Acrylic copolymer emulsion, water-based ink and preparation method thereof

A technology of copolymerization emulsion and water-based ink, which is applied in the direction of ink, application, household utensils, etc., to achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

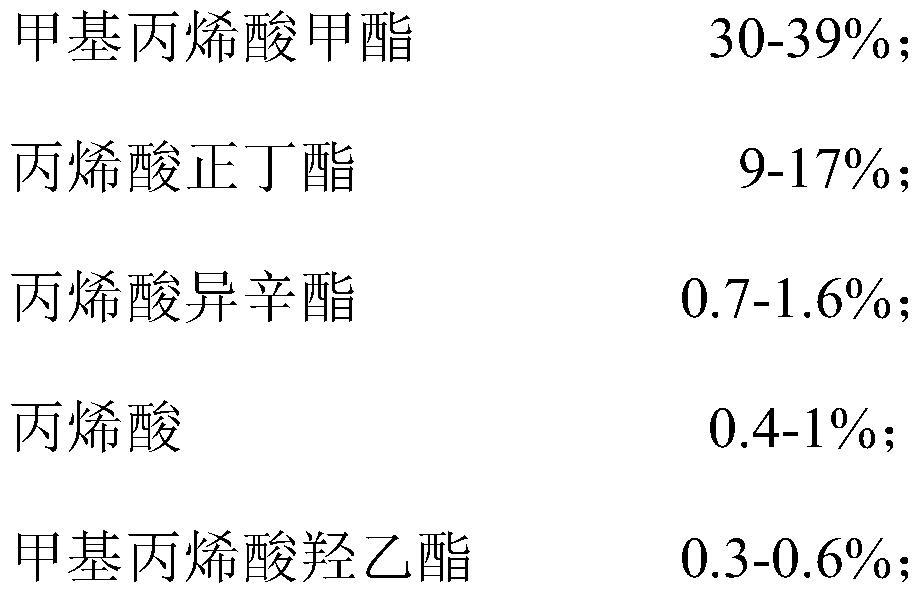

[0039] An acrylic acid copolymer emulsion is characterized in that it is prepared by the following preparation method:

[0040] Add the base material of component A into the reaction kettle at room temperature, stir at 300-400r / Min, raise the temperature to 70°C, add 1 / 4 of the initiator solution of component C, and keep warm for 30 minutes for copolymerization;

[0041] Stir component B in the pre-emulsification tank for 15 minutes to make a pre-emulsification monomer at a speed of 300r / min;

[0042] Raise the temperature and control the temperature at 81°C, add the pre-emulsified monomer and the remaining C component initiator solution dropwise into the reaction kettle equipped with the base material of A component at the same time, finish adding dropwise in 3 hours, and continue the insulation and copolymerization for 1 hour ;

[0043] Cool down to 60°C, add ammonia water, adjust the pH to 7-8, cool down to below 45°C, filter and discharge to prepare acrylic acid copolymer...

Embodiment 2

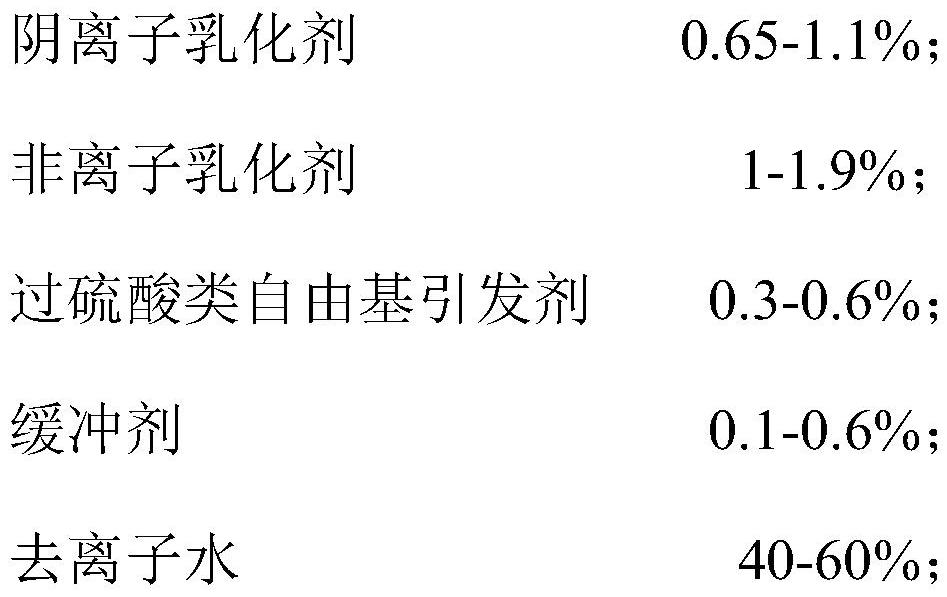

[0058] A kind of water-based ink, comprises the component of following mass fraction:

