Deformable grip for a writing implement

a writing implement and grip technology, applied in the field of writing implements, can solve the problems of hand fatigue, excessive stress, limited use of such materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

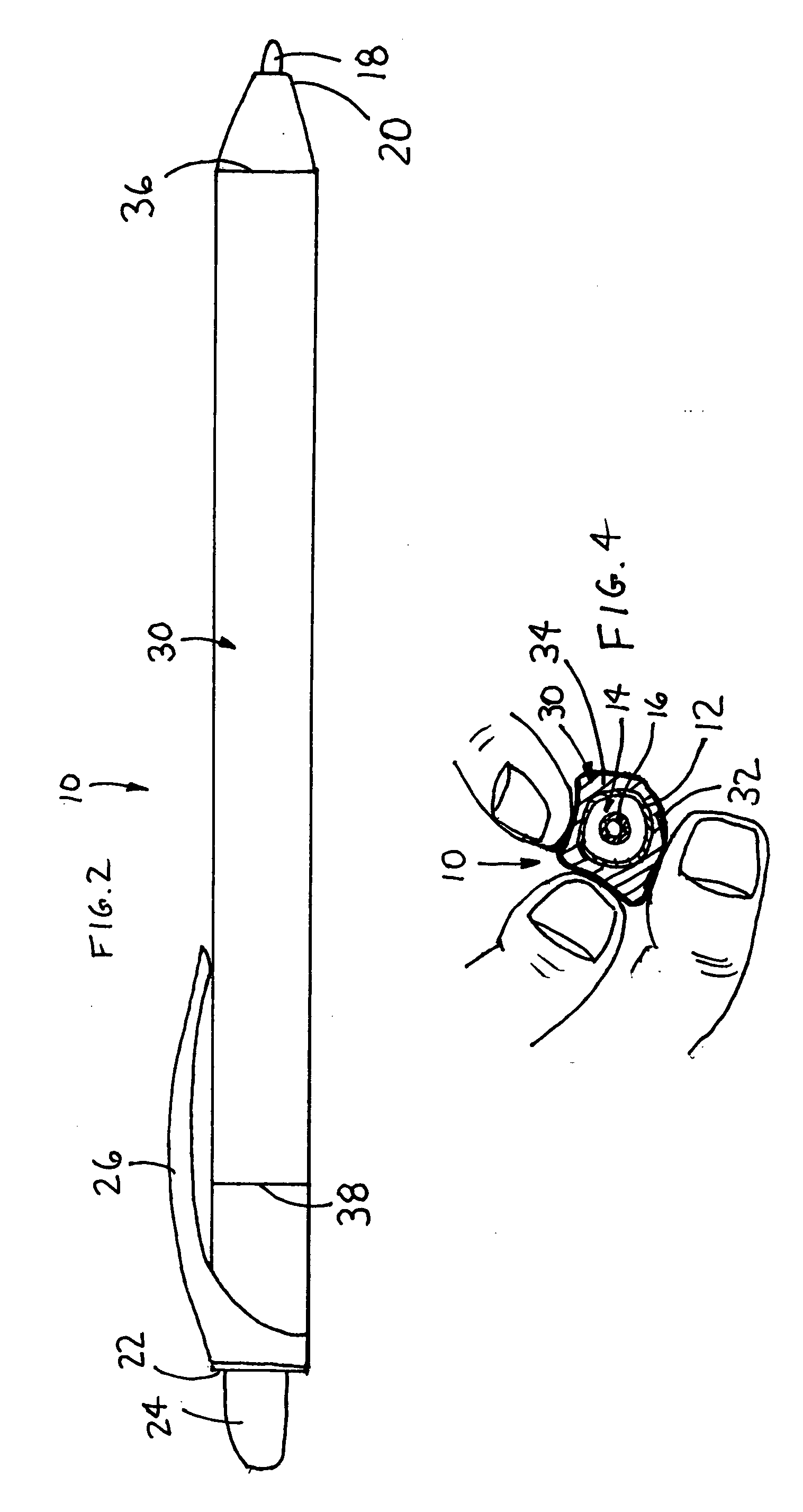

[0010] Deformable grips for writing implements in accordance with this disclosure generally comprise a grip layer adhered to a structural portion of the writing implement, such as a barrel. A coating layer is disposed over the grip layer to provide a more durable skin for the grip and to mask any tackiness exhibited by the material used for the grip layer. The deformable grip may be formed on the writing implement using relatively inexpensive automatic processes. For example, the grip layer may be formed by low pressure casting while the coating may be sprayed over the grip layer, thereby to form a composite grip. Still further, the deformable grip may be formed over a majority of the barrel surface, thereby to accommodate a greater variety of grip positions and to more comfortably fit a user's hand.

