[0015] It is a further

advantage of the present invention that the product singulation achieved in the singulator area of the conveyor system provides virtually zero product

back pressure during either accumulation or straight through

discharge of the product items. Since singulation of product items is effected with very

low speed requirements of this area, the present conveyor system will

handle an array of different materials without the

impact noise or

impact damage generated by conventional accumulators. This also will eliminate the undesirable “gel wobble” effect that occurs when a

viscous liquid inside a product item container has a different spin characteristic than the container itself, resulting in product toppling particularly at opposing conveyor chain direction transfers. The present invention, therefore, permits glass containers, for example, to be conveyed and processed with much less

ringing noise during accumulation than in convention arrangements, and without consequential

impact damage to the containers.

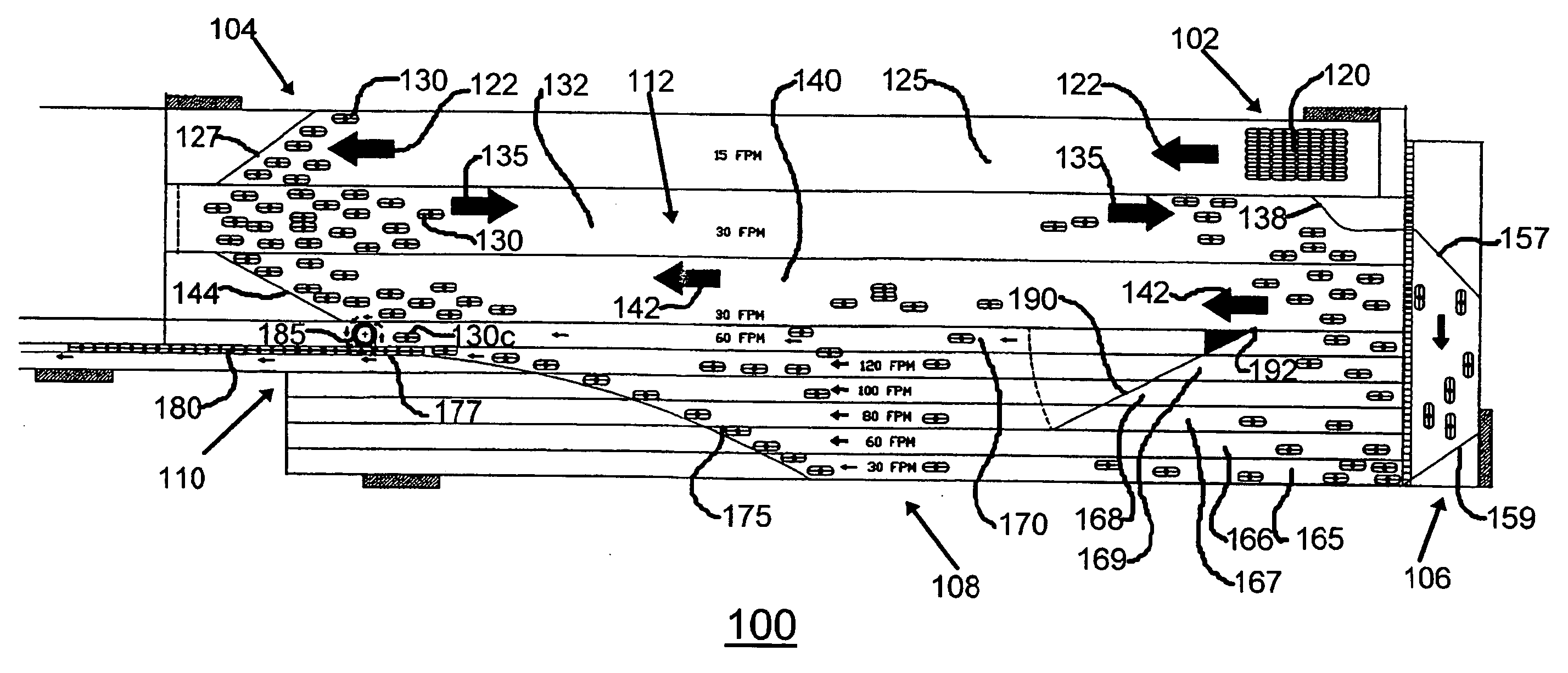

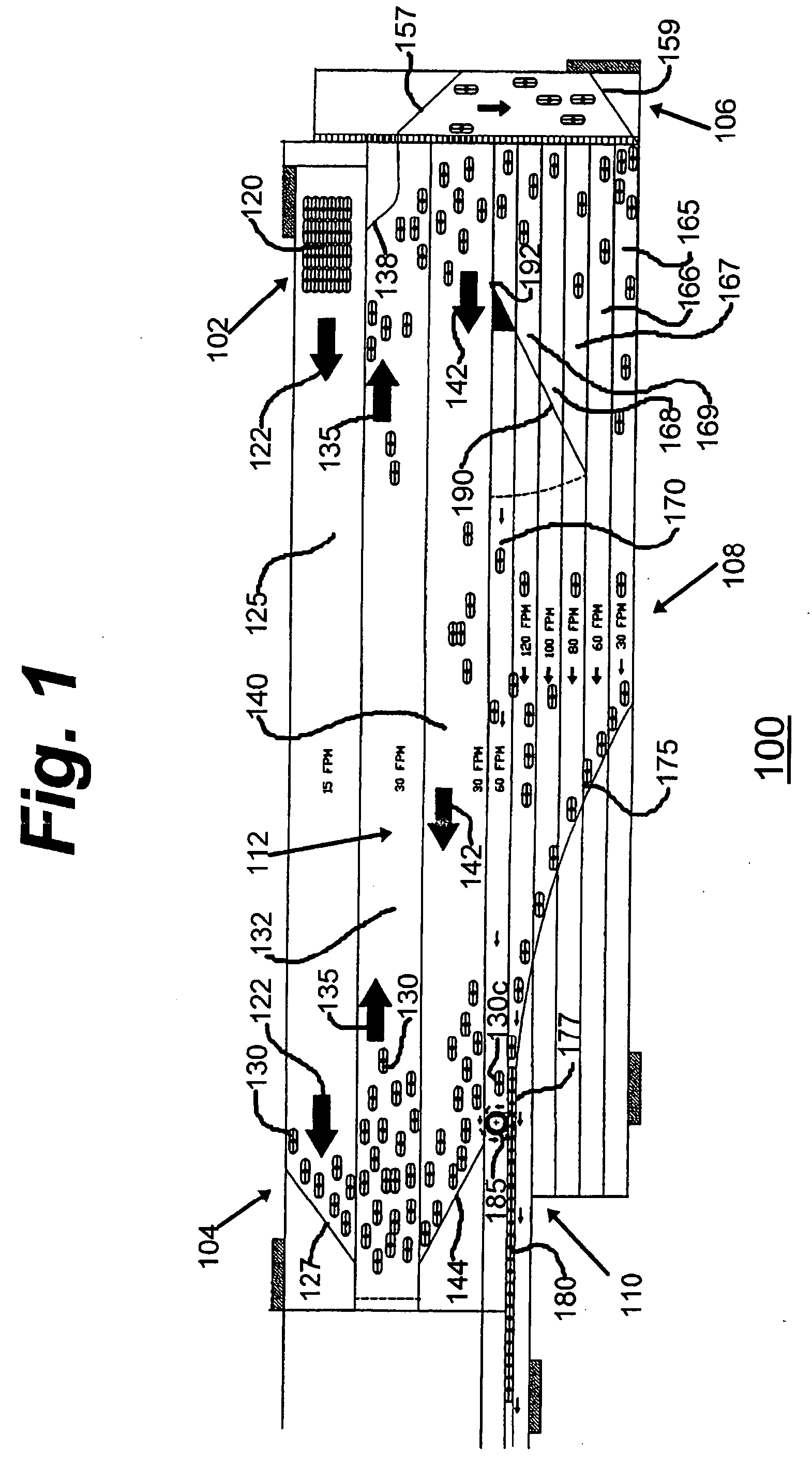

[0016] There is additionally provided in the conveyor system of the present invention a dynamic transfer section for accelerating product movement from the

slow speed accumulator section to the high speed singulation area where

discharge is effected. It is an

advantage of the present invention that the dynamic transfer section will not require dead plates, and movement of product through this transition will be stepless and without product bumping as in conventional transfer arrangements. Thus, product items can be conveyed in

mass, yet the product transfer is controlled.

[0017] As will be described in greater detail herein, the high speed singulation area is provided with multiple speed-up lanes that provide controlled single file and oriented product

discharge. A variable speed

control arm is provided to control production flow balance between low and high speed areas. More specifically, the product items are directed to the exit area by the variable speed

control arm, but as the quantity of products is increased, the

control arm allows the product items to be directed to the accumulation region. This ensures efficient

slow speed recirculation of the product items being conveyed with a nominal flow of product in the singulating area without diminishing the discharge rates. In a specific illustrative embodiment of the invention, a curved discharge rail enhances the discharge rates by physically pre-orienting product prior to single file release at discharge via the one or more exit ports of the conveyor system.

[0018] There is additionally provided in some embodiments of the conveyor system of the present invention a variable speed controlled impetus apparatus, illustratively in the form of a rotating orienter wheel disposed at the discharge region of the conveyor system. One benefit of the inventive orienter wheel is that it addresses and overcomes the bridge problems that occur when the product items being conveyed are not round. In operation, the impetus apparatus will automatically urge each product item toward the

slow speed accumulation area for circulation therein. In some embodiments, the impetus device serves the additional purpose of accelerating the product items into the discharge channel of the exit port to ensure a back-to-back properly oriented single file exit of the product items.

