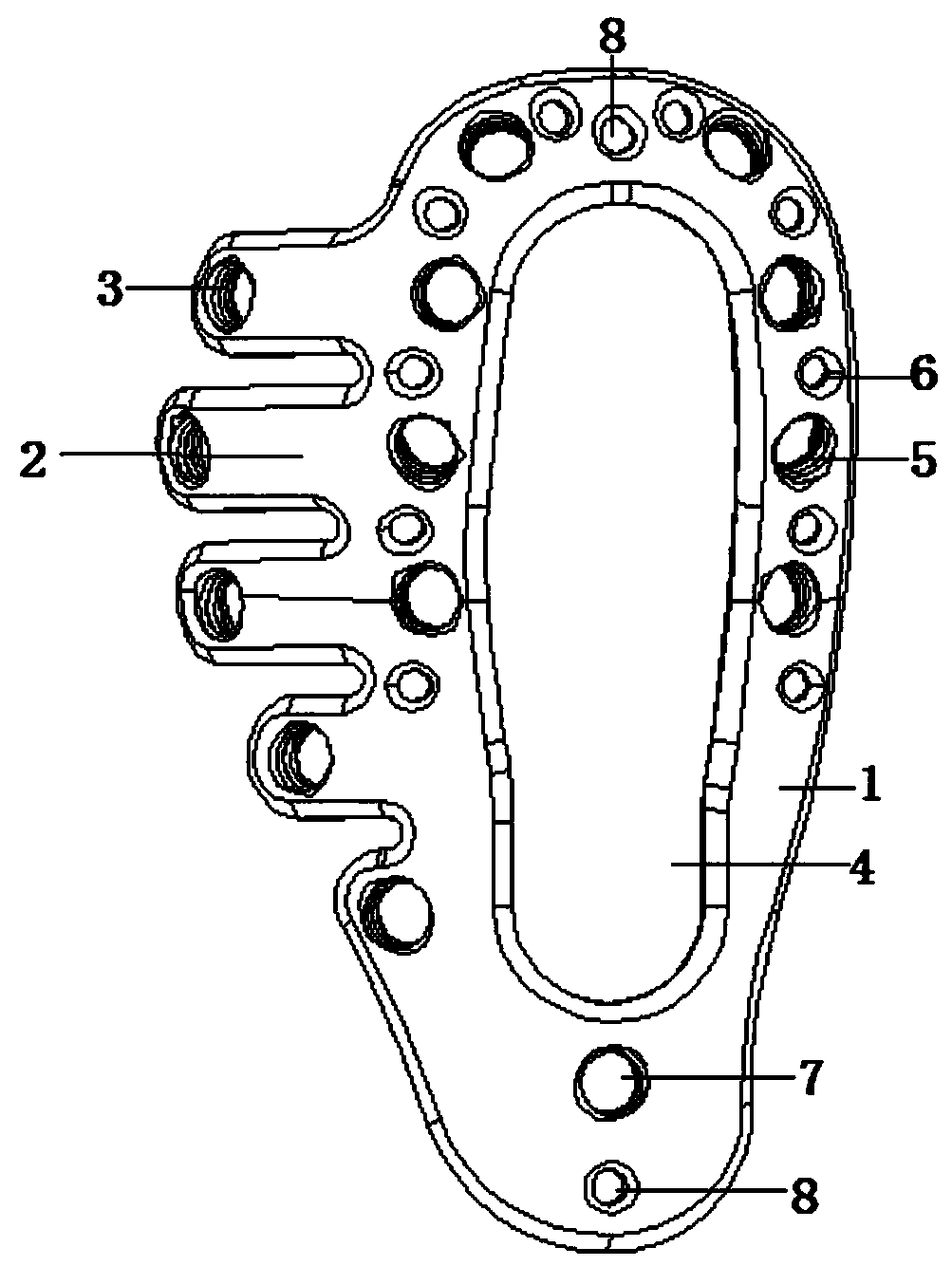

[0014] Such as figure 1 The shown protection steel plate for the lateral femur wall includes a protection steel plate for the lateral femur wall, including a main body 1 of the protection steel plate. The main body 1 of the protection steel plate is provided with a steel plate extension end 2 on the side close to the small nodules of the femur. One end of the extension end 2 of the steel plate is connected to the main body 1 of the protective steel plate, and the other end is bent to fit the small nodules of the femur and is provided with a small nodule fixing hole 3. The main body of the protective steel plate 1 is provided with a spiral blade passing hole 4 in the middle. 1 On both sides of the upper spiral blade passing hole 4, there are large nodules fixing holes 5 and suture holes 6, and a femoral shaft fixing hole 7 is opened at the lower part. The spiral blade of the protective steel plate body 1 passes through the upper and lower sides of the hole 4 Temporary fixing hole...

