Patents

Literature

59 results about "Shore durometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Shore durometer is a device for measuring the hardness of a material, typically of polymers, elastomers, and rubbers. Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

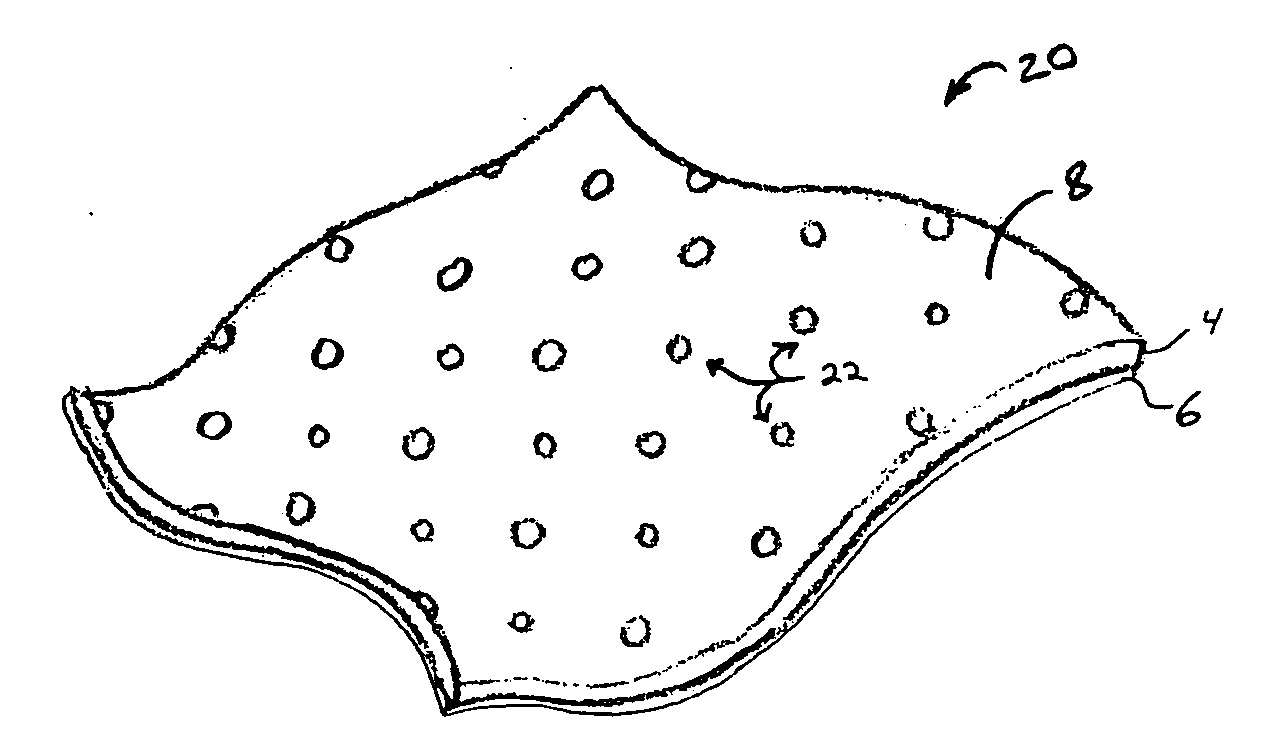

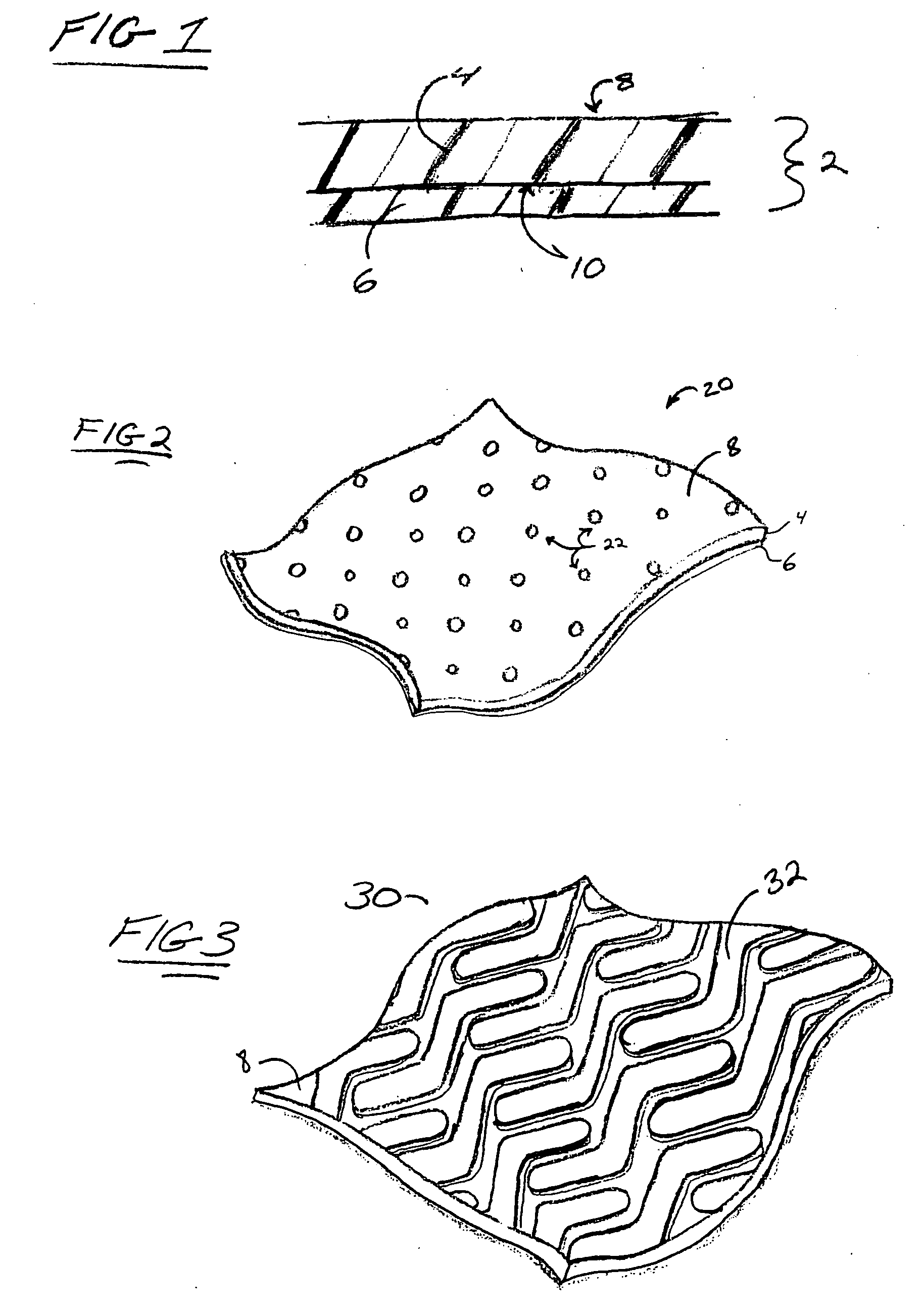

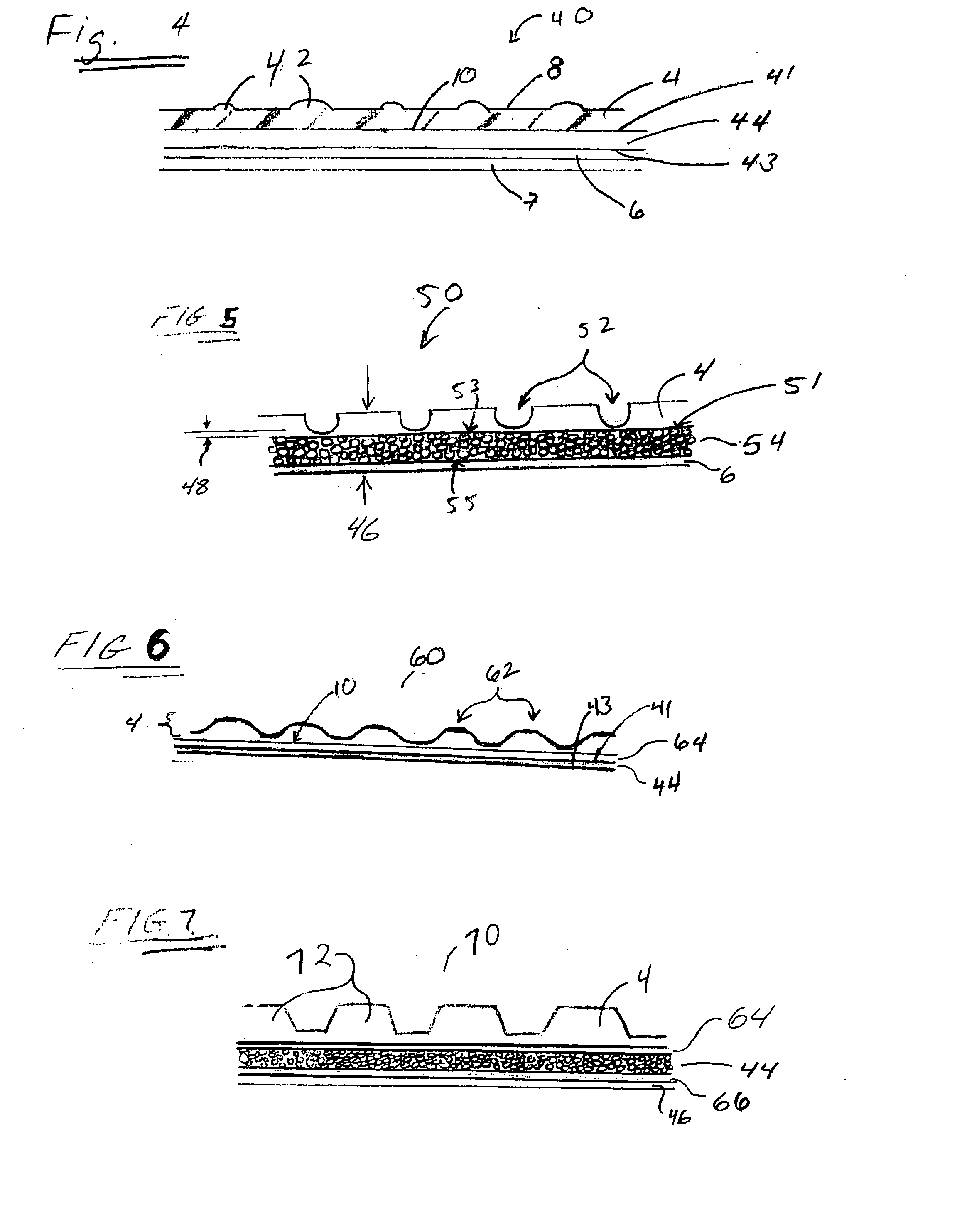

Silicone compositions, methods of manufacture, and articles formed therefrom

InactiveUS20070148409A1Balanced coefficient of frictionImprove gripSolesWater sport boardsHydrogenHydrogen atom

A silicone grip comprising a cured silicone film layer with a Shore A Durometer of less than or equal to about 60 wherein the silicone film layer is formed from a curable silicone composition comprising a catalyst that promotes cure of the silicone composition, a higher molecular weight organopolysiloxane having at least two alkenyl groups per molecule, a lower molecular weight organopolysiloxane having at least two alkenyl groups per molecule, and an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule. The cured silicone layer is used in combination with an adhesive to provide a flexible and malleable grip, and / or in combination with a backing layer that can be solid or foamed.

