Stackable rolling rack apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

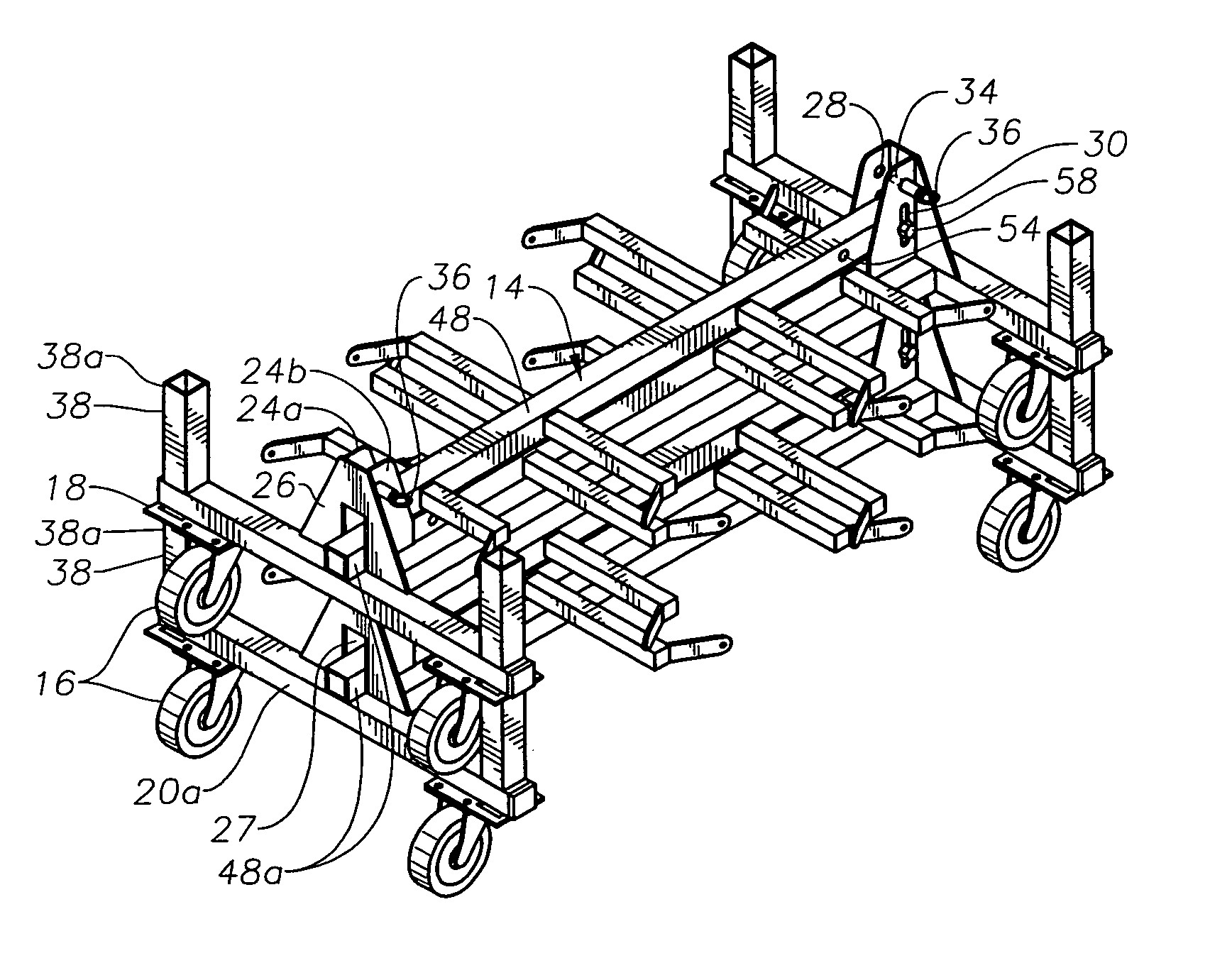

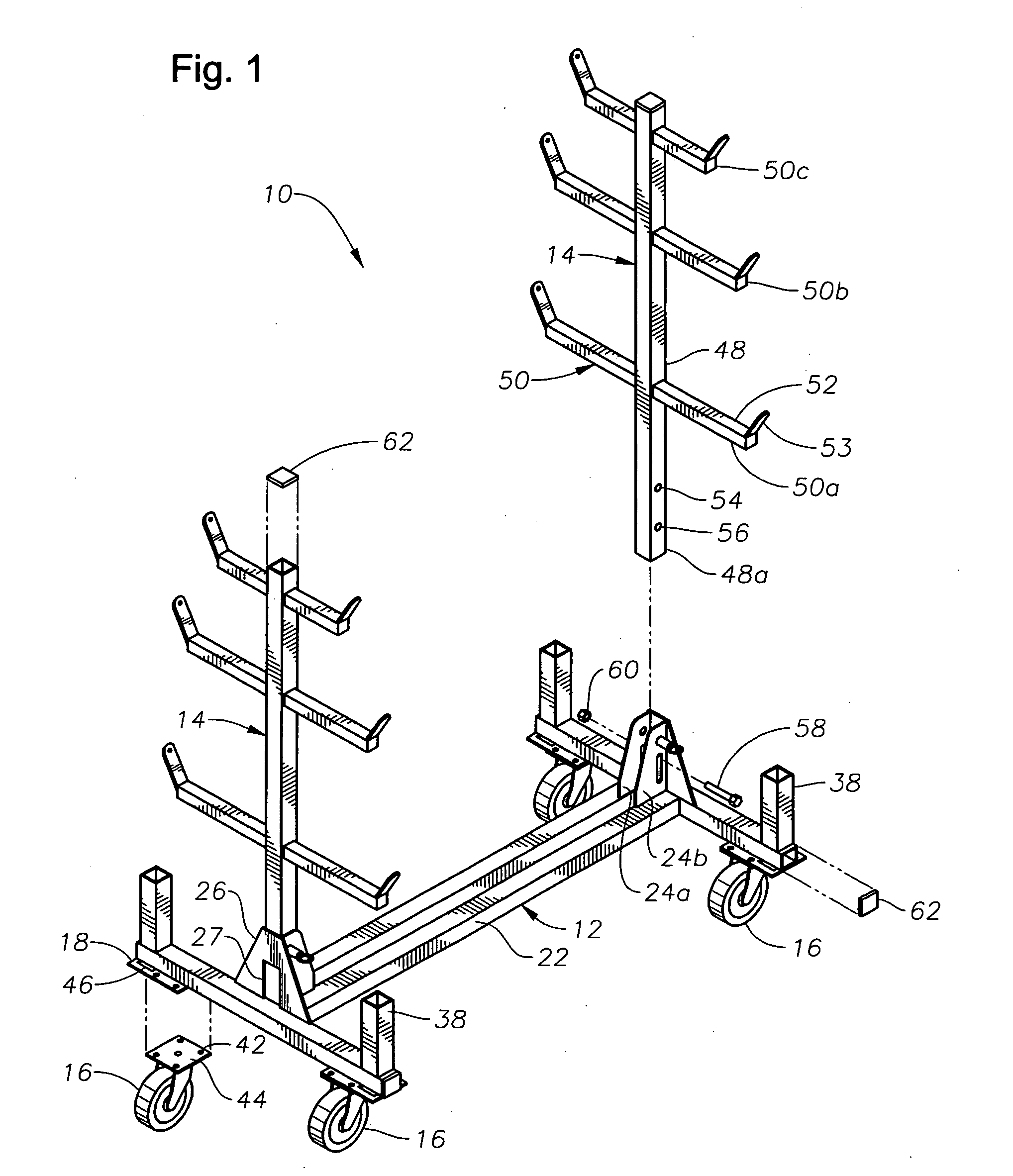

[0031] The stackable rolling rack apparatus according to the present invention, generally designated as numeral 10, is shown in FIGS. 1-4. The rack apparatus 10 includes a base unit 12 having a pair of upright support assemblies 14 attached to the base unit 12. Preferably, four wheels, more preferably casters 16, are mounted to caster mounts 18 attached to the base unit 12. Preferably, at least two of the four casters 16 are swivel-mount casters.