Embodiment 2

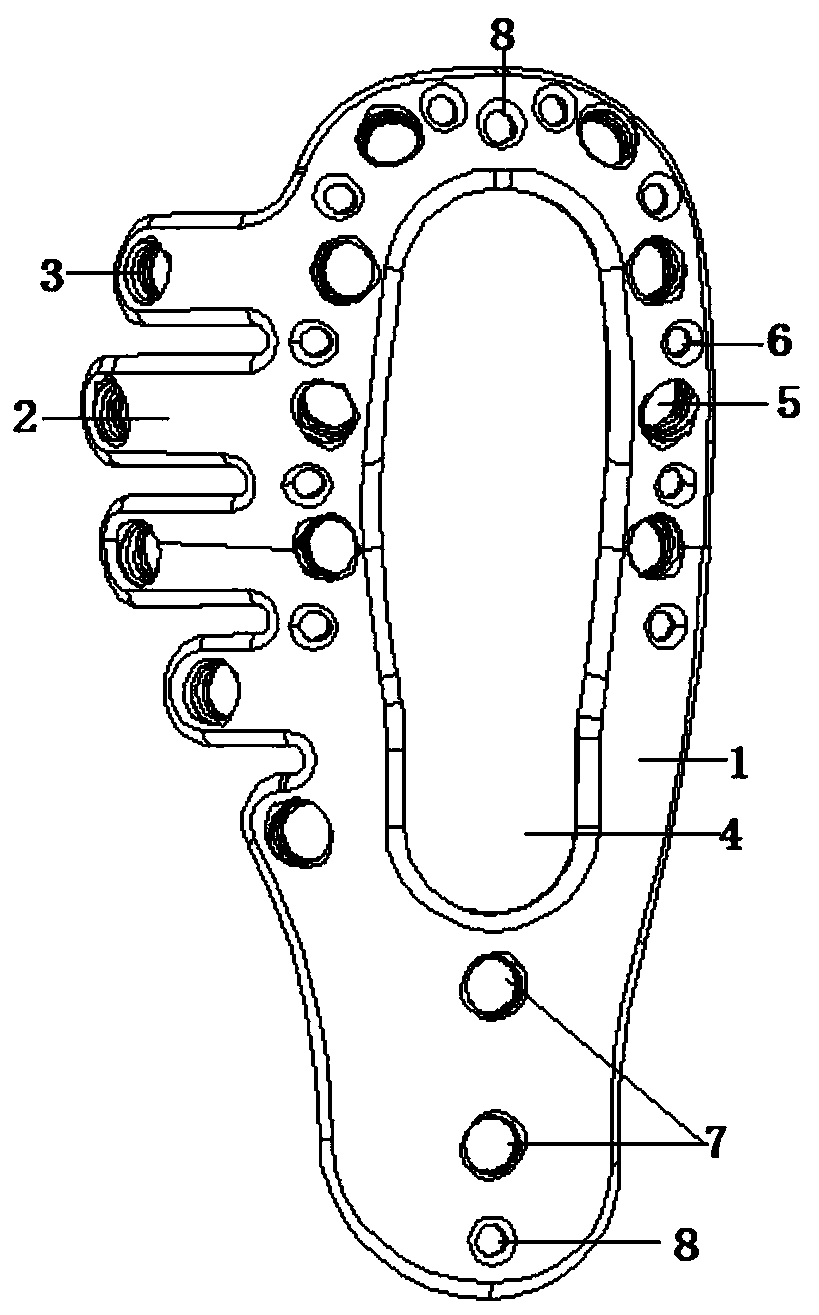

[0017] Such as figure 2 The shown protection steel plate for the lateral femur wall includes a protection steel plate for the lateral femur wall, including a main body 1 of the protection steel plate. The main body 1 of the protection steel plate is provided with a steel plate extension end 2 on the side close to the small nodules of the femur. One end of the extension end 2 of the steel plate is connected to the main body 1 of the protective steel plate, and the other end is bent to fit the small nodules of the femur and is provided with a small nodule fixing hole 3. The main body of the protective steel plate 1 is provided with a spiral blade passing hole 4 in the middle. 1 On both sides of the upper spiral blade passing hole 4 are opened large nodules fixing holes 5 and suture holes 6, and the lower part is opened with 2 femoral shaft fixing holes 7. The spiral blade of the protective steel plate body 1 passes through the upper and lower sides of the hole 4 Temporary fixing ...

