Self-assembly storage system

a self-assembly and storage system technology, applied in the direction of folding cabinets, show hangers, show stands, etc., can solve the problems of increasing transport costs or inconvenience, requiring awkward attachment operations, and complicated construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

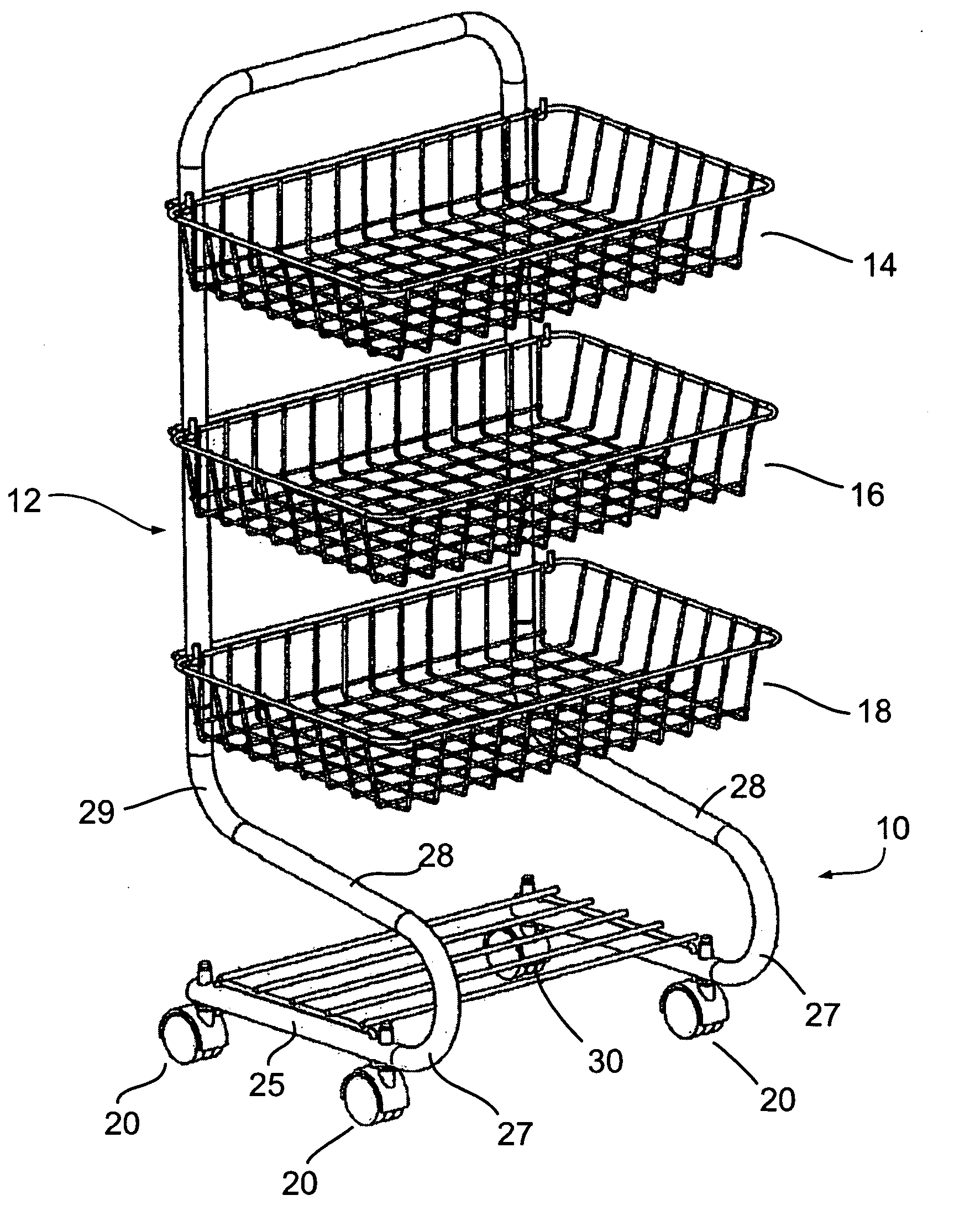

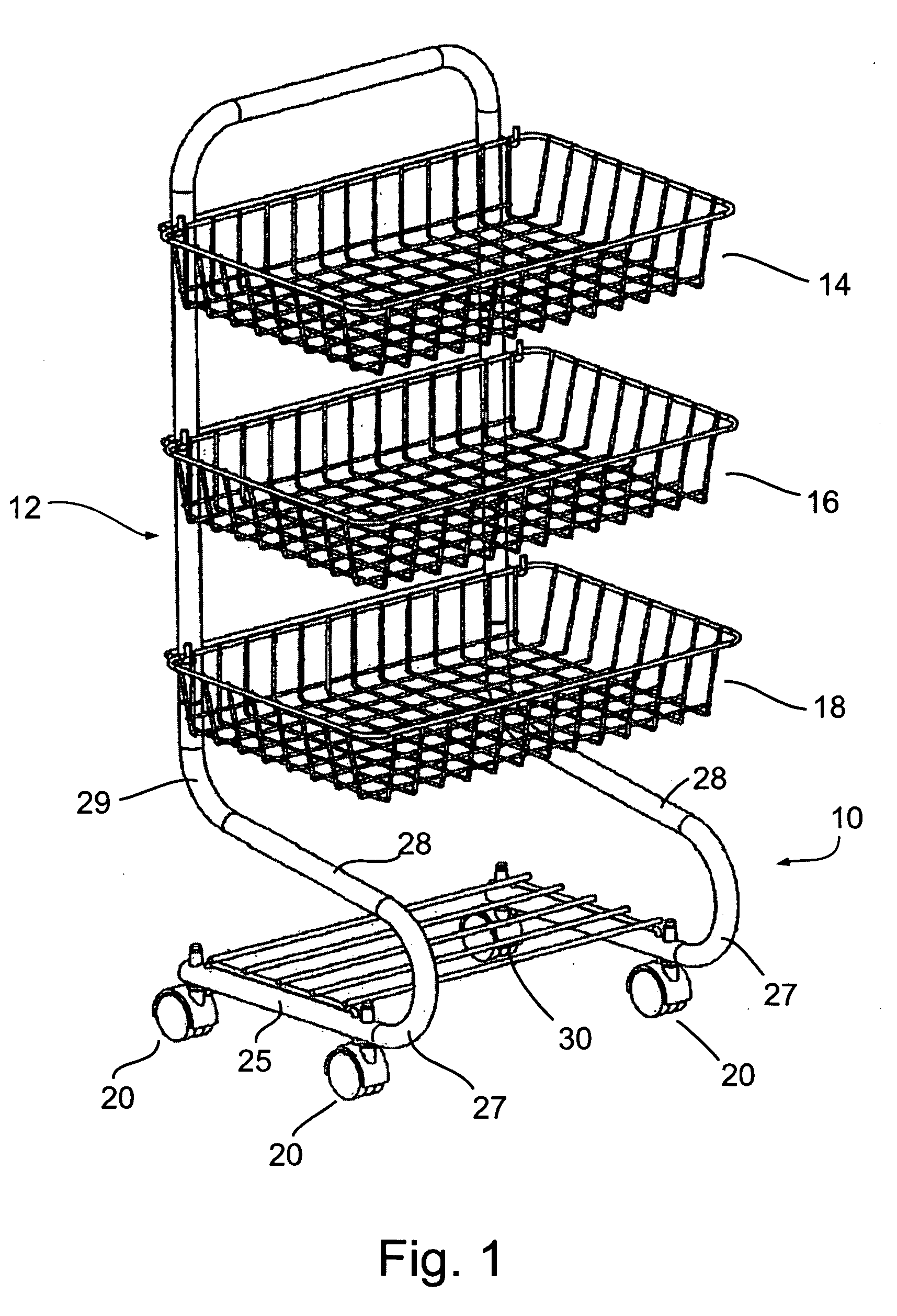

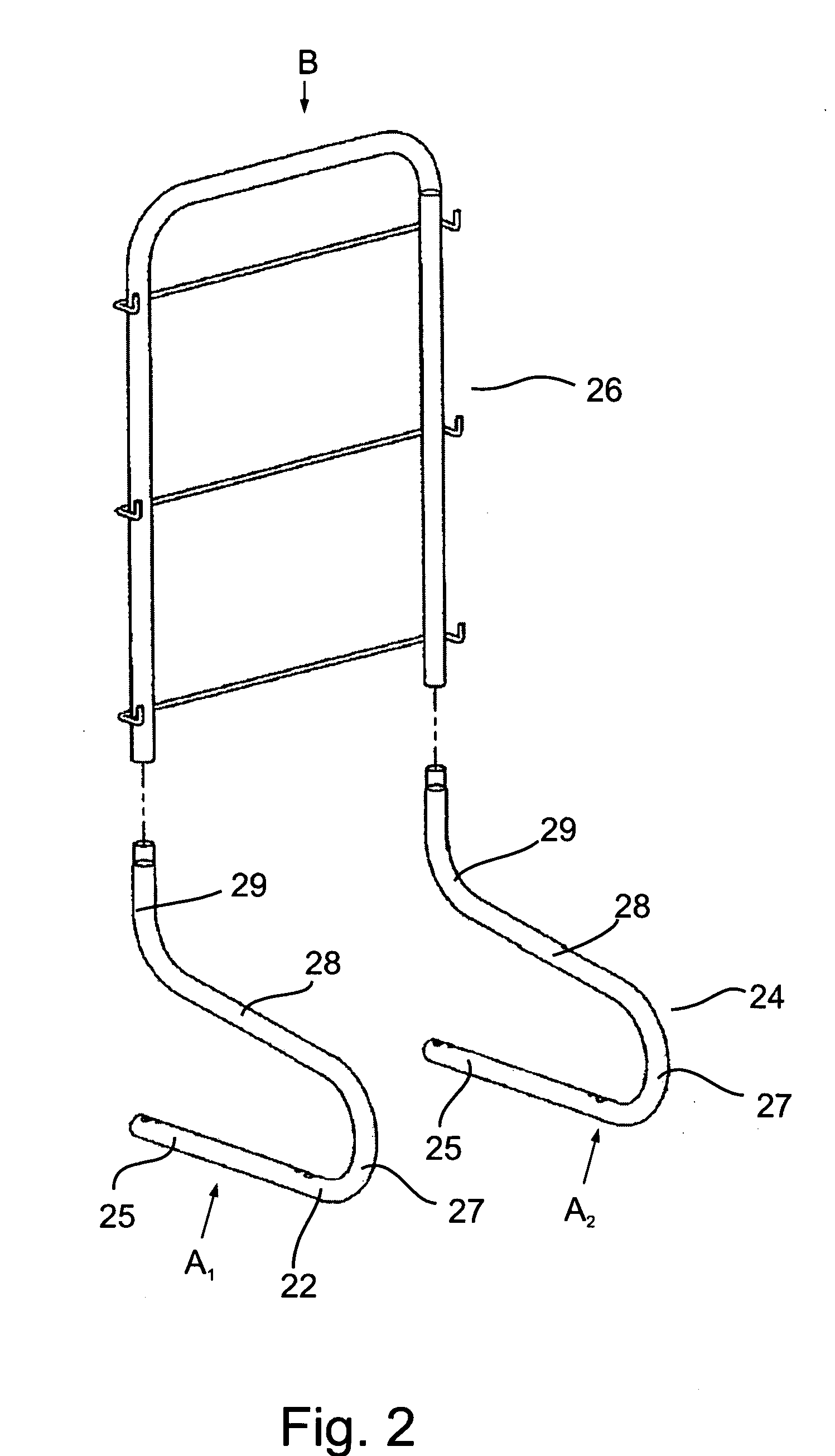

[0035] The present embodiments comprise a kit of parts for construction into a storage system. The parts are substantially flat for easy packaging and storage, and yet are designed so that when constructed they provide a storage system in three dimensions having a stable center of gravity. A preferred embodiment has wheels or castors attached to the base to provide a storage trolley system.

[0036] The principles and operation of a storage system according to the present invention may be better understood with reference to the drawings and accompanying description.

[0037] Before explaining at least one embodiment of the invention in detail, it is to be understood that the invention is not limited in its application to the details of construction and the arrangement of the components set forth in the following description or illustrated in the drawings. The invention is capable of other embodiments or of being practiced or carried out in various ways. Also, it is to be understood that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com