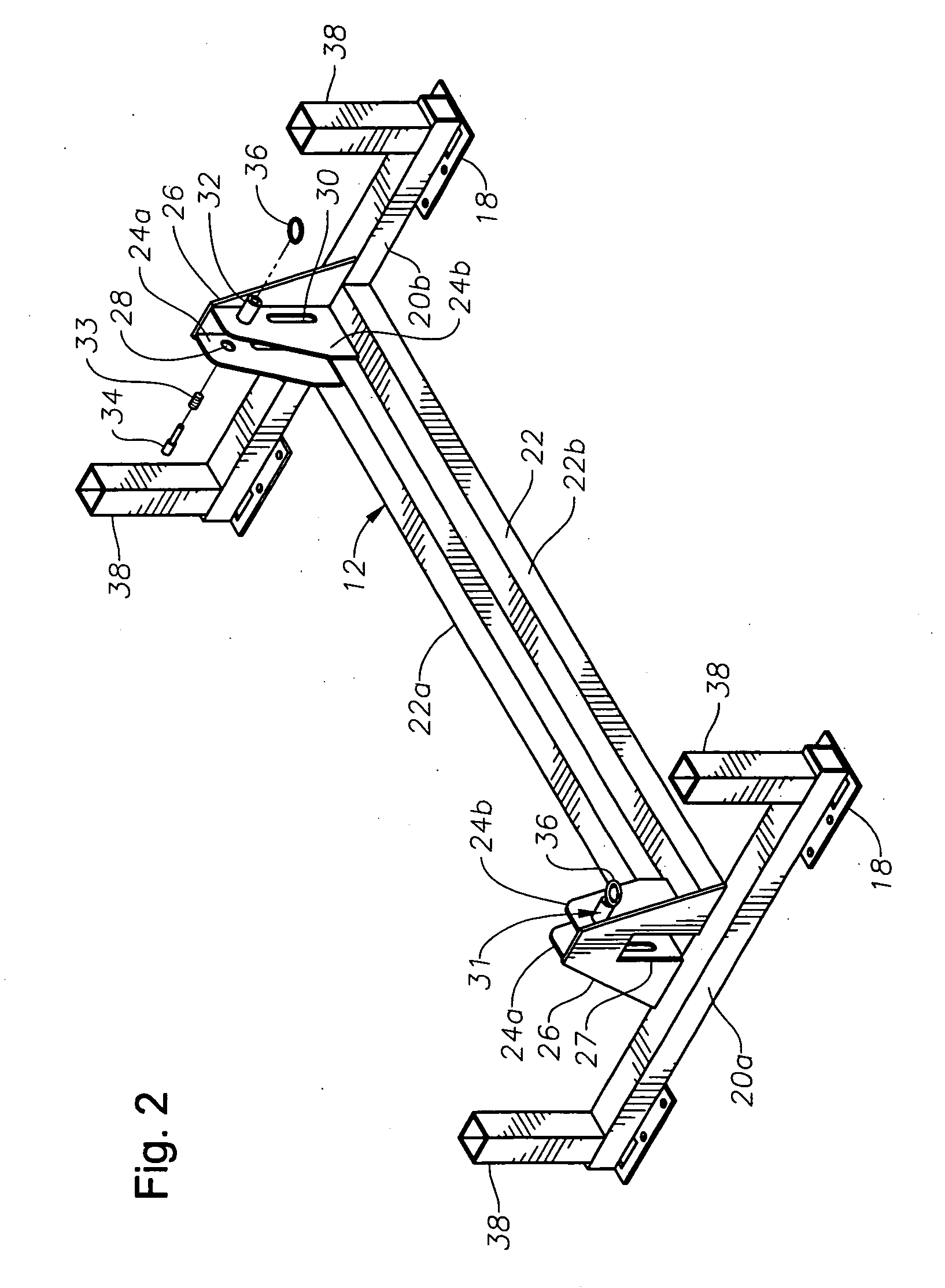

[0032] As shown in FIG. 2, the base unit 12 includes a pair of transverse end members 20a and 20b transversely oriented relative to center rail 22, preferably a pair of center rails 22a and 22b. The end members 20a and 20b are preferably attached to the ends of the pair of center rails 22a and 22b. Preferably, the center rails 22a and 22b are parallel with each other and have a gap between them. At each end of the pair of center rails 22a, 22b, there is a pair of upright mounting plates 24a and 24b, and a transverse support plate 26. Each up...

fourth embodiment

[0049]FIGS. 7 and 8 show the rolling rack apparatus, generally designated 100. The rack apparatus 100 includes a base unit 112 and preferably four wheels or casters 16 mounted to caster mounts 18 attached to the base unit 112. As shown in FIG. 8, the base unit 112 includes a pair of transverse end members 120a and 120b transversely oriented relative to a center rail 22, preferably a pair of center rails 22a and 22b. The end members 120a and 120b are preferably attached to the ends of the pair of center rails 22a and 22b. Preferably, the center rails 22a and 22b are parallel with each other and have a gap between them. The base unit 112 preferably includes a pair of base side rails 121a and 121b spanning between and connected to the ends of the transverse end members 120a and 120b. The pair of base side rails 121a and 121b provide additional structural rigidity and integrity to the base unit 112. In the preferred embodiment, the side rails 121a, 121b are made from structural angle me...

fifth embodiment

[0057]FIGS. 10 and 11 show the rolling rack apparatus, generally designated 200. The rack apparatus 200 includes a base unit 212 and preferably four wheels or casters 16 mounted to caster mounts 18 attached to the base unit 212. As shown in FIG. 11, the base unit 212 includes a pair of transverse end members 220a and 220b transversely oriented relative to a center rail 22, preferably a pair of center rails 22a and 22b. The end members 220a and 220b are preferably attached to the ends of the pair of center rails 22a and 22b. The base unit 212 preferably includes a pair of base side rails 221a and 221b spanning between and connected to the ends of the transverse end members 220a and 220b. The pair of base side rails 221a and 221b provide additional structural rigidity and integrity to the base unit 212. Preferably, a screen 264 or plate is attached to the base unit 212. As shown in FIG. 11, the screen 264 is preferably attached to the lower surface of the rails 221a, 22a, 22b and 221b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com