Roof module for a motor vehicle and process for producing same

a technology for motor vehicles and roof modules, applied in the field of roof modules, can solve the problems of high cost of glass fiber mats, time-consuming and complicated production of multi-layer roof modules based on honeycomb structures, and the positioning of honeycomb layers within negative molds used for pressing processes, etc., and achieves low total weight and high stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

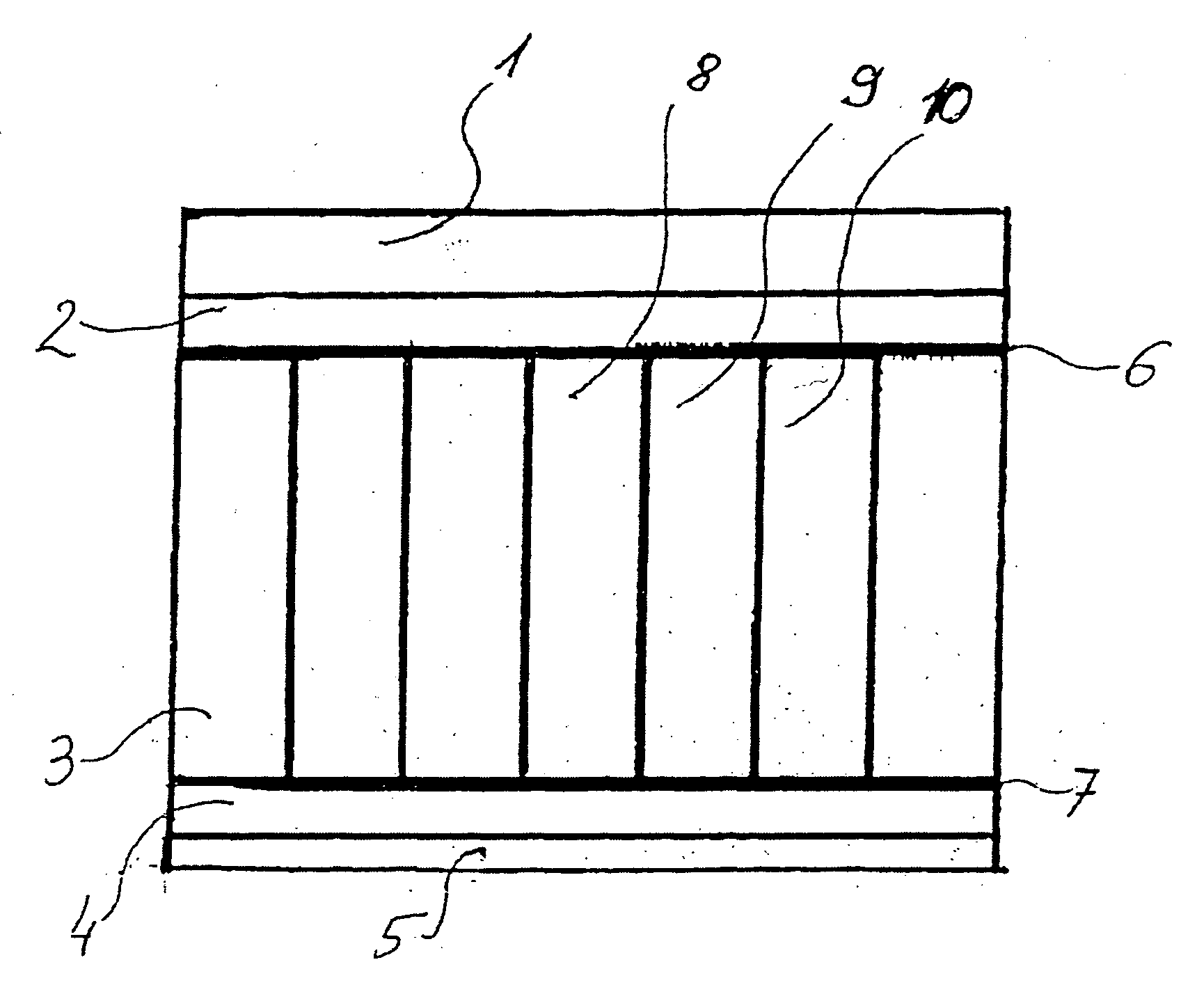

