Heat exchange system for a cavitation chamber

a cavitation chamber and heat exchange technology, applied in the field of sonoluminescence, can solve the problems of limited control of the conditions applied to the liquid, many aspects of the phenomena have not yet been characterized, etc., and achieve the effect of promoting specific reactions in the cavitation chamber and lowering the temperature of the cavitation medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

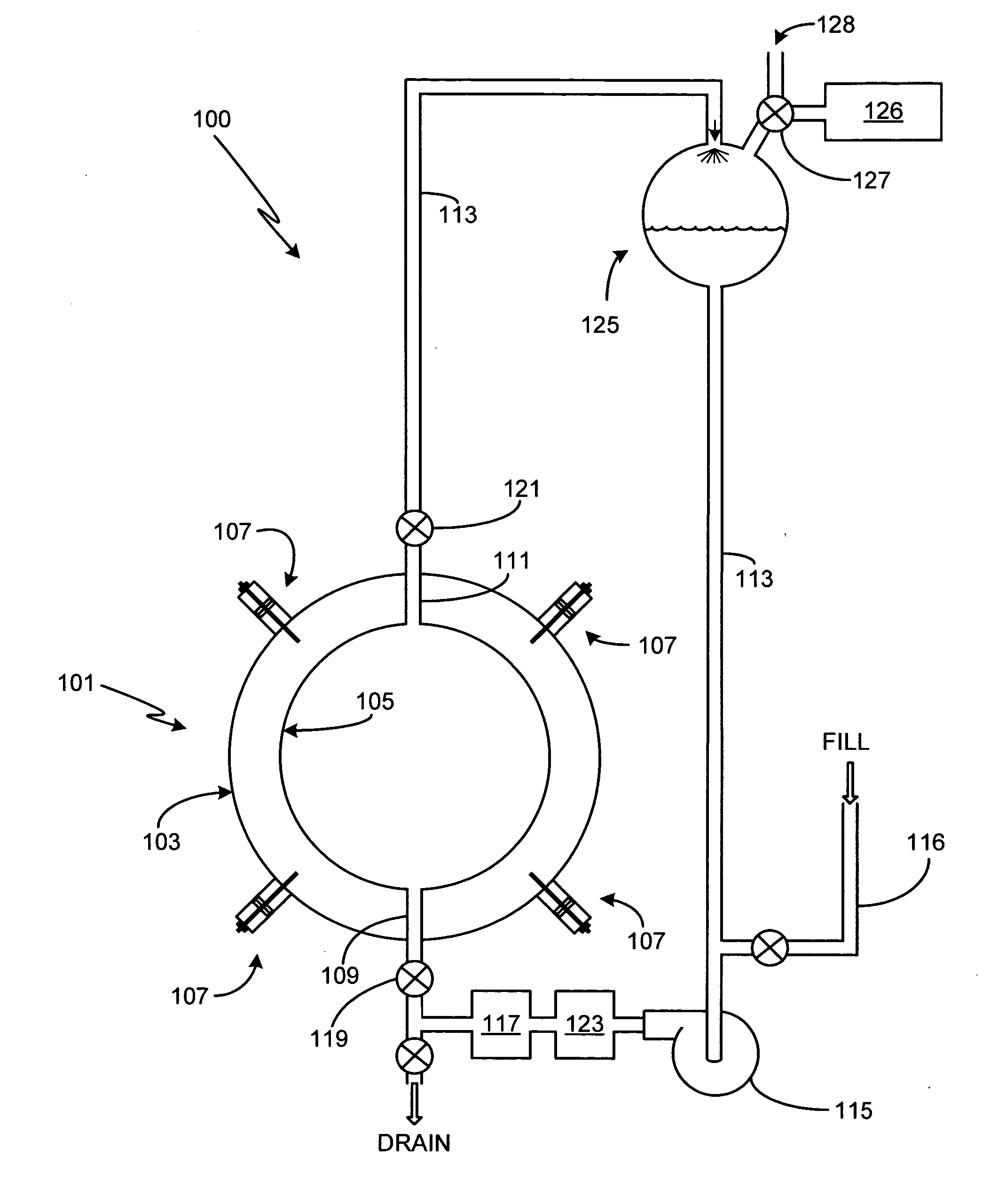

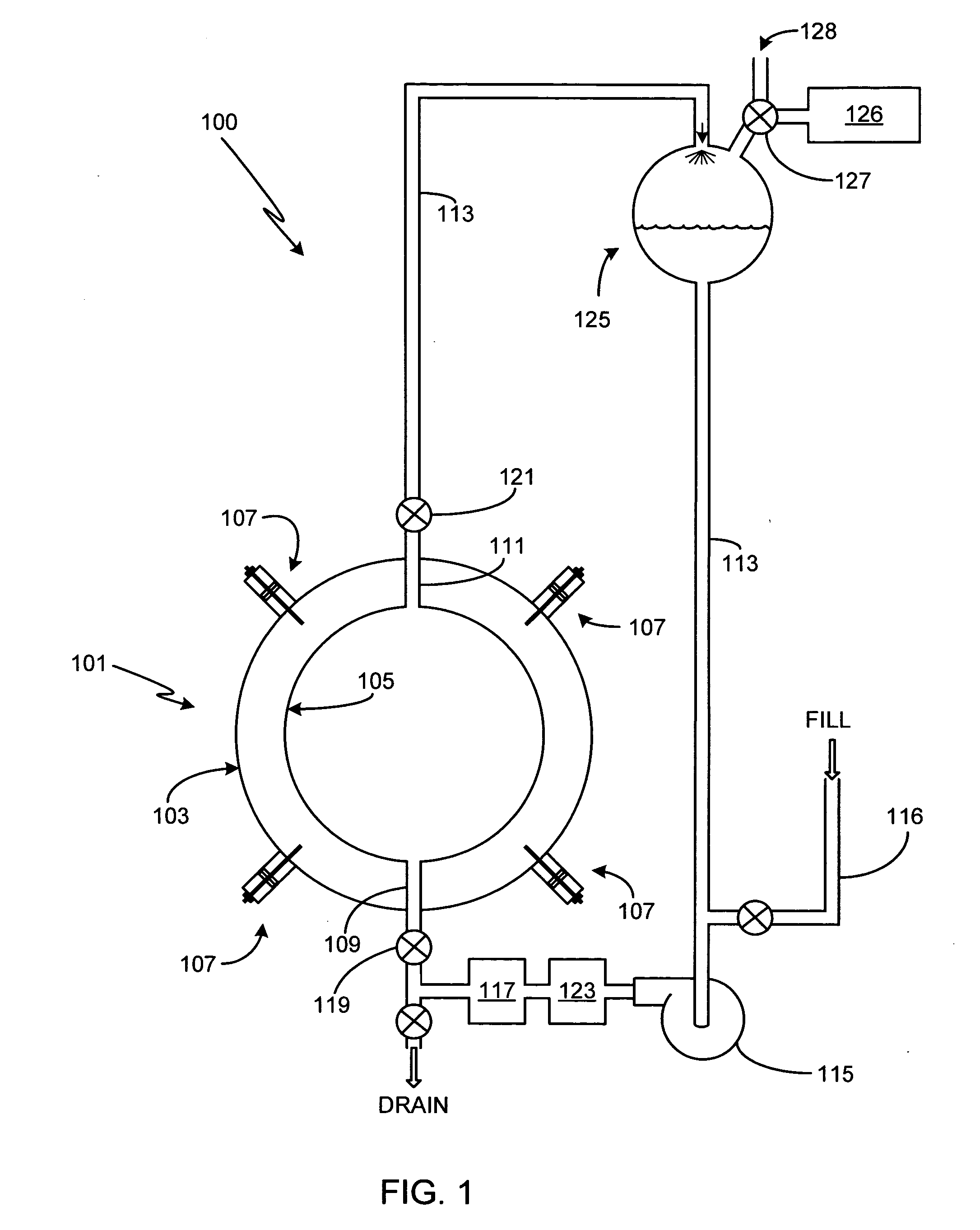

[0030]FIG. 1 is an illustration of the primary elements of a cavitation system 100 in accordance with the invention. The principal component is the sonoluminescence cavitation chamber 101, hereafter referred to as simply a cavitation chamber. Preferably cavitation chamber 101 is spherical, although it will be appreciated that the invention is not so limited and that cavitation chambers of other configurations (e.g., cylinder, conical, cubic, rectangular, irregular, etc.) can also be used with the present invention. One method of fabricating chamber 101 is described in detail in co-pending U.S. patent application Ser. No. 10 / 925,070, filed Aug. 23, 2004, entitled Method of Fabricating a Spherical Cavitation Chamber, the entire disclosure of which is incorporated herein for any and all purposes.