Owner:WORLD PROPERTIES

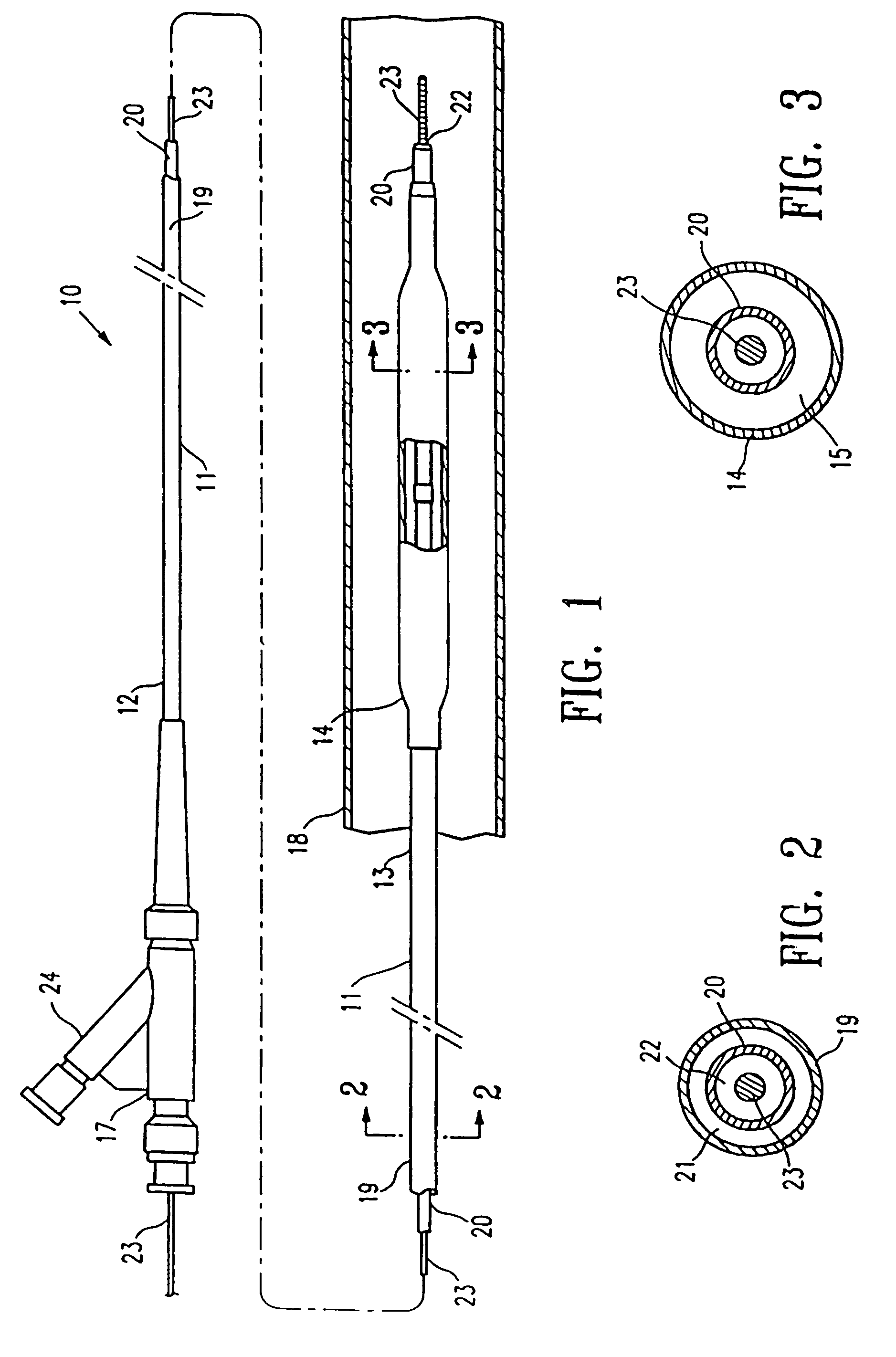

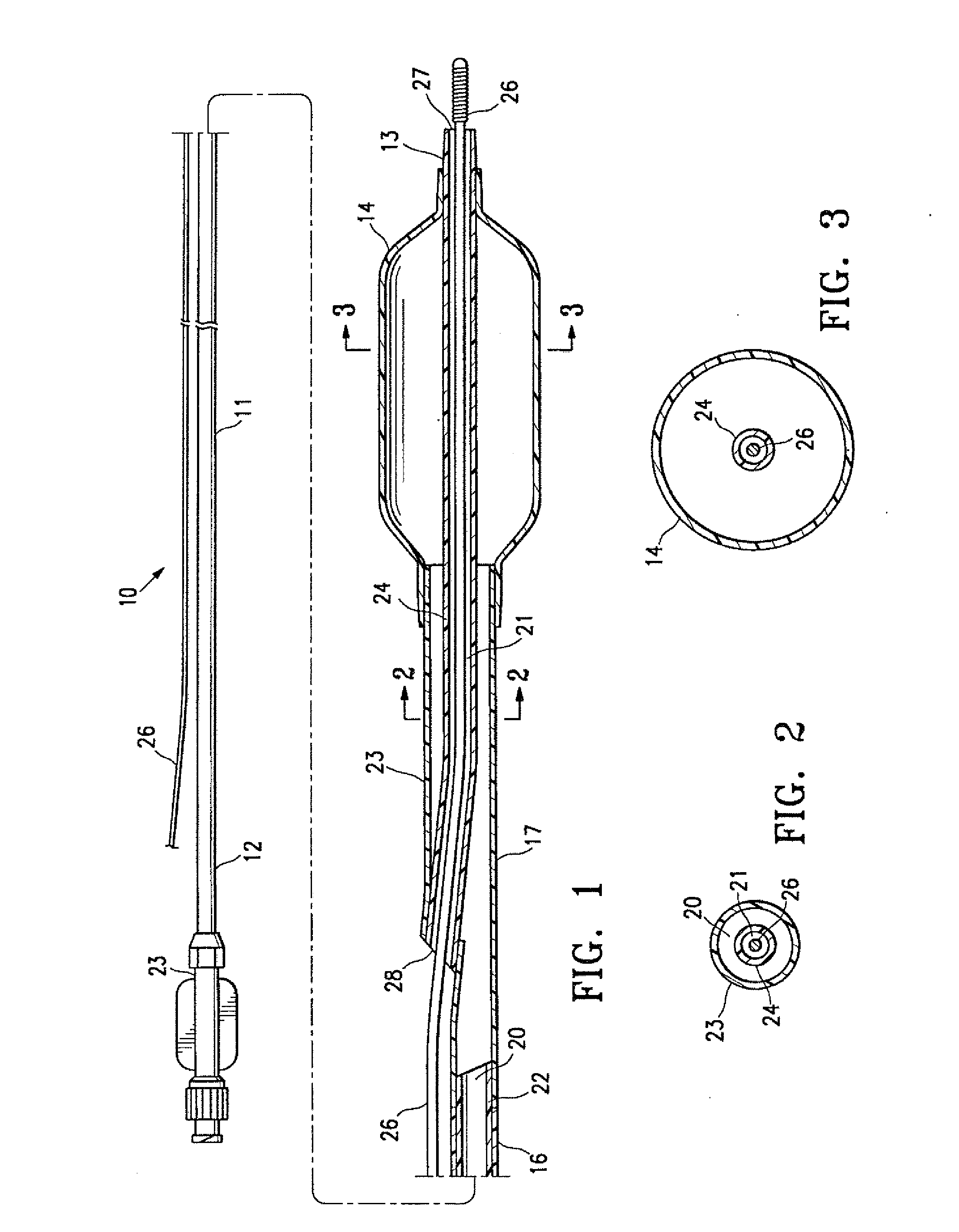

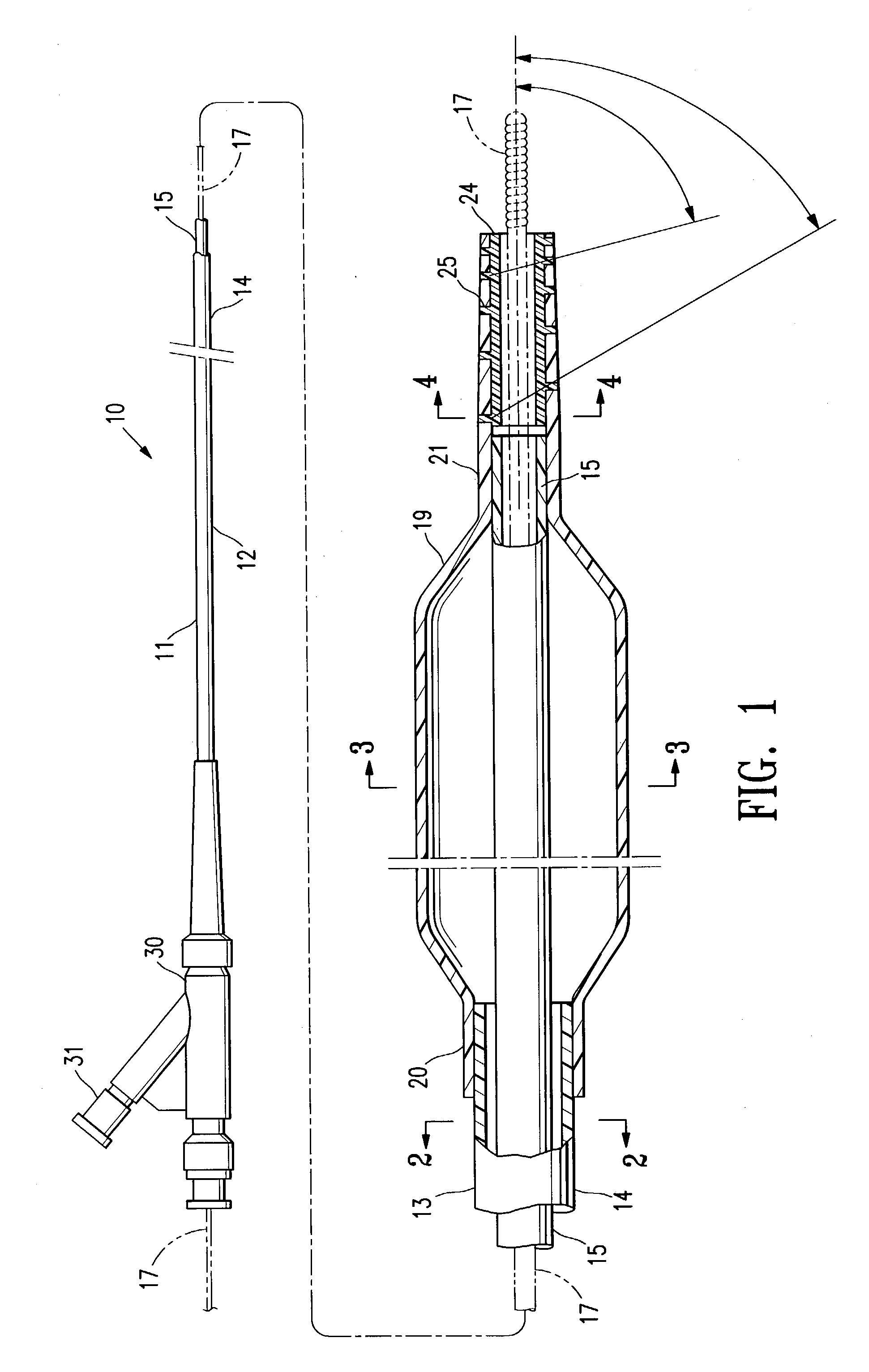

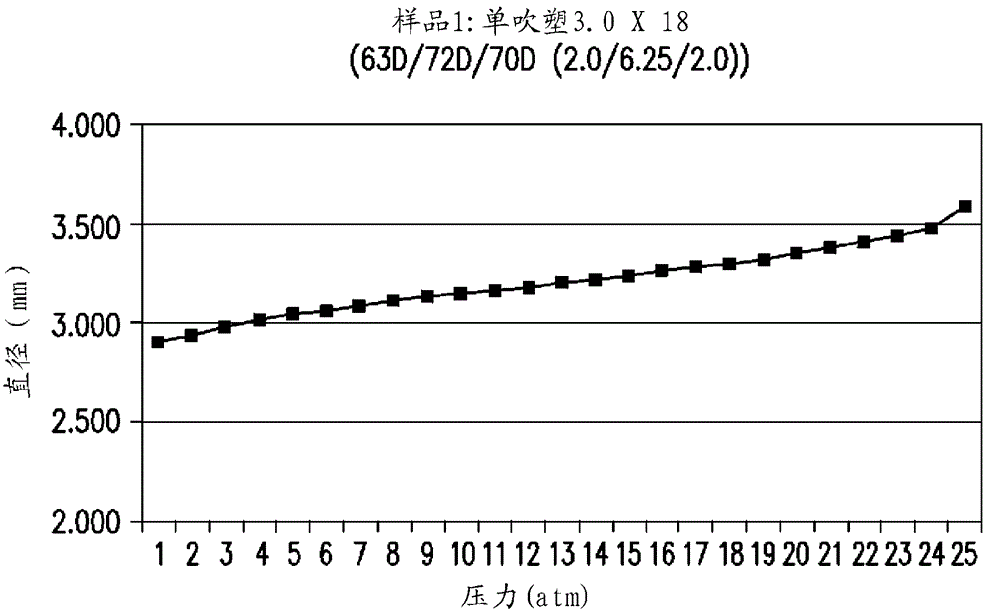

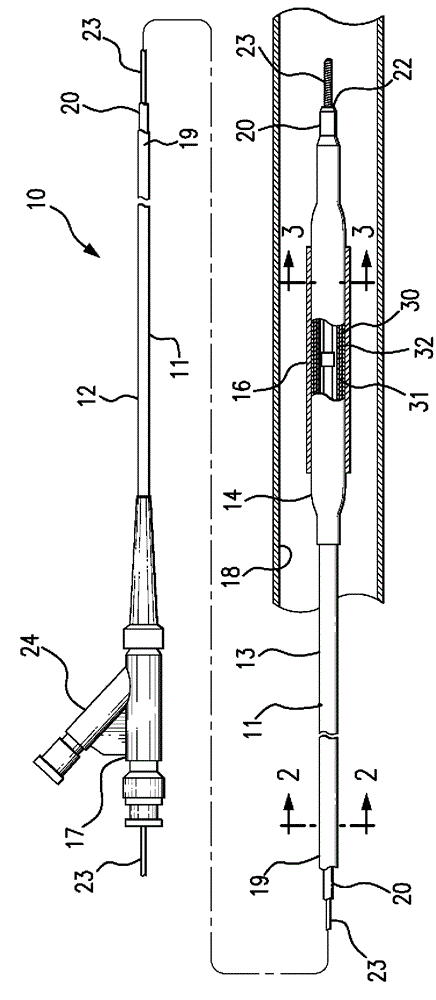

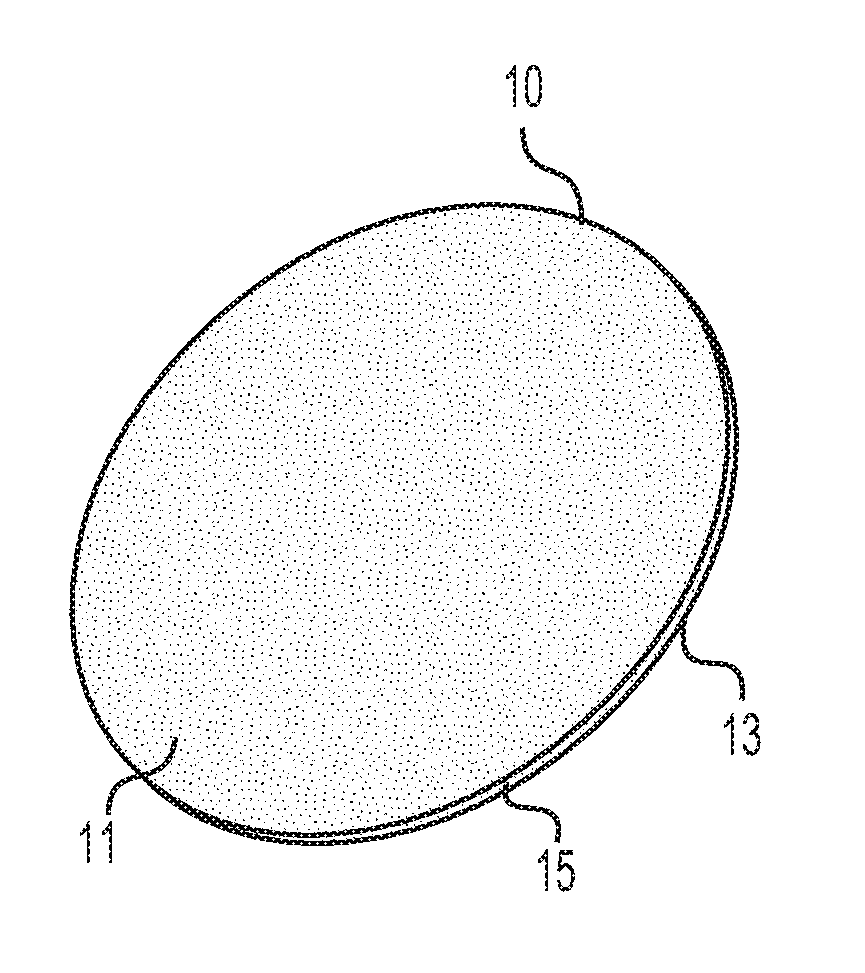

Medical device balloon

InactiveUS7074206B2Good flexibilityIncrease flexibilitySynthetic resin layered productsSurgeryMedicinePliability

A balloon catheter having a balloon formed at least in part of a blend of a first polymeric material having a first Shore durometer hardness, and at least a second polymeric material having a second Shore durometer hardness less than the Shore durometer hardness of the first polymeric material. The balloon of the invention has enhanced softness and flexibility due to the presence of the second polymeric material, and a lower than expected compliance. In a presently preferred embodiment, the balloon is formed of a blend of polymeric materials comprising polyether block amides.

Owner:ABBOTT CARDIOVASCULAR

Low-smoke halogen-free flame retardant thermoplastic elastomer alloy for flexible wire rod and preparation method thereof

InactiveCN101225224AHigh tensile strengthHigh elongationInsulated cablesInsulated conductorsLow voltageAntioxidant

The invention discloses a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires and a preparation method of the alloy, which is characterized in that: the material comprises thermoplastic polyurethane elastomer, thermoplastic styrene elastomer, compatilizer, phosphorus-nitrogen compound flame retardant, flame-retarding potentiating agent, lubricant, antioxidant and colorant; the weight ratio of the thermoplastic polyurethane elastomer, the thermoplastic styrene elastomer, the compatilizer, the phosphor-nitrogen compound flame retardant, the flame-retarding potentiating agent, the lubricant, the antioxidant and the colorant is 40 to 55 : 5 to 25 : 5 to 10 : 20 to 25 : 3 to 10 : 1.5 : 0.25 : 0.25; the preparation method is that the all components are evenly mixed in a high-speed mixer, and then extruded, drew and granulated at 170 to 210 degree centigrade, and then a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires is obtained. The low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires has the advantages of achieving distinct flame-retarding effect at a small quantity of flame retardant dosage, satisfying the flame-retarding requirement of low-voltage wires, adjusting the Shore durometer number of the material between 80 to 95, good pliability, high physical mechanical property and according with the halogen-free and environment-friendly requirement.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

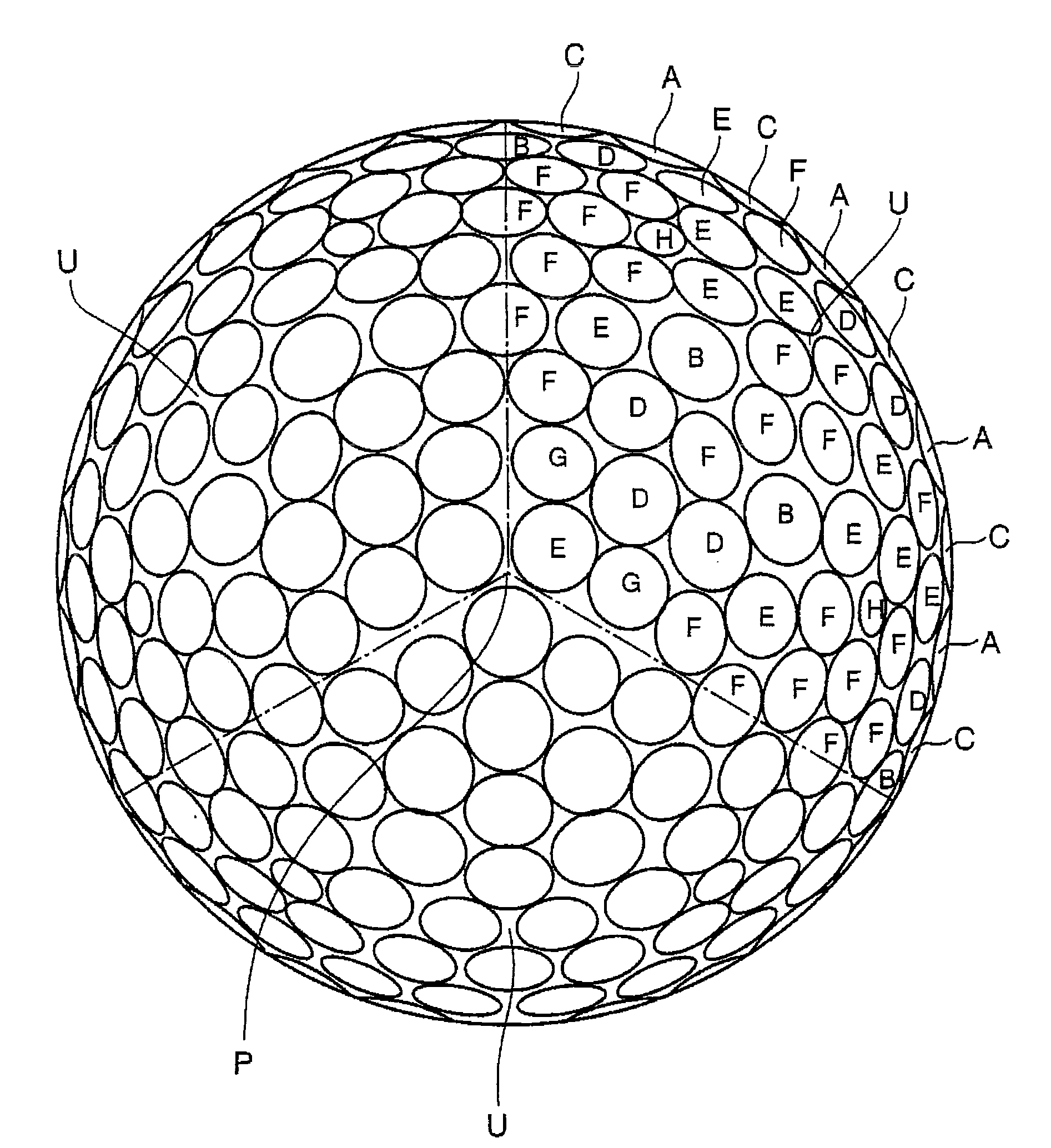

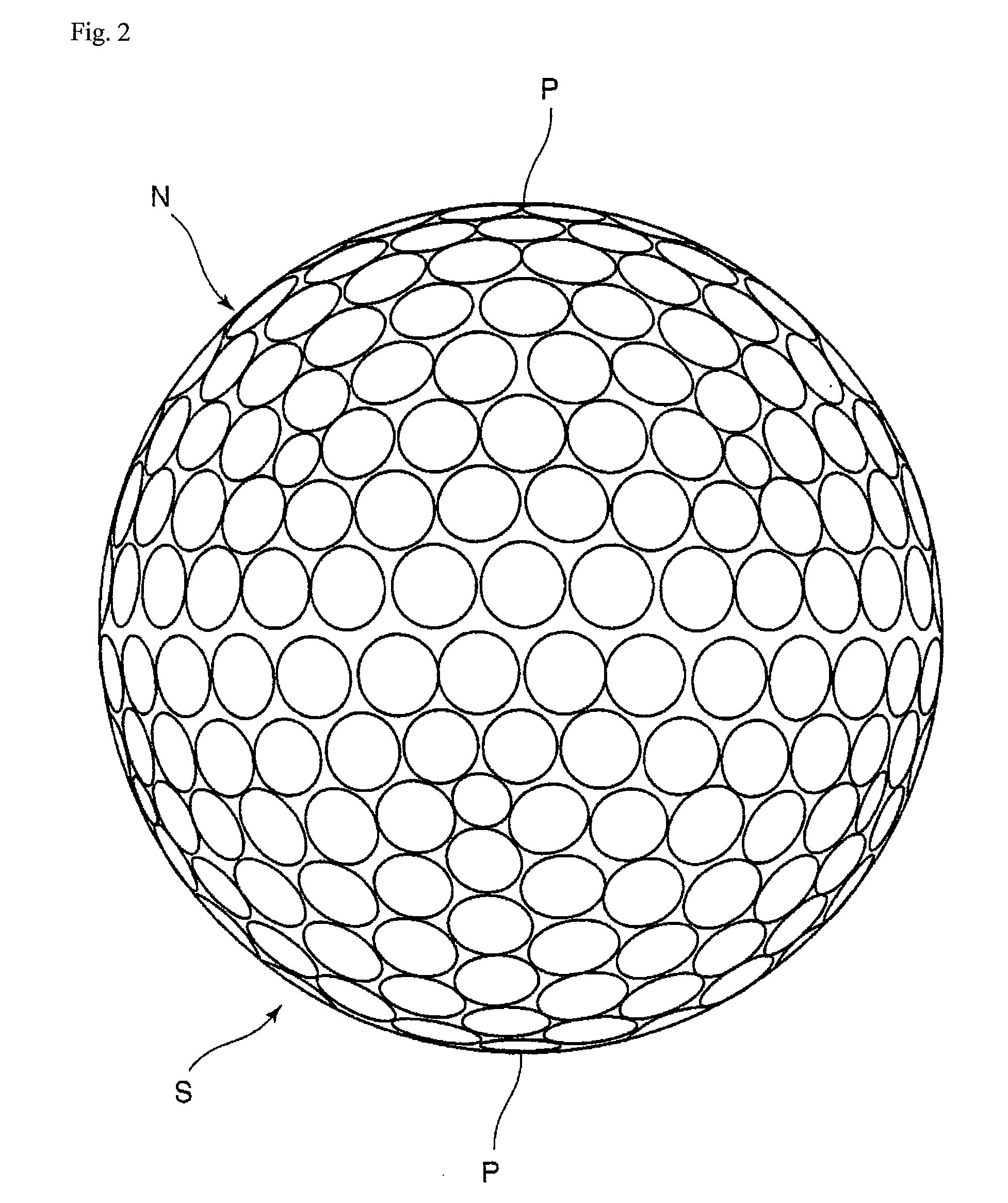

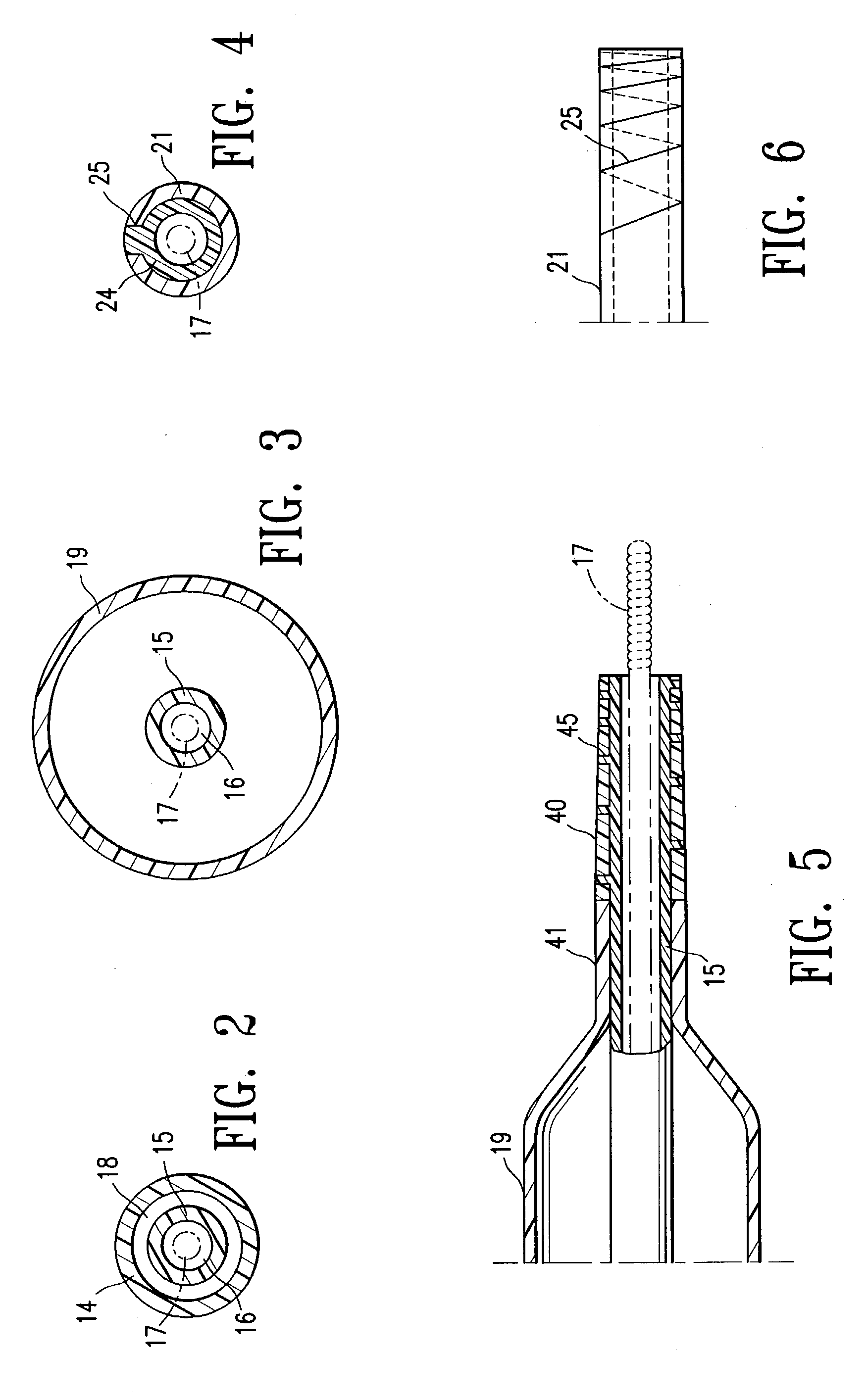

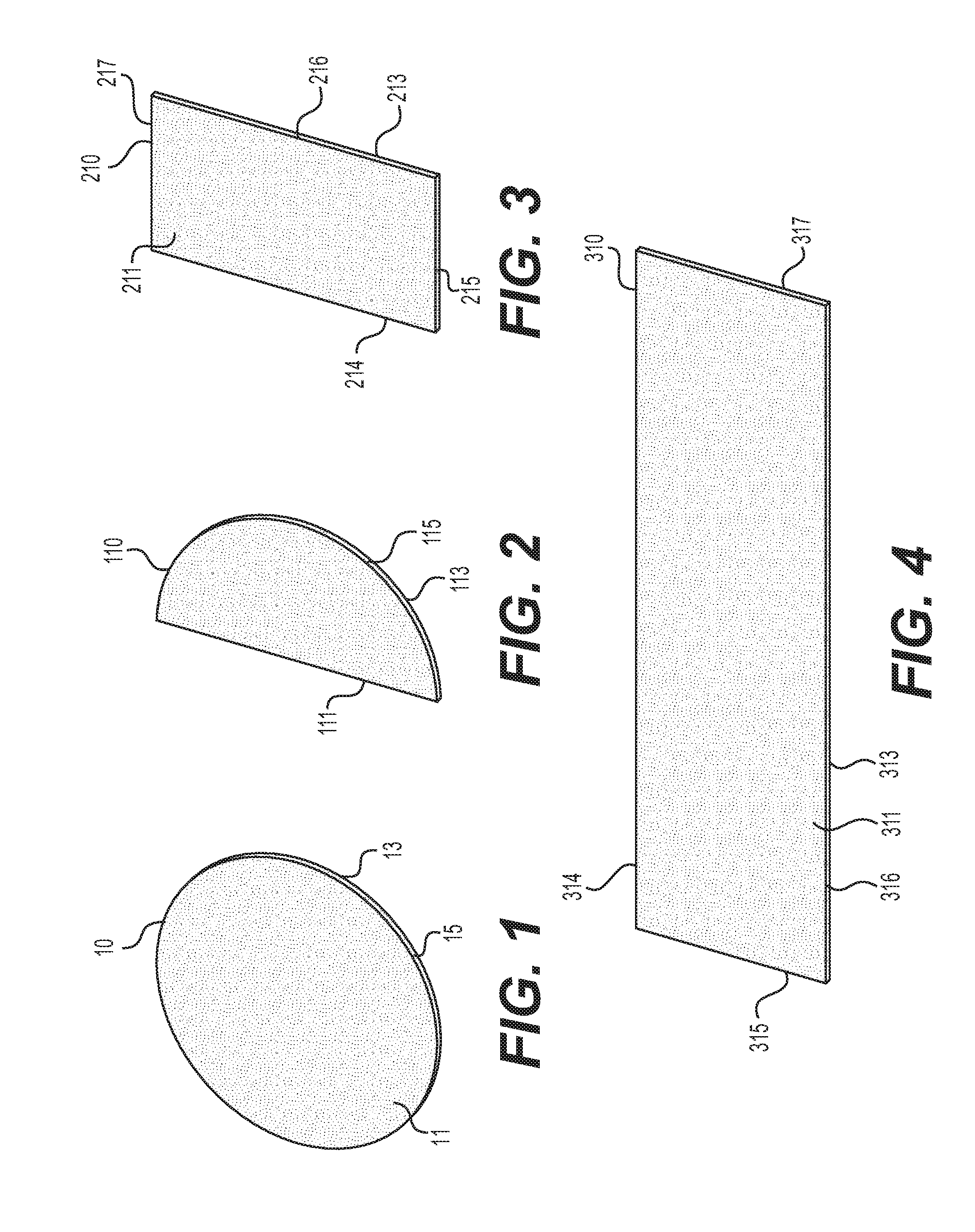

Golf ball

ActiveUS20100093466A1Increase repulsionIncrease stiffnessGolf ballsSolid ballsIonomerFlexural modulus

An objective of the present invention is to provide a golf ball striking a balance between the flight distance on the driver shots and the approach performance on the approach shots and having the excellent shot feeling and durability. The present invention provides a golf ball comprising a core consisting of a center and a surrounding layer covering the center; at least one intermediate layer covering the core; and a cover covering the intermediate layer; wherein at least one piece or one layer of the intermediate layer is formed from a highly elastic intermediate layer composition that contains (A) a highly elastic resin having a flexural modulus in a range from 700 MPa to 5,000 MPa and (B) an ionomer resin having a flexural modulus in a range from 150 MPa to 1,000 MPa in a content ratio ((A) / (B)) of (A) the highly elastic resin to (B) the ionomer resin (B) being (20 mass % to 80 mass %) / (80 mass % to 20 mass %) (the total is 100 mass %), and wherein a surface hardness (Hm) of the intermediate layer and a surface hardness (Hs) of the core satisfy the equation: Hm≧Hs, and the cover has a slab hardness (Hc) of 45 or less in Shore D hardness.

