Toy steel ball and preparation method thereof

A technology for steel balls and toys, which is applied to the formulation of toy steel balls and the field of preparation thereof, can solve the problems of easy occurrence of paint peeling, unreasonable raw materials and processes, affecting the aesthetics of toy steel balls, etc., and achieves the effect of solving paint peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

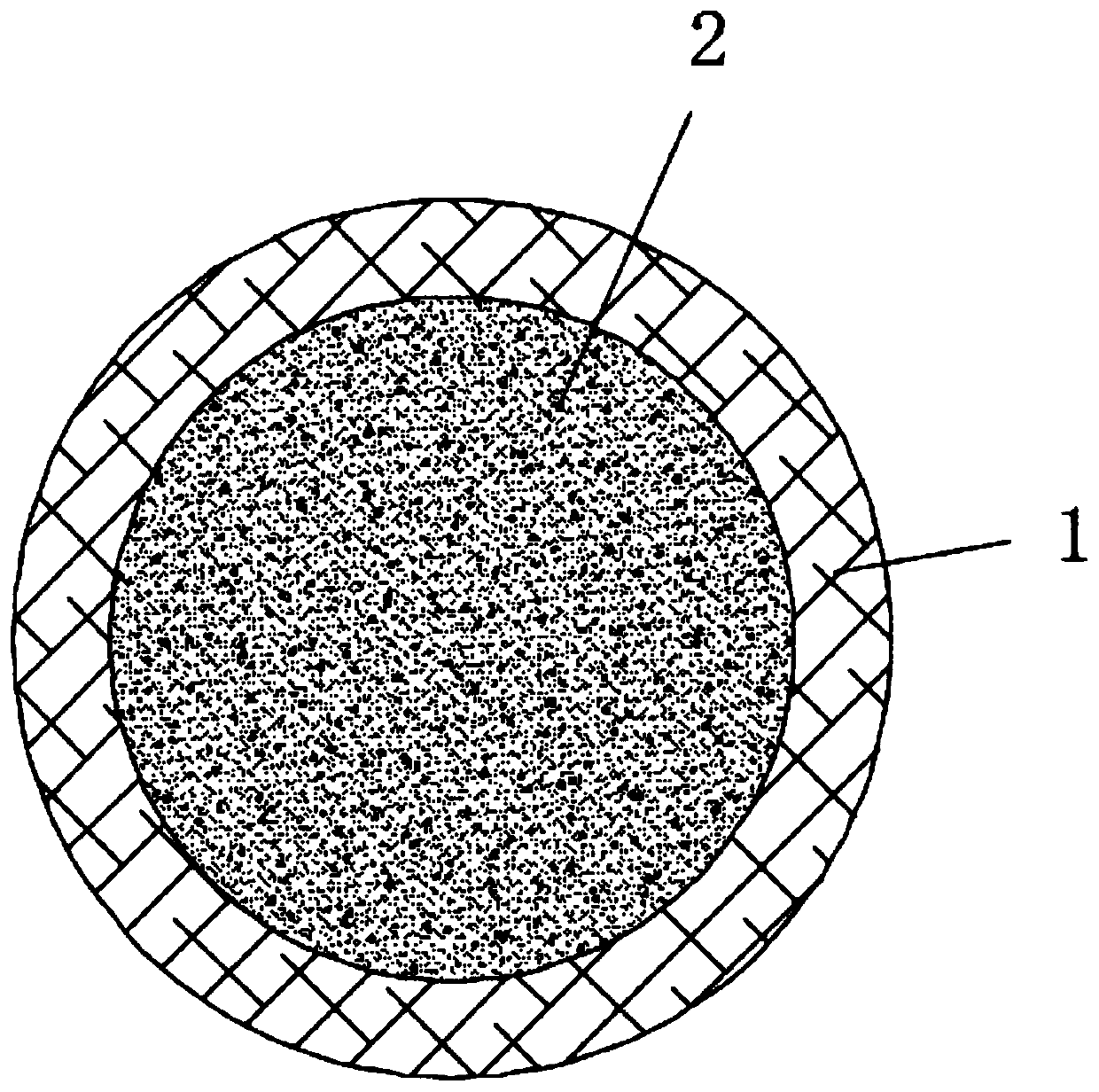

[0031] Embodiment 1 of the present invention provides a toy steel ball and its preparation method, please refer to figure 1 , the toy steel ball comprises a magnetic bead body 2 and a colloid 1 covering the surface of the magnetic bead body 2, and the colloid 1 includes the following components by weight:

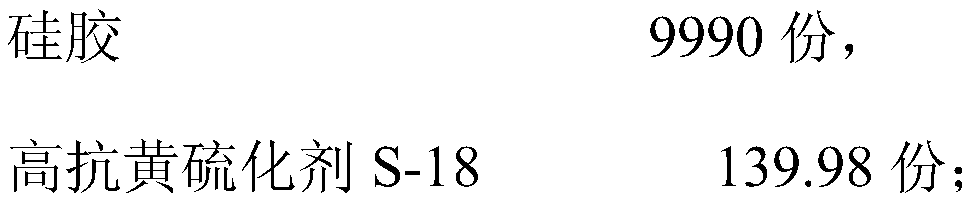

[0032] Silicone 9990 parts,

[0033] High anti-yellowing vulcanizing agent S-18 139.98 parts,

[0034] Silicone masterbatch 93-109 parts.

[0035] The silica gel masterbatch in this embodiment is preferably the following three silica gel masterbatches and parts by weight:

[0036] Color glue 1400 3 parts,

[0037] Color glue 1333 75 parts,

[0038] Color glue 1924 15 parts.

[0039] The type of silica gel in this embodiment is preferably GFE163.

[0040] The preparation method of the toy steel ball includes a mixing preparation method of the colloid 1 and a molding preparation method of the toy steel ball, and the mixing preparation method of the colloid 1 comprises t...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a toy steel ball. The difference between Embodiment 2 and Embodiment 1 is that the colloid 1 includes the following ingredients in parts by weight:

[0059]

[0060] The type of silica gel in this embodiment is preferably GFE163.

[0061] The kneading preparation method and ball molding preparation method of colloid 1 in this embodiment are consistent with those in Embodiment 1, and will not be repeated here.

[0062] The color glue 1400, the color glue 1333 and the color glue 1924 are several color glue combinations selected in this embodiment. In other embodiments, other pigments can also be used as the coloring material for the colloid, which can be selected according to the actual color. It is required to add color gels of different color numbers and mass parts.

[0063] Color glue is added to control the color of the ball, no need to paint, to solve the problem of paint falling off the ball, and at the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com