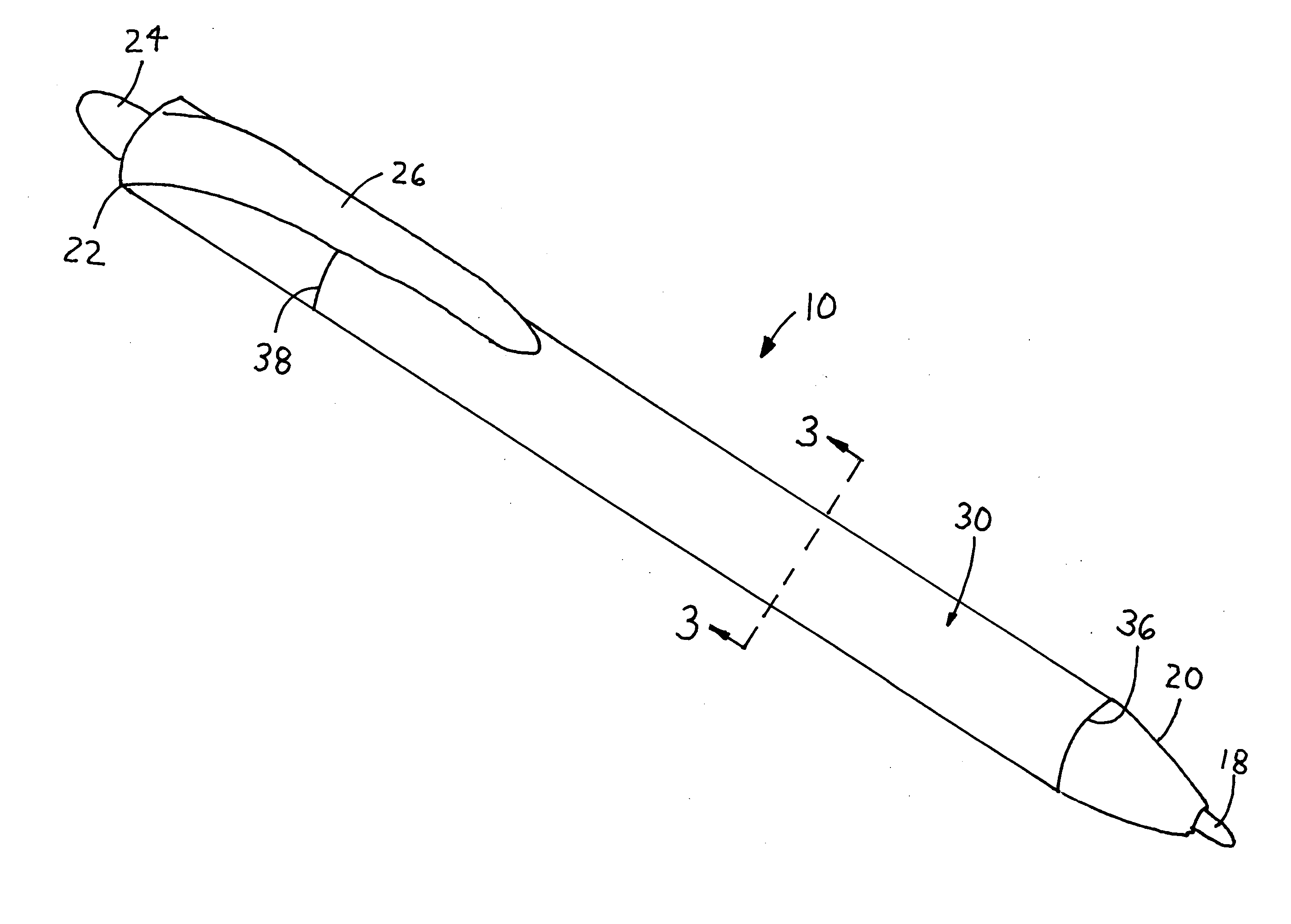

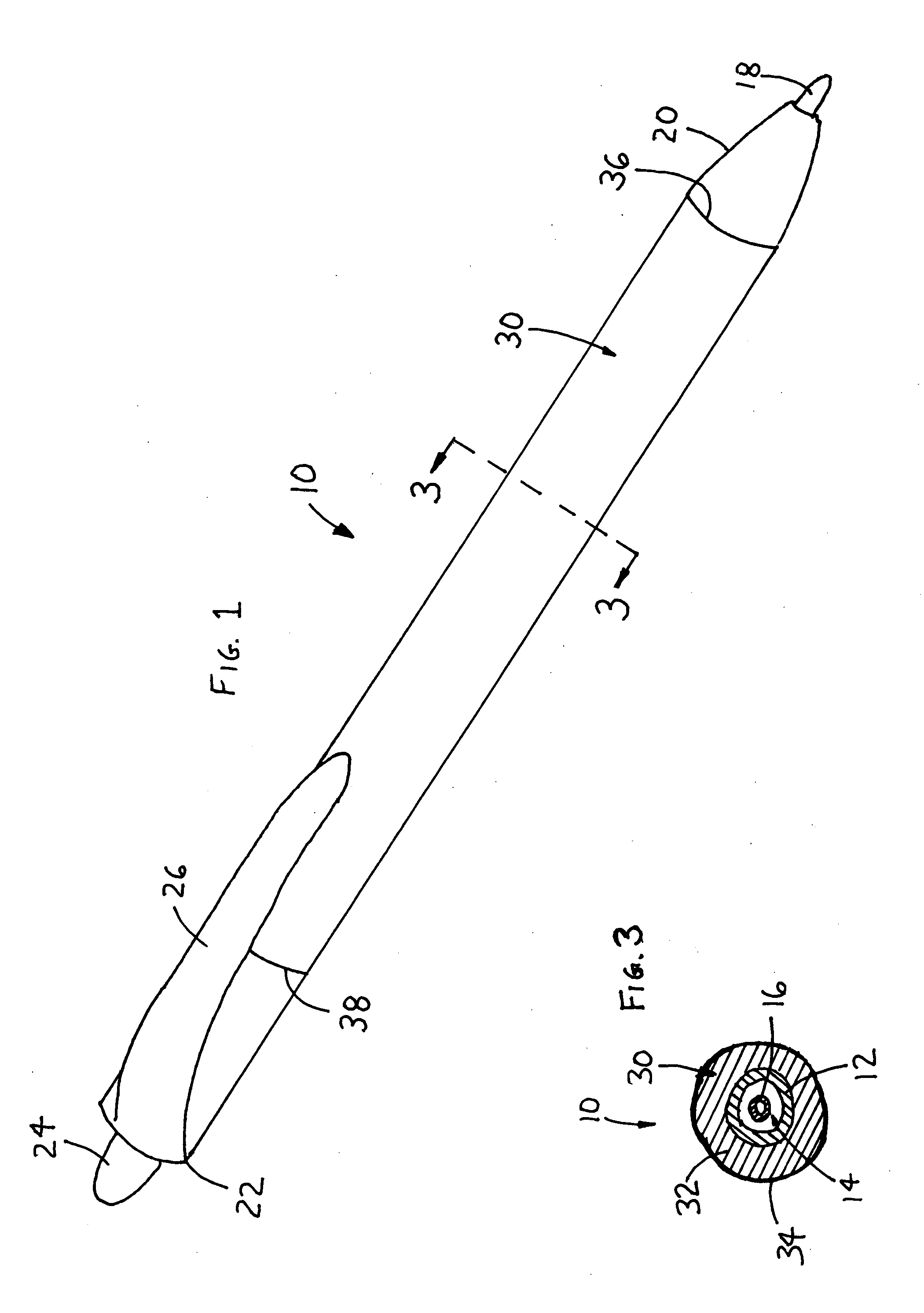

[0011] In the exemplary embodiment illustrated as FIGS. 1-4, a writing implement 10 includes an elongate, rigid barrel 12. The barrel 12 defines a chamber 14 for housing a marking mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com