Owner:SUMITOMO RUBBER IND LTD

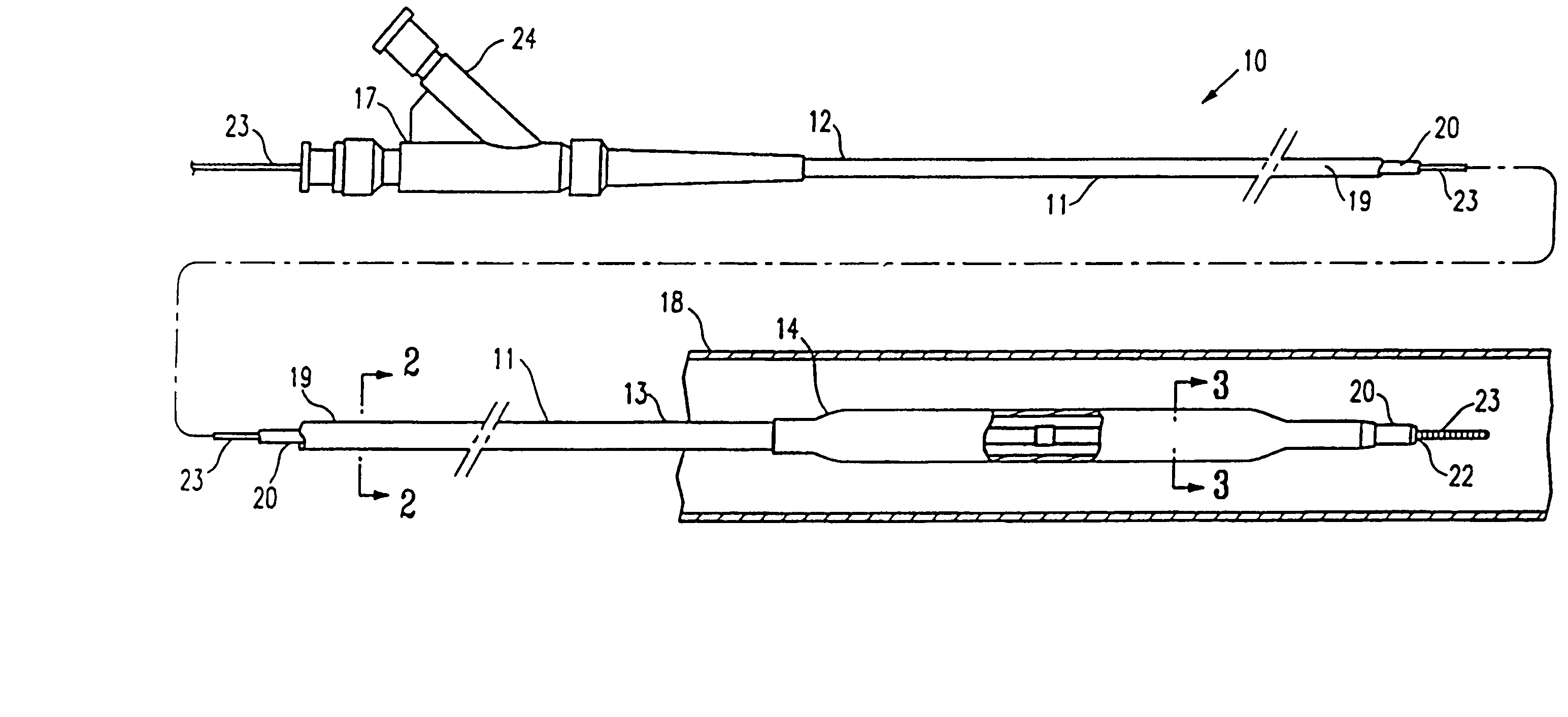

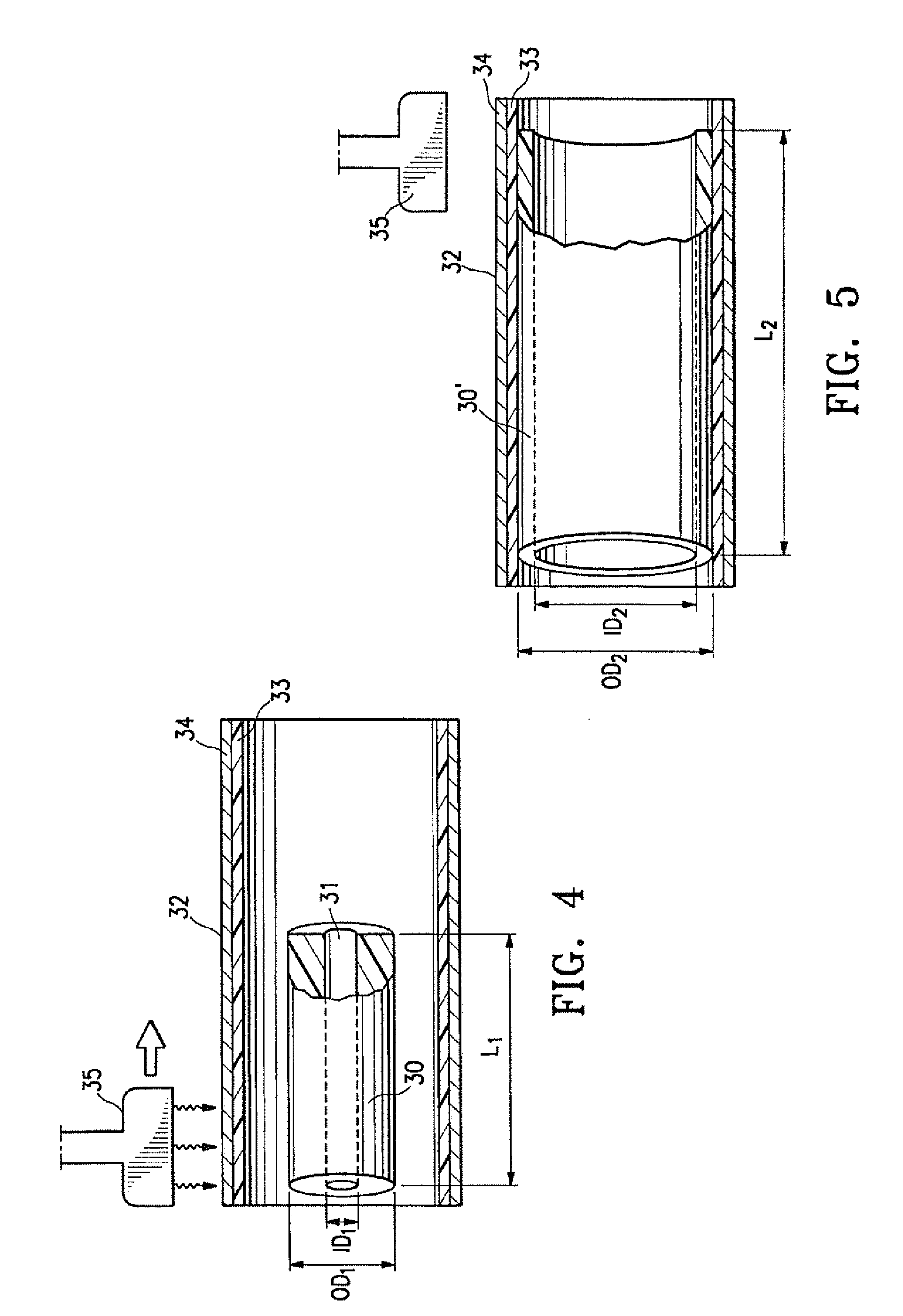

Balloon catheter shaft having high strength and flexibility

Balloon catheter comprises an elongated shaft having a proximal end, a distal end, an inflation lumen extending therein, and a biaxially oriented nonporous thermoplastic polymer tubular member having a Shore durometer hardness of less than about 75D and having the inflation lumen therein. The balloon catheter also comprises a balloon sealing secured proximate the distal end of the shaft and having an interior in fluid communication with the inflation lumen.

Owner:ABBOTT CARDIOVASCULAR

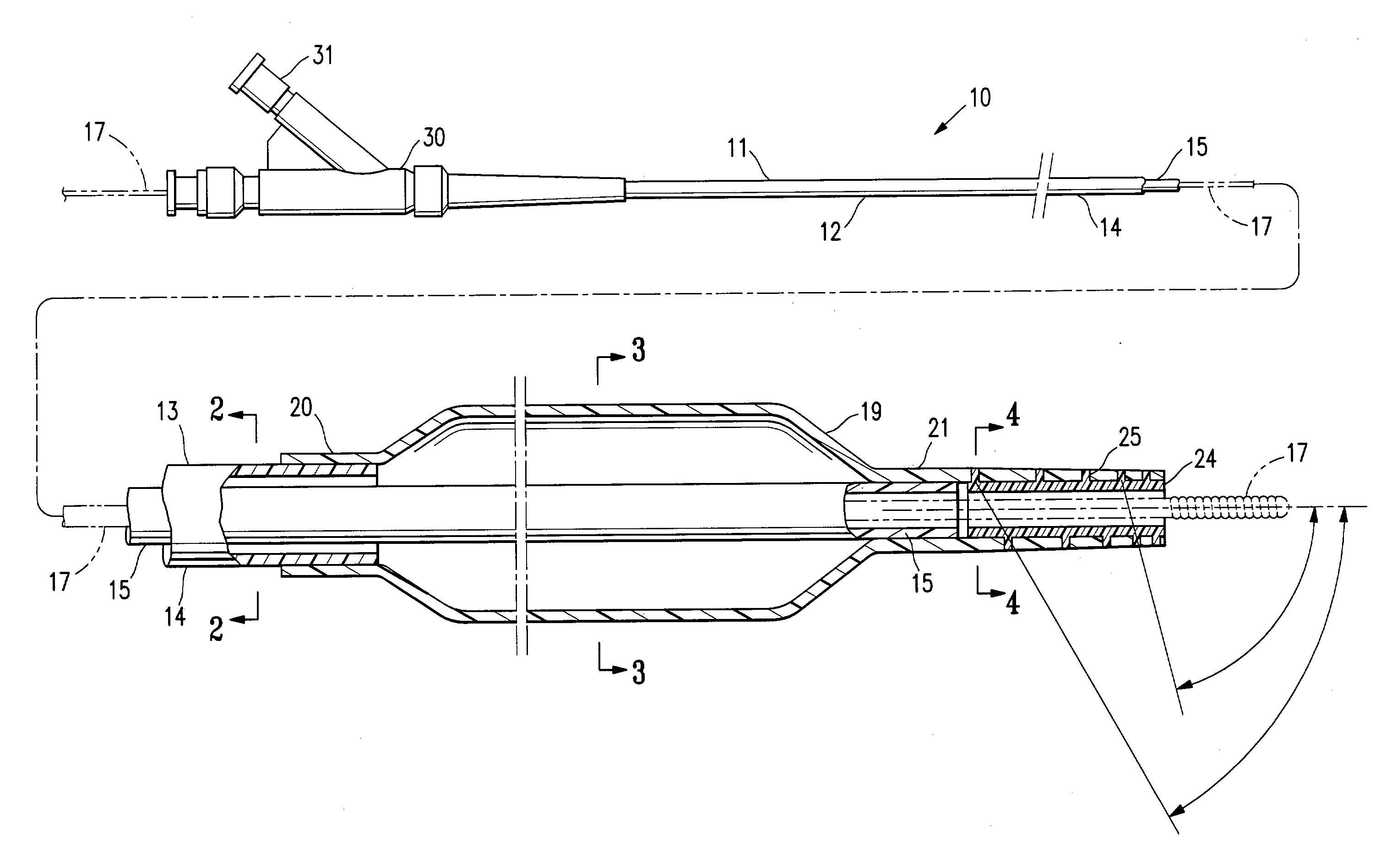

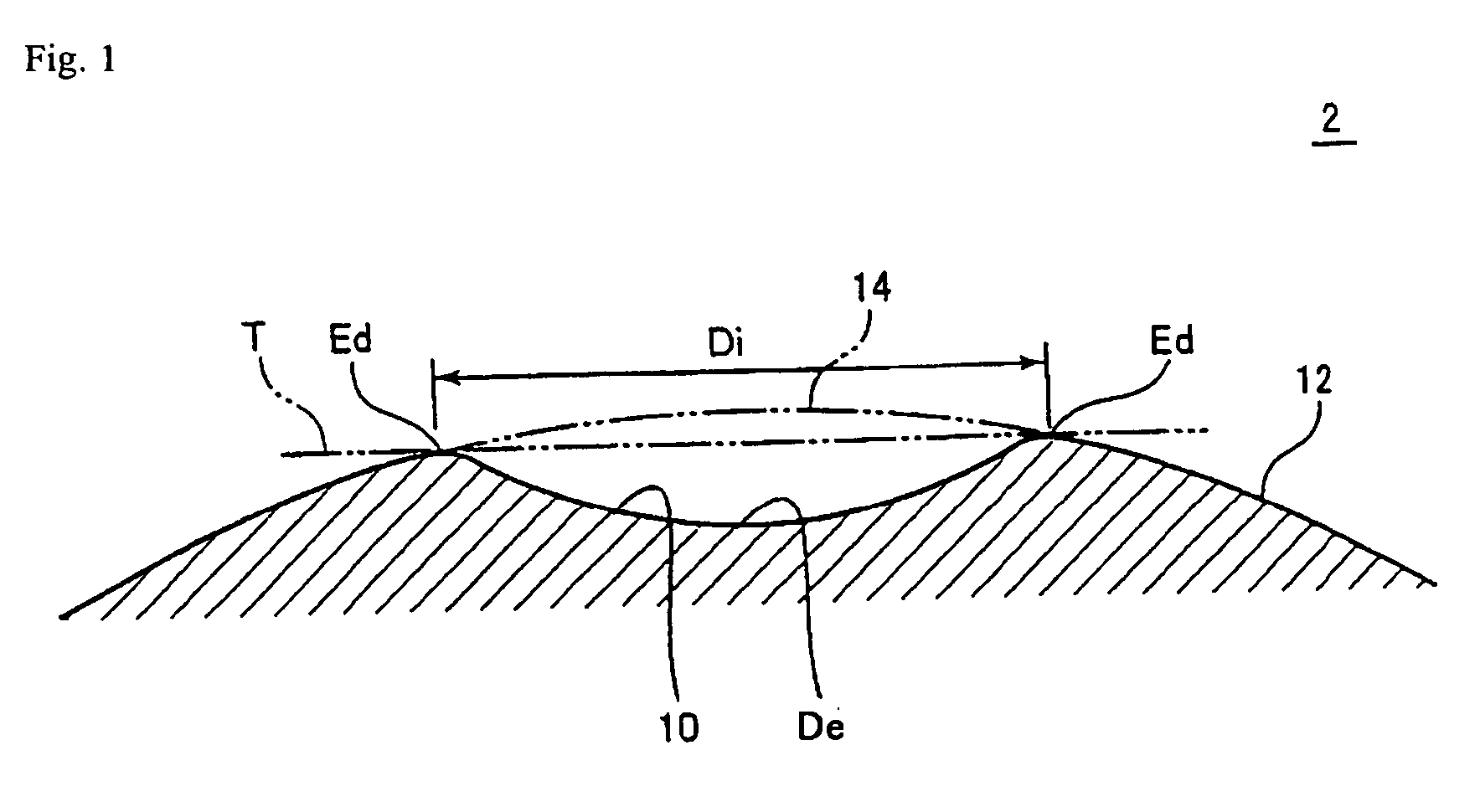

Balloon catheter having a spiral cut distal end

InactiveUS6881201B1Easy to operateExcellent crossabilityStentsBalloon catheterBalloon catheterBiomedical engineering

A catheter having an elongated shaft, a balloon on a distal shaft section, and a distal tip having at least a section formed by a distal end portion of the shaft and an outer sheath member fused together. The outer sheath member has a sidewall break at least partially filled with the polymeric material of the outer surface of the distal end portion of the shaft. The outer sheath member preferably comprises a first polymeric material having a higher Shore durometer hardness than a second polymeric material forming the outer surface of the shaft distal end portion. One aspect of the invention is directed to a method of making a balloon catheter, in which the polymeric material of the outer surface of the shaft is caused to soften and flow into the opening formed by the break in the sidewall of the outer sheath, thus forming the distal tip.

Owner:ABBOTT CARDIOVASCULAR

Golf ball

The object of the present invention is to provide a golf ball that satisfies both of the flight distance at the shot with a driver, a long iron, and a middle iron and the controllability at the approach shot with a short iron and is also excellent in the abrasion resistance of the cover. The present invention provides a golf ball comprising a core consisting of a center and at least one intermediate layer covering the center, and a cover covering the core, wherein the cover is formed from a cover composition containing, as a resin component, a thermoplastic polyurethane (A) and a polyisocyanate mixture (B) in which a urethane prepolymer (b-1) having at least two isocyanate groups or a polyisocyanate (b-2) having at least three isocyanate groups is dispersed in a thermoplastic resin (b-3) which does not substantially react with an isocyanate group; and wherein the cover composition has a slab hardness of 60 or less in Shore D hardness, and the core has a hardness difference (Hs−Ho) between a surface hardness Hs and a center hardness Ho of from 15 to 50 in Shore D hardness.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

InactiveUS20100087275A1Increased durabilityImprove stabilityGolf ballsSolid ballsPolyamideEngineering

An object of the invention is to provide a golf ball excellent in the durability at the normal and low temperatures, flight distance, and shot feeling on the shots. Another object of the present invention is to provide a golf ball excellent in a direction stability on the shots. The present invention provides a golf ball comprising: a core consisting of at least one layer; and a cover covering the core and having a thickness ranging from 0.3 mm to 1.0 mm, wherein the cover is formed from a cover composition that contains as a resin component, (A) a highly elastic polyamide resin (B) a metal-neutralized product of binary copolymer and / or ternary copolymer, and (C) a resin having a polar functional group in a specific amount, and wherein the cover composition has a slab hardness ranging from 65 to 75 in Shore D hardness.

Owner:SUMITOMO RUBBER IND LTD

Method for detecting strength of soil-cement admixture by using hardness test

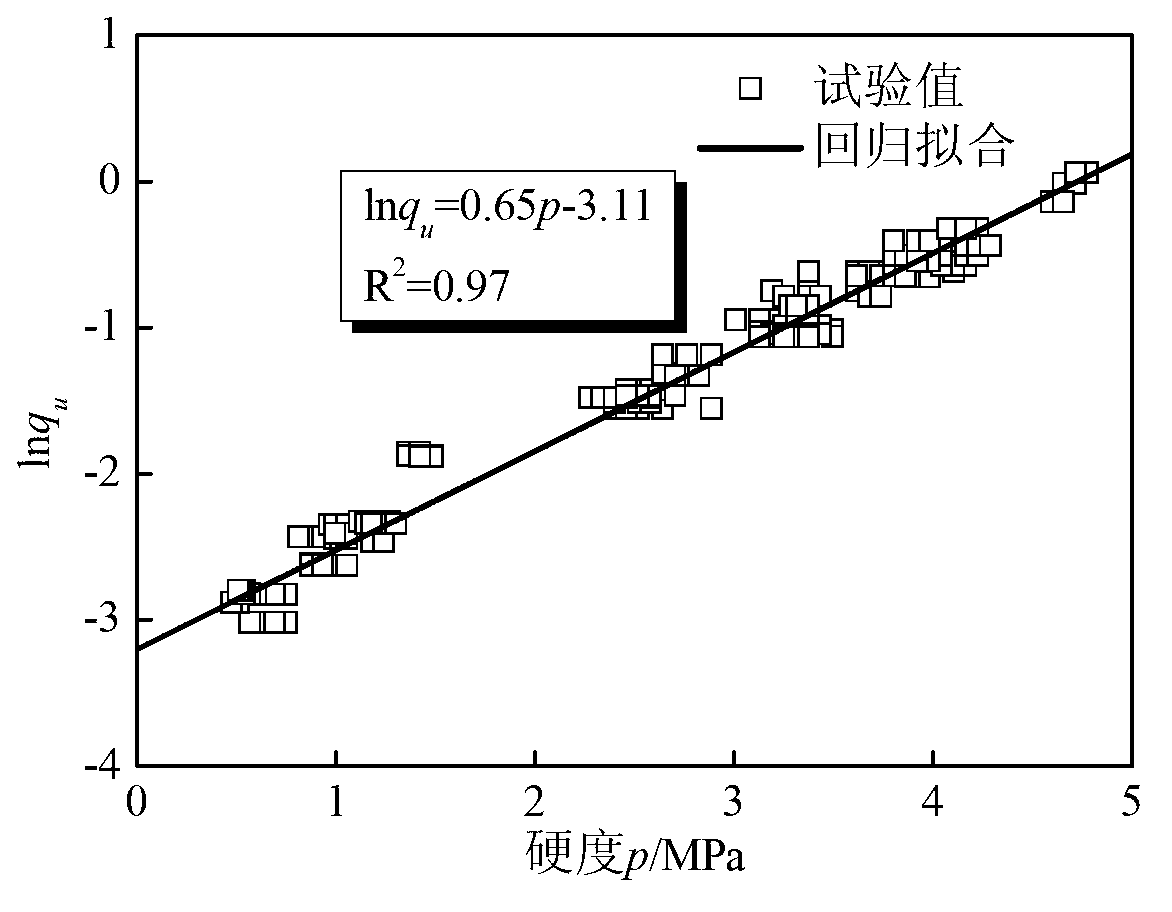

InactiveCN102980819AAvoid destructionAvoid delayPreparing sample for investigationMaterial strength using tensile/compressive forcesKnoop hardness testHardness

The invention provides a method for detecting the strength of a soil-cement admixture by using a hardness test. The method comprises the following steps: acquiring soil samples from a variety of soil layers within on-site construction depth; carrying out sample preparation on the on-site soil samples and cement and then carrying out a hardness test and a lateral confinement-free compressive strength indoor test; collating hardness values of soil cement test pieces obtained in the test and corresponding lateral confinement-free compressive strength values and drafting a graph of relation; subjecting the graph of relation to linear-regression analysis to obtain a relation between the hardness values of soil cement at the construction site and natural logarithm values of confinement-free compressive strength; during reinforcing and maintenance of on-site construction soil cement, digging out the surface of a few reinforcing sections to expose the soil cement, testing hardness of the soil cement with a Shore durometer and calculating a confinement-free compressive strength value by directly using the linear regression relation obtained through the tests. According to the invention, destroy of reinforced soil and delay of a construction period caused by boring and sampling of the reinforced soil after reinforcement construction are avoided, and the method is concise, economic, effective and fast.

Owner:SHANGHAI JIAO TONG UNIV

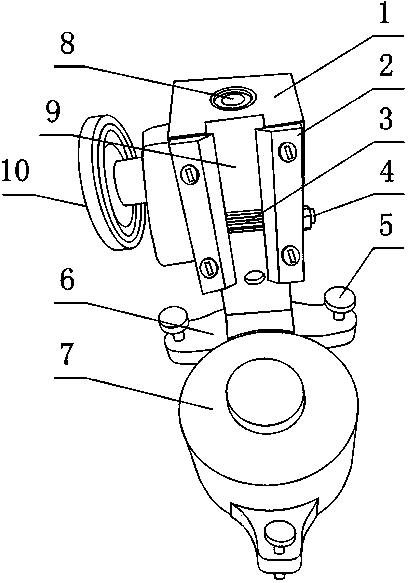

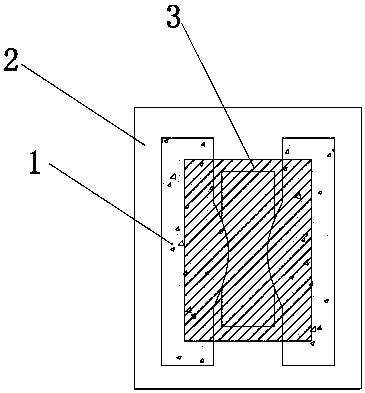

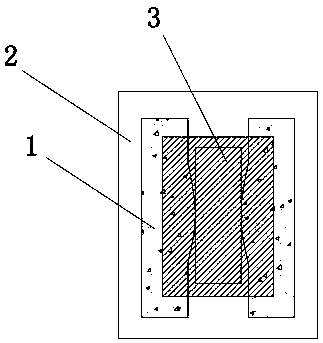

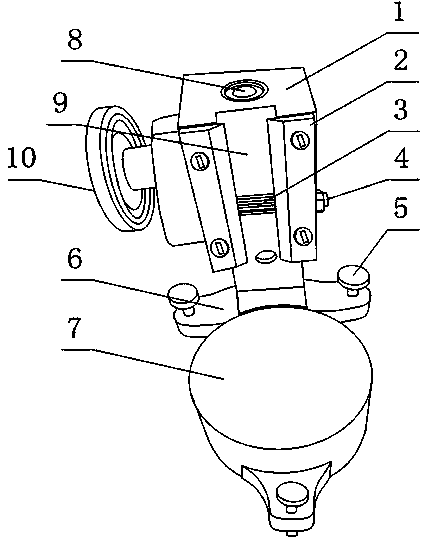

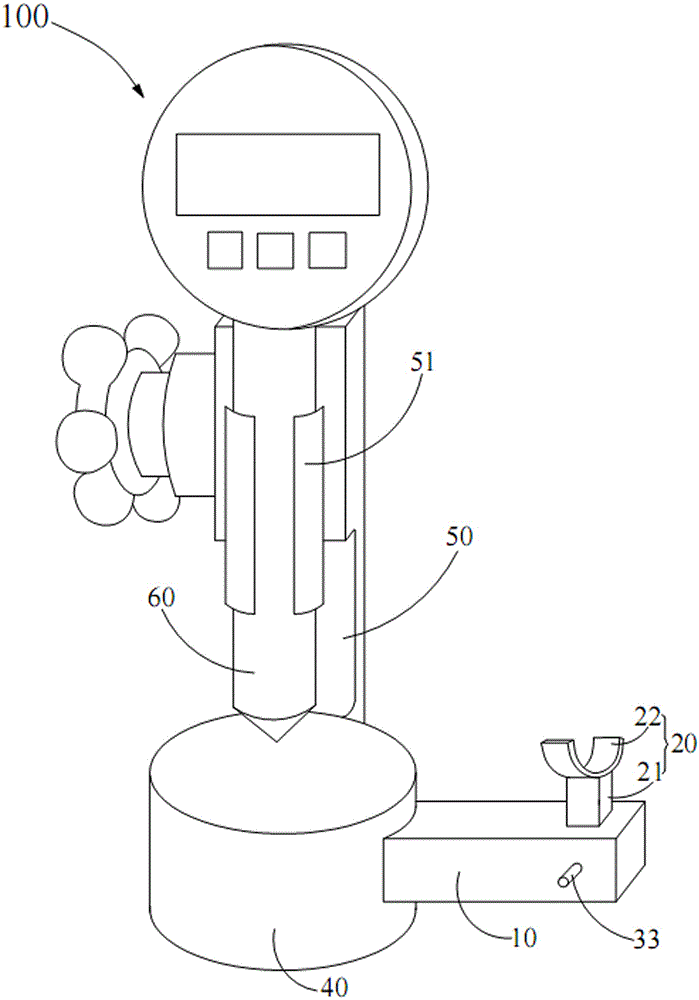

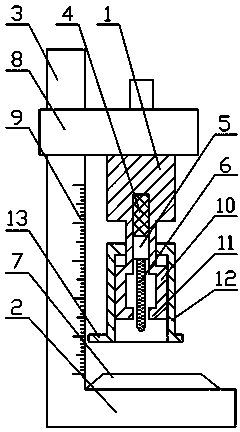

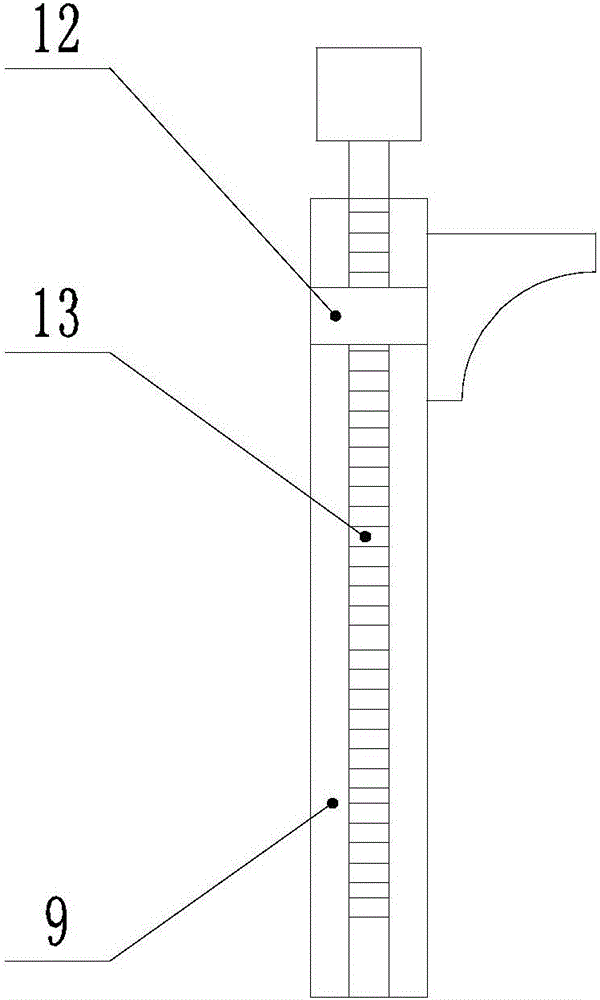

Hardness tester rack device beneficial for measurement accuracy

ActiveCN104034619AEasy height adjustmentGood precisionInvestigating material hardnessThree levelEngineering

The invention discloses a hardness tester rack device beneficial for measurement accuracy. The hardness tester rack device comprises a base, a material platform and a vertically arranged fixing base, wherein the material platform is arranged on the base; the lower end of the fixing base is fixedly connected with the base; a hardness tester groove in the vertical direction is also formed in the fixing base and is formed above the material platform; a spline shaft with an axial direction in the horizontal direction is also arranged on the fixing base, protrudes relative to the bottom surface of the hardness tester groove and can rotate around the axis of the spline shaft; at least three leveling bolts with axis directions in the vertical direction are also arranged on the base and are not on the same straight line; the material platform comprises a primary platform and a secondary platform arranged above the primary platform; the secondary platform and the primary platform are in threaded connection. The hardness tester rack device has a simple structure, achieves simplicity in adjustment of the height of the Shore hardness tester, and is beneficial for the measurement accuracy of the HS tester.