Embodiment 3

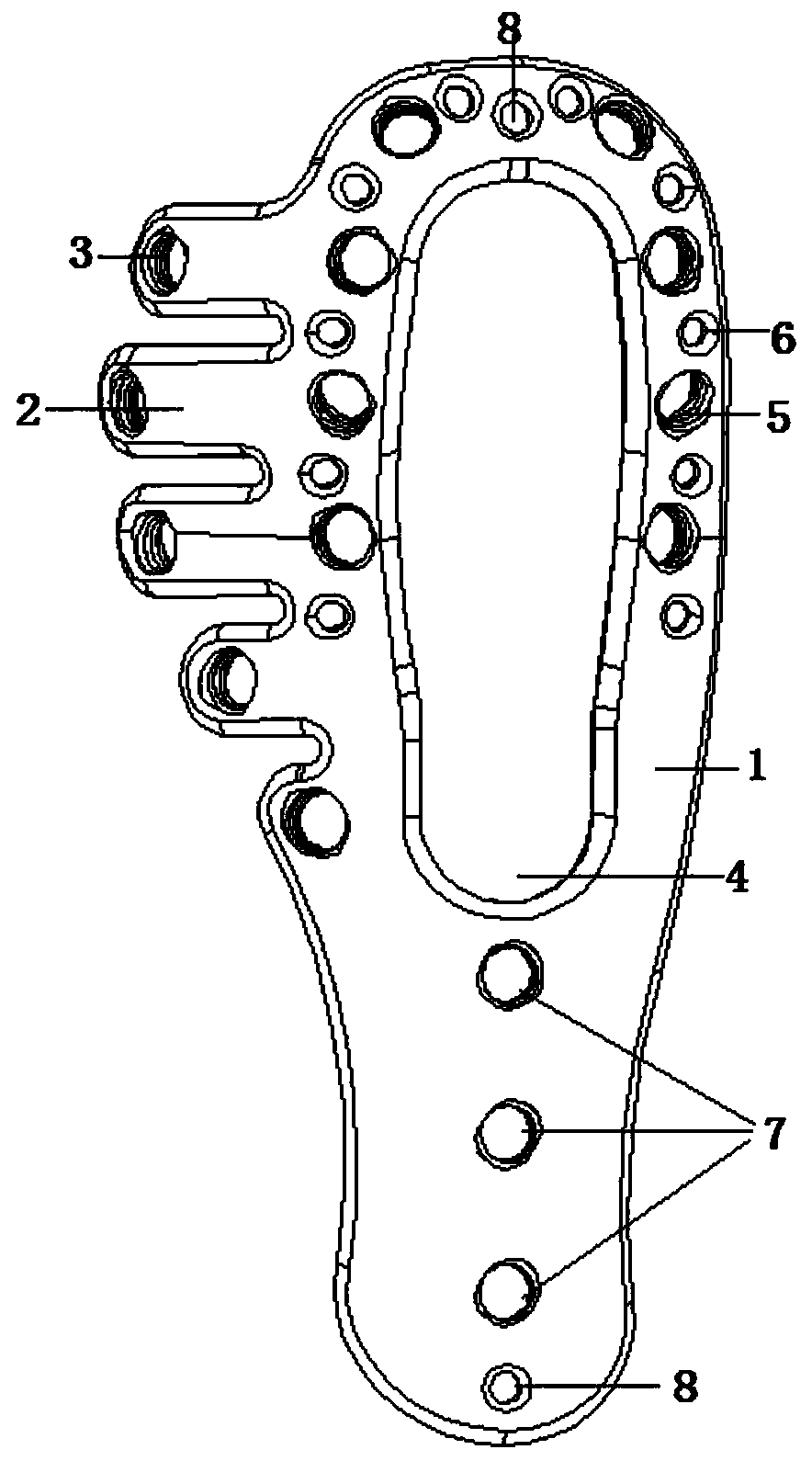

[0020] Such as image 3 with Figure 4 The shown protection steel plate for the lateral femur wall includes a protection steel plate for the lateral femur wall, including a main body 1 of the protection steel plate. The main body 1 of the protection steel plate is provided with a steel plate extension end 2 on the side close to the small nodules of the femur. One end of the extension end 2 of the steel plate is connected to the main body 1 of the protective steel plate, and the other end is bent to fit the small nodules of the femur and is provided with a small nodule fixing hole 3. The main body of the protective steel plate 1 is provided with a spiral blade passing hole 4 in the middle. 1 On both sides of the upper spiral blade passing hole 4 are provided large nodules fixing holes 5 and suture holes 6, and 3 femoral shaft fixing holes 7 are opened in the lower part. The spiral blade of the protective steel plate body 1 passes through the upper and lower sides of the holes 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com