Galley cart storage system and method of use

a technology for galley carts and storage systems, applied in the field of aircraft galley cart storage and retrieval systems, can solve the problems of reducing the available stowage space for cargo in the lower level, unsatisfactory expansion of the “footprint” of the galley, and undesirable increase of the number of galleys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

[0034] Galley cart storage systems as provided herein are described in reference to exemplary aircraft applications. Galley cart storage systems of the present invention are not intended to be limited to aircraft applications, but can be used in any mobile platform also including, but not limited to ships, trains, buses, etc.

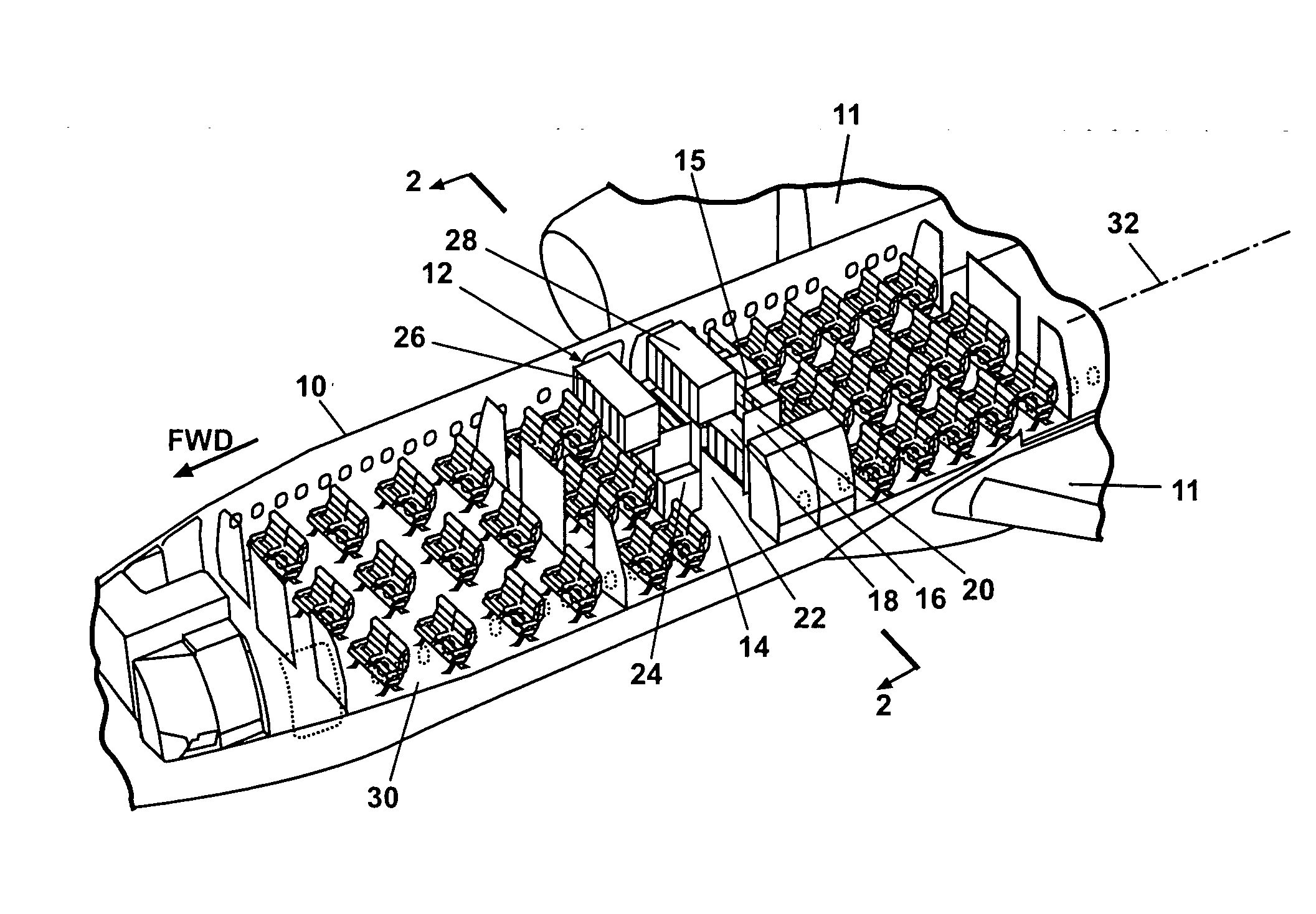

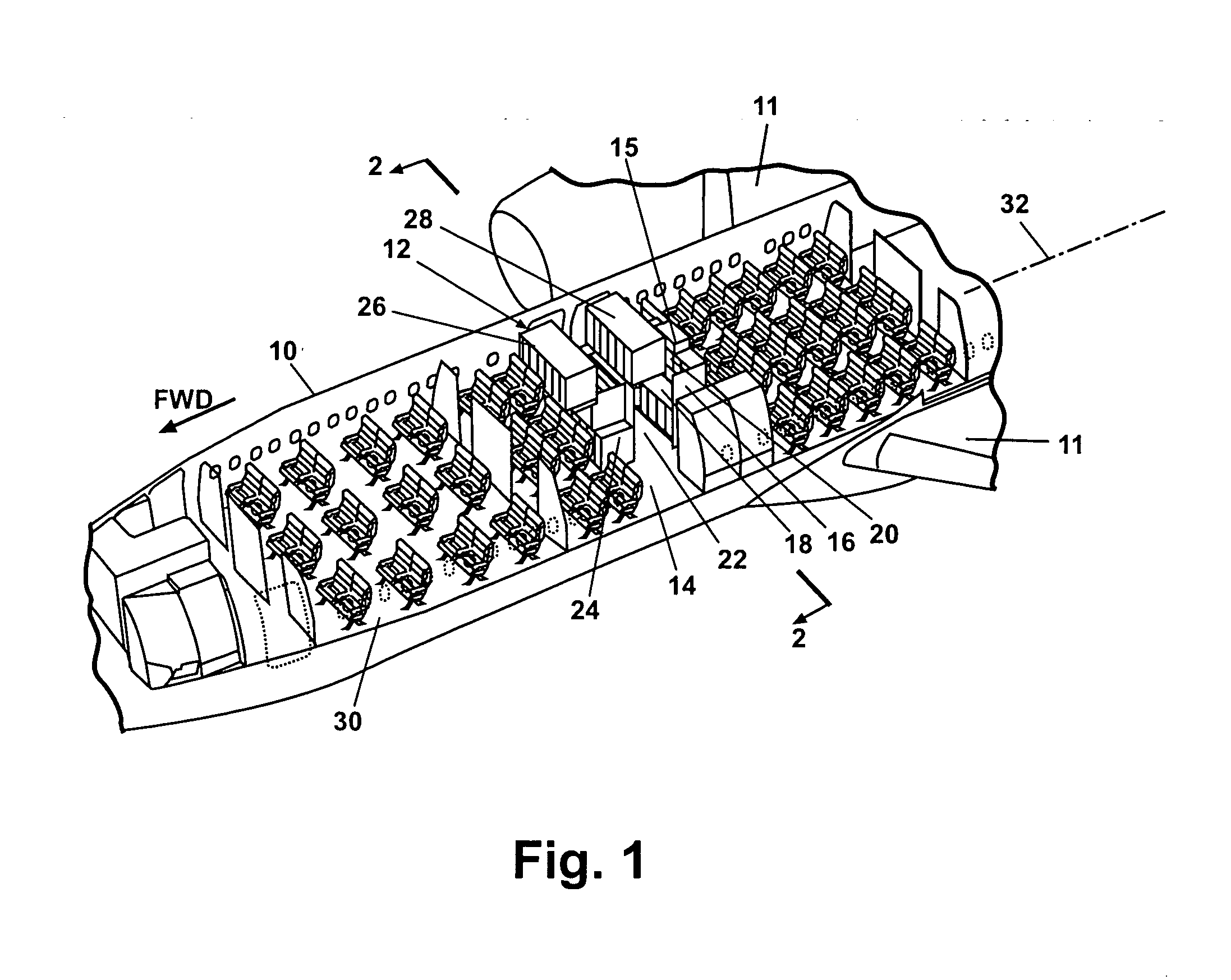

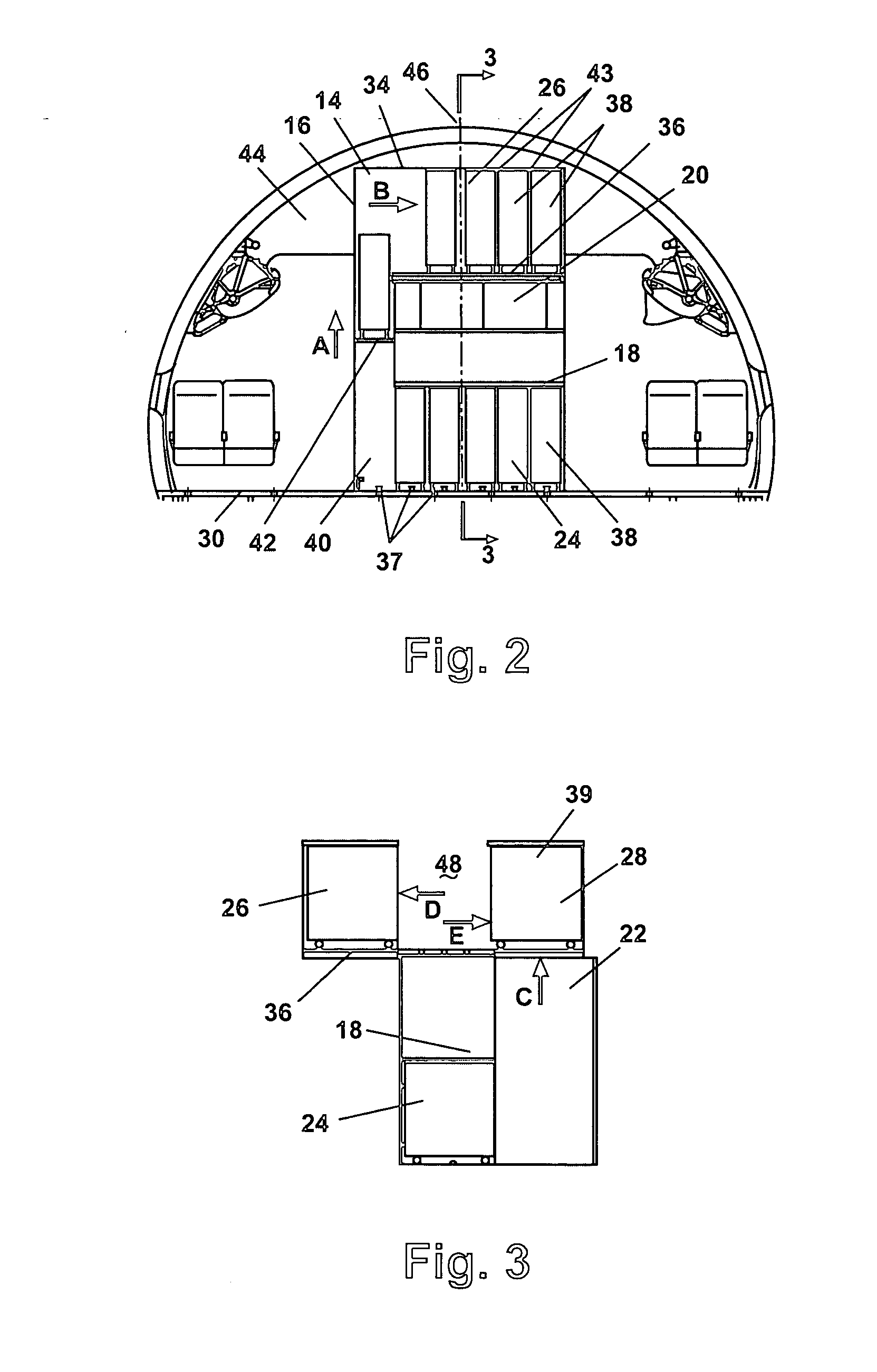

[0035] According to a preferred embodiment of the present invention, and referring to FIG. 1, an aircraft 10 includes wings 11 and a galley cart storage system 12 of the present invention, positioned within a passenger seating area of aircraft 10. Galley cart storage system 12 is shown positioned forward of wings 11, but is also preferably positioned aft of wings 11 when used in economy class seating areas of aircraft 10, normally positioned aft of wings 11. Galley cart storage system 12 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com