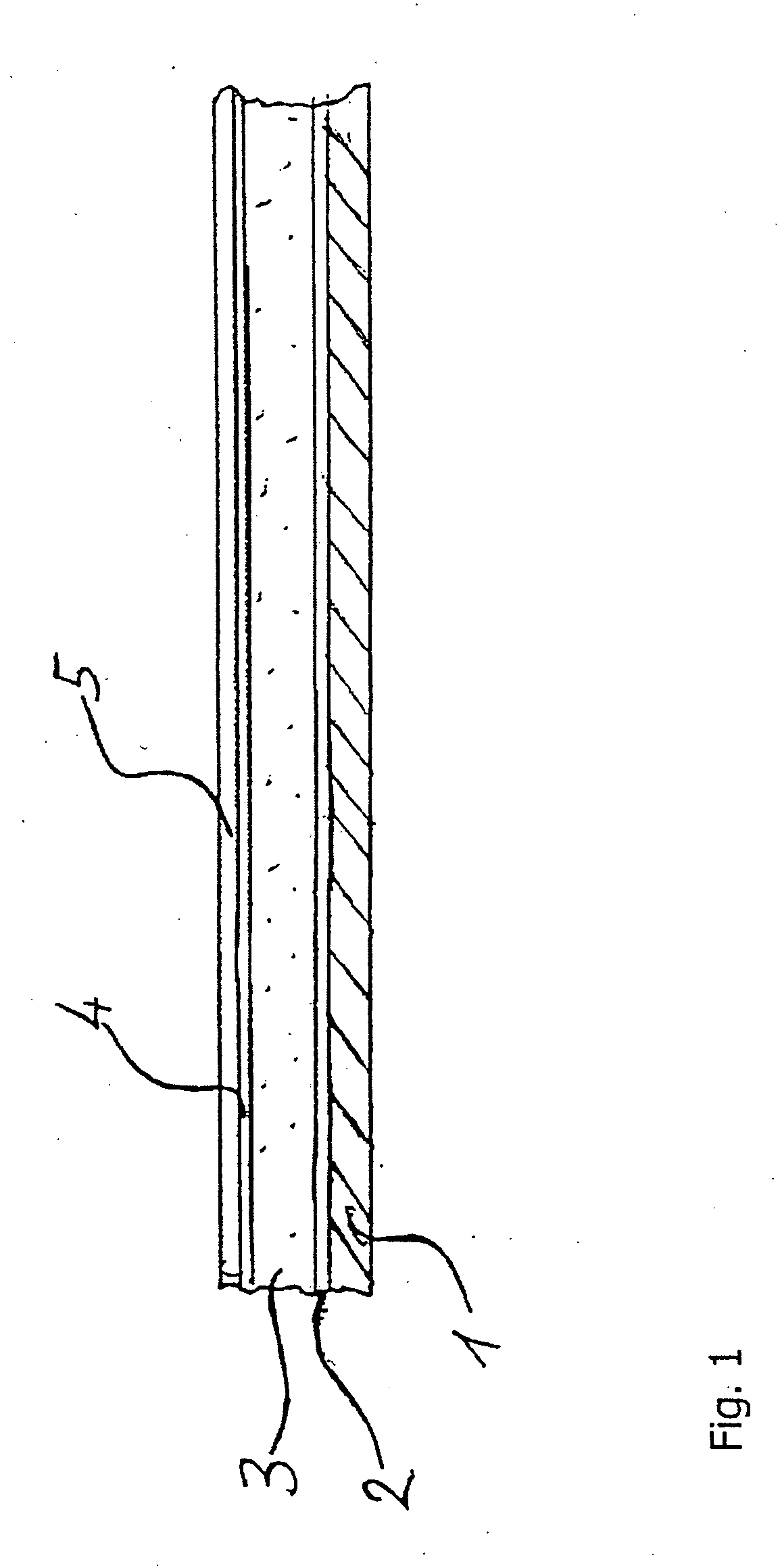

[0035]FIG. 1 shows the layered structure of a roof module which comprises an outside roof skin 1, a first glass-fiber containing layer 2 produced using the LFI process, a preferably honeycomb carrier layer 3 of stiffening material, such as PHC, a second glass fiber-containing layer 4 based on the LFI process, and a laminated layer 5 for a termination of the layered structure in the vehicle interior, which termination acts has a visually attractive appearance.

