Fixable flange gasket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

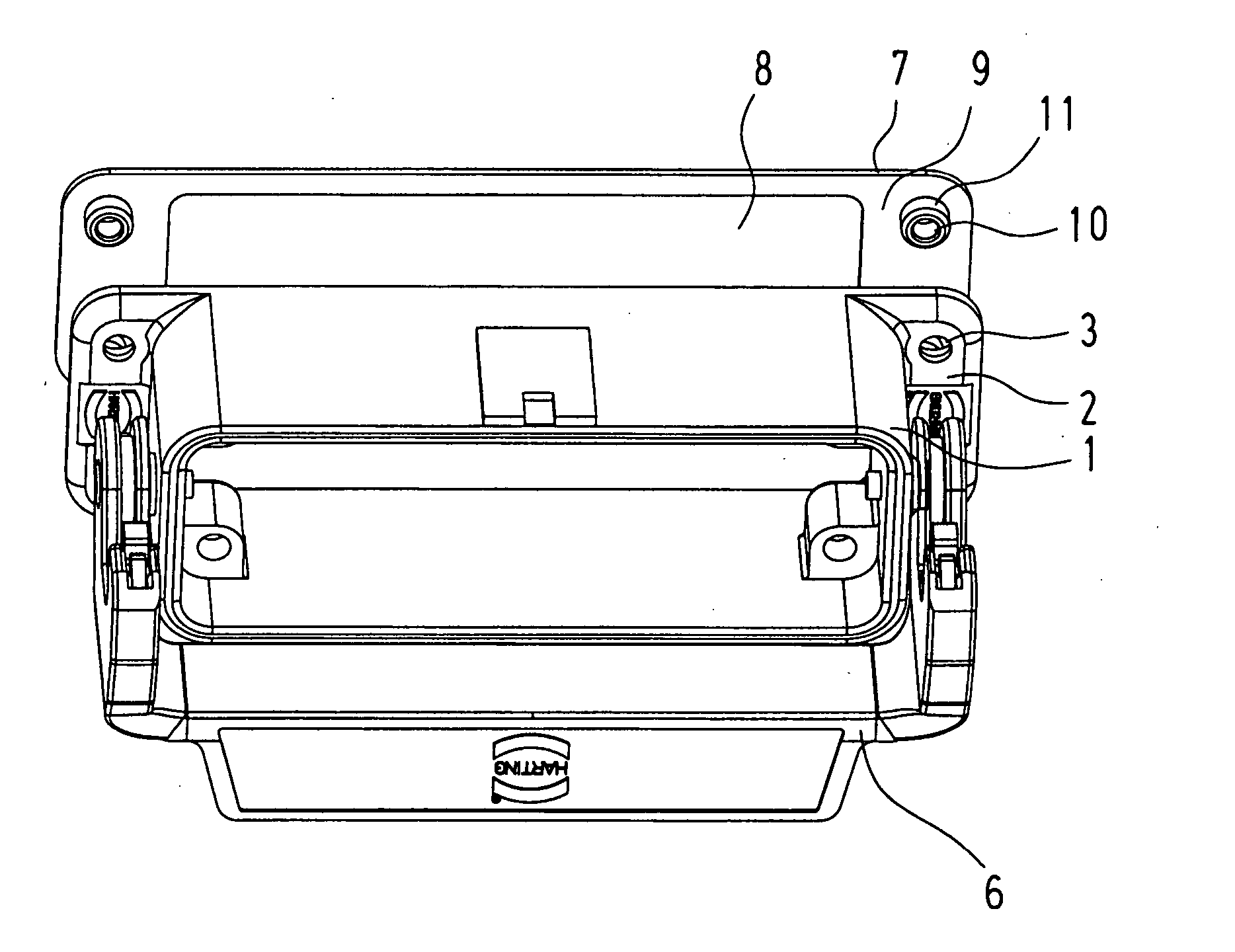

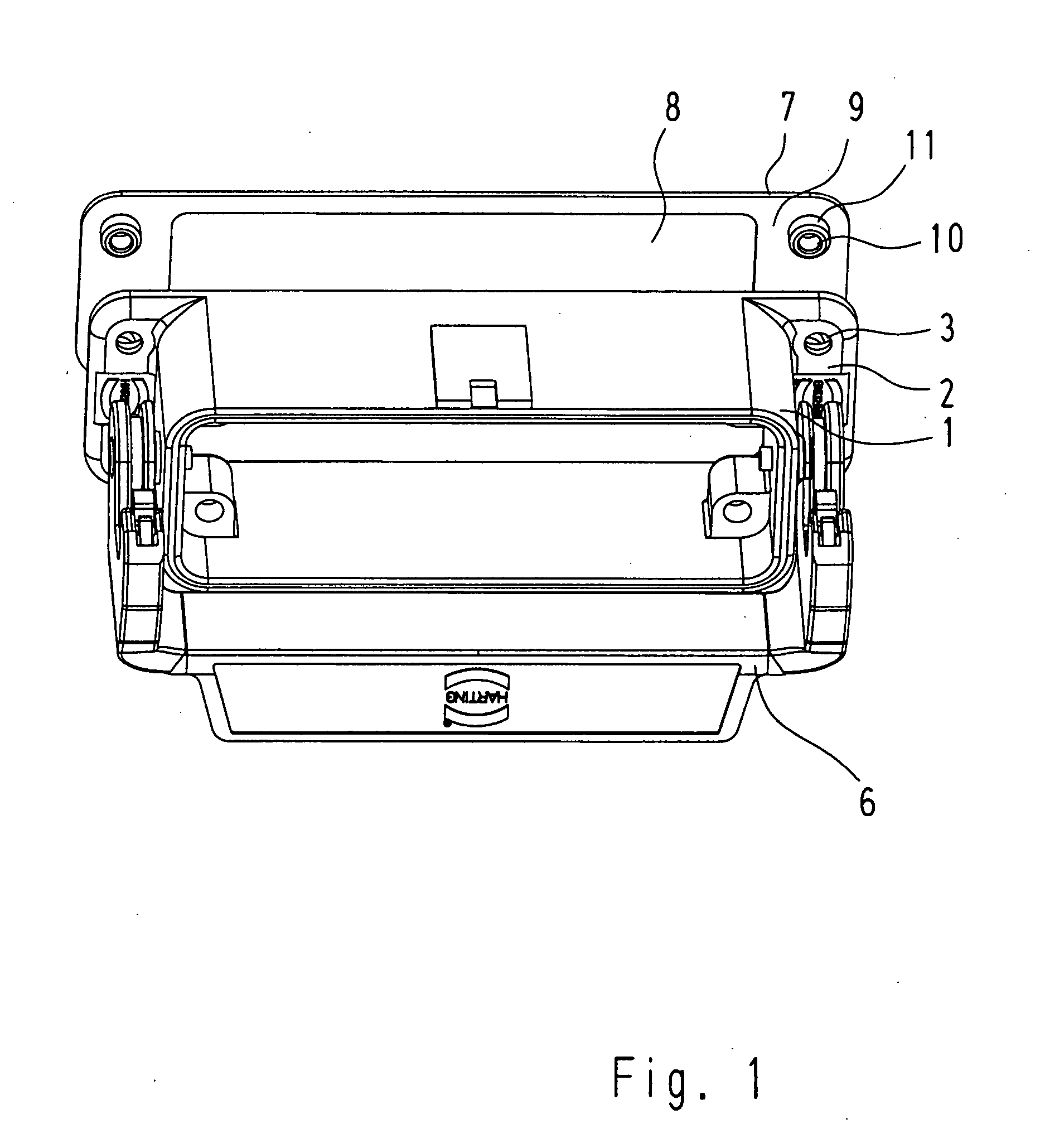

[0017]FIG. 1 shows a connector housing 1 with a flange 2 in the form of a perspective representation of the open connecting side of the connector.

[0018] Due to the chosen viewing angle, a flange gasket 7 is visible behind the housing 1, wherein this flange gasket serves for producing an absolutely tight connection with a not-shown housing or another flange. In addition to the cutout 8 for the cables leading out of the connector, the flange gasket 7 also contains openings 10 for mounting screws that are respectively surrounded by a collar 11 protruding from the material plane 9 of the flange gasket 7.

[0019] This figure also shows a clip 6 for producing a separable connection with a not-shown mating connector.

