Controlling system with fixed frequency driver for controlling an electrochromic element and method for the same

a control system and electrochromic element technology, applied in non-linear optics, instruments, optics, etc., can solve problems such as unreliability, complexity in design, and variable output duty cycle, and achieve cost savings for electrochromic elements, and reduce the complexity of the whole system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

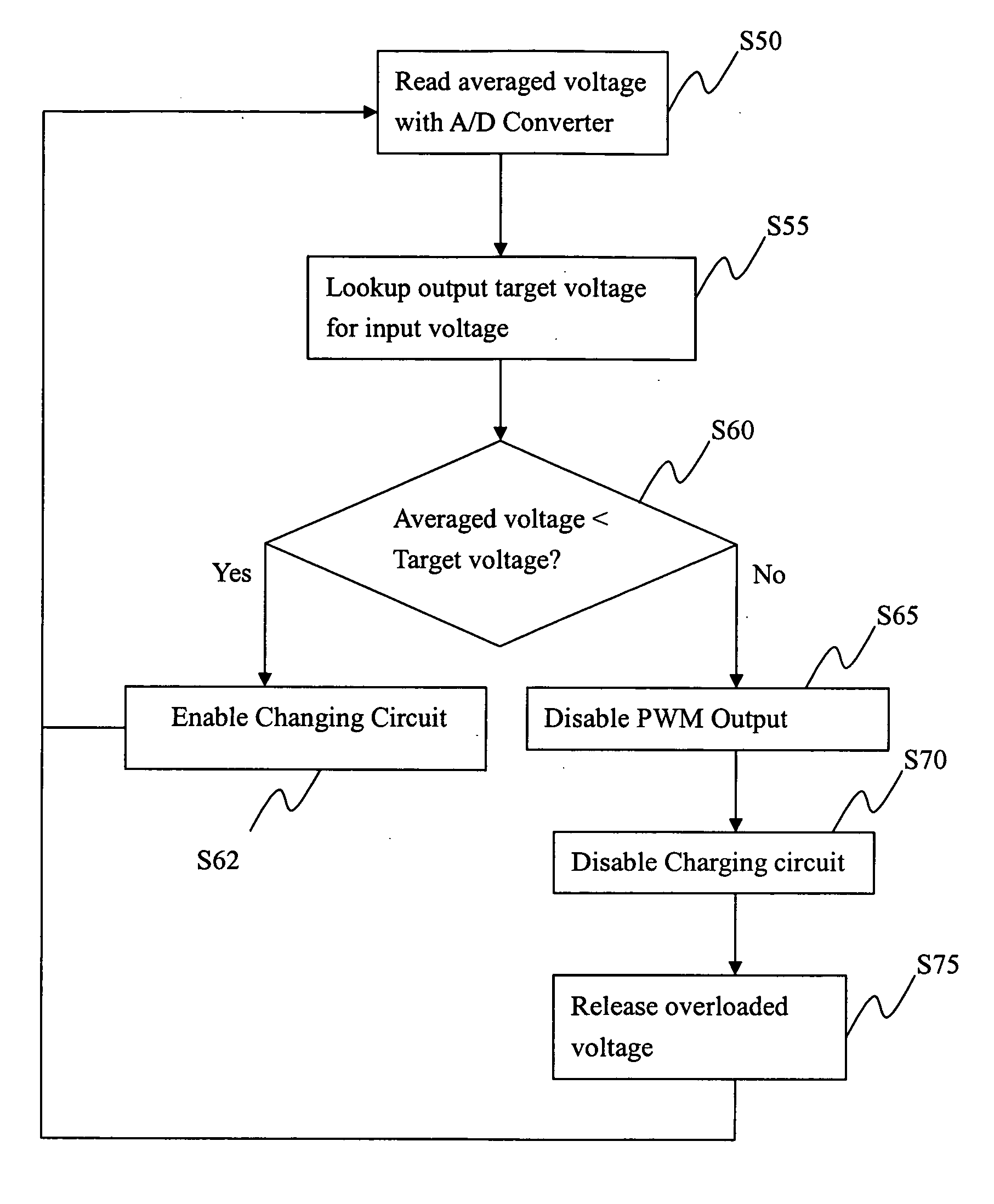

[0022] Differently from the prior art as mentioned above, the present invention relates to an controlling system for an electrochromic element driven by a pulse width modulated (PWM) signal which incorporates averaging of the modulated signal before the modulated signal is applied to the electrochromic element (hereinafter detailed).

[0023] Referring first to illustration in FIG. 3, the controlling system according to a preferred embodiment of the present invention, has a simplified architecture and therein includes a microcontroller 10, an amplifier 20, an analog-to-digital (A / D) converter 35, and a charging circuit 40.

[0024] Meanwhile, said microcontroller 10 is further provided with at least a programmable memory like ROM for pre-setting a look up table thereon, and a PWM unit for providing PWM function. The amplifier 20 is electrically coupled with a limited current circuit 25 for amplifying a PWM output signal with fixed frequency generated from PWM unit of the microcontroller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| output voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com