Owner:API ZC PRECISION INSTUMENT CO LTD

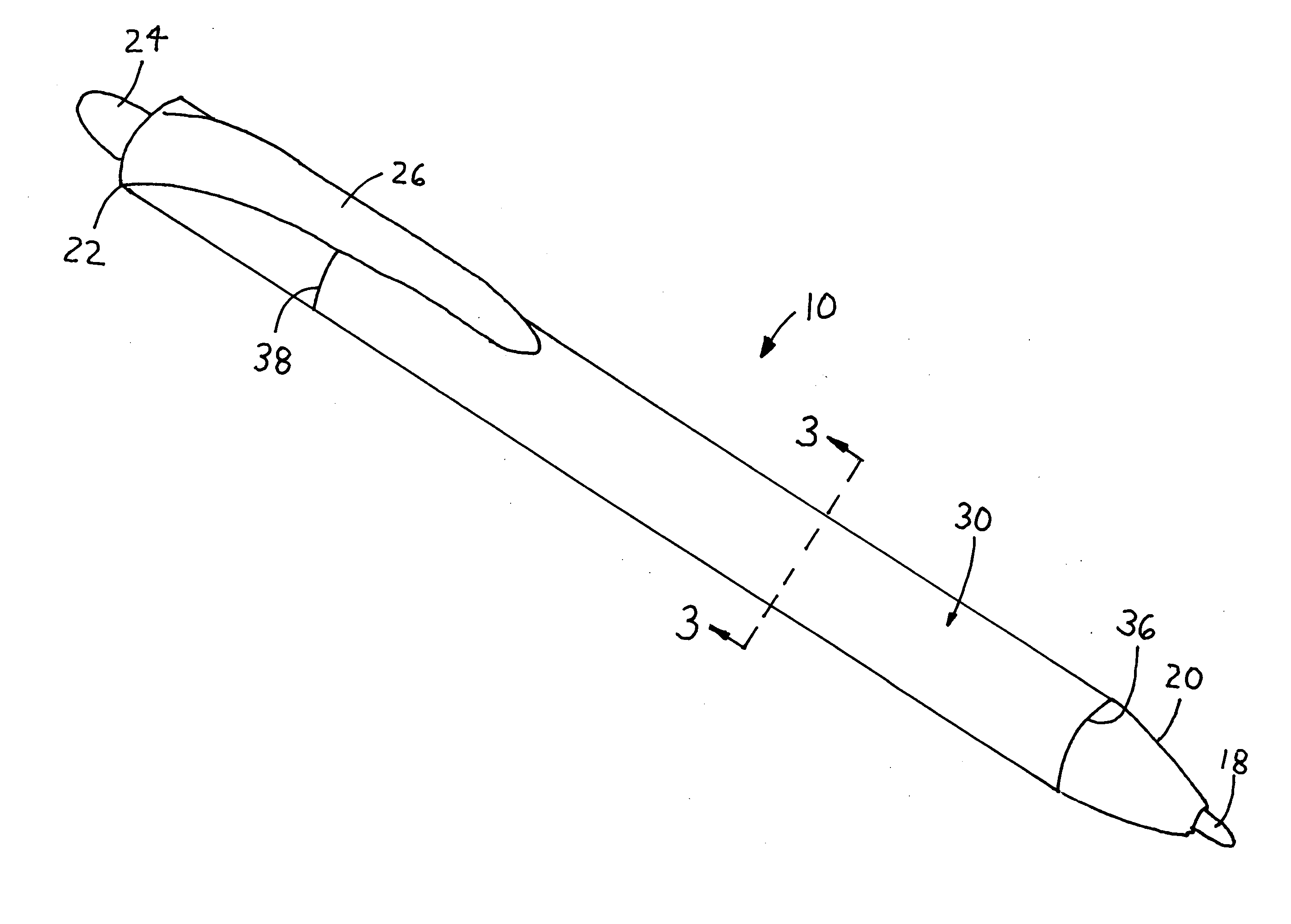

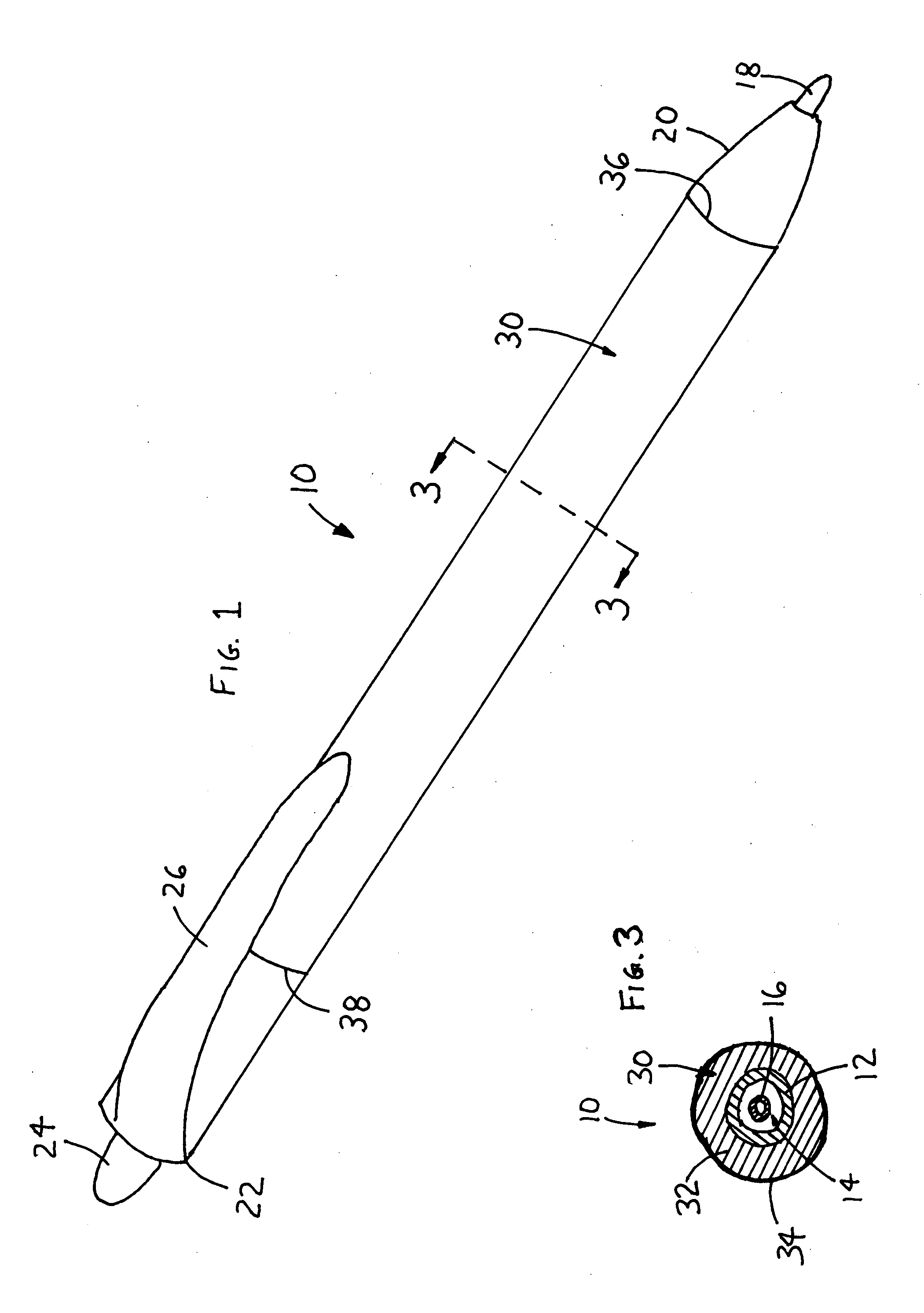

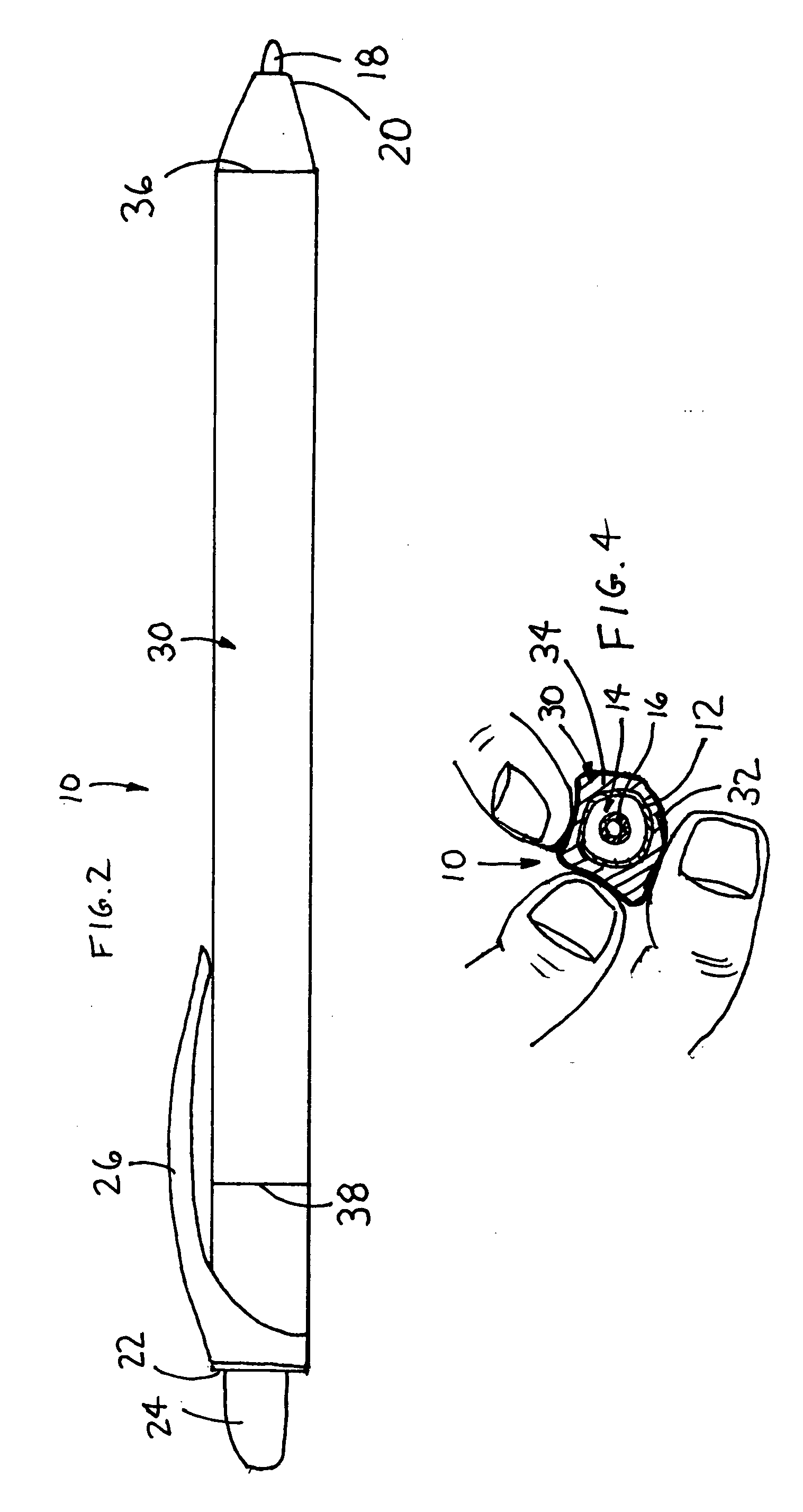

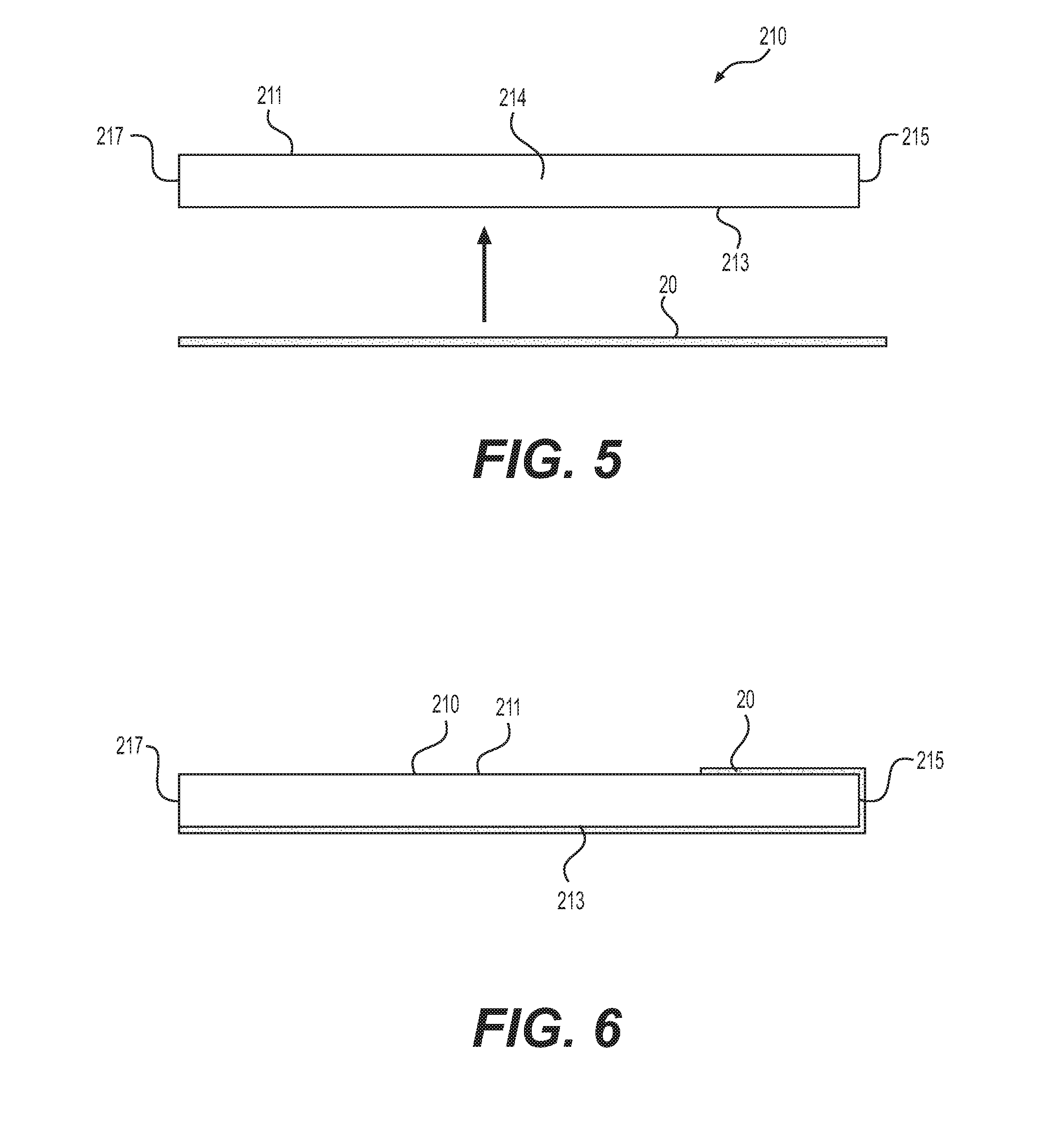

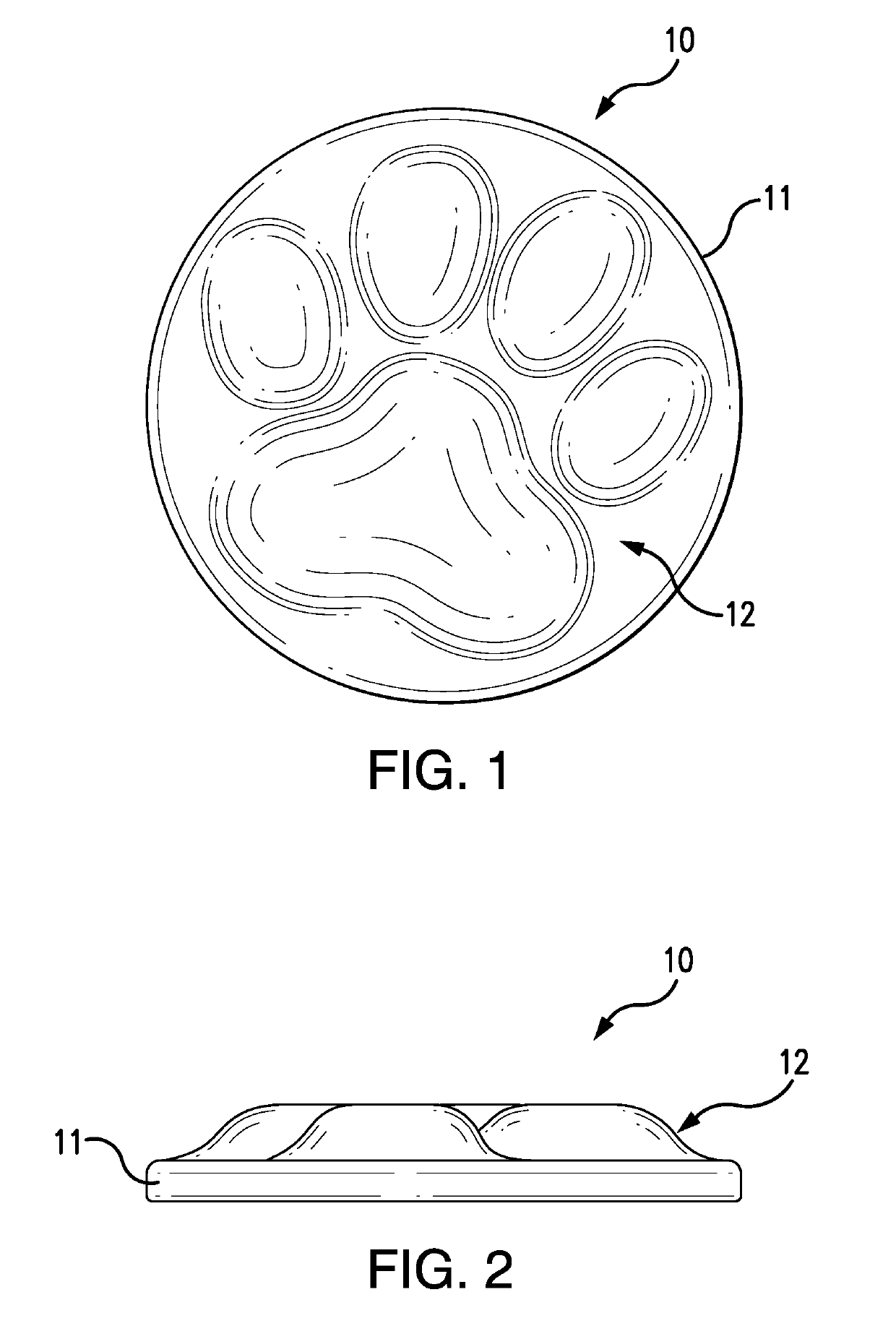

Deformable grip for a writing implement

A deformable grip for a writing implement having a rigid barrel includes a grip layer connected to the rigid barrel. The grip layer is formed of a solid viscoelastic grip material having a hardness of approximately 1 to 80 Shore OO durometer allowing the grip layer to achieve a deformed shape under manual pressure. The grip material further has a shape retention adapted to retain the deformed shape for at least 1 second. A coating is disposed over the grip layer and is formed of a coating material having a tensile strength of at least approximately 50 to 1000 psi and an elongation ratio of at least approximately 50 to 2000 percent. The grip may be formed over a majority of the barrel length to accommodate a variety of grip points and to improve comfort to a user.