[0036] According to the production process, an outside roof skin is inserted into a negative mold of a pressing device, and by means of the LFI process, is covered with a layer 2 which contains PUR-wetted glass fibers and which are blown by means of compressed air into the negative mold. The glass fibers are preferably 10-100 mm long.

[0037] The honeycomb carrier layer 3, is preferably made of the stiffening material PHC and is placed on the first layer 2 which contains the glass fibers. Then, a second glass-fiber containing lay...

second embodiment

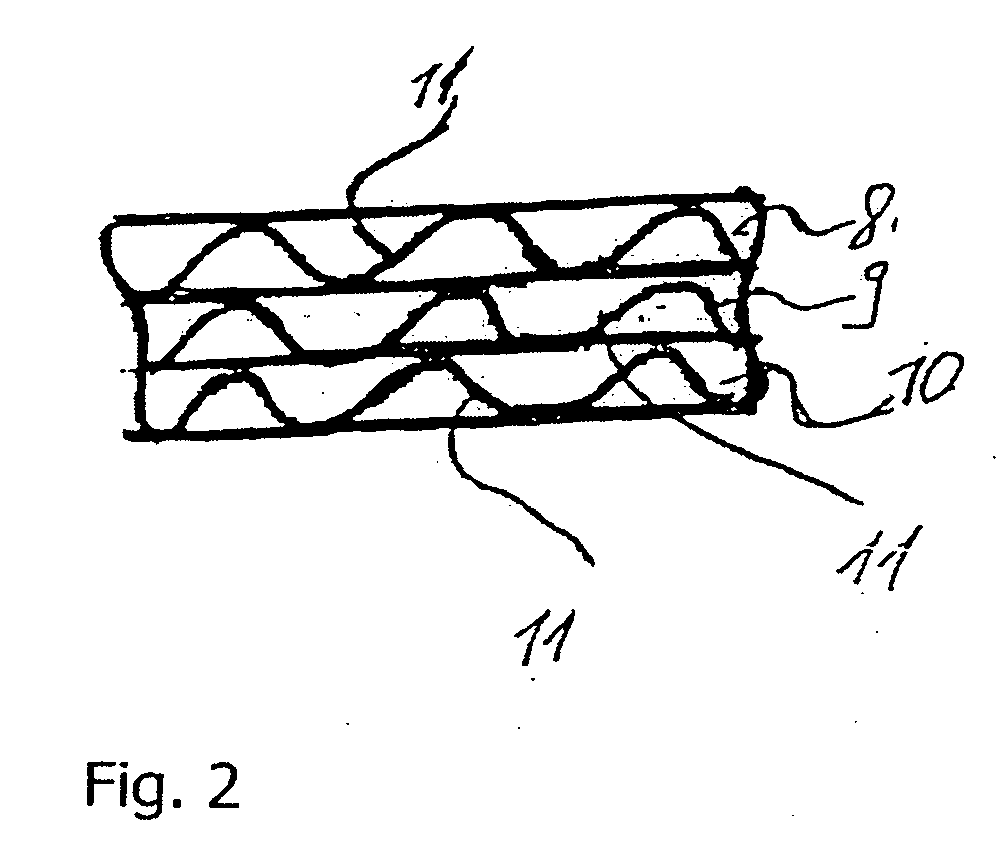

[0039] In order to reduce the unnecessarily high consumption of PUR, as is shown in FIG. 3, according to the layered structure of the roof module of the invention, the carrier layer 3 is covered with a blocking nonwoven material 6, 7, on the top and bottom sides, so that the PUR penetrates only to a predefined penetration depth into the honeycomb structure to ensure adhesion of the glass fiber-containing layers 2, 4 to the carrier layer. The glass fibers which are contained in the glass fiber-containing layers 2, 4 are kept by the blocking nonwoven material 6, 7 from penetrating into the honeycomb structure. In this way, the required amount of glass fiber and amount of PUR are reduced, and thus, weight and money are saved.

[0040]FIG. 4 shows a schematic cross section of a third embodiment of the layered structure of the roof module as in accordance with the invention. The layered structure according to the third embodiment differs from the layered structure according to the second em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com