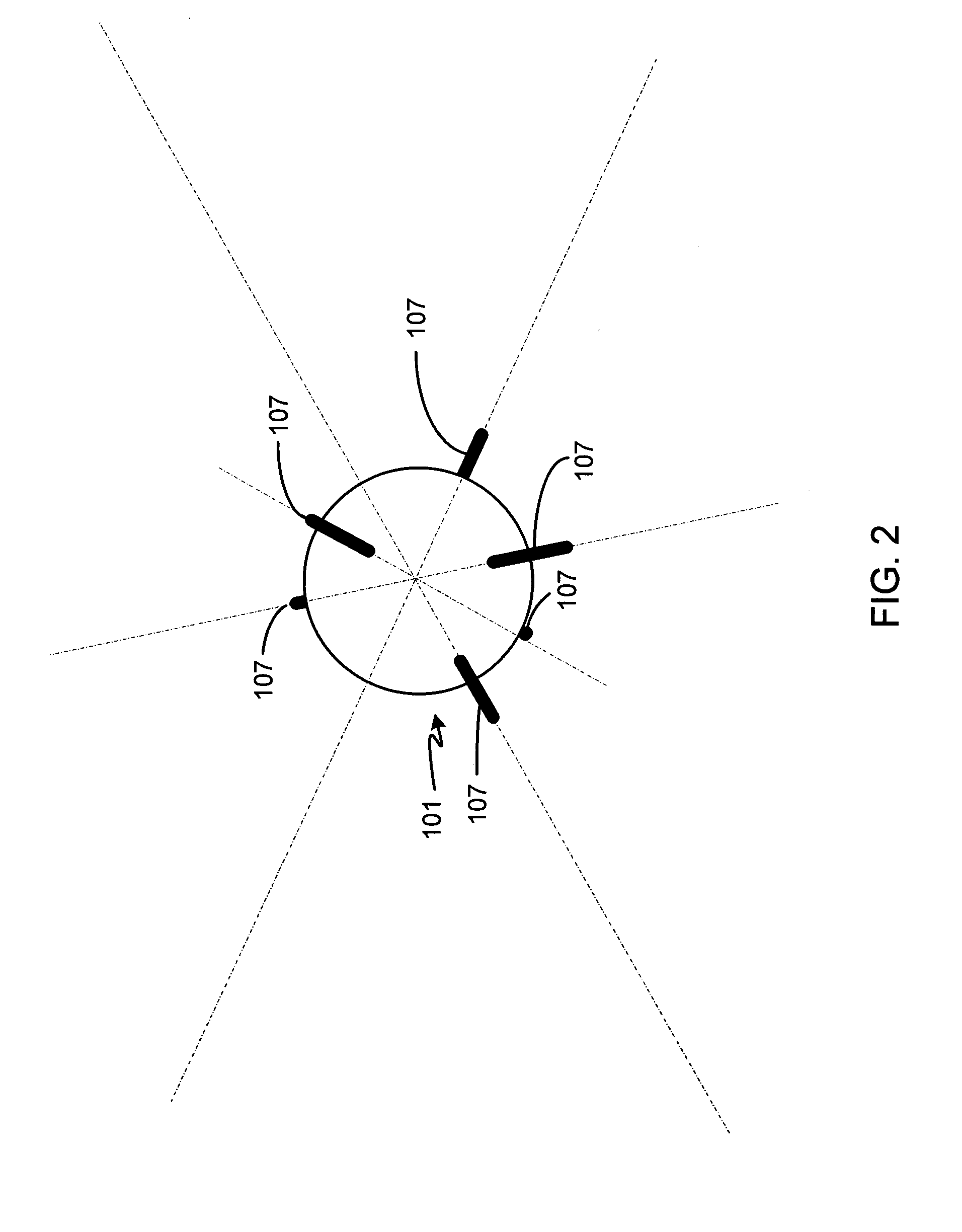

[0031] Illustrated chamber 101 has an outer spherical surface 103 defining the outer diameter of the chamber and an inner spherical surface 105 defining the inner diameter of the chamber. Cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com