Owner:SANFORD LP

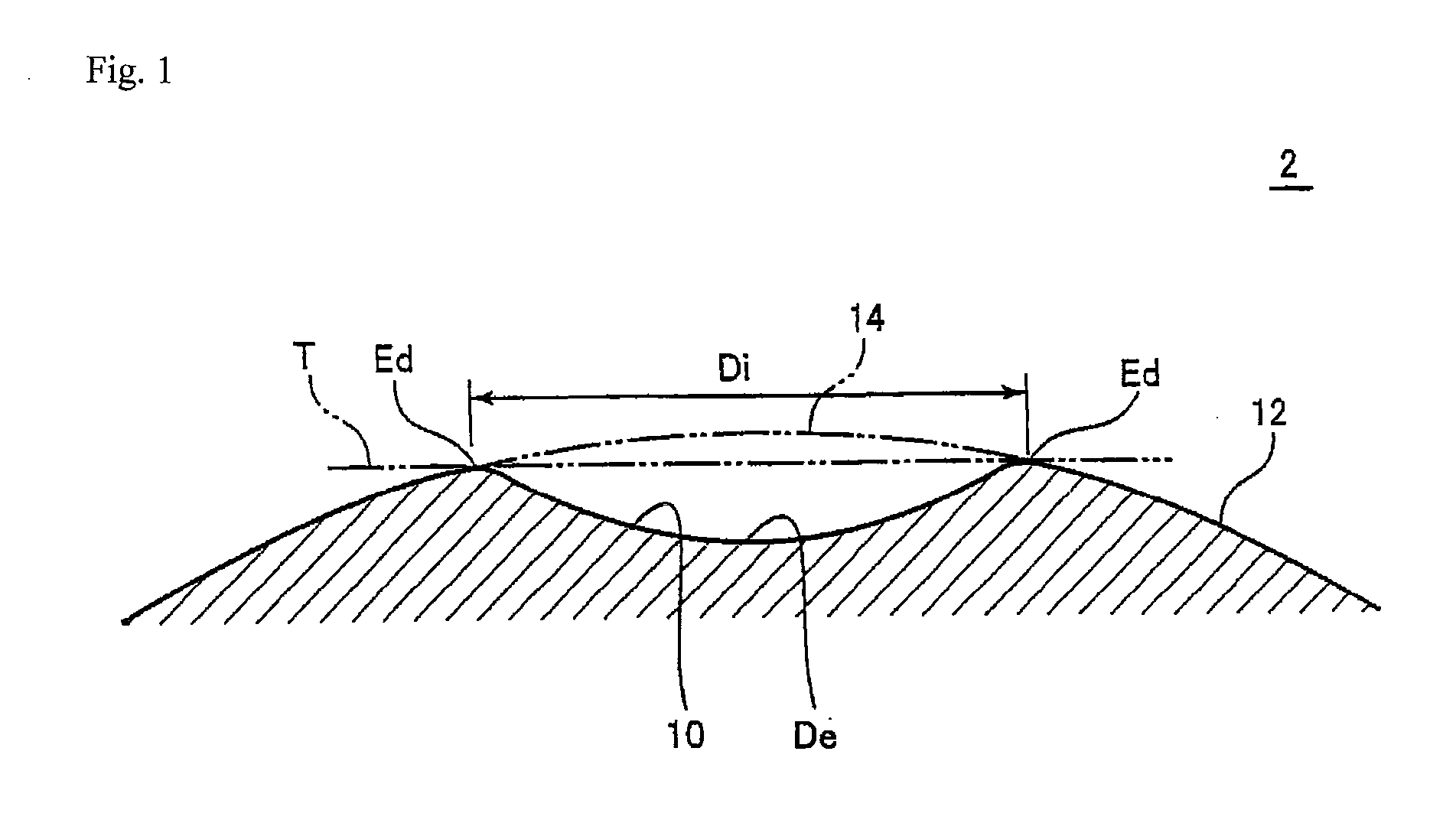

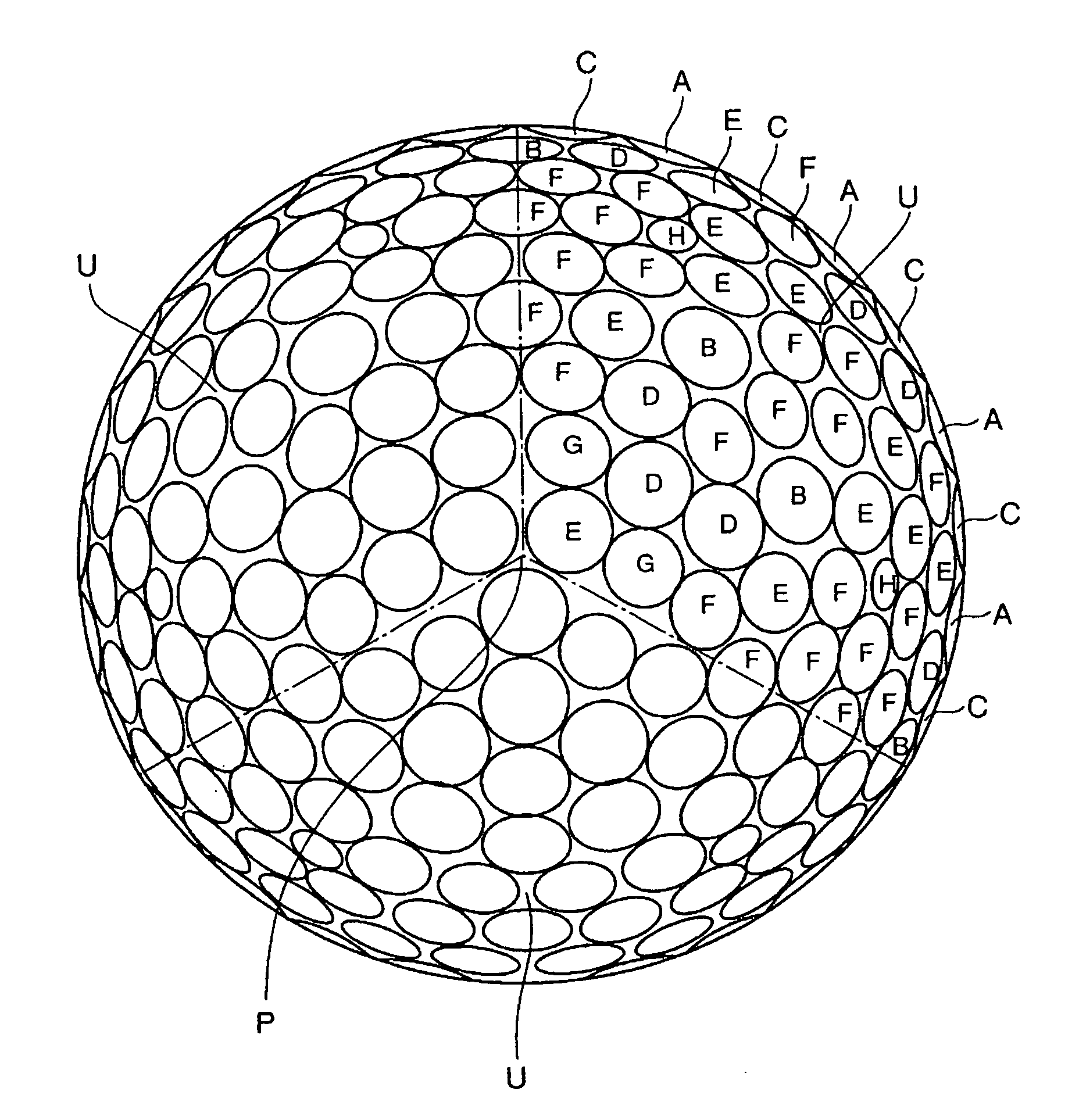

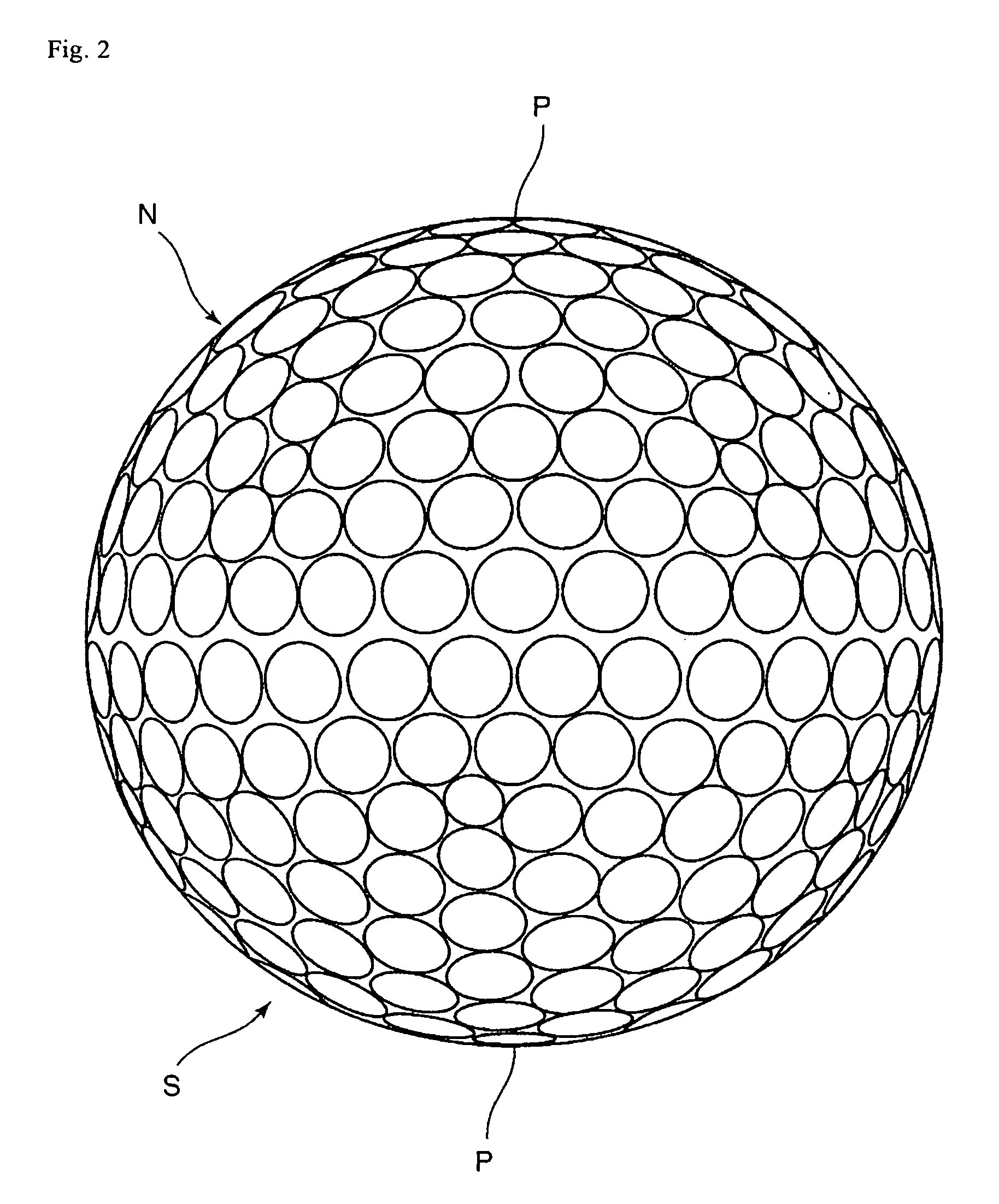

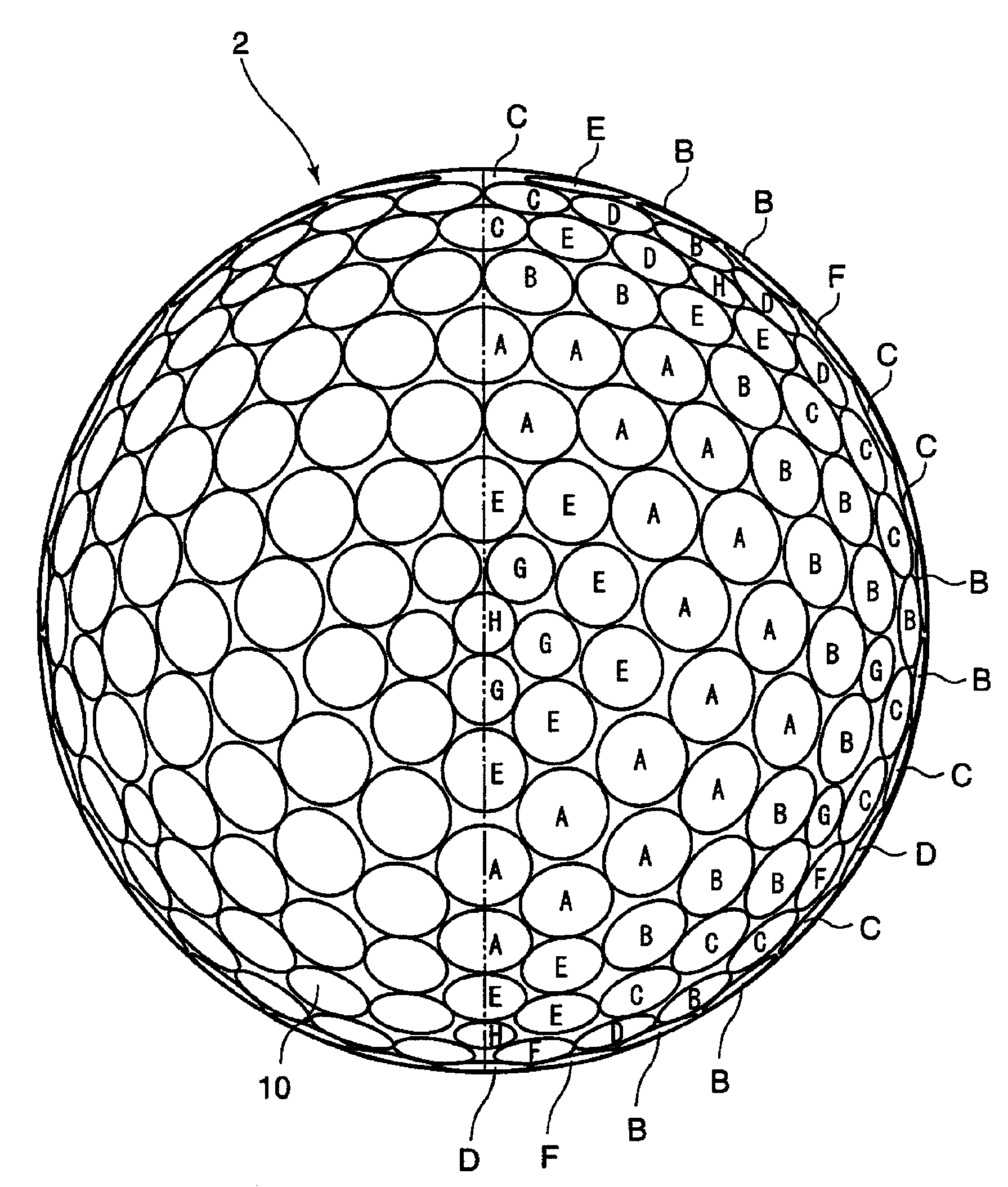

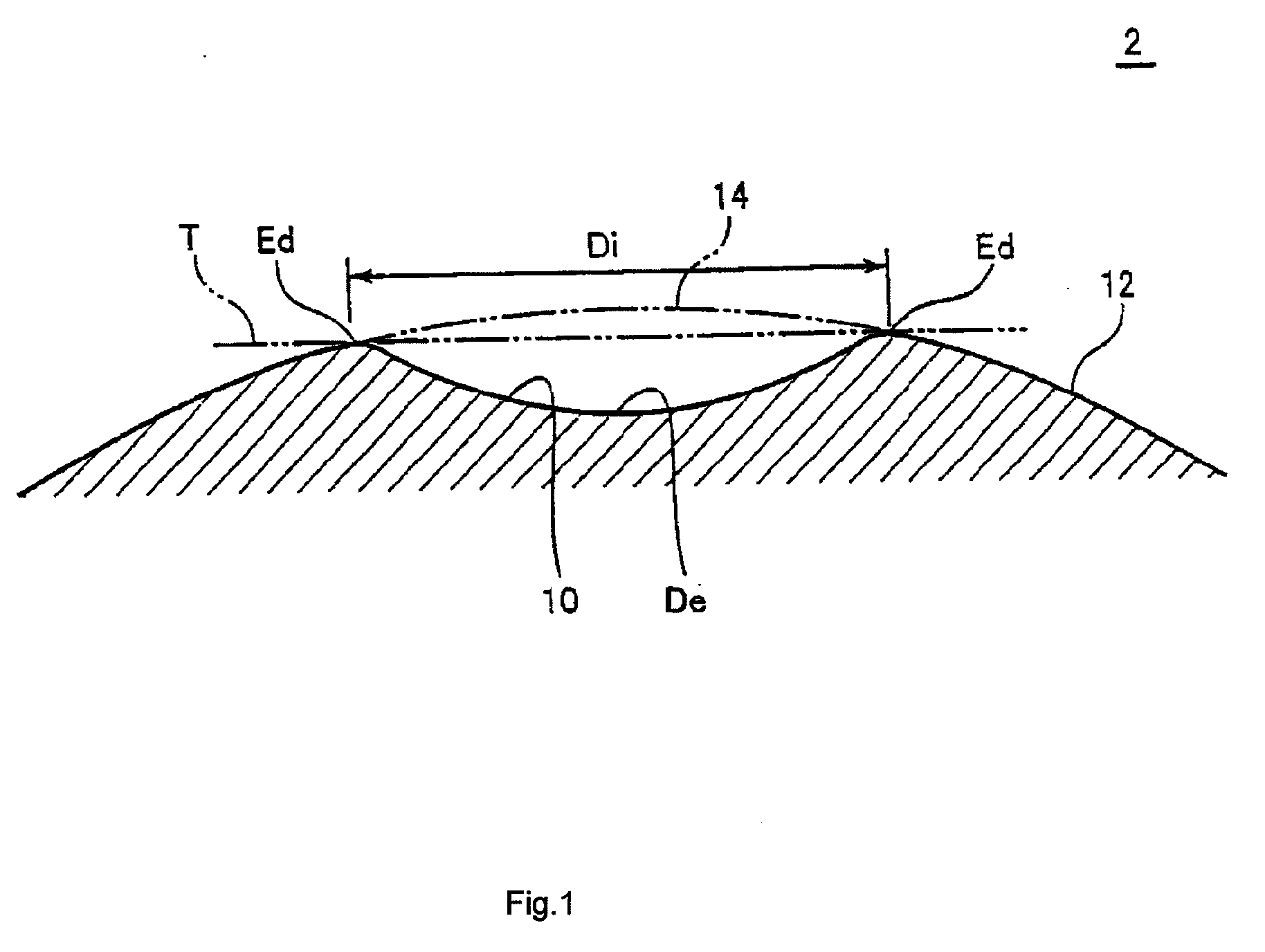

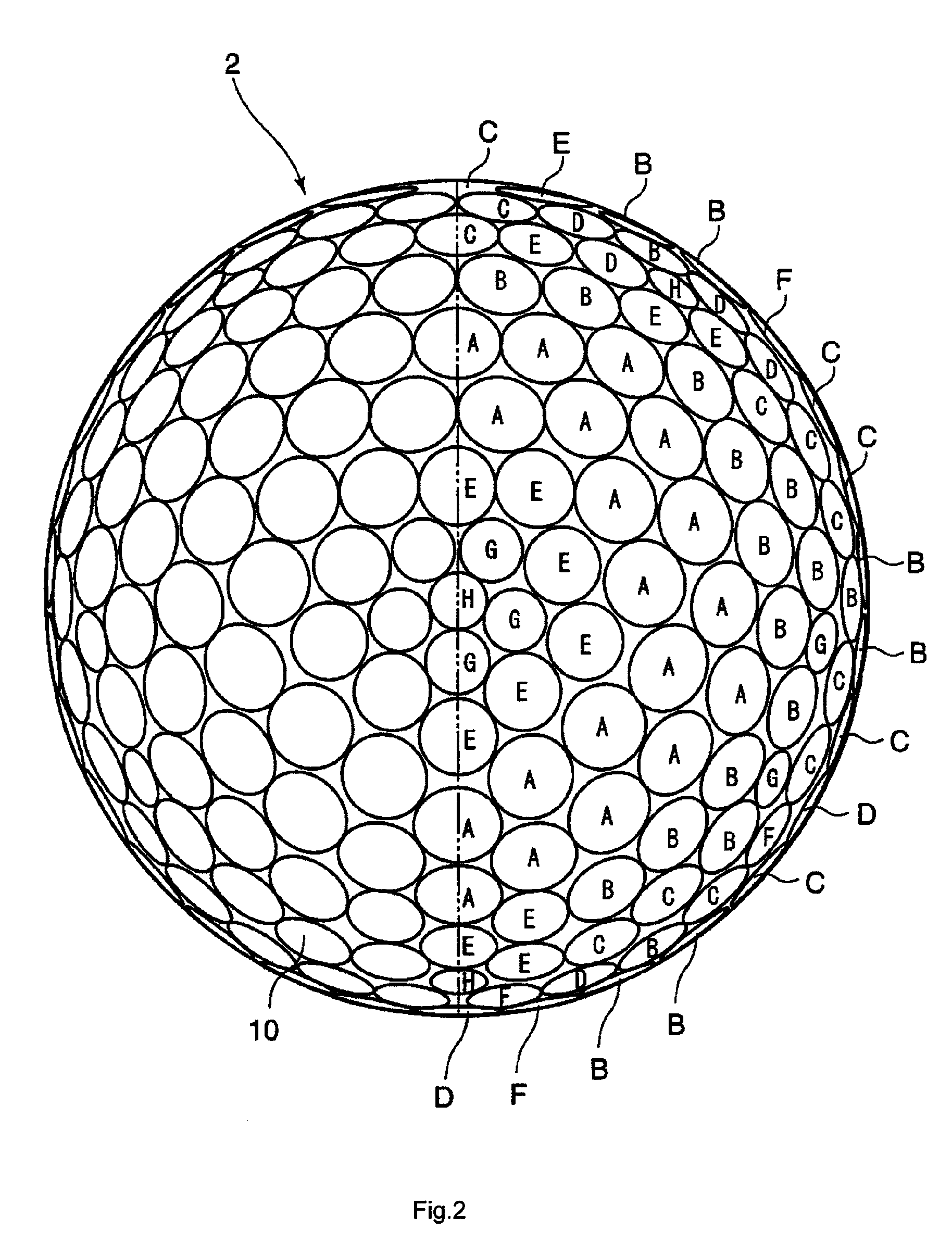

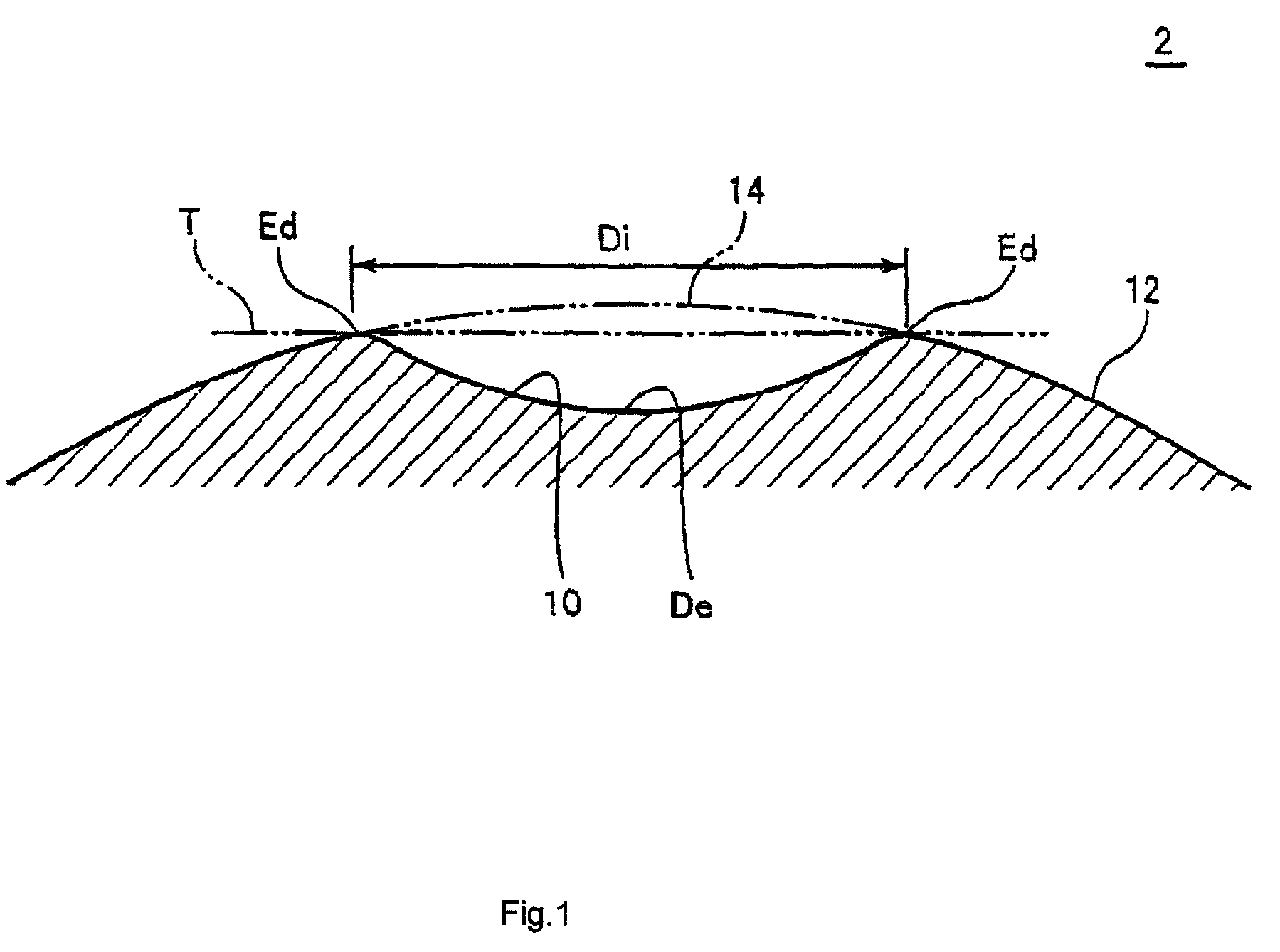

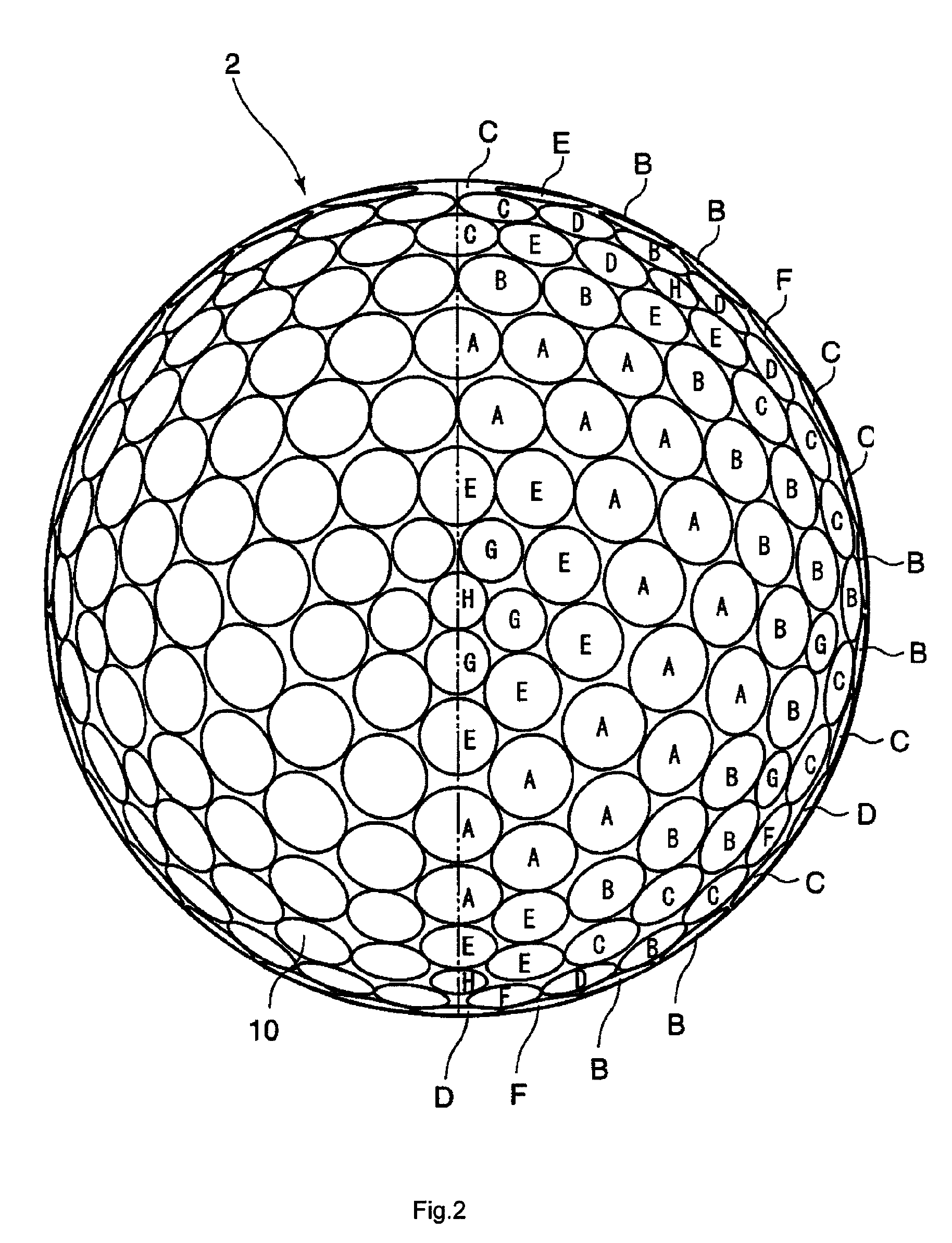

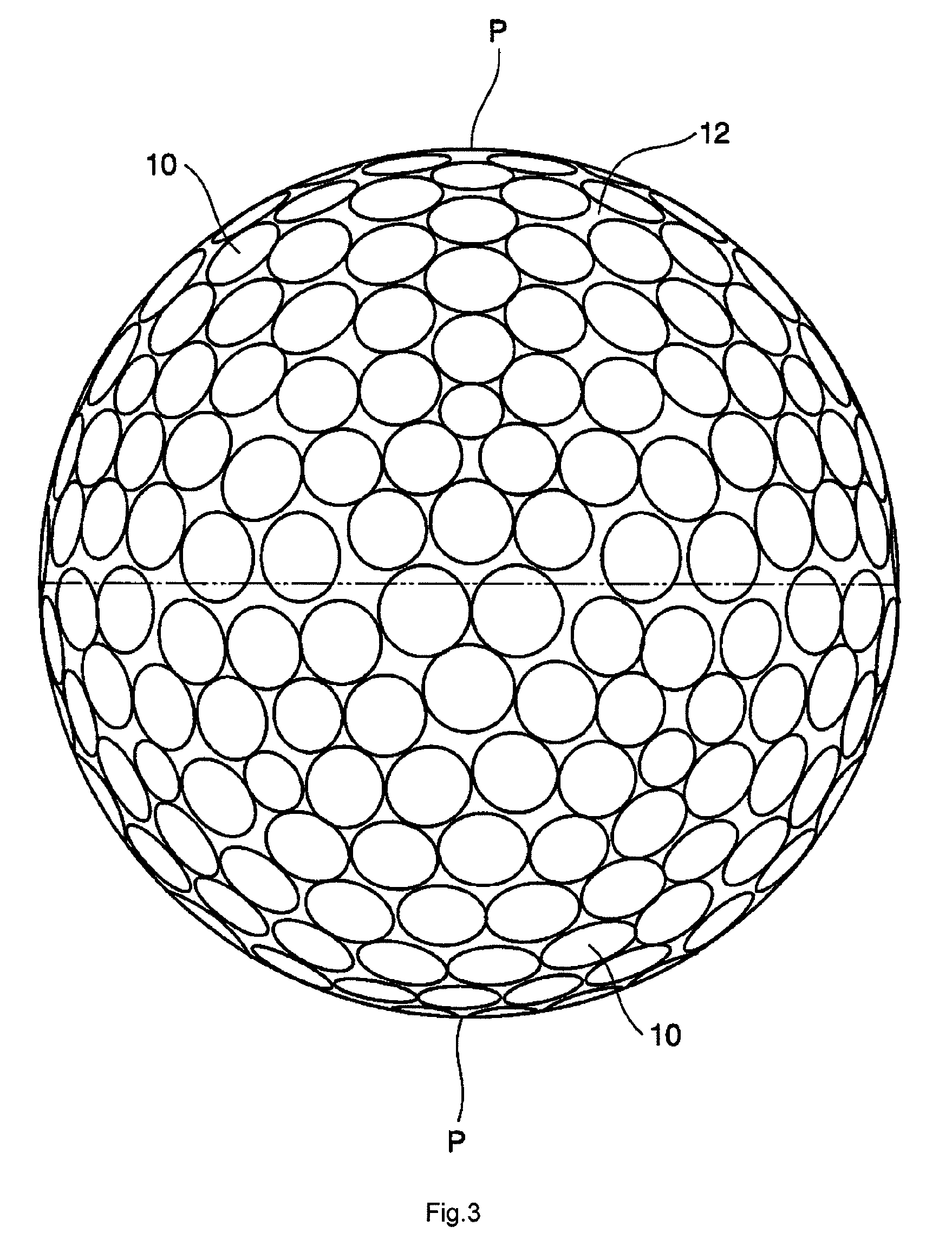

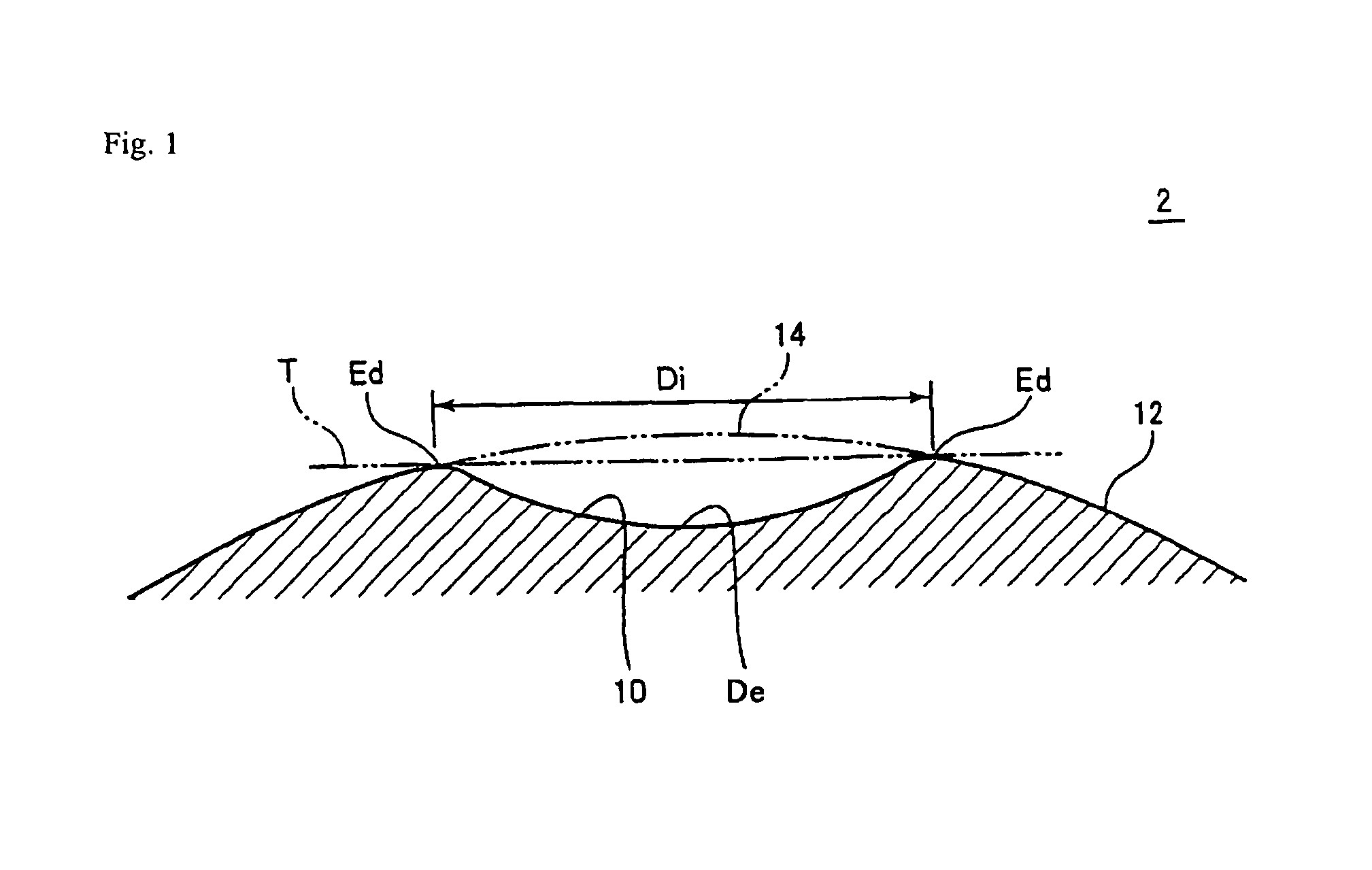

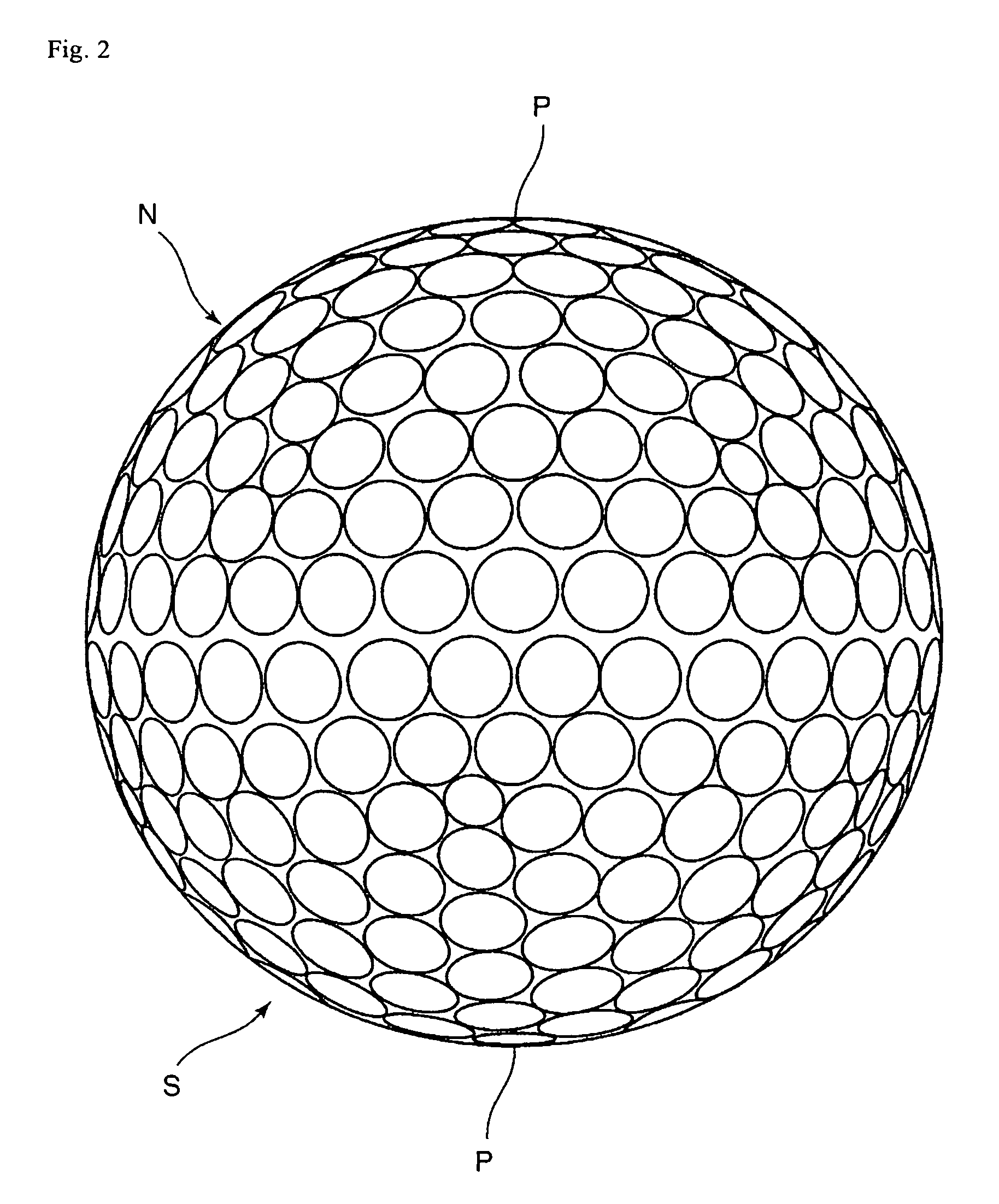

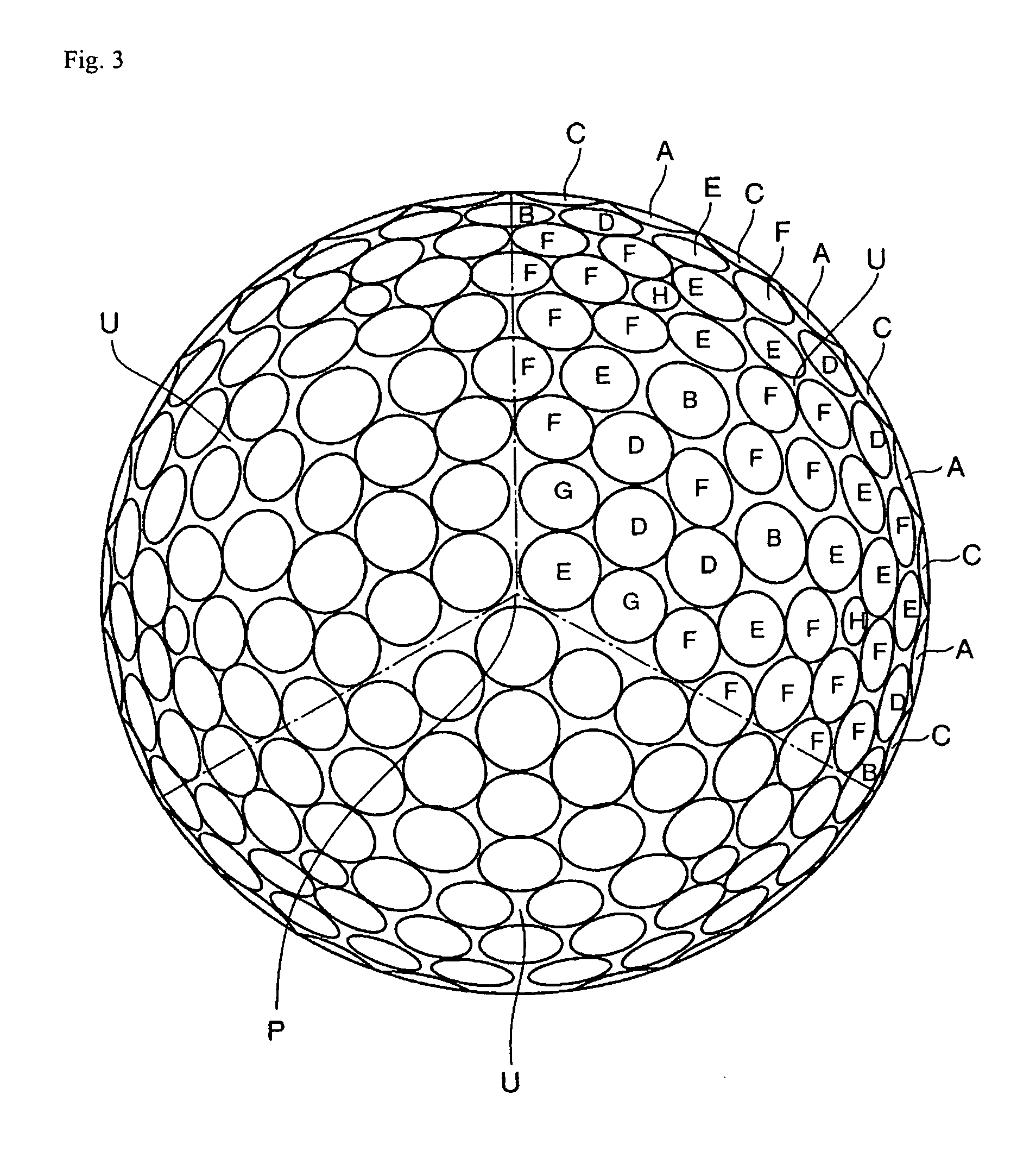

Three-piece solid golf ball

InactiveUS20050181892A1Adequate spin performanceGood flying performanceGolf ballsSolid ballsThermoplastic polyurethaneHardness

A three-piece solid golf ball having a solid core, an intermediate layer enclosing the solid core, and a cover layer enclosing the intermediate layer and having a large number of dimples formed in its surface, characterized in that the core deforms as much as 2.6 to 3.2 mm under a load which changes from 10 kg to 130 kg, the cover layer is formed mainly from thermoplastic polyurethane such that it has a lower hardness than the intermediate layer, a surface hardness of the cover layer being 58 to 64 in terms of Shore D hardness, with the difference in hardness between the cover layer and the intermediate layer being 