Corner connection block for assembly container

a technology for connecting blocks and assembly containers, applied in the direction of connecting rods, girders, dismountable cabinets, etc., can solve the problem of inability to reuse, and achieve the effect of fast and firm connection of frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

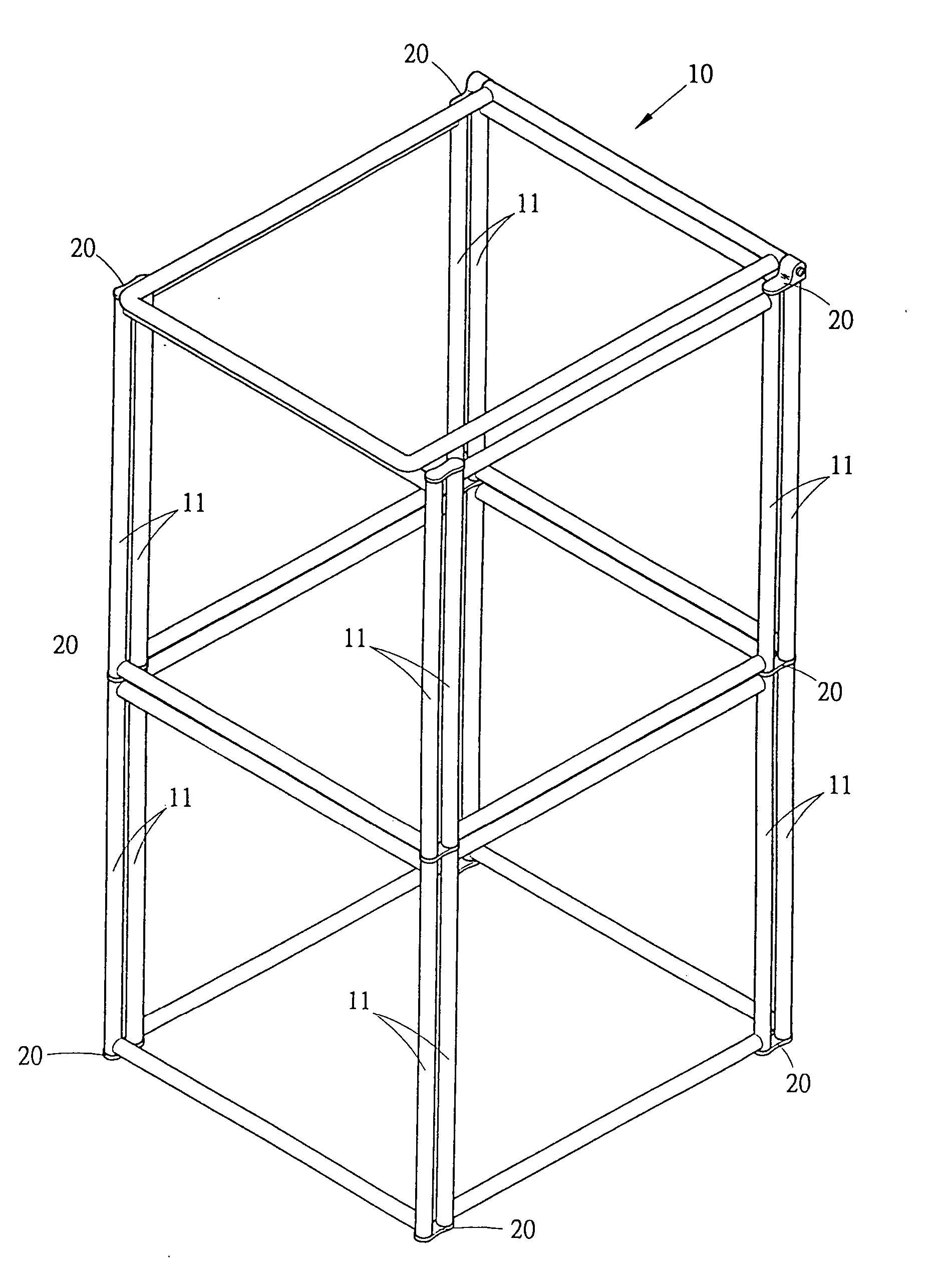

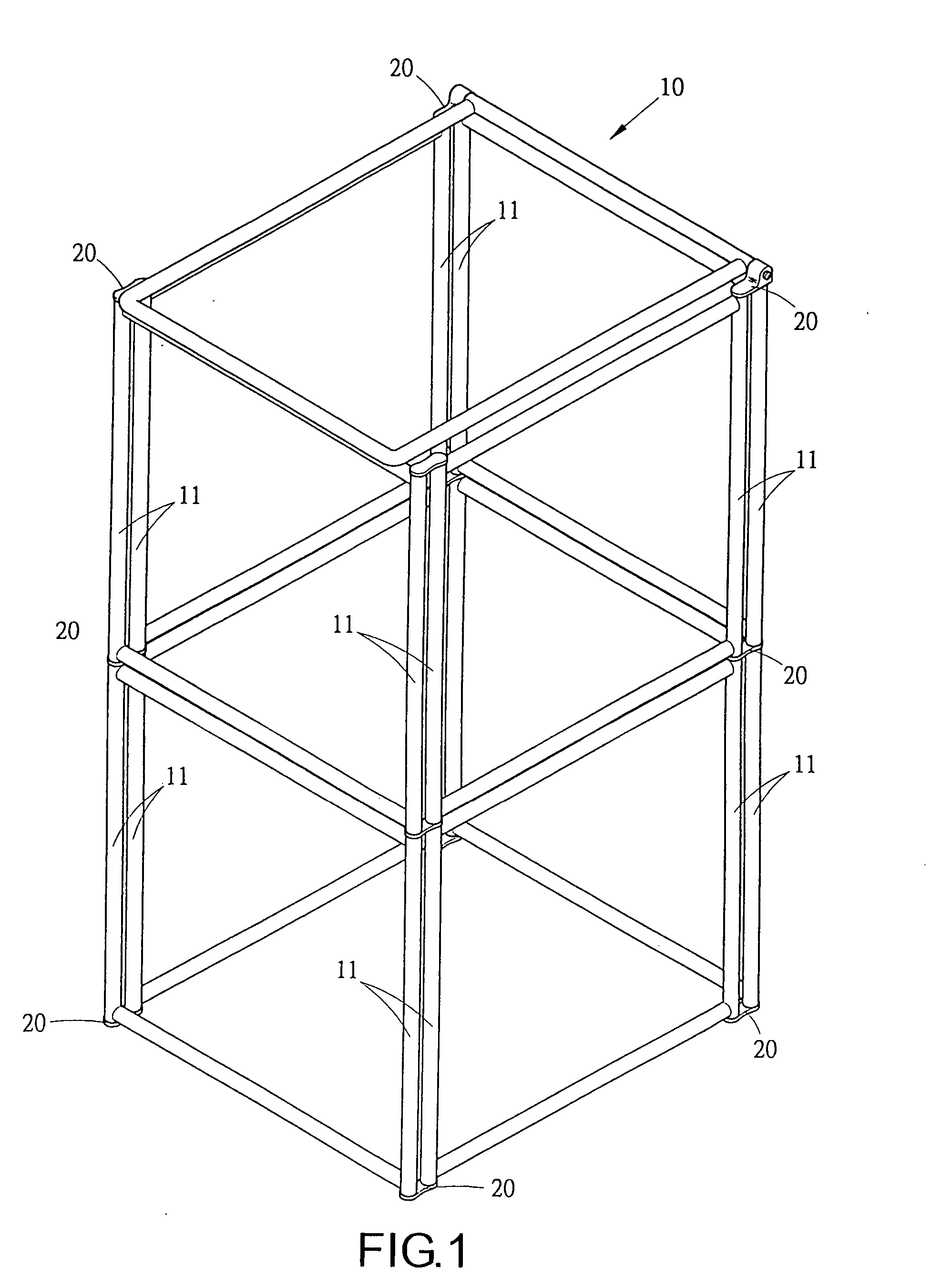

[0015] Referring to FIGS. 1 and 2. An application, an assembly cabinet 10 (or an assembly drawer, or assembly box, or an assembly frame, etc), to be surrounded by weaving material of cloth or rattan, is formed by circular tube frames 11 on each corner, wherein a hole 12 formed on each end of a frame, to be inserted by a corner connection block 20 to form a connection with other frames.

