Core-double shell hydrophobic magnetic microsphere and preparation method thereof

A magnetic microsphere, hydrophobic technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem of not being able to effectively remove organic pollutants in industrial wastewater, and achieve high reuse rate and method Simple, the effect of improving the water environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

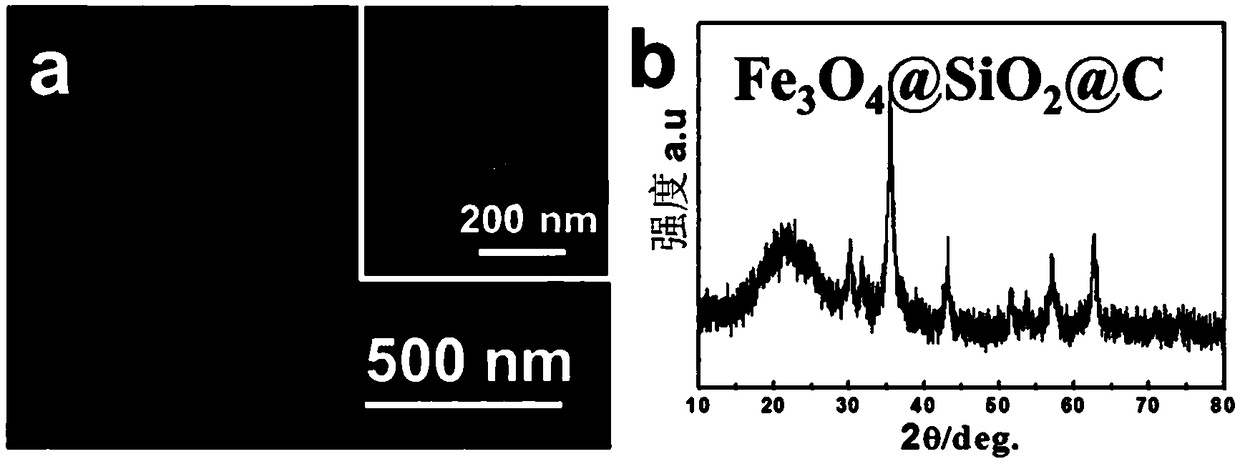

[0036] Follow the steps below to prepare double-core-shell hydrophobic magnetic microspheres

[0037] 1. Preparation of magnetic iron ferric oxide nanoparticles by hydrothermal solvothermal method: Dissolve 4.3g of ferric chloride hexahydrate and 1g of trisodium citrate in 10mL of water, add 70mL of ethylene glycol, stir in a water bath at 60°C for 15min, and wait for the solution Add 4g of anhydrous sodium acetate after clarification, stir for 10min, then transfer to 100mL polytetrafluoroethylene lining, 200°C hydrothermal reaction for 10h, after cooling, wash with distilled water and ethanol for 3 times, and vacuum dry at 60°C for 10h to obtain Magnetic Fe3O4 nanoparticles.

[0038] 2. Coating the silicon dioxide layer: take 250 mg of ferric oxide nanoparticles and disperse them into a mixed solution of 45 mL of ethanol and 3 mL of water, ultrasonicate for 15 min, and add 7.5 mL of ammonia solution with a mass fraction of 28% under mechanical stirring After stirring for 30 ...

Embodiment 2

[0045] Adsorption oil bead test

[0046] Such as Figure 4 As shown, measure 10mL of distilled water into a small glass bottle, add Sudan Red III into dichloromethane, and make the concentration 0.284*10 -3 M solution, drop 100 μL of Sudan Red III solution in distilled water to form small droplets, add a small amount of magnetic microspheres of Example 1, and absorb the Sudan Red III oil beads in distilled water under the action of magnetism until the adsorption is out of the liquid surface .

[0047] Measure 10mL of 10M hydrochloric acid and sodium hydroxide solutions and pour them into small glass bottles, add Sudan Red III into dichloromethane to make the concentration 0.284*10 -3 M solution, drop 100 μL of Sudan Red III solution in hydrochloric acid and sodium hydroxide solution respectively to form small droplets, add a small amount of magnetic microspheres in Example 1, and absorb the hydrochloric acid and sodium hydroxide solution under the magnetic effect. Sudan Red...

Embodiment 3

[0054] Anti-corrosion test

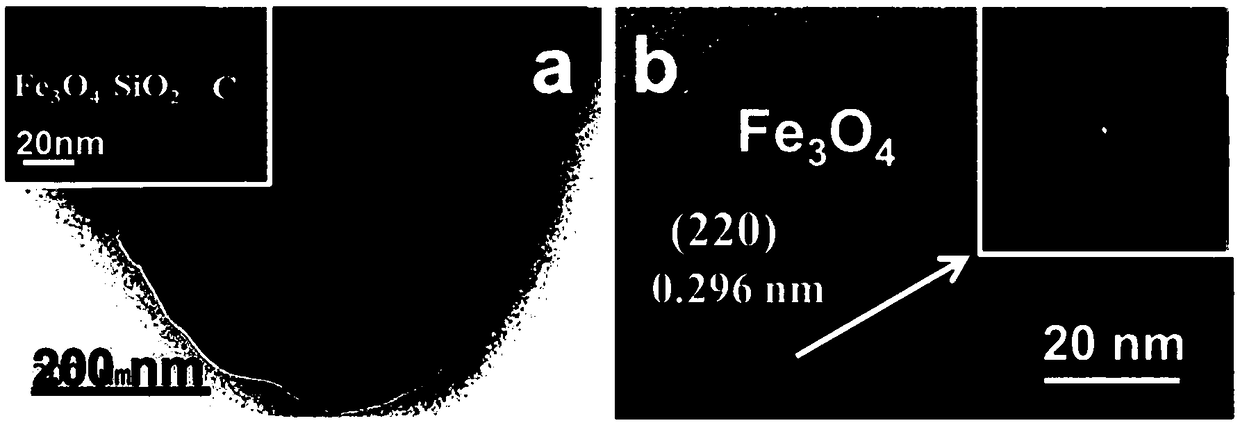

[0055] Soak the magnetic microspheres of Example 2 in 10mL of 10M hydrochloric acid solution, and keep for 14 days, finally centrifuge the magnetic microspheres and wash them with water and ethanol three times, and disperse them all in the ethanol solution, take 2 to 3 Drop the dispersed liquid on the copper grid, and do TEM test after drying. The results are as follows: Figure 5 As shown, the core ferric oxide was not corroded by hydrochloric acid, which may be due to the protection of the dense silicon dioxide layer and the hydrophobic carbon layer, indicating that the magnetic microspheres have good corrosion resistance.

[0056] With reference to the prior art and the preparation method of Example 1, the magnetic material-silicon dioxide layer magnetic microspheres and the magnetic material-hydrophobic carbon layer magnetic microspheres are successively prepared through steps 1 and 2, steps 1 and 3, and the magnetic material- Silica layer mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com