4 to 10 in terms of Shore D hardness, the intermediate layer and the cover layer have a total thickness of 2.2 to 3.0 mm, the cover layer has a thickness of 0.8 to 1.3 mm, and the dimples have at least four different diameters and / or depths, with the average depth being 0.125 to 0.150 mm, and amount to 250 to 390 in all. The three-piece solid golf ball exhibits adequate spin performance by iron shot and approach shot. It also exhibits good flying performance.

Owner:BRIDGESTONE SPORTS

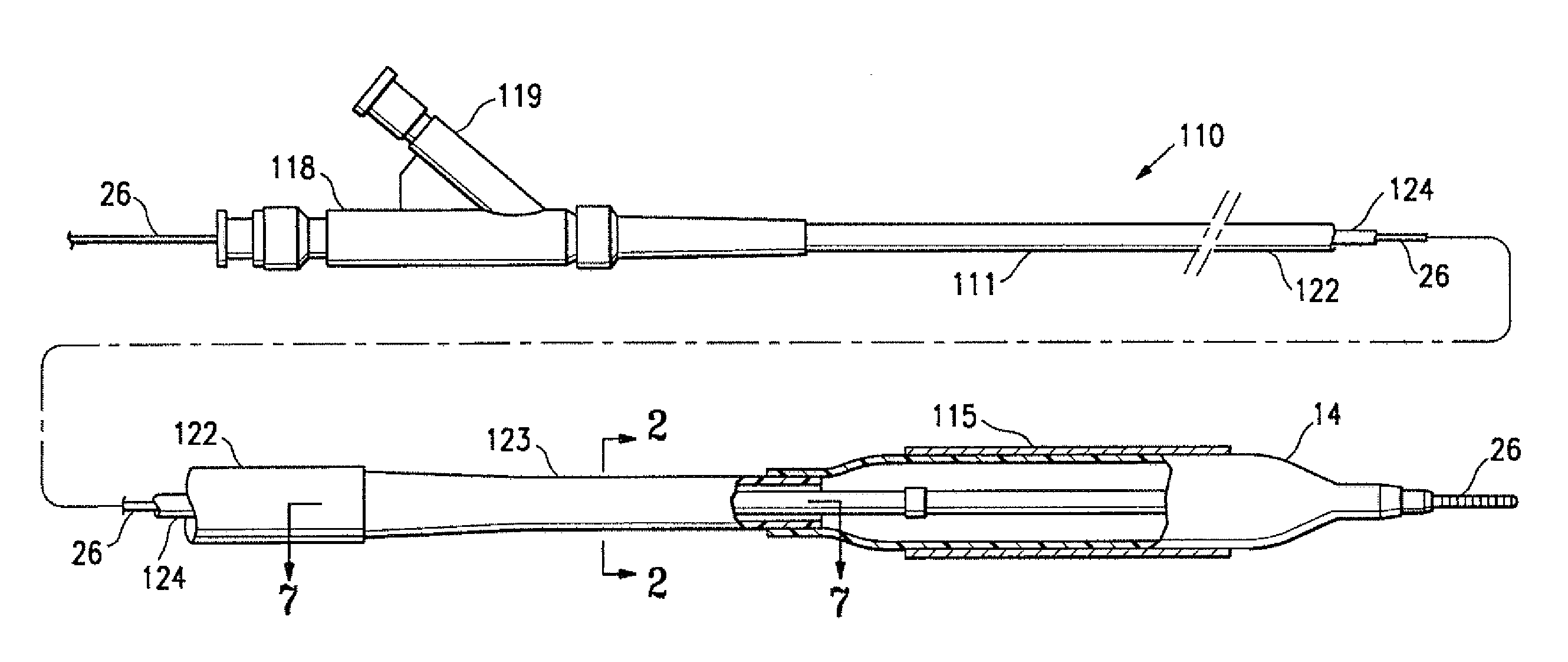

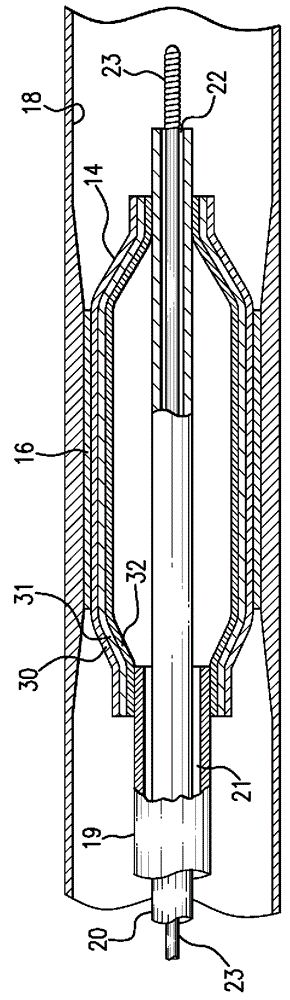

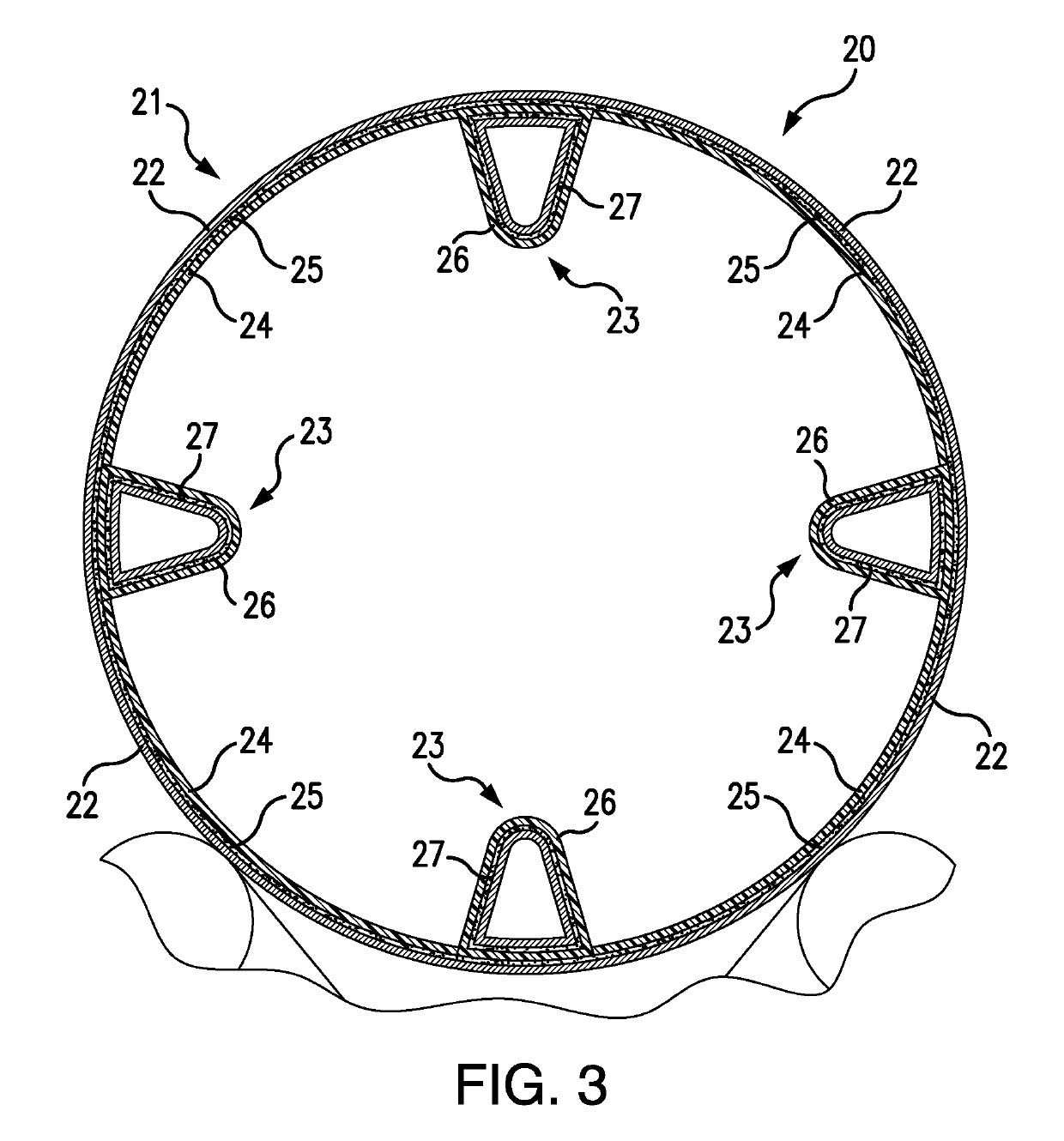

Multilayer balloon for a catheter

Multilayer balloon for a catheter comprises a first layer made of a first polymer material having a first Shore durometer hardness, a second layer made of a second polymer material having a second Shore durometer hardness greater than the first Shore durometer hardness, wherein the second layer is an inner layer relative to the first layer, and a third layer made of a third polymer material having a third Shore durometer hardness less the first Shore durometer hardness, wherein the third layer is an inner layer relative to the second layer. Method of making a multilayer balloon for a catheter and a balloon catheter are also provided.

