A kind of toilet seat cushion and vacuum foaming preparation process

A preparation process and vacuuming technology, which is applied in the field of toilet seat cushions, can solve the problems such as poor waterproofing of seat cushions, and achieve a good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Attached below Figure 1-12 The specific implementation manner of the present invention will be described in further detail.

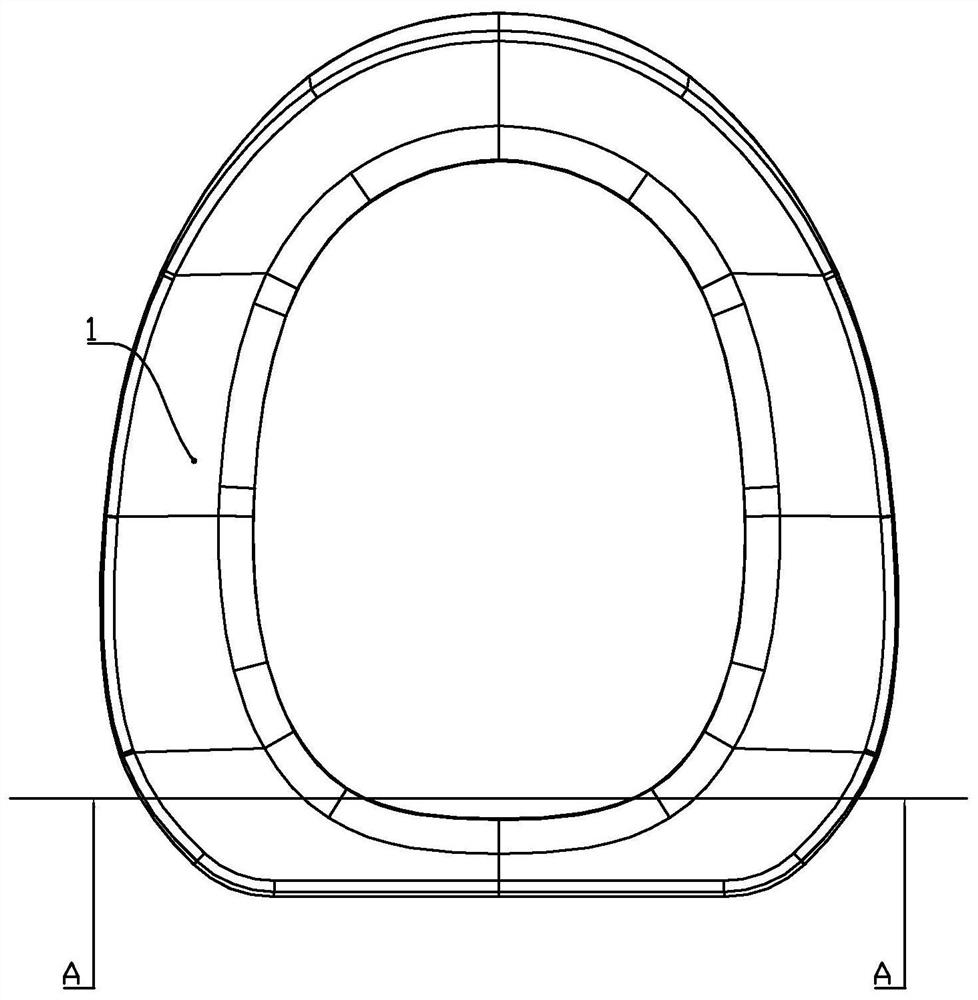

[0045] A toilet seat.

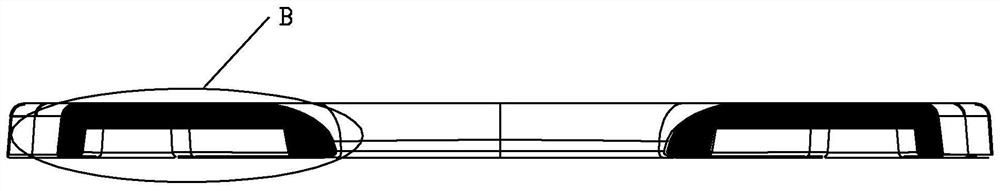

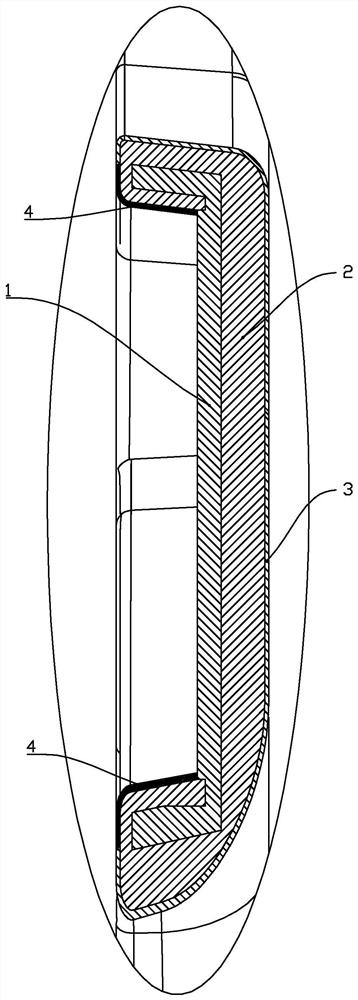

[0046] Such as image 3 As shown, the outer surface of the cushion support 1 is covered with a half polyurethane and half polyether foamed plastic 2, and the outer surface of the half polyurethane and half polyether foamed plastic 2 is covered with a TPU waterproof film 3, and the TPU waterproof film 3, half The polyurethane semi-polyether foamed plastic 2 and the cushion bracket 1 are combined and integrated, and the TPU waterproof film 3 is coated on the outer surface of the semi-polyurethane semi-polyether foamed plastic 2. The semi-polyurethane The outer surface of the inner side of the semi-polyether foamed plastic 2 is sprayed with waterproof ink 4 .

[0047] Existing patents combine foam and rubber shell, but the present invention integrates the three materials of waterproof membrane, foam and rubber shell throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com