[0019] The foregoing notwithstanding, the primary function of this conveyor system is to achieve

low speed accumulation for product in excess of discharge production requirements and provide only enough product into high speed singulation discharge area to meet those requirements. As will be described herein, the present invention facilitates multiple in-feed product item entry points and single or multiple discharge ports.

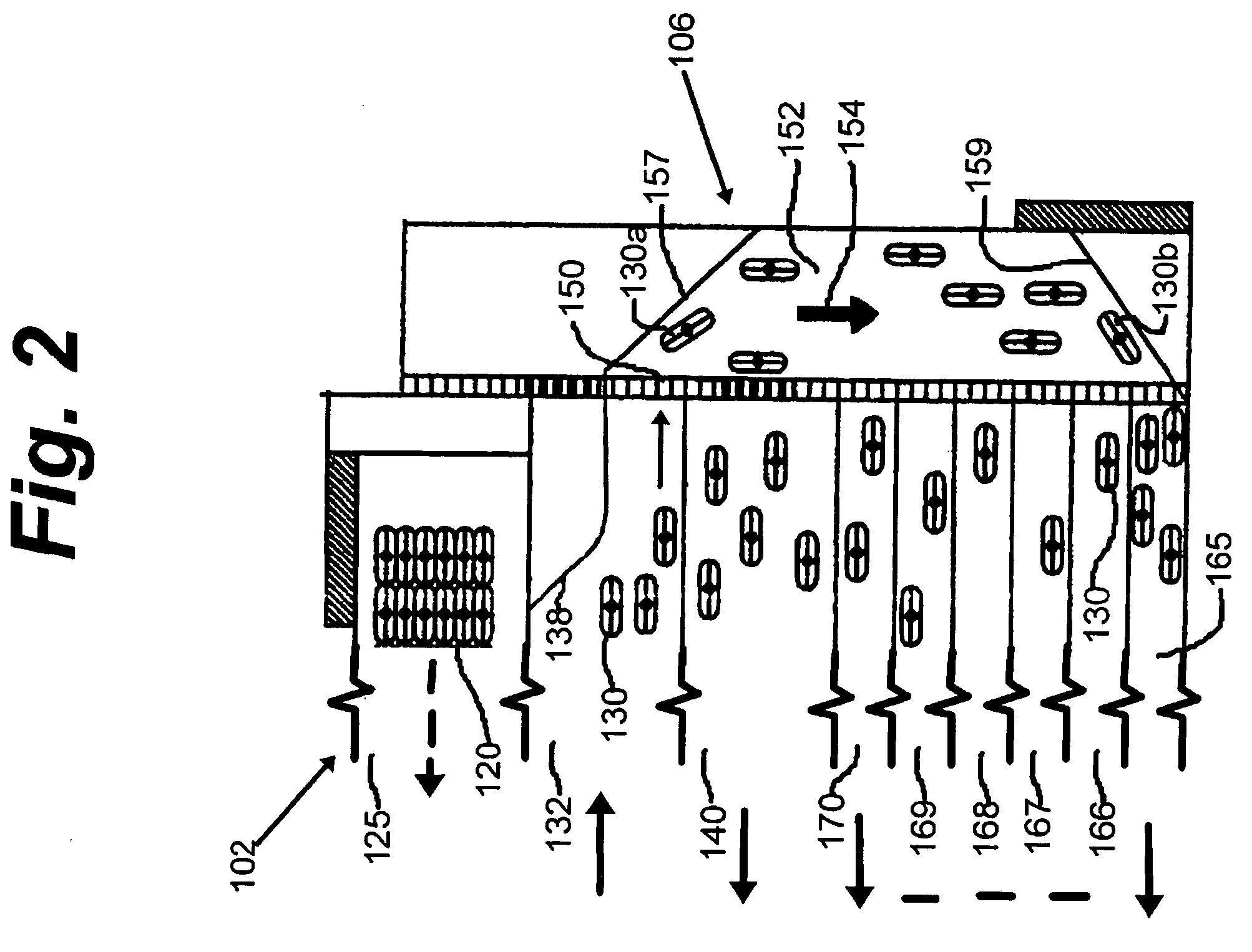

[0020] In accordance with a first system aspect of the invention, there is provided a conveyor system for transporting a multiplicity of product items from an input portion to an output portion. The conveyor system is provided with an input

station located at the input portion for receiving the multiplicity of product items. A first conveyor transports the product items from the input portion to a distal turnaround region. A second conveyor transports the product items from the distal turnaround region to a redistribution region. There is additionally provided a first product transfer arrangement for urging the product items from the first conveyor to the second conveyor. A plurality of exit conveyors are arranged to be parallel to each other for transporting the product items from the redistribution region to a product exit region located at the output portion. The plurality of exit conveyors are arranged to transport the product items at a respectively associated rates of transport. A product redistribution arrangement directs the product items to respective input ends of the plurality of exit conveyors. There is additionally provided a transverse element for directing the product items on the plurality of exit conveyors to a predetermined one of the plurality of exit conveyors.

Login to View More

Login to View More  Login to View More

Login to View More