Owner:ABBOTT CARDIOVASCULAR

Golf ball

An object of the present invention is to provide a golf ball comprising a core consisting of a center and at least one intermediate layer covering the center, and a cover covering the core, wherein the cover is made from a cover composition containing, as a resin component, a thermoplastic polyurethane (A) and a polyisocyanate mixture (B) in which a urethane prepolymer (b-1) having at least two isocyanate groups is dispersed in a thermoplastic resin (b-2) which does not substantially react with an isocyanate group; and wherein the cover composition has a slab hardness of more than 60 and not more than 75 in Shore D hardness, and at least one piece or one layer of the intermediate layer is formed from a low hardness intermediate layer composition which has a slab hardness of 40 or less in Shore D hardness.

Owner:SUMITOMO RUBBER IND LTD

Transparent rubber sole material and preparation method thereof

The invention discloses a transparent rubber sole material, comprising the following components in parts by weight: 45-55 parts of butadiene styrene rubber, 45-55 parts of butadiene rubber, 3-5 parts of zinc carbonate, 0.3-0.6 part of accelerant M, 1-2 parts of rubber accelerant DM, 0.3-0.6 part of microcrystalline wax, 1-2 parts of stearic acid, 1-2 parts of anti-aging agent SP, 45-55 parts of white carbon black, 13-18 parts of naphthenic oil and 1-3 parts of sulfur. The material has high transparency, the elongation at break of the material is above 560%, and the toughness of the material is good; and the strength of the material is above 13MPa, the specific weight is about 1.18, the abrasion is 0.45, and the hardness measured by a Shore durometer is about 65 DEG.

Owner:NANJING DONGYA RUBBER & PLASTICS

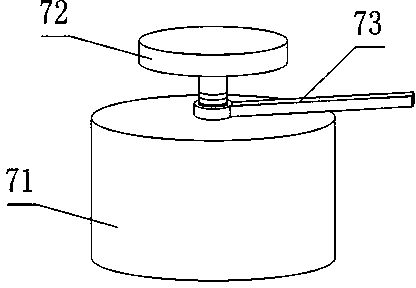

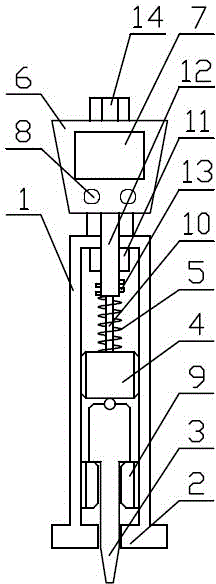

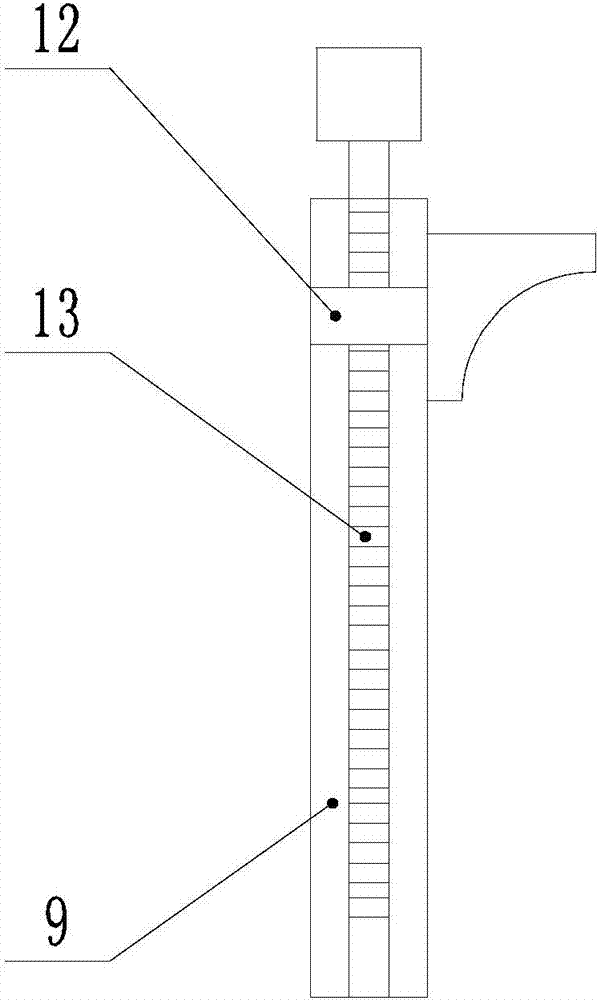

Novel shore durometer

InactiveCN104913991AReduce the impactHigh measurement accuracyInvestigating material hardnessShore durometerEngineering

The invention provides a novel shore durometer which comprises a housing, an indenter, an adjusting screw rod and the like, wherein an indenter fixing ring is mounted on an internal wall of the housing; the indenter is clamped at the upper end of the indenter fixing ring; a slide block is arranged at the upper end of the indenter; an electronic extension measuring scale is arranged at the upper end of the slide block; the adjusting screw rod is arranged at the upper end of the electronic extension measuring scale; a spring is arranged on the outer side of the electronic extension measuring scale; a mounting nut is arranged on the outer side of the adjusting screw rod; a control panel is arranged at the upper end of the housing; and a display screen and control buttons are arranged on the control panel. According to the durometer, the indenter fixing ring is added, the length of the indenter extending out of an indenter foot can be adjusted, and the measuring precision is improved; the adjusting screw rod is further added, a compression deformation degree of the spring can be changed by adjusting the height of the adjusting screw rod; and the length of the indenter and the deformation degree of the spring are adjusted as required, so that a precise hardness value is obtained.

Owner:TIANJIN LIANJIE PLASTIC PROD

Detection method for curing degree of glue

InactiveCN108333068AAvoid it happening againPracticalInvestigating material hardnessSemiconductor packageHardness

The invention provides a detection method for the curing degree of glue. The method aims to overcome the problem that detection of the semi-curing degree of glue in semiconductor packaging relies on naked eyes and experience in the prior art. The detection method comprises the following steps: providing an A type Shore durometer and a semi-cured glue sample; placing the semi-cured glue sample ontoa firm plane; allowing the indenter of the A type Shore durometer to move to the edge; parallely and downwardly pressing pressure feet onto the surface of the semi-cured glue sample; vertically pressing the indenter into the sample; immediately carrying out reading after completion of downward pressing; and carrying out measurement according to the hardening degree of glue so as to obtain hardness values and determining whether the sample has hidden quality troubles in reference to grades corresponding to different hardness ranges.

Owner:HITECH SEMICON WUXI

Golf ball

Owner:SUMITOMO RUBBER IND LTD

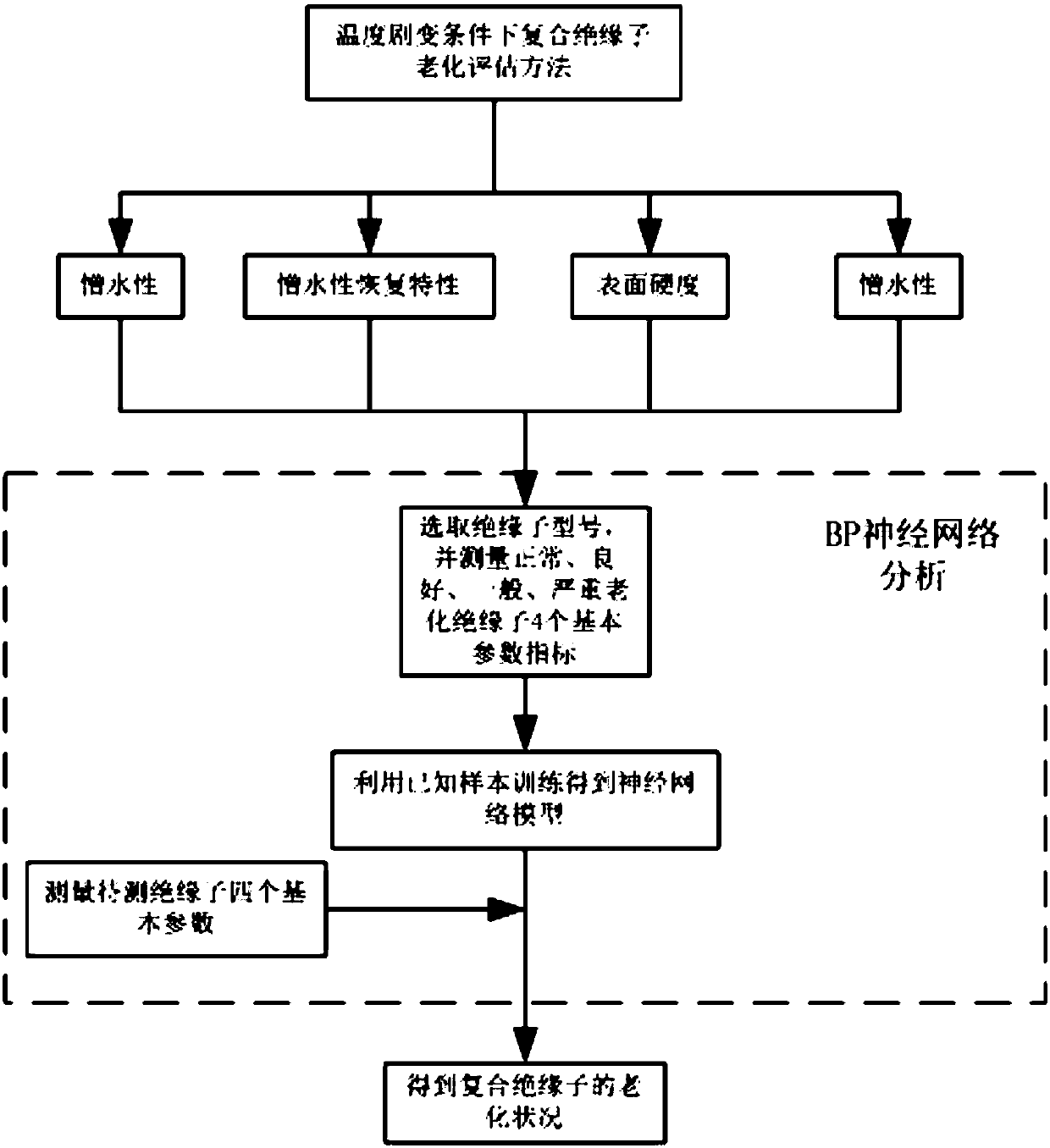

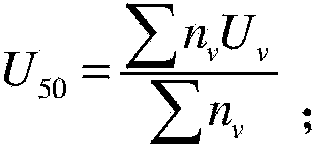

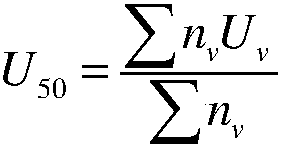

Method for aging evaluation of composite insulator on condition of rapid temperature change

InactiveCN107942156AAging state is accurate and realEasy to operateTesting dielectric strengthEnvironmental/reliability testsComposite insulatorsHigh pressure

The invention relates to a method for aging evaluation of a composite insulator on condition of rapid temperature change. The method comprises: step one, a hydrophobic level of the upper surface of ahigh-voltage-side shed of a composite insulator is measured by using an HC water-spraying rank method and hydrophobic information is recorded; step two, a to-be-tested composite insulator is boiled and is wiped with absolute ethyl alcohol, so that the hydrophobic property is eliminated completely; and then the processed composite insulator is placed in a dust-free environment and time of restoration of the hydrophobic level of the composite insulator to the level before boiling is measured; and step three, a shore hardness value of the edge of the high-voltage-side shed surface of the composite insulator is measured by using a Shore durometer, wherein five points arranged at equal intervals are selected during the measurement and then the average value of the hardness values of the five points is calculated. According to the invention, the insulator aging state in an area with the special weather condition having the large temperature difference is evaluated by extracting typical feature parameters, so that the aging state of the composite insulator is reflected accurately and truly. The method has the certain guidance significance in composite insulator usage.

Owner:STATE GRID CORP OF CHINA +1

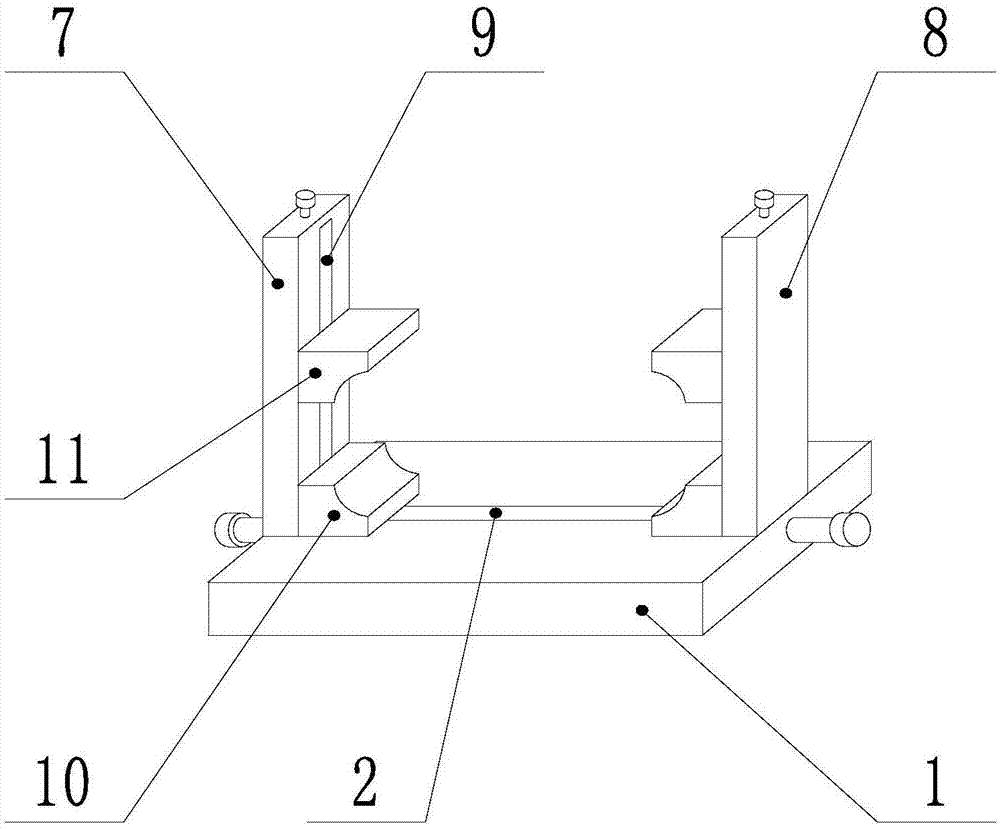

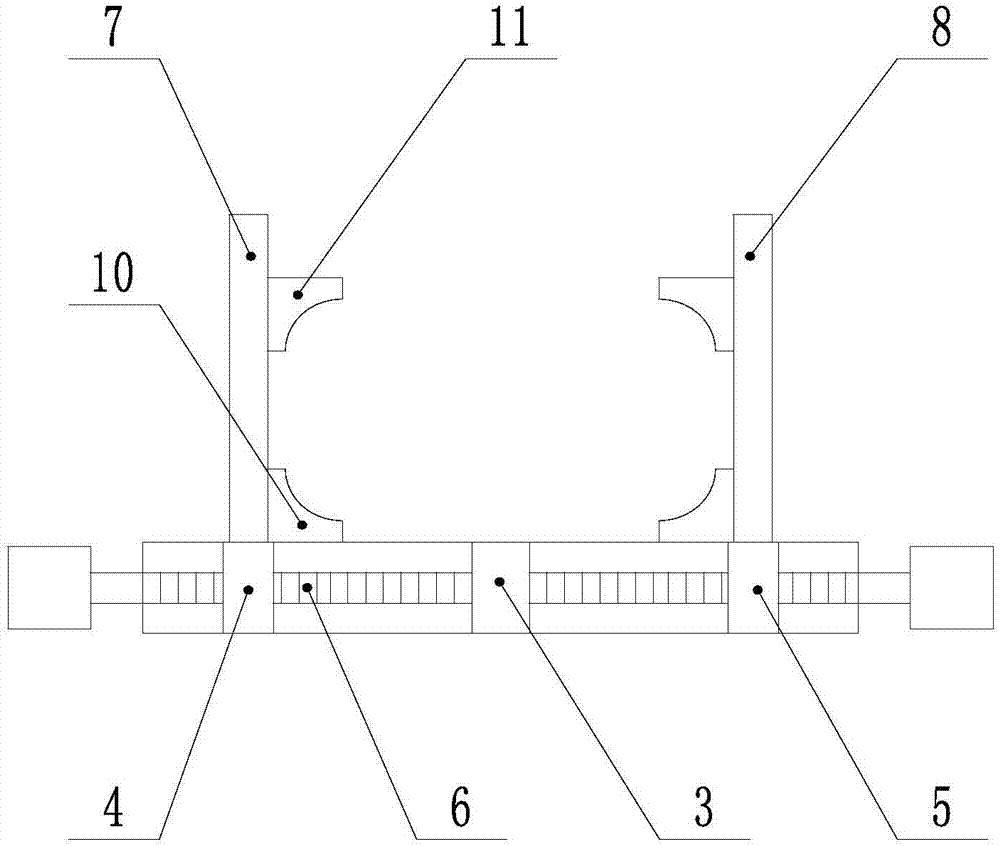

Rack device for Shore hardness tester

The invention discloses a rack device for a Shore hardness tester. The rack device comprises a base, a material platform and a vertically arranged fixing base, wherein the material platform is arranged on the base; the lower end of the fixing base is fixedly connected with the base; a hardness tester groove in the vertical direction is also formed in the fixing base and is formed above the material platform; a spline shaft with an axial direction in the horizontal direction is also arranged on the fixing base, protrudes relative to the bottom surface of the hardness tester groove and can rotate around the axis of the spline shaft; at least three leveling bolts with axis directions in the vertical direction are also arranged on the base and are not on the same straight line. The rack device has a simple structure, achieves simplicity in adjustment of the height of the HS tester, and is beneficial for the measurement accuracy of the HS tester.

Owner:API ZC PRECISION INSTUMENT CO LTD

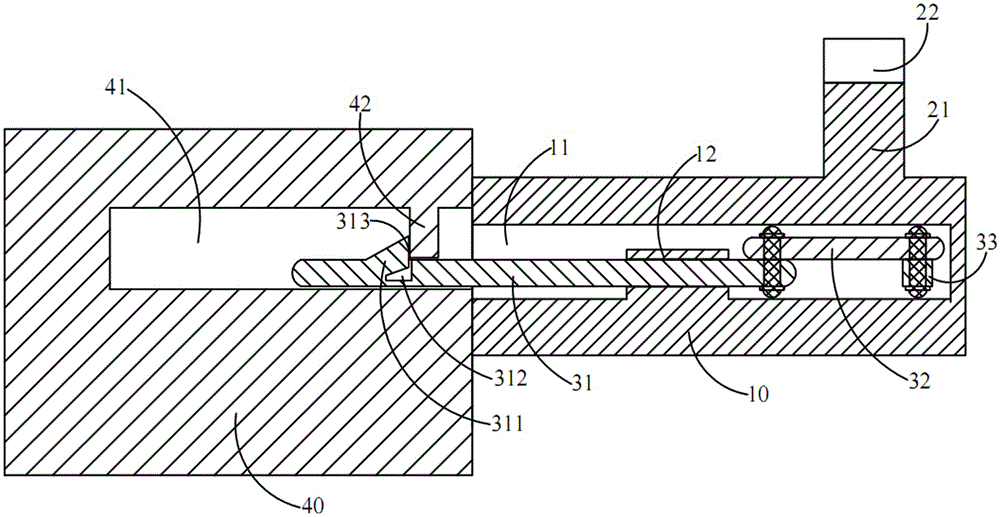

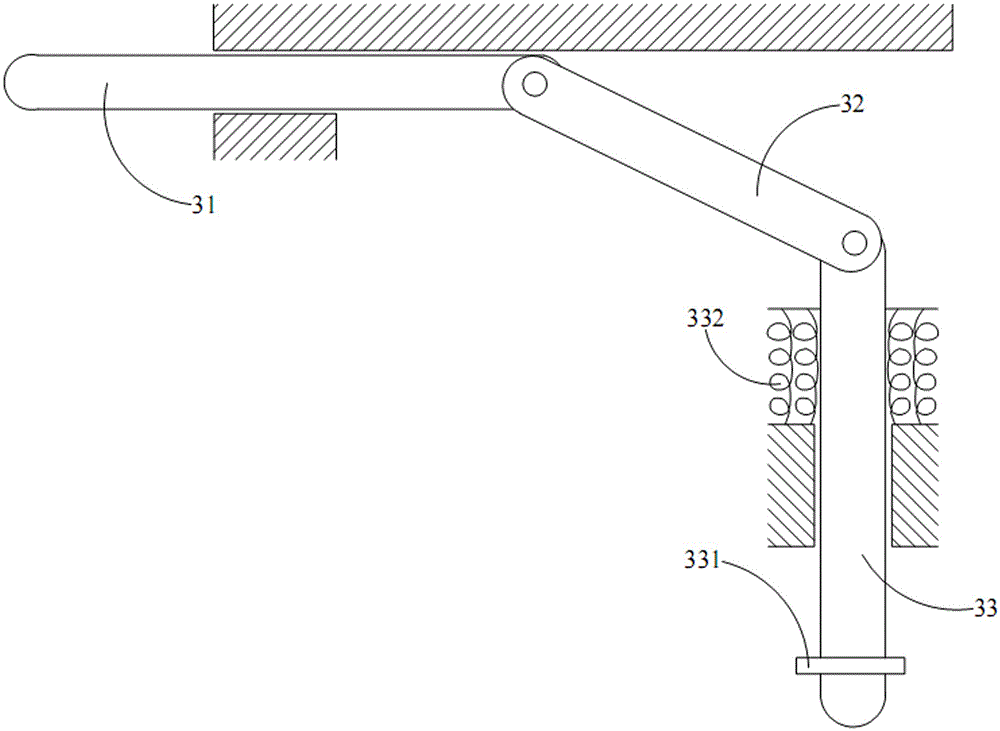

Hardness testing device beneficial to test precision

ActiveCN105067462APlace stableThe test result is accurateInvestigating material hardnessShore durometerTester device

The invention discloses a hardness testing device beneficial to test precision. The hardness testing device comprises a base, a stand column fixedly connected with the base, a shore hardness tester clamped on the stand column, and an external insertion piece fixedly connected with the base. A fixing hole with a clamping block is formed in the side wall of the base. The external insertion piece comprises a base body with a cavity, a fixing piece and an insertion connection assembly. A boss protrudes and extends out of the cavity. The fixing piece comprises a column body fixedly connected with the base body, and an arc-shaped fixing block. The arc-shaped fixing block is used for fixing a columnar workpiece. The insertion connection assembly comprises an insertion rod, a connection rod and a push rod. One end of the connection rod is hinged to the insertion rod, and the other end of the connection rod is hinged to the push rod. The insertion rod penetrates through the boss. A containing groove is formed in the end, away from the connection rod, of the insertion rod. One end of an elastic protruding strip is fixedly connected with the side wall of the containing groove, and the other end of the elastic protruding strip is supported and held by the clamping block. The push rod and the insertion rod are arranged in a perpendicular mode. The push rod can slide relative to the base body. The hardness testing device is suitable for hardness detection of the columnar workpiece.