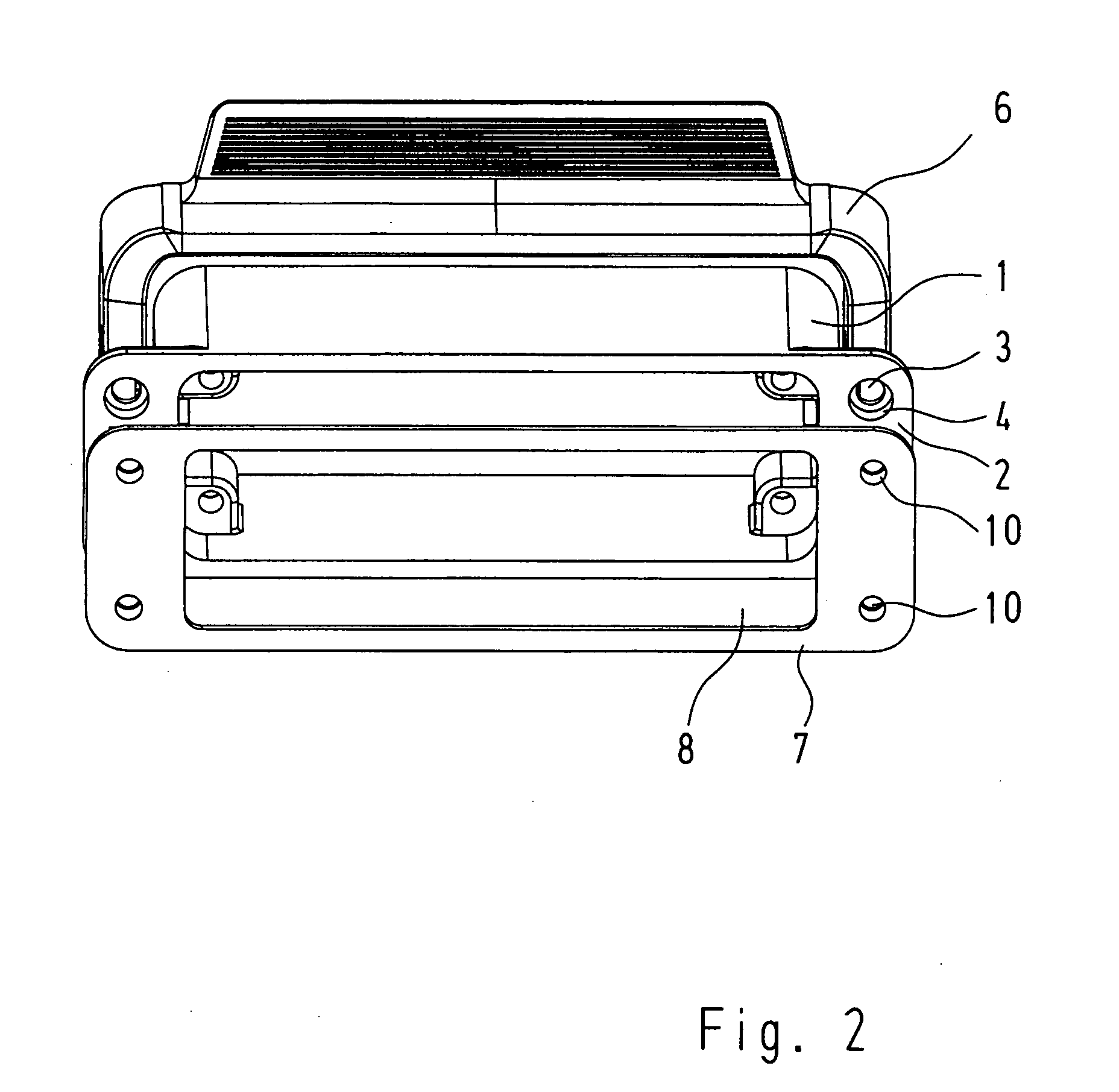

[0020]FIG. 2 also shows a perspective representation, however, of the opposite side of the flange gasket 7 and the housing 1 referred to FIG. 1.

[0021] This figure clearly shows the cutout 8 as well as the arrangement of the openings 10 in the flange gasket 7.

[0022] The mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com