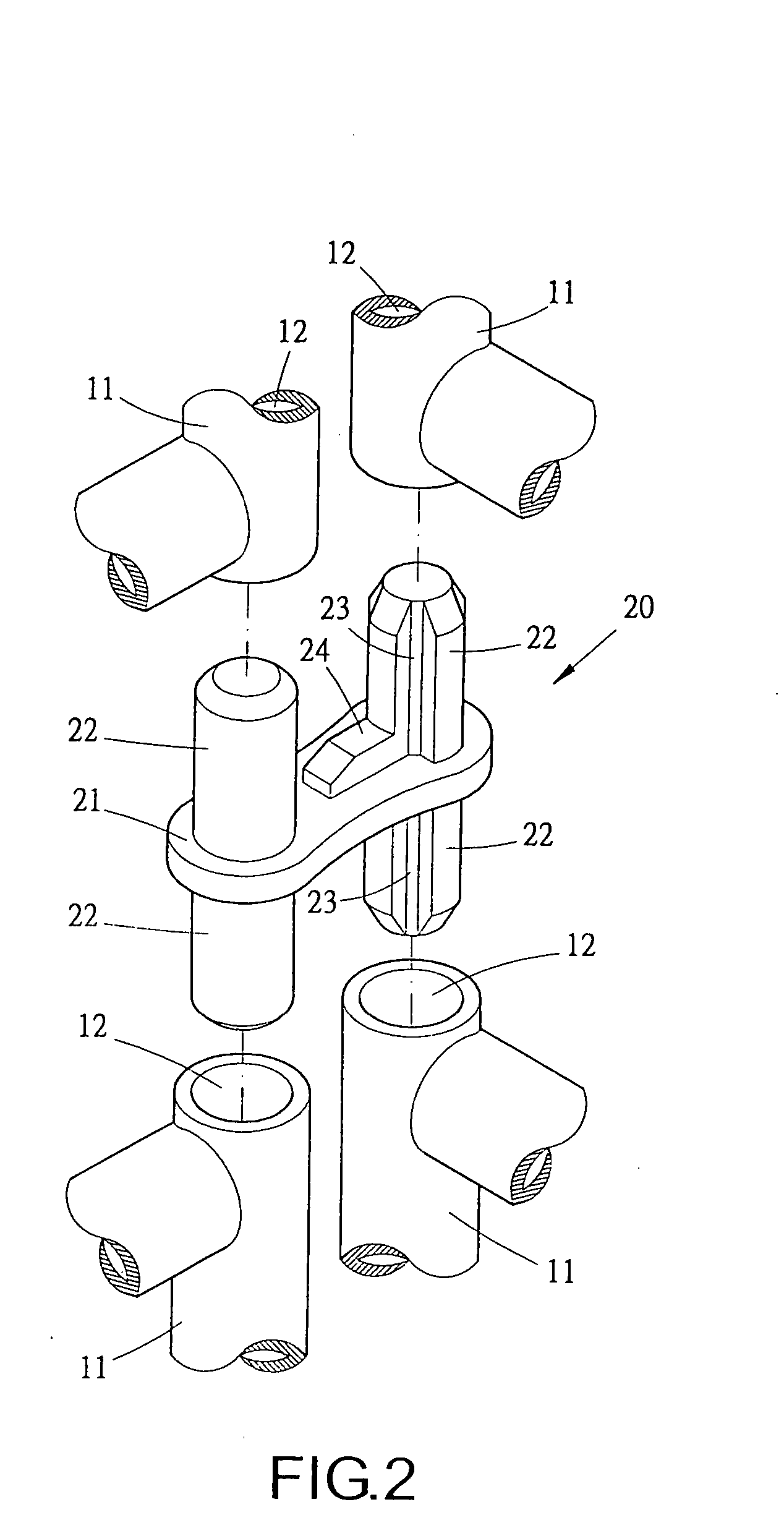

[0016] Referring to FIGS. 2 and 3. The corner connection block 20 is formed by a base 21 having a fixed thickness, wherein two cylinder rods 22, paralleling to each other, formed beneath the base 21, to be inserted into holes 12 thereof to connect frames, thereby forming a layer of an assembly container. The corner connection block 20 can be formed with a flat surface to enhance appearance. Additionally, rods 22 thereof can also be formed on the base 21, each in align with rods formed beneath the base 21, thereby forming an upper and a lower layer of an assembly container.

[0017] Referring to FIG. 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com