Owner:API ZC PRECISION INSTUMENT CO LTD

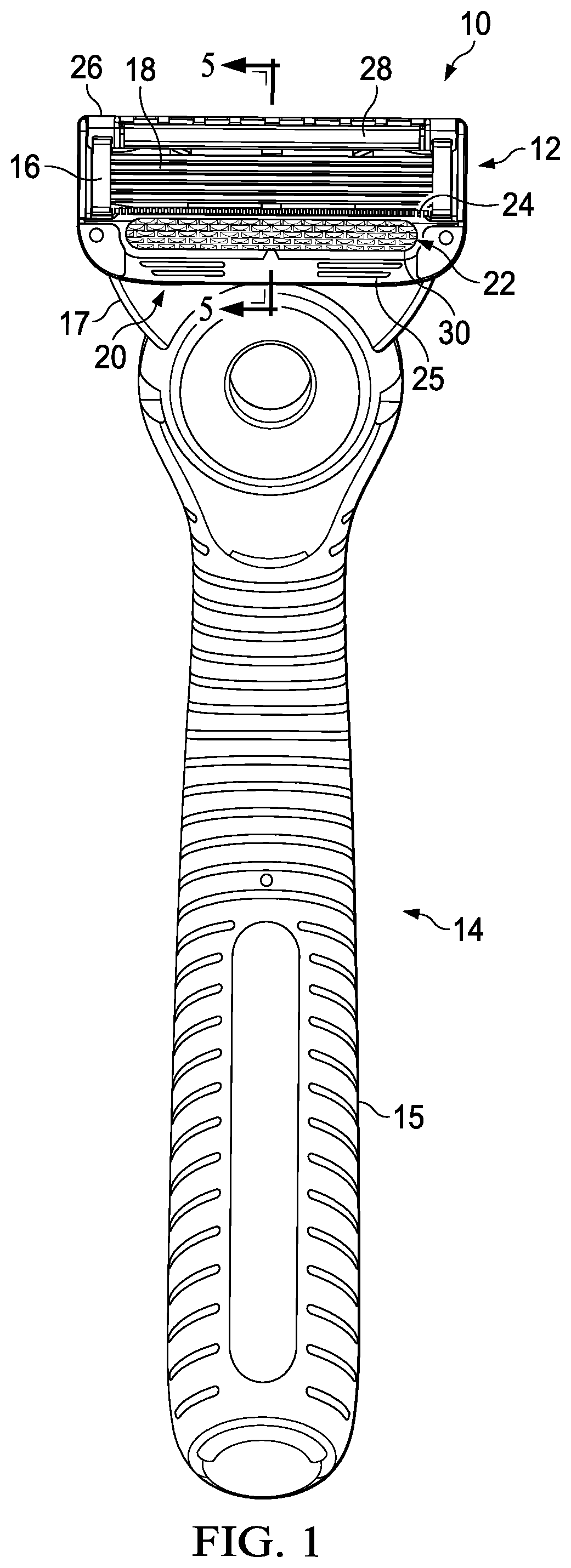

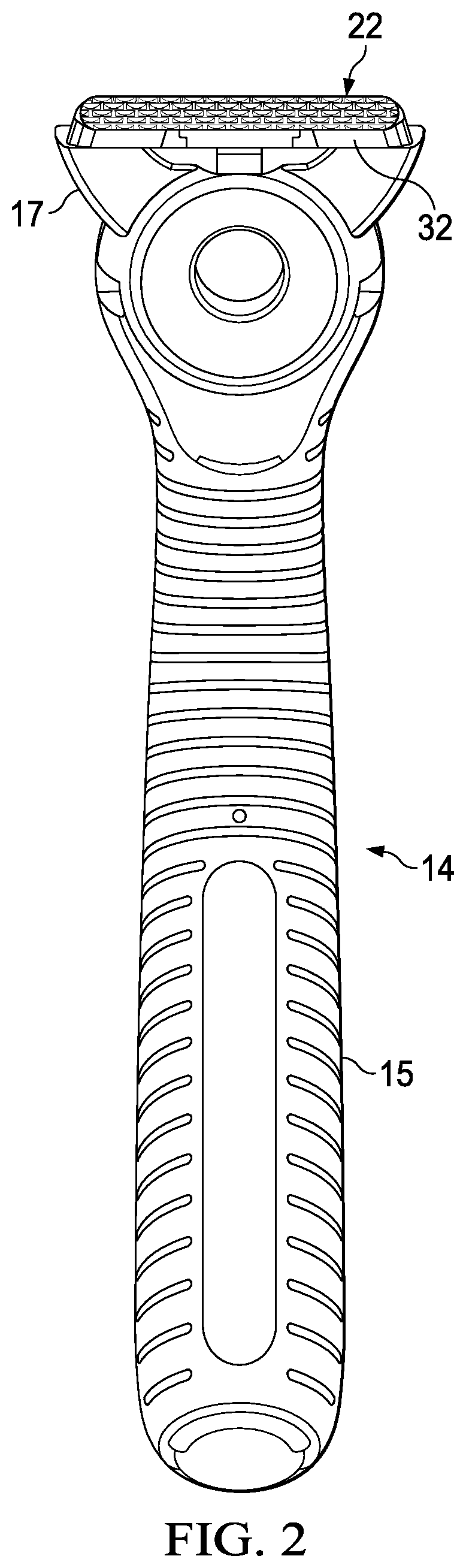

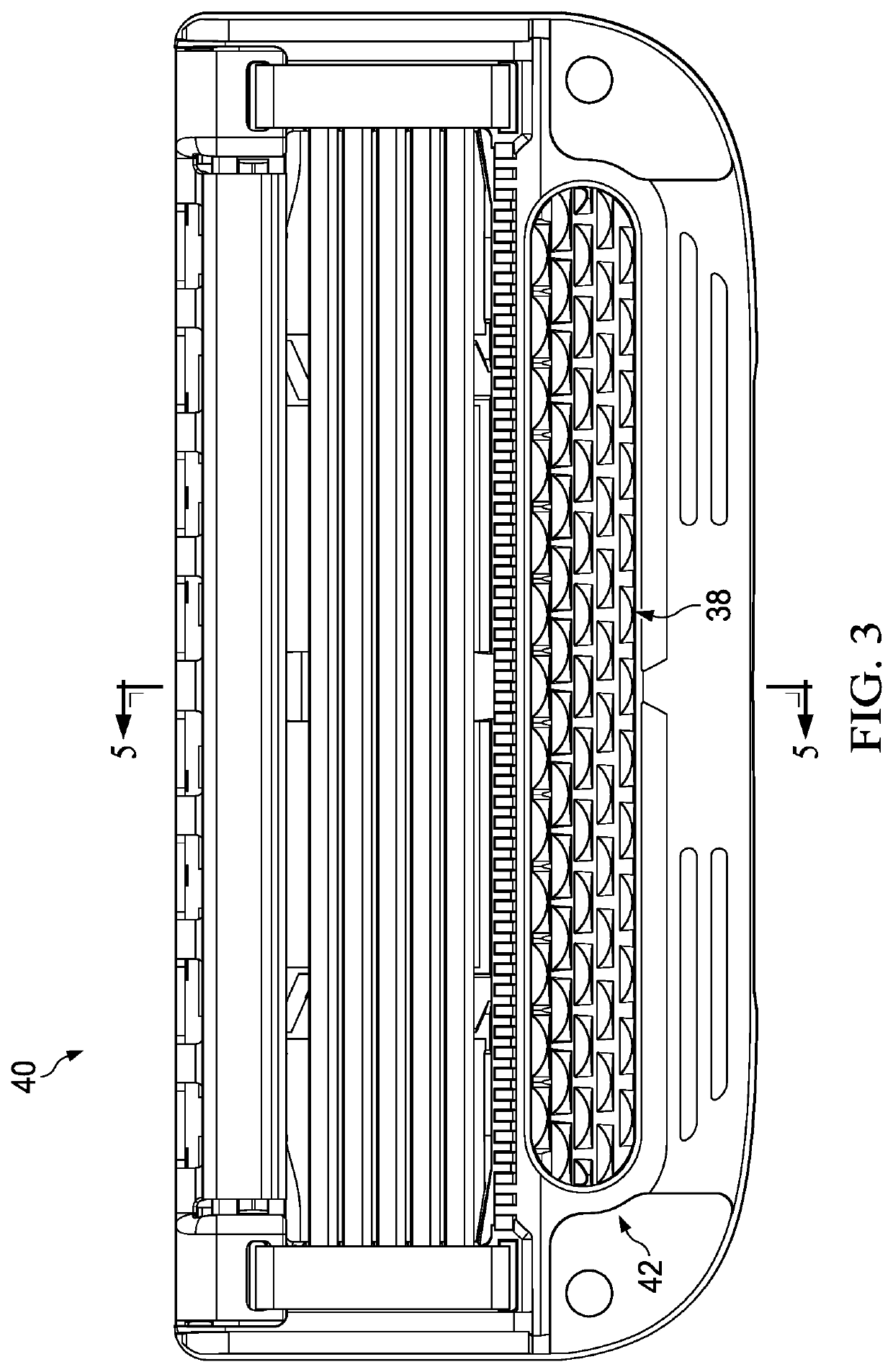

Exfoliation bar for shaving razor

An exfoliation bar for a shaving razor with a skin contacting footprint area of at least 30 mm2 and comprising a material having a Shore A durometer greater than 50. The exfoliation bar has a plurality of skin protrusion elements with a tip having radius of 0.02 mm to 0.25 mm positioned within the skin contacting footprint area. The skin protrusion elements have a leading face that intersects an average tip plane at an angle of 80 degrees to 145 degrees. A volume isolated by a construction plane 0.1 mm below the tip of the skin protrusion elements divided by the skin contacting footprint area is 0.003 mm3 to 0.04 mm3 per mm2 of footprint area.

Owner:THE GILLETTE CO

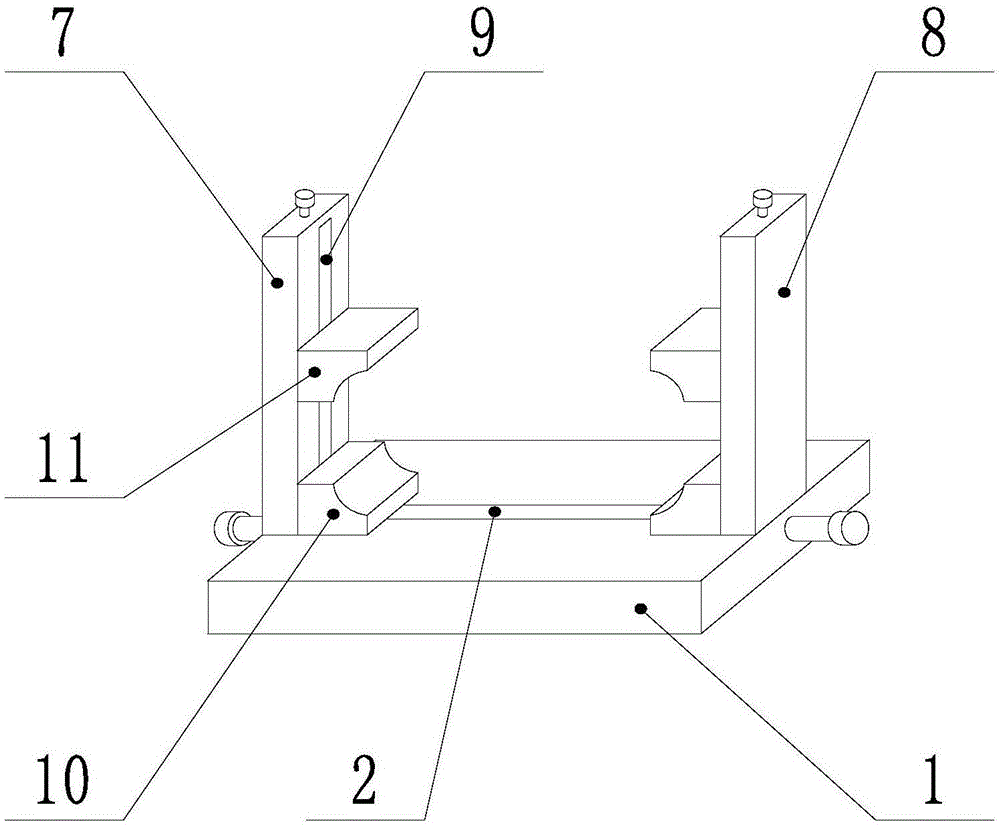

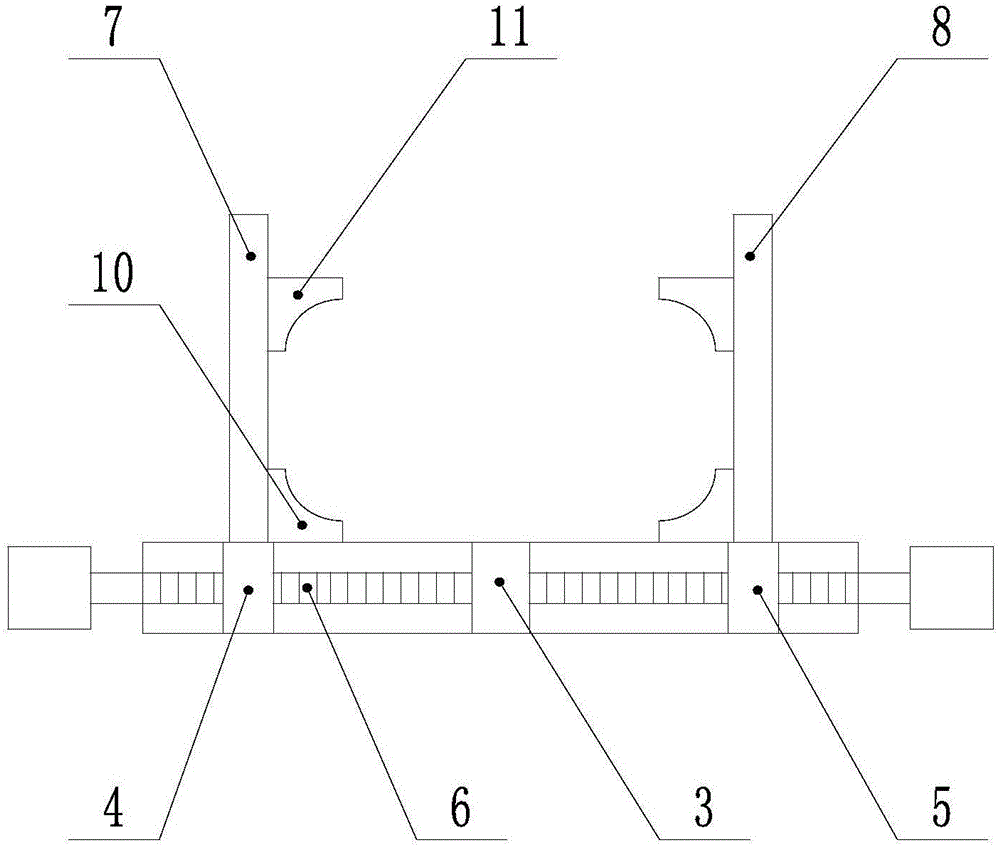

Auxiliary fixing device for Shaw hardness tester rack with adjustable size

InactiveCN107336157AMeasurement stabilityReduce measurement errorInvestigating material hardnessClampsHardnessEngineering

The invention discloses an auxiliary fixing device for a Shaw hardness tester rack with the adjustable size. The auxiliary fixing device comprises a base. A guiding groove is formed in the base. A stop block is arranged in the guiding groove. A left sliding block and a right sliding block are arranged on the two sides of the stop block. A first screw is in screw joint with the left sliding block and the right sliding block. The left sliding block is provided with a left adjusting plate, and the right sliding block is provided with a right adjusting plate. Adjusting grooves are formed in the opposite sides of the first adjusting plate and the right adjusting plate. A fixed supporting part is arranged at one end of each adjusting groove, a movable supporting part is arranged at the other end of each adjusting groove, and the movable supporting parts can move along the adjusting grooves. According to the auxiliary fixing device, measurement can be stably conducted, the measurement errors are reduced, the auxiliary fixing device is suitable for columnar components different in size, and the beneficial effects that reliability is good, and the application range is wide are achieved.

Owner:API ZC PRECISION INSTUMENT CO LTD

Shore durometer for detecting plastic hardness

InactiveCN105571964AExtended service lifeRich practical functionsInvestigating material hardnessHardnessEngineering

The invention provides a multifunctional shore durometer for detecting the plastic hardness. The shore durometer comprises a detection body, a base, a side arm, a press needle installing block, a sensor and the like, wherein a measuring table is arranged at the upper end of the base, the side arm is installed at the upper end of the base, a graduation ruler is arranged on the side arm, a lifting slide block is installed on the side arm, a detection body is installed at the lower end of the lifting slide block, an installing inner cylinder is arranged inside the detection body, a press foot is arranged at the lower end of the installing inner cylinder, the press needle installing block is installed inside the installing inner cylinder, and a press needle is installed at the lower end of the press needle installing block through a sensor. The detection body is configured to include the installing inner cylinder and a protecting outer cylinder which can move relatively, the protecting outer cylinder can protect the press needle, bump and abrasion suffered by the press needle in the using process are greatly decreased, and accordingly the service life of the shore durometer is prolonged.

Owner:天津思迈德高分子科技股份有限公司

Thermoplastic elastomer composition

The present invention provides a thermoplastic elastomer composition containing: (A-1) a crosslinked ethylene copolymer containing monomer units derived from ethylene and monomer units derived from propylene and / or α-olefins having 4 to 10 carbon atoms, (B) a propylene polymer containing monomer units derived from propylene and having a content of the monomer units derived from propylene of greater than 50% by weight, and (E) an inorganic filler having an average particle diameter of less than 1.0 μm. In the thermoplastic elastomer composition, the content of the component (E) is 10% by weight to 23% by weight and the Shore A durometer hardness of the thermoplastic elastomer composition is 30 to 99. Molded articles formed of the thermoplastic elastomer composition are superior in adhesiveness to thermoplastic elastomer molded articles.

Owner:SUMITOMO CHEM CO LTD

Cylindrical part fixing method suitable for measurement of Shaw hardness tester

InactiveCN107525714AMeasurement stabilityReduce measurement errorStrength propertiesEngineeringHardness

The invention discloses a cylindrical part fixing method suitable for the measurement of a Shaw hardness tester. The method comprises the following steps: S1: arranging a base on a Shaw hardness tester stand; S2: arranging a left slide block and a right slide block at two sides of a stop block, wherein both the left slide block and the right slide block can move along a guide groove; S3: installing a left adjusting plate on the left slide block, and installing a right adjusting plate on the right slide block; S4: installing a fixed supporting portion on one end, close to the base, of an adjusting groove, and installing a movable supporting portion on the other end; S5: arranging a component to be measured on two opposite fixed supporting portions, rotating a screw I at two sides of the stop block, and adjusting a distance between the two fixed supporting portion; and S6: enabling the movable supporting portion to slide in the adjusting groove, adjusting the movable supporting portion at an appropriate height, pressing and fixing the component to be measured, and performing the measurement. By adopting the method, the measurement can be stably performed, the measurement error can be reduced, and the method is suitable for cylindrical components of different sizes and has the advantages of good reliability and wide application range.

Owner:API ZC PRECISION INSTUMENT CO LTD

Sanding pad

Sanding pads are disclosed. A sanding pad has at least about 1 / 32 inch thickness, having one top flat surface and an opposite flat bottom surface. The top and bottom surfaces are capable of providing attachment for an abrasive material, such as a pressure adhesive sand paper. The sanding pad is formed of various geometric shapes and made from an expanded PVT material which has a Shore D durometer hardness value between 30 and 60. The sanding pad comes in a kit that includes several sanding pads, each of a different shape and situated purpose.

Owner:JOHNNY BLOX LLC

Device and method for removing fur and hair from fabrics

Owner:BAJA UNLIMITED LLC

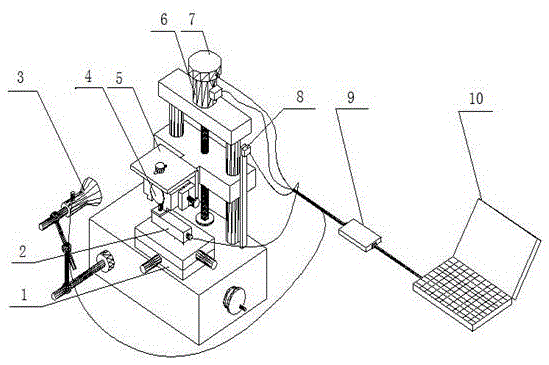

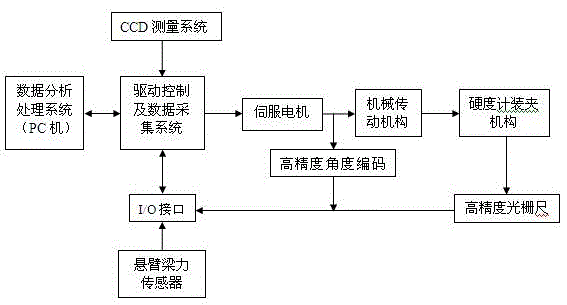

Full-automatic detection device of Shore durometer and method thereof

ActiveCN105651640AQuick installationEasy to installInvestigating material hardnessLoop controlControl system

The invention discloses a full-automatic detection device of a Shore durometer and a method thereof. The device comprises a working platform, a force measurement mechanism, a CCD measurement system, a detected Shore durometer, a durometer clamping mechanism, a servo motor, a drive control and data acquisition system and a PC machine, wherein the PC machine drives the servo motor to drive the durometer clamping mechanism to move down via a screw rod; meanwhile, output signals of the force measurement mechanism are also simultaneously transmitted to the drive control and data acquisition system, so that the closed-loop control of the whole action is implemented. The device is capable of quickly and reliably mounting various durometers different in shape and size; a servo motor closed-loop control system can be used for slowly enabling a pressing pin of the detected Shore durometer to act on the force measurement mechanism; the PC machine is used for collecting the output signals of a force sensor; the output signals of the force sensor are used as standards; the CCD measurement system is used for automatically collecting indicating values of the Shore durometer and applying measurement results to calculation of error of the indicating values, so that the full-automatic detection of the Shore durometer is implemented.

Owner:CHANGZHOU INST OF MEASUREMENT & TESTING TECH

Golf ball

The object of the present invention is to provide a golf ball that satisfies both of the flight distance at the shot with a driver, a long iron, and a middle iron and the controllability at the approach shot with a short iron and is also excellent in the abrasion resistance of the cover. The present invention provides a golf ball comprising a core consisting of a center and at least one intermediate layer covering the center, and a cover covering the core, wherein the cover is formed from a cover composition containing, as a resin component, a thermoplastic polyurethane (A) and a polyisocyanate mixture (B) in which a urethane prepolymer (b-1) having at least two isocyanate groups or a polyisocyanate (b-2) having at least three isocyanate groups is dispersed in a thermoplastic resin (b-3) which does not substantially react with an isocyanate group; and wherein the cover composition has a slab hardness of 60 or less in Shore D hardness, and the core has a hardness difference (Hs−Ho) between a surface hardness Hs and a center hardness Ho of from 15 to 50 in Shore D hardness.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com