Thermoplastic printed film innersole for shoes

a printed film and thermal film technology, applied in the direction of uppers, insoles, bootlegs, etc., can solve the problems of conventional innersoles, cannot be printed, and cannot be used in the construction of post-mounted innersoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

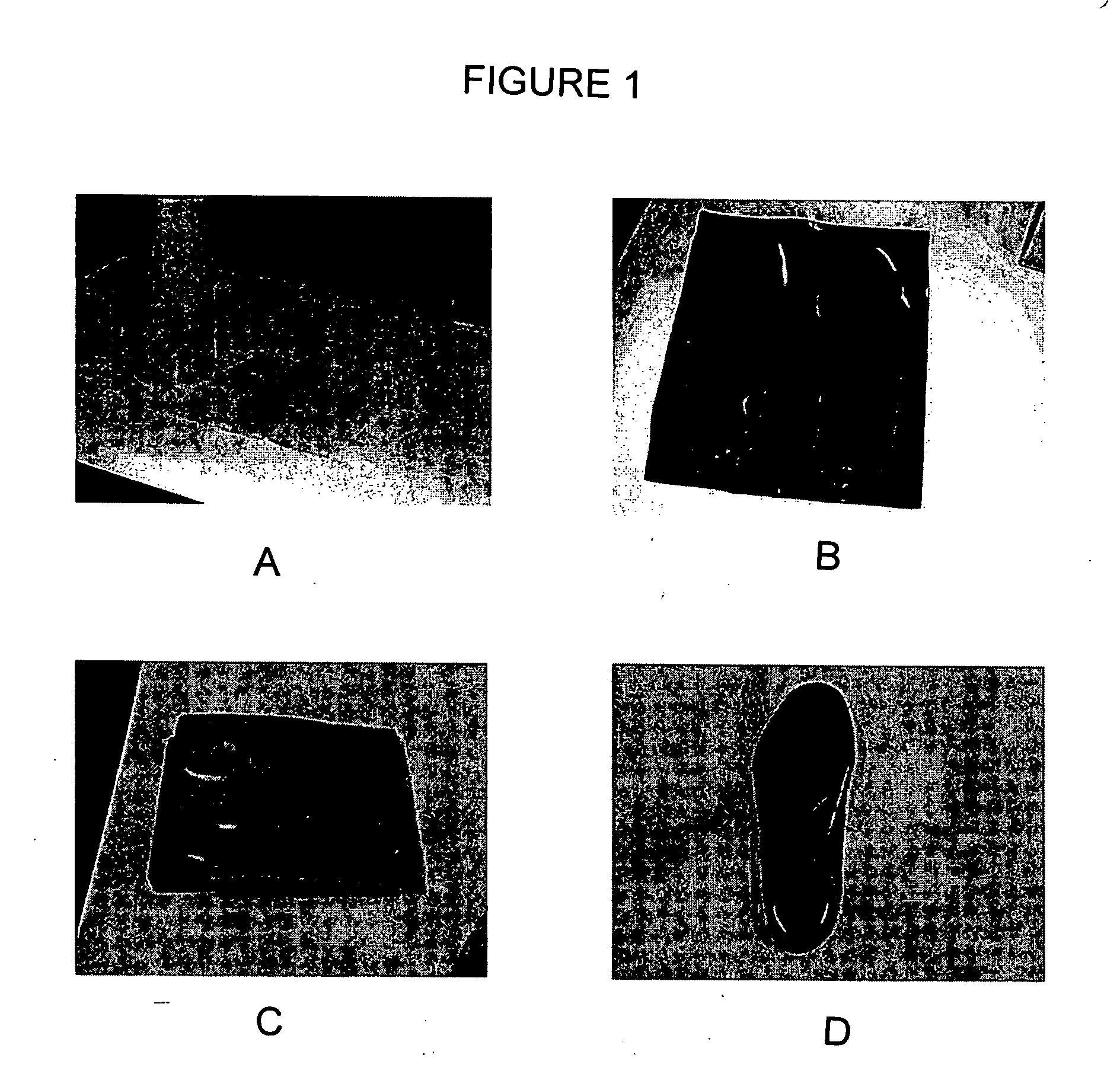

Image

Examples

Embodiment Construction

[0010] It is to be appreciated that certain aspects, modes, embodiments, variations and features of the invention are described below in various levels of detail in order to provide a substantial understanding of the present invention. The PFI for shoes according to the present invention substantially departs from the conventional concepts and designs of conventional innersole devices, by providing an apparatus primarily developed for the purpose of the construction of an innersole for post-insertion into a shoe that can have significant design details added to the bottom surfaces.

[0011] In one aspect, the present invention provides a PFI device for shoes that overcomes the shortcomings of the conventional innersole devices. In one embodiment, the PFI present invention comprises: a thermoformable film, a printed film, a formed shell and a cast cushioning foam materials. In one embodiment of the invention the thermoformable film is a thermoplastic film. In a preferred embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com