[0059]

[0060] It is characterized in that it also includes the acrylic acid copolymer emulsion in the above embodiment 1, the mass fraction of the acrylic acid copolymer emulsion is 40.5%, and the film-forming aid is composed of diethylene glycol with a mass fraction of 1%-5%. Alcohol ether and mass fraction are 2%-10% dipropylene glycol butyl ether composition, in the present embodiment, the mass fraction of described diethylene glycol ether is 5%, and the mass fraction of described dipropylene glycol butyl ether is 9% , the defoamer is composed of 0.2% TEGO 902W and 0.2% TEGO 904W by mass fraction, the leveling agent is BYK-333, the wetting agent is TEGO 4100, the neutralizer It is dimethylethanolamine, the thickener is PS 166, and the matting powder is OK500.

Embodiment 3

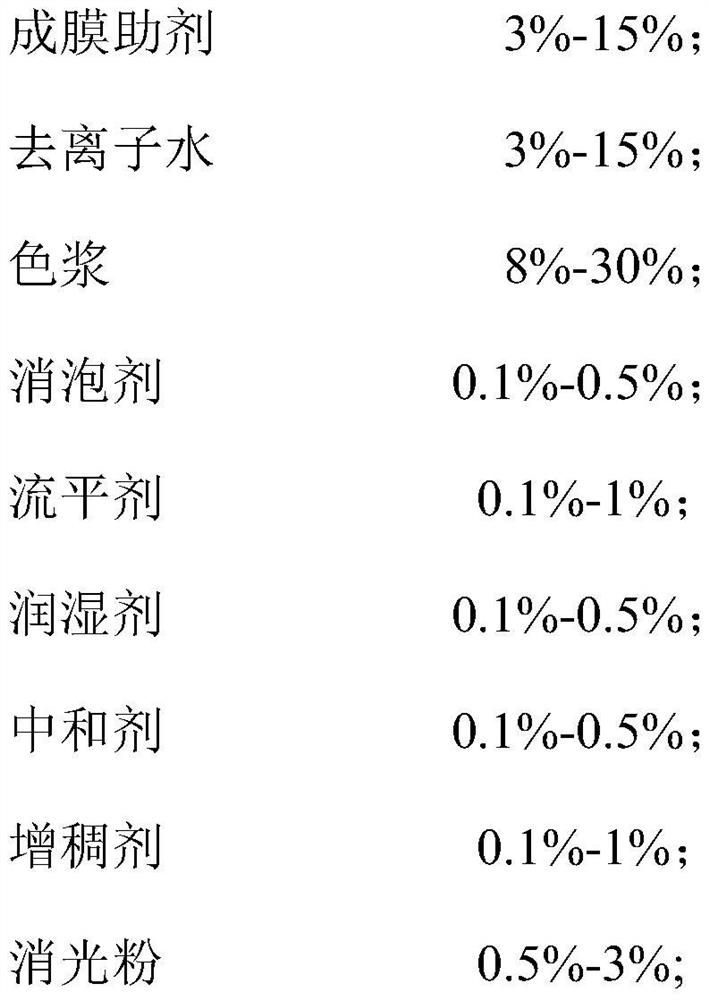

[0062] A kind of water-based ink, comprises the component of following mass fraction:

[0063]

[0064]

[0065] It is characterized in that it also includes the acrylic acid copolymer emulsion in the above-mentioned embodiment 1, the mass fraction of the acrylic acid copolymer emulsion is 45.5%, and the film-forming aid is composed of diethylene glycol with a mass fraction of 1%-5%. Alcohol ether and mass fraction are 2%-10% dipropylene glycol butyl ether composition, in the present embodiment, the mass fraction of described diethylene glycol ether is 5%, and the mass fraction of described dipropylene glycol butyl ether is 9% , the defoamer is composed of 0.2% TEGO 902W and 0.2% TEGO 904W by mass fraction, the leveling agent is BYK-333, the wetting agent is TEGO 4100, the neutralizer It is dimethylethanolamine, the thickener is PS 166